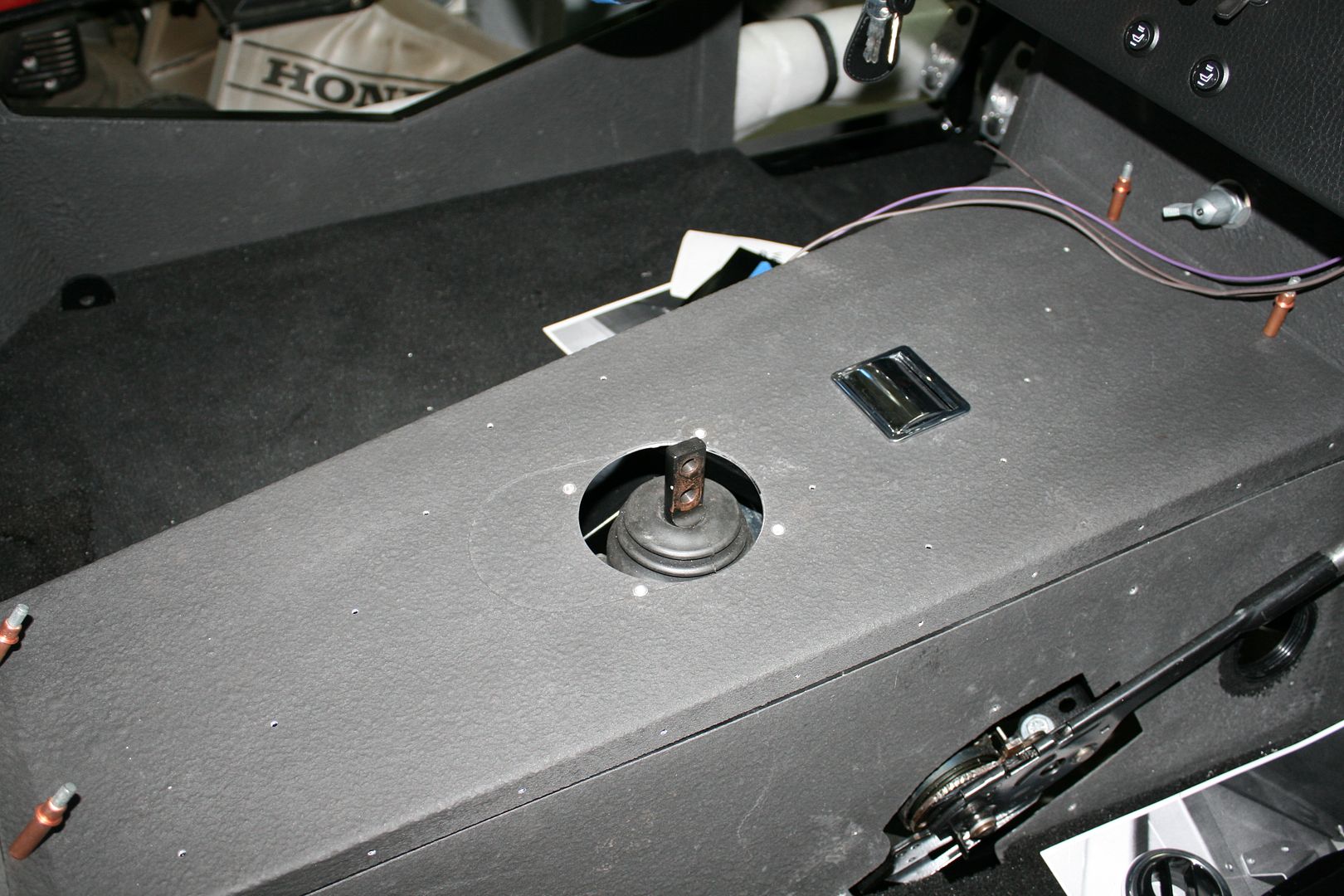

Thanks for the compliment. Curious why you're suggesting a more horizontal angle for the throttle pushrod to the carb. Appearance only or something else? I played with a lot of combinations and locations and looked at a lot of pictures before deciding on this arrangement. My main motivation for having the levers down was the pushrod from the accelerator to the inside lever. The top pivot point of the Russ Thompson pedal was already well below where the rod end could be mounted. Pointing the levers up would cause that pushrod to be up at an even sharper angle. Somewhere in the 50-60 degrees range. By pointing the levers down both pushrods had the straightest shot to their respective pivot points. It's a bit of a moot point, because I don't have room to flip it over in the footbox. But still wondering about your suggestion.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote