I made a reference above to the tubes I used for securing the side curtain ferrules in the doors. The original cars actually had the ferrules set into tubes that were tack welded to the door frame for added support. On an FFR, the old-style soft top used the original style side curtains, which are an aluminum frame with a sliding plexiglass window. I really like the old-school look of those, but one of the issues with the ferrules and the shape of the FFR door is that the ferrules aren't long enough to extend all the way through the outer and inner skins - which would mean they would potentially drain water down into the door (which in my case will be filled with low expansion foam - potentially causing mold and rot issues). So, in keeping with my other attempts to make the car look a bit more original, I came up with a way to add the drain/support tubes to my car. The tubes are 1/2" i.d. - 5/8" o.d. tubing. The outside skin holes are 1/2" and the ones in the inner skins are 5/8", meaning that when the drain/support tubes are inserted in from the bottom (inside the cockpit), they can't come up through the outer holes. The ferrules then slip down inside the drain/support tubes. The plan is to install the drain/support tubes before foaming the inside of the doors so that the foam holds them in place - I'll also use some filler or caulk of some sort to smooth and fill the gap between the tube and the inner door skin. Then, once paint is done, I can insert the chrome ferrules from the outside and secure them in the tubes using epoxy, JB Weld, or (if I want them to remain somewhat removeable) seam sealer. These tubes also give me someplace to mount the leather door pull strap that hangs from the door release lever to the middle tube.

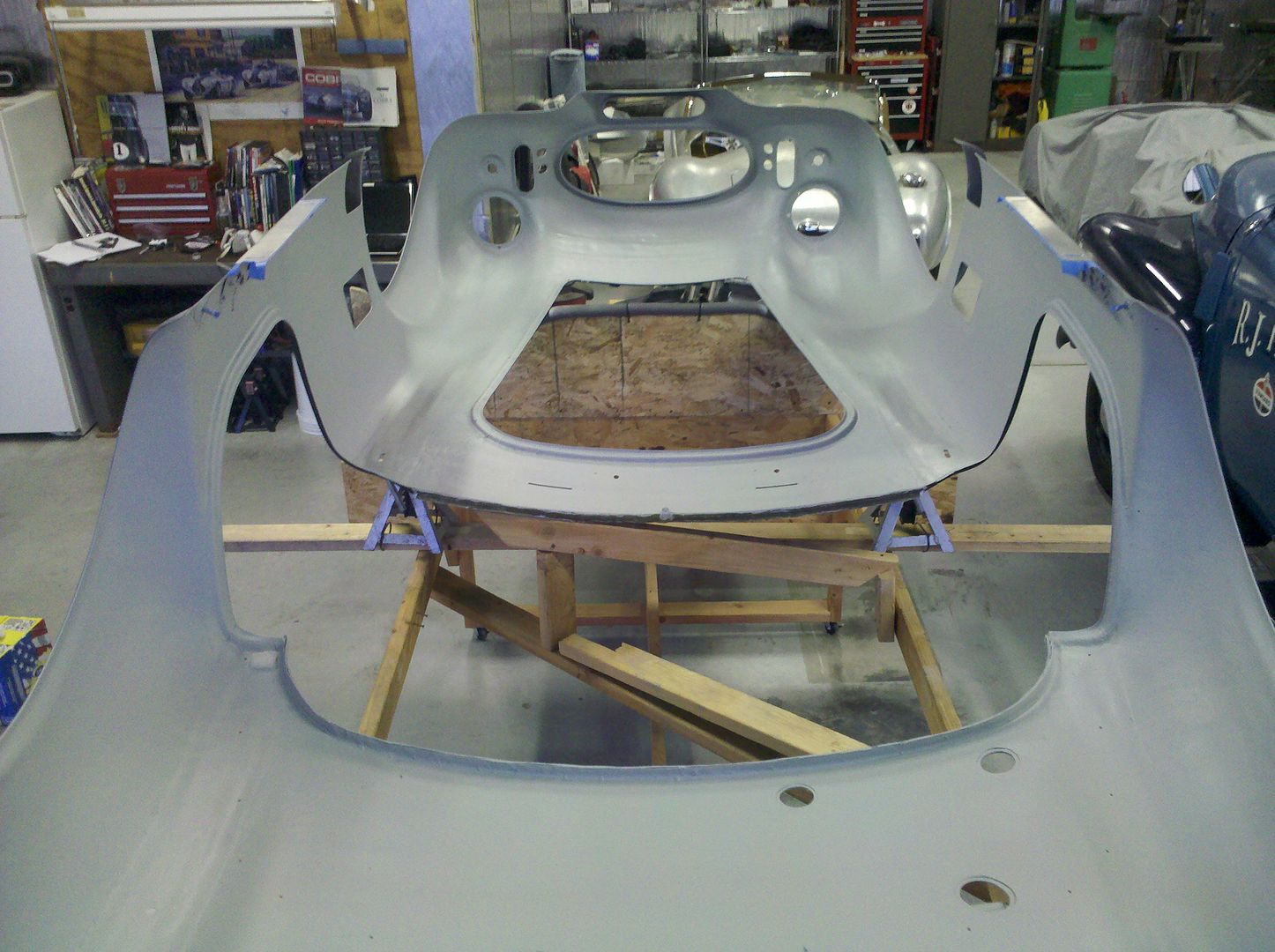

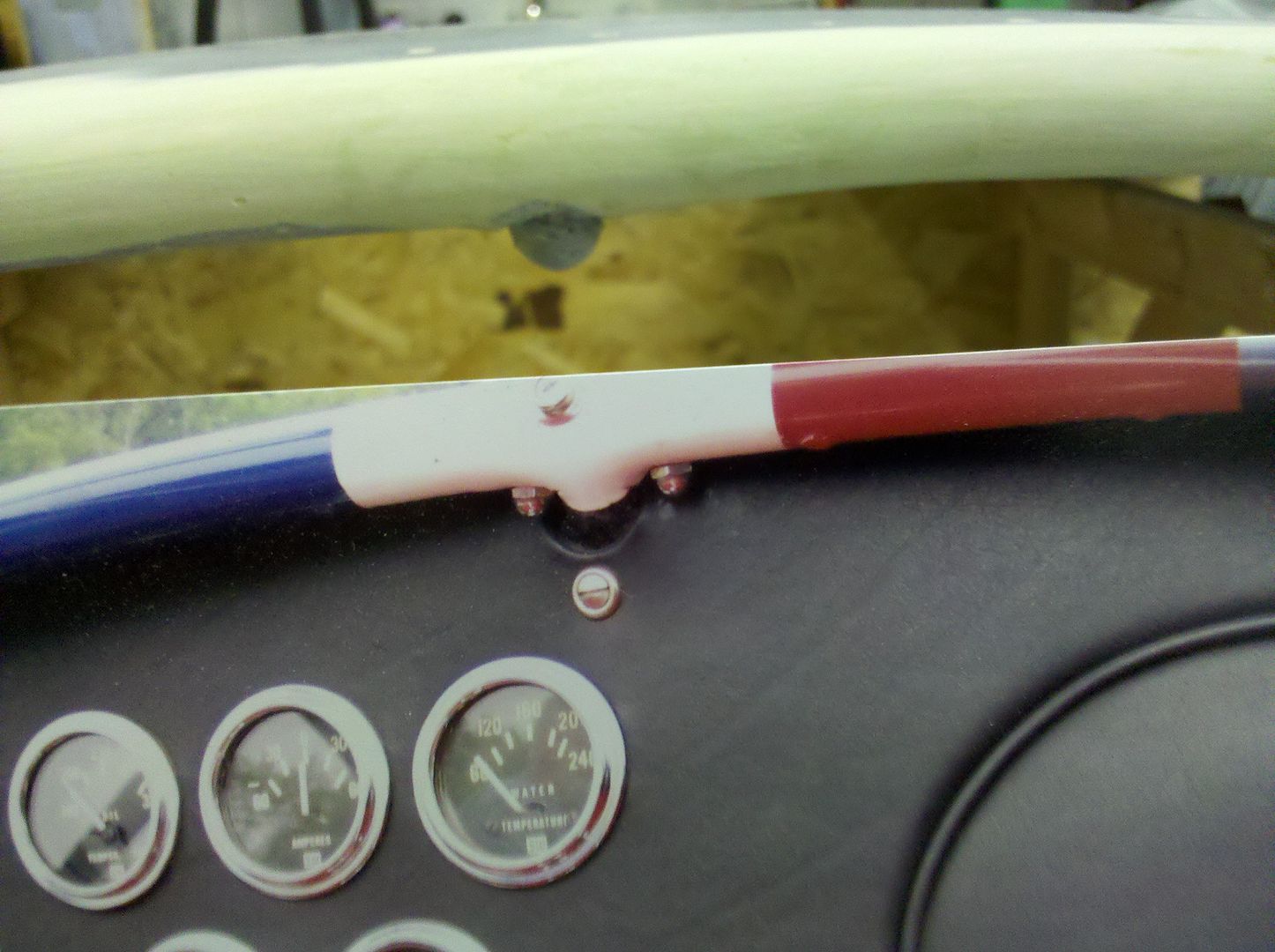

Here are a few pics of this body mod:

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote