Hey guys, figured I'd make a build thread to document my Factory Five 818R build. My goal is to have it be street legal, so I can scare friends in it, and of course, to be on track with it as often as I possibly can. Shoutout to my friend Frank at FFR who helped peer pressure me to do this and is helping with every step of the process. Of course, I'm always open to suggestions for this car, so if you have an idea- speak up! I'm not new to Subarus (3rd one) but I'm by no means an expert. Brand new to the Factory Five Forums and I'm excited to see how this build goes!

A quick little 'about me':

At the time of writing- I'm 22, single, Clarkson grad, working as an electrical engineer for a company in upstate NY making automotive aluminum (narrows it down quite a bit). Done a bit of car work, nothing quite this intense. Done a little tracking/autox, nothing too serious either. Currently drive a 2012 WRX that's a bit modded. Want something a little....faster

Timeline: Build: Cost to get running: -Ordered on 10/30/13, (re)scheduled pick up on 7/5/14 Full aero 818R for track use; hopefully NASA ST2. Street legal as well. 818R order: $11,807 -Got donor car on 2/8/14, towed away on 5/12/14 EJ257/205 hybrid with forged internals with a VF39 Donor car: $4,800 -First drive (driveway) on 3/22/15 2007 WRX 5 speed Street legality parts: $2,125 -First autox (CVMP) 5/30/15 17x8 +35 front wheels with 215/40 Direzza Z2's Sold parts total: -$1,560 -First track day (NYST) 8/28/15 17x9 +35 rear wheels with 255/40 Direzza Z2's Aftermarket parts purchased: ~$10,800 Fully street legal as of 3/14/16 Total cost to get legal/on track: ~ $27,970

Highlights (Click to see post- to help those stuck on a step!)

Donor:

Picked up my donor locally on 2/8/14 after buying it on 1/25/14

Started teardown

Removed wiring harness

Donor car towed away

Parts:

Electrolysis

New Garage!

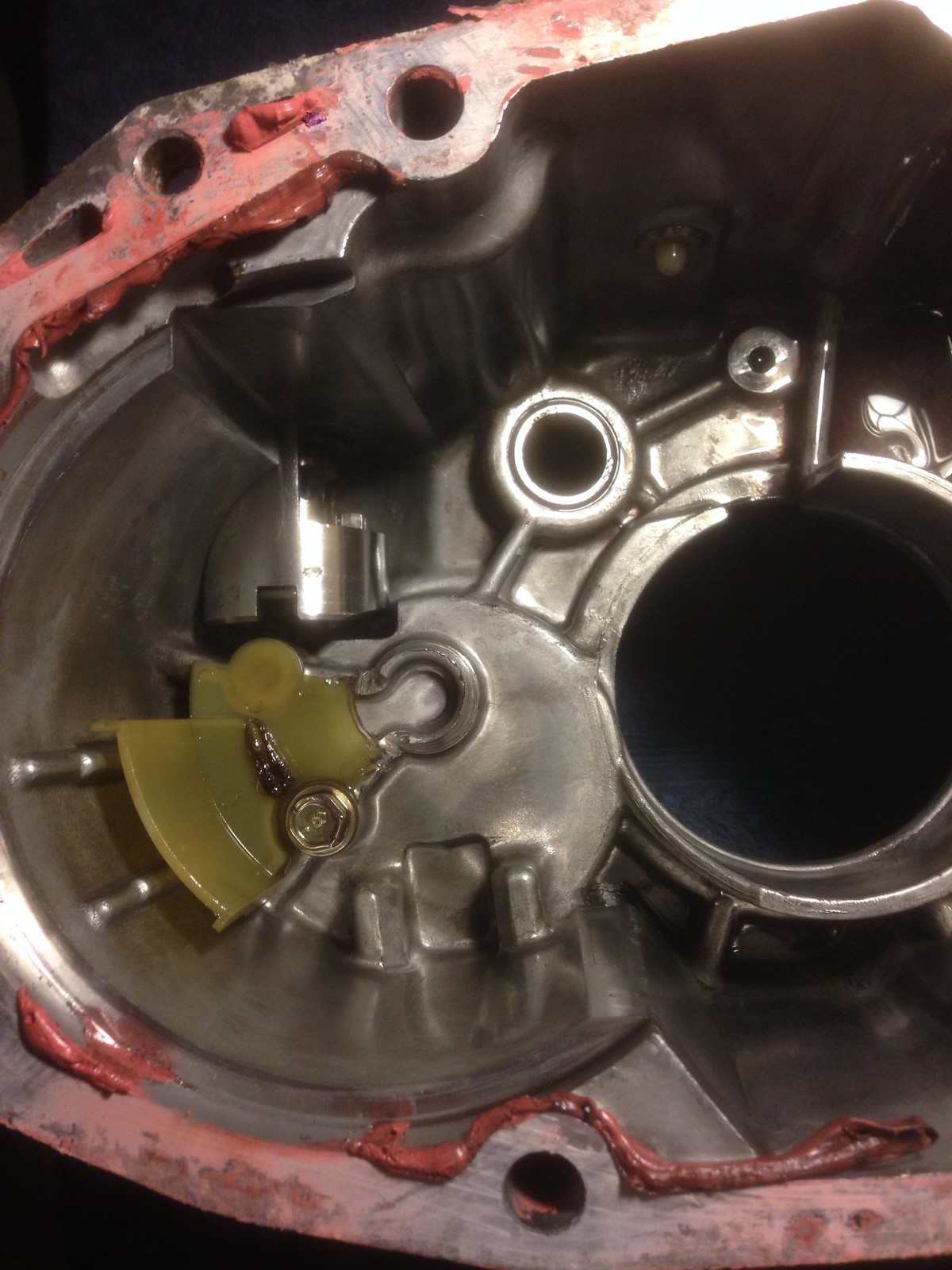

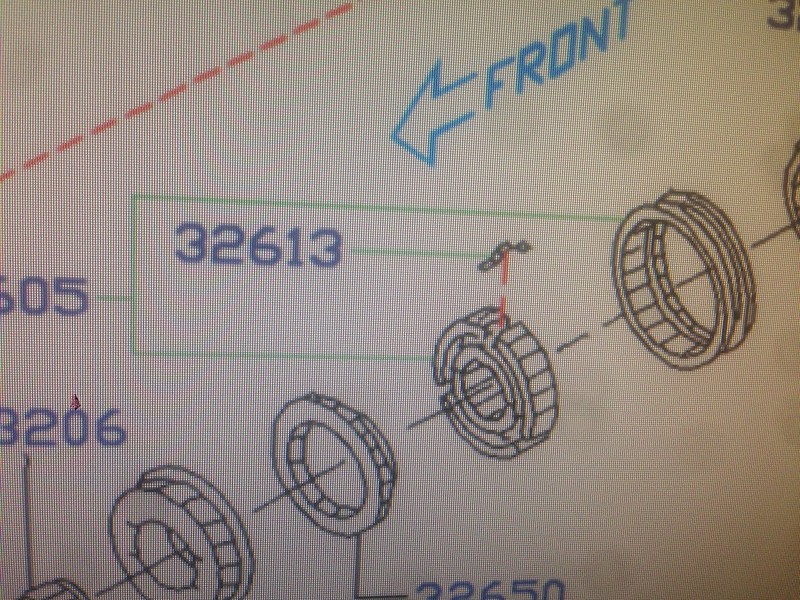

Transmission work

Steering work

818:

Delivery day! Brought the 818 home. (7/5/14)

Mounted fuel tank

Front suspension

Installed engine

Brake lines

Seat mounting

Clutch and trans installed

Coolant lines

Wheels

First start

First drive

Tune and Alignment

First autox(bad angle)

Started Body Work

Better autox angle

Race wind screen and dash

Fender liners

Race height

Relocated intake

Broke Transmission

Side Scoops

Shortened front upper A-arms for more aggressive alignment

Shift linkage

Track:

First track day(NYST)

Second track day (SLMP)

More NYST track time

The quest for street legality:

Windshield

Rear bumper

License plate lights

Defroster

Wipers

Side marker lights

VIN

Plates and timeline recap of street legality process

Other:

Engine swapped lawn mower

First tow

Blew up daily driver (WRX)

Visited Canada Frank

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

We realized that mistake as soon as we looked at axles. Got crafty with a crowbar placed between studs (broke one in the process, but I needed new ones as the old ones were destroyed) and got them off.

We realized that mistake as soon as we looked at axles. Got crafty with a crowbar placed between studs (broke one in the process, but I needed new ones as the old ones were destroyed) and got them off.