I gotta tell you. And you know me . I have no problem sinking tons of time in car. Bodywork takes FOREVER!!

A few lessons learned.

Lesson one. Painting a car that has been on the race track for 2 years is MUCH harder than painting your clean and un damaged body shell from factory five.

WOW I did not realize how much that body had been abused. On the good side the fiberglass is over built and stands up to that type of punishment. On the bad side I had lots of scrapes and other damage from projectiles that really took a while to fix.

Oh the fact that the car is covered in oil from its duty as a track weapon also makes things harder. Lots of cleaning before you even start working

[URL=http://s1073.photobucket.com/user/kabacj/media/Factory%20Five%20GTM%20roll%20cage%20modifications/21BEBAC0-D561-412F-A5C2-1342BBA3E2BB_zpsouhmbfpf.jpg.html][/URL

The body goes on and off lots and lots of times.

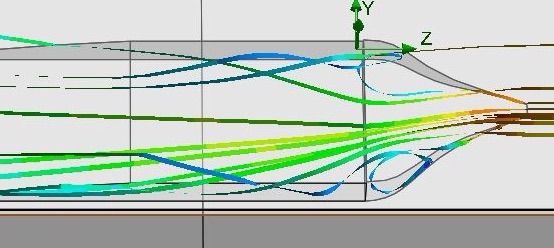

Here is a mid work view of the body back on.

After the body work phase then its the block and prime, block and prime, block and prime. Boy I did lots of sanding.. A good body buck is essential. I actually made this one a bit higher so I could spray under the rockers more easily.

Did I mention that bodywork takes a long time!

But to answer your question, YES! Absolutely I will be driving around town in the next few weeks. That's going to be weird but I cant wait!

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote