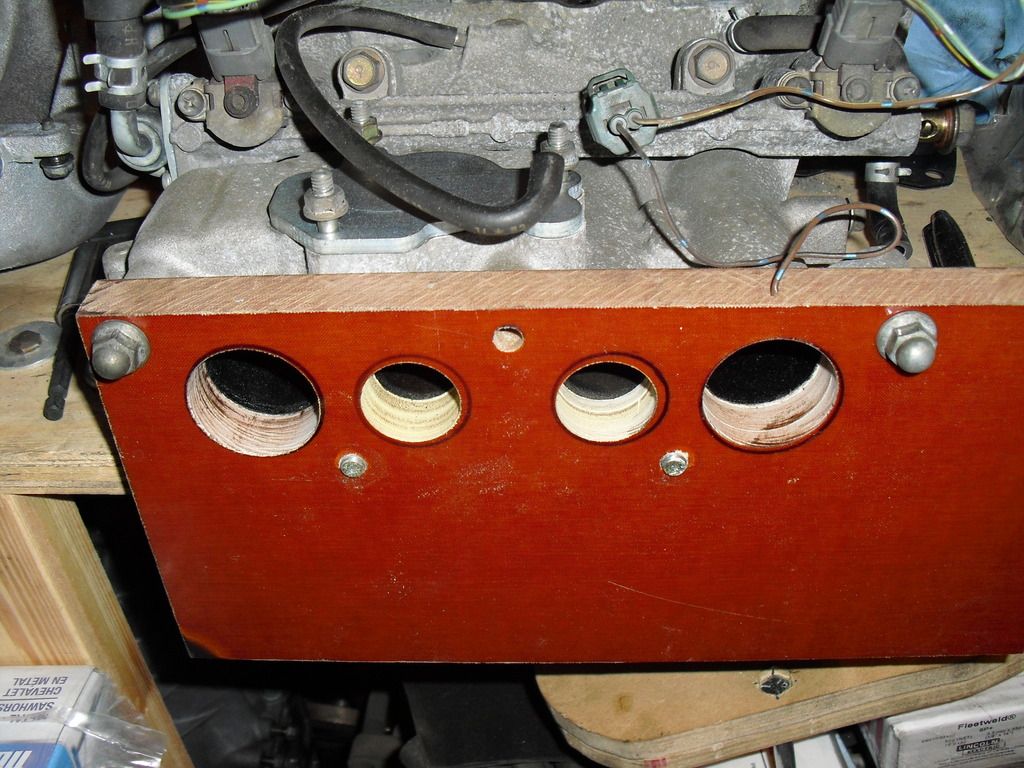

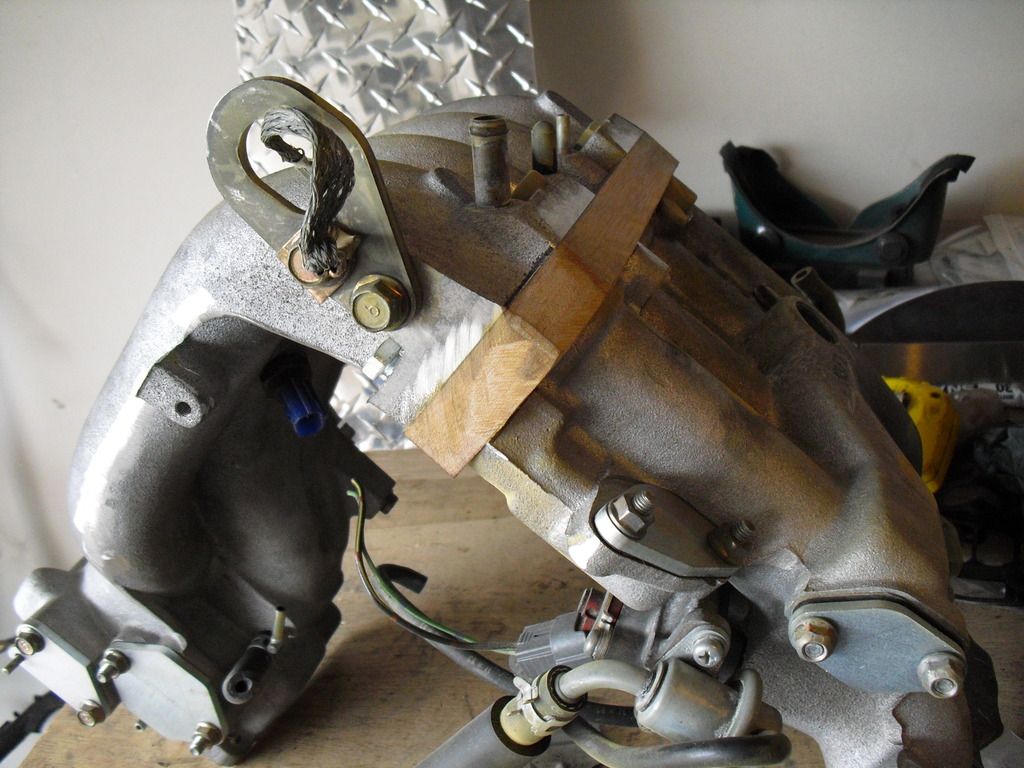

Small update, no pics. I've found an adapter kit, includes flywheel. Unfortunately it costs about half of what the engine cost. It's 800AUD +400AUD for shipping. I'll bite the bullet and order it, but first I'll make a spacer out of wood to mock up the engine/trans before spending anymore on it. I also ordered some wrx rear brake backing plates. Is it bad that I had to re-read my own build thread to see where I left off?

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote