-

Senior Member

C5 a/c compressor aftermarket fitting/adapter options? vs other compressor options?

Looking out of the shop at an unusual mid-April snow got me thinking about air conditioning. I wrestled the compressor into position and looked at my options. The fittings come right off the rear of the compressor right by the Kooks headers.

I have approximately 33mm or 1 5/16 inches between the back of the compressor and the header. The C5 fitting is about 24mm thick.

I have the Vintage Air lines that come off the compressor, but they are pointed at the tunnel and my condenser is behind my passenger side rear side-intake and my evaporator is behind the passenger seat. So I am looking at 2 options:

1. Get a different fitting for the C5 compressor to tie into my custom lines

Is anyone aware of a low profile 90 degree fitting? It looks like this one might work but I don't see dimensions in the description?

https://www.hawksmotorsports.com/lsx...fitting-black/

2. Switch compressor to a different one.

Does anyone know which compressors will bolt in and line up correctly with the pulleys? I believe the ~06 CTS-V bracket and compressor are an option...

This also looks like a possibility, mounts an aftermarket compressor :

http://www.kwikperf.com/lsx_ac.html

IS ANYONE RUNNING A DIFFERENT FITTING OFF THE C5 COMPRESSOR OR RUNNING A DIFFERENT COMPRESSOR?

Thanks!

Last edited by beeman; 04-15-2020 at 09:19 PM.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Senior Member

-

Senior Member

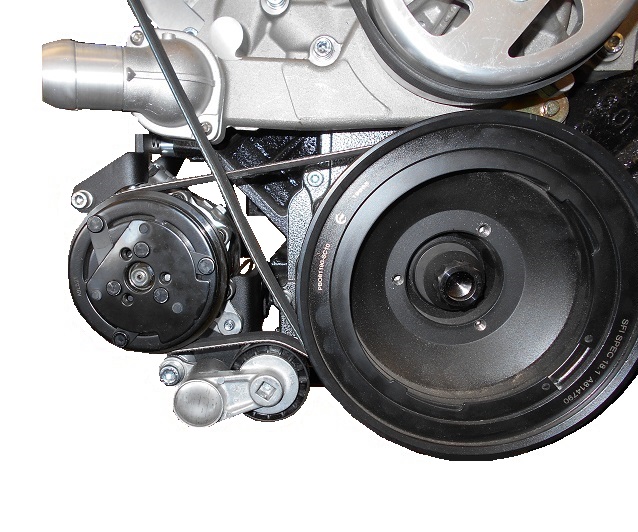

I'm at work, the only thing that could be an issue is that the tensioner sits lower with the DD setup than the C5 compressor tensioner.

Looking at this GTM pic, looks like there is plenty of room to drop the tensioner:

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Senior Member

Ordered the Dirty Dingo Sanden low mount, the Sanden compressor, and the Dirty Dingo compressor fitting. Yeehaw!

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Senior Member

Beeman

It will be interesting to see how that works out. Not sure I could have fit it that way but might have been able to get it in lowered. Seems like a better setup than the standard mounting position. I am using a GM compressor mounted in the standard location with BBK replacement headers for LS3 and a fitting like you showed above to hoses into the compressor. I did make all my A/C hoses and did not use the hoses from Vintage Air but did however use some of the pieces from the hoses they shipped. My hoses are pretty close the the header but I believe I have more room than you are indicating between the two. Haven't charged the system and might consider mounting lower to get more clearance between the header the the compressor.

-

Senior Member

James -

I think the key is moving the compressor forward, away from the header, ie getting a shorter compressor.

My C5 OEM compressor measures just under 8" from the front of the pulley to the back of the unit (about 7 3/4"). But then the fitting comes off the back another 1" or so, putting the fitting just over 1/4" from the Kooks header. And that's before any header wrap.

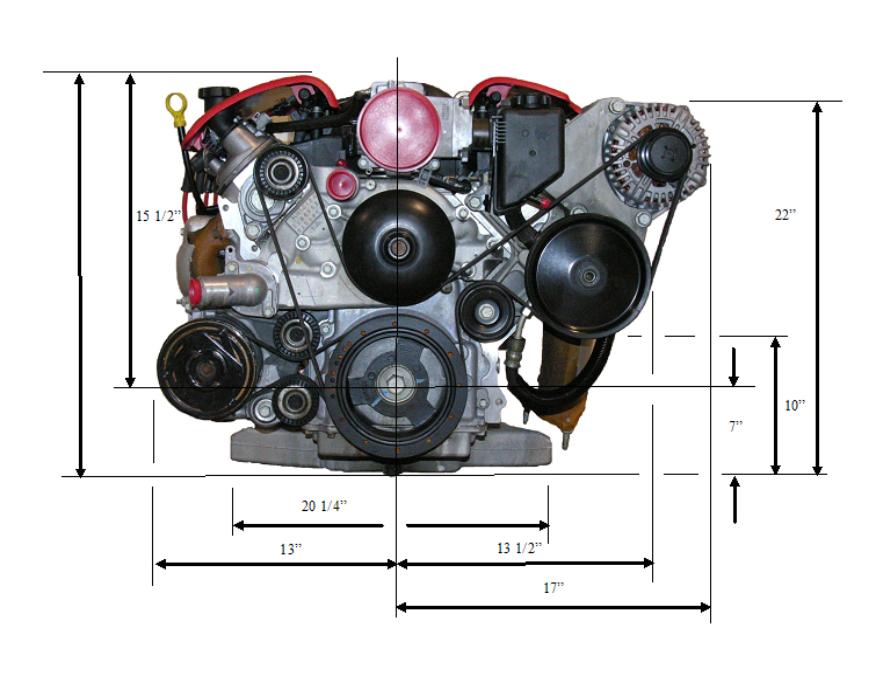

Here's a schematic of the sanden sd7b10 (unit on the right side of the schematic), it looks like I'll have an additional 3/4" between the header and the compressor body, PLUS the fittings come off the side of the compressor which saves another inch behind the compressor. So I'll have about 2 inches of clearance from the header to the new unit. Plus the lines aren't exiting next to the headers.

As far as side clearance, my current setup measures about 12.5" from the center of the balancer to the edge of the compressor pulley. This works but is close to the chassis tube, so it'll be nice to gain 2" of clearance there.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Post Thanks / Like - 0 Thanks, 1 Likes

RR46

RR46 liked this post

-

Senior Member

Thanks for the information Beeman, I'll check it out...

-

Beeman, what did you do for the lines? There seems to be bendable aluminum lines that could replace the GTM Vintage Air lines that normally go from the C5 compressor to match up with the lines in the tunnel. May stick with the C5 setup but having more info on this DD setup might be useful if more space is desired at some stage.

Last edited by RR46; 11-02-2020 at 11:16 AM.

Reason: typo

-

Senior Member

I bought a generic a/c line kit and cut my hoses to length and marked the rotation of each fitting, then took them into a radiator repair shop who crimped them for me. So you would only need to remove the GM fitting on the compressor end of your GTM lines and crimp on the standard metric fittings, probably splicing in some more line since you will lose some length. So probably 4 crimps @$10 per shop doing crimp plus 2 fittings @ $12 ea. Plus a few $ worth of hose and 4 more extension crimps for the 2 extension unions @$10 ea. Hopefully that makes sense..

Here's a splice, 2 crimps each.

Last edited by beeman; 11-02-2020 at 07:45 AM.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Post Thanks / Like - 0 Thanks, 1 Likes

RR46

RR46 liked this post

-

Pardon all the grime in this photo, this was taken when I disassembled an 11 year old car after buying it and I currently don't have photo access to this space.

This is directly fwd of the C5 AC compressor in a Gen 1 GTM. It appears to be where the GTM AC lines tie into the "pigtail lines" from the C5 compressor. To me not knowing or seeing exactly what these joints consist of it seems effective to get new "pigtails" that fit the Dirty Dingo threaded adapater at the 10 o'clock position (#10 and #8 fittings when using the fitting that comes with the LS kit), and on the other end of these "pigtail lines" there would be the fittings to connect to the GTM lines (GM threads?). This would eliminate the need to pull out and have custom lines made.

They do seem to be threaded connections so basically ~12-15" bendable alu lines or hose lines with #10 to GM?? and #8 to GM?? and then one could use the DD compressor. Or even off the shelf lines ,#10 to #10 with an adapter with different threads each end where it mates to the existing GTM hoses, and similar for the #8 to #8.

Is this feasible? Still doing research and not sure what exact threads are on pressure vs suction GTM lines and what adapters to look for in that case. VA has the U bend alu lines in all kinds of size fittings and lengths so all it would take is get those, and find two adapters to connect to the GTM hoses.

ac.PNG

Last edited by RR46; 11-02-2020 at 11:35 AM.

Reason: more details

-

Senior Member

Funny you should ask, I have a complete FFR Vintage air system in my shop (some one needs to buy this from me). Here's the proprietary C5 compressor outputs, just o-rings with a bolt on fitting, and the compressor end of the GTM a/c lines. So if you are going aftermarket compressor, you need to cut off the proprietary GM C5 fitting and crimp on the universal metric fittings. Simple enough.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Senior Member

What is your ultimate goal? I wanted my compressor fittings away from the headers.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

I'm curious - how well do the stock systems keep up with GTM cooling? We recently tested this unit from a UK company in a highly built 72 RSR/993 Turbo hybrid build, and it's really not up to the task in Southern California... But if they dot get it right I can see it being a game changer for lots of different builds:

https://www.classicretrofit.com/coll...r-conditioning

-

I have a Penske bi-metal unit that lowers the ambient 20 degrees, but it is ridiculously expensive and only does air in small volumes for helmets. I think this unit only does water, but looks very capable. Never used one but the numbers are good...until you see the price numbers!

https://www.chilloutsystems.com/prod...ler-pro-series

I have heard that the VA systems seem to do the job. My guess is that the more sealed and insulated one can get the GTM interior, the better any system will work. I'm guess that is the weakest link.

-

Originally Posted by

beeman

Funny you should ask, I have a complete FFR Vintage air system in my shop (some one needs to buy this from me). Here's the proprietary C5 compressor outputs, just o-rings with a bolt on fitting, and the compressor end of the GTM a/c lines. So if you are going aftermarket compressor, you need to cut off the proprietary GM C5 fitting and crimp on the universal metric fittings. Simple enough.

This photo shows the connections I was attempting to describe. If these connectors connect to the GTM AC hoses going to the front of the car, and they start from the back of the C5 compressor, it should be possible to get these two short pipes/lines starting from a Dirty Dingo to the same fittings you see in this photo. Maybe not all GTMs have this junction?

GTM engine with serpintine belt b.jpg

-

Senior Member

Those just look like crimp fittings to attach to the flexible a/c rubber lines. I received a partially built kit, they were already crimped to rubber lines. To clarify, Dirty Dingo makes the aftermarket compressor mount, the compressor is the Sanden sd7b10. The rubber hoses are relatively cheap, so you could easily run new hoses from the front of the car to the compressor, but you would need to crimp new fittings to the new rubber hose at the front of the car too, so you might as well just splice in an extension if needed.

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Senior Member

Here's a typical Sanden adapter:

https://www.amazon.com/Dirty-Dingo-S...43784926&psc=1

Then you would need a #8 and #10 crimp fitting, here's a 90 degree #10 for example, but another angle may fit your setup better

https://www.amazon.com/Vintage-Air-3...343963&sr=8-12

MK3.1 2004 Mach 1 donor. ABS, PS, TC.

GTM #304 LPE 525hp LS3

2000 C5 Lingenfelter LS1@489hp

1999 Corvette FRC/Z06 track car

-

Originally Posted by

beeman

Those just look like crimp fittings to attach to the flexible a/c rubber lines. I received a partially built kit, they were already crimped to rubber lines. To clarify, Dirty Dingo makes the aftermarket compressor mount, the compressor is the Sanden sd7b10. The rubber hoses are relatively cheap, so you could easily run new hoses from the front of the car to the compressor, but you would need to crimp new fittings to the new rubber hose at the front of the car too, so you might as well just splice in an extension if needed.

Gotcha, the hex heads where throwing me off. Thank you. (yes I meant to reference Sanden compressor)

-

I don't see that Shane has chimed in here but IIRC he has some sort of adaptive solution for the tight space and the A/C hoses.

-

There was an issue for a while where the VA manifold block (part of the AC hoses from FFR) had one of the ports that came out of the back of the block...toward the back of the car. Those manifold blocks would interfere with the Kooks headers, so we sold a different manifold block for a while that had both ports coming off the side of the aluminum manifold....staying flush to the back of the compressor to clear the headers. Later, FFR/VA changed that manifold block so that what shipped with the kit was the same as the manifold block I had available (what RR46 posted the photo of above) and no longer needed to be replaced.

Shane Vacek

VRaptor SpeedWorks, LLC

www.vraptorspeedworks.com

Turn-key GTM, SL-C & Ultima GTR Built to Your Specs!

Offering a full line of GTM Upgrades and Custom Parts

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote