Visit our community sponsor

Thanks:

0

Likes:

0

-

THE Engine Thread

This is a Direct Copy of FuJi K's post on Nasioc.

I want to build a 2.x engine

I refer to this post a LOT, i figure this could help a lot of people here too.

With Subaru engines being like legos, you can assemble an engine with a size of anywhere from a 2.0L to like say a 2.7L. Of course you have to have the know how and some experience in engine building to understand what you are doing. Which ever combination you choose will determine how your power-band will look like with your whole setup. Here we will look at how you can swap parts around to make a few combination's and also some other crazy ideas if you have some money to burn.

First lets determine what your engine management is going to be because it will determine what heads you can run. If you have a 2002+WRX/2004+STi/FXT/Baja XT/Legacy&Outback 2005+ this will make it easy for you since your factory ECU is supported from AccessPort by Cobb Tuning, ECUTec, OpenSource, as well as a full replacement after market ECU such as Hydra, AEM, and even Motec. If you own an older engine swap that is in the Impreza GC8 era, Legacy BF/BG, Forester SF, you may need to find alternatives like chipping the ECU, piggyback as well as full aftermarket ECU swap to Apexi PowerFC, Link, Hydra, or Motec just to name a few.

Knowing what engine setup you have plays a big factor in fitting those heads onto the block because of bore size vs combustion chamber size. It can alter compression ratio as well as detonation problems and air flow into and out of the engine. The EJ205 combustion chamber matches the 92mm bore of the EJ20. The EJ257 combustion chamber matches the 99.5mm bore of the EJ25. The EJ20K/EJ25D heads have a clover combustion chamber and was made for the EJ20 bore. However the USDM 1996 EJ25D specifically was made with a wider combustion camber to fit the EJ25 bore. You do not ever want to put like a EJ257 head onto a smaller bore than what it was made for.

What turbo size are you planning to go with and what fuel? Knowing what turbo you are going with determines how you build your engine. The fuel type allows you to better make use of larger turbos and even small turbos. The turbo produces the power-band and you can broaden it by using the right matching parts to work with the engine operation speeds. Smaller turbos focus more in the lower mid range power band. Medium turbos focus more mid range. Big turbos are more in the upper engine speeds. Build your heads to suit that power-band so you make the most out of your whole setup. The engine combination you choose alters the power-band where it's more focus.

Let's try to understand the EJ-phase1 and phase2 blocks. Phase1 EJ-blocks are the first blocks Subaru made and for US models started in 1990-1998. There are less bolts on the bell housing holding the engine to the transmission. You have your top two bolts, which are longer with the driver side going through the starter, and the passenger side going through the transmission and which ever bracket there is for NA engines. Then you just have the studs that come out at the bottom of the block. Phase2 blocks start in 1999+ and use six bolts holding the transmission onto the engine with the two studs at the bottom.

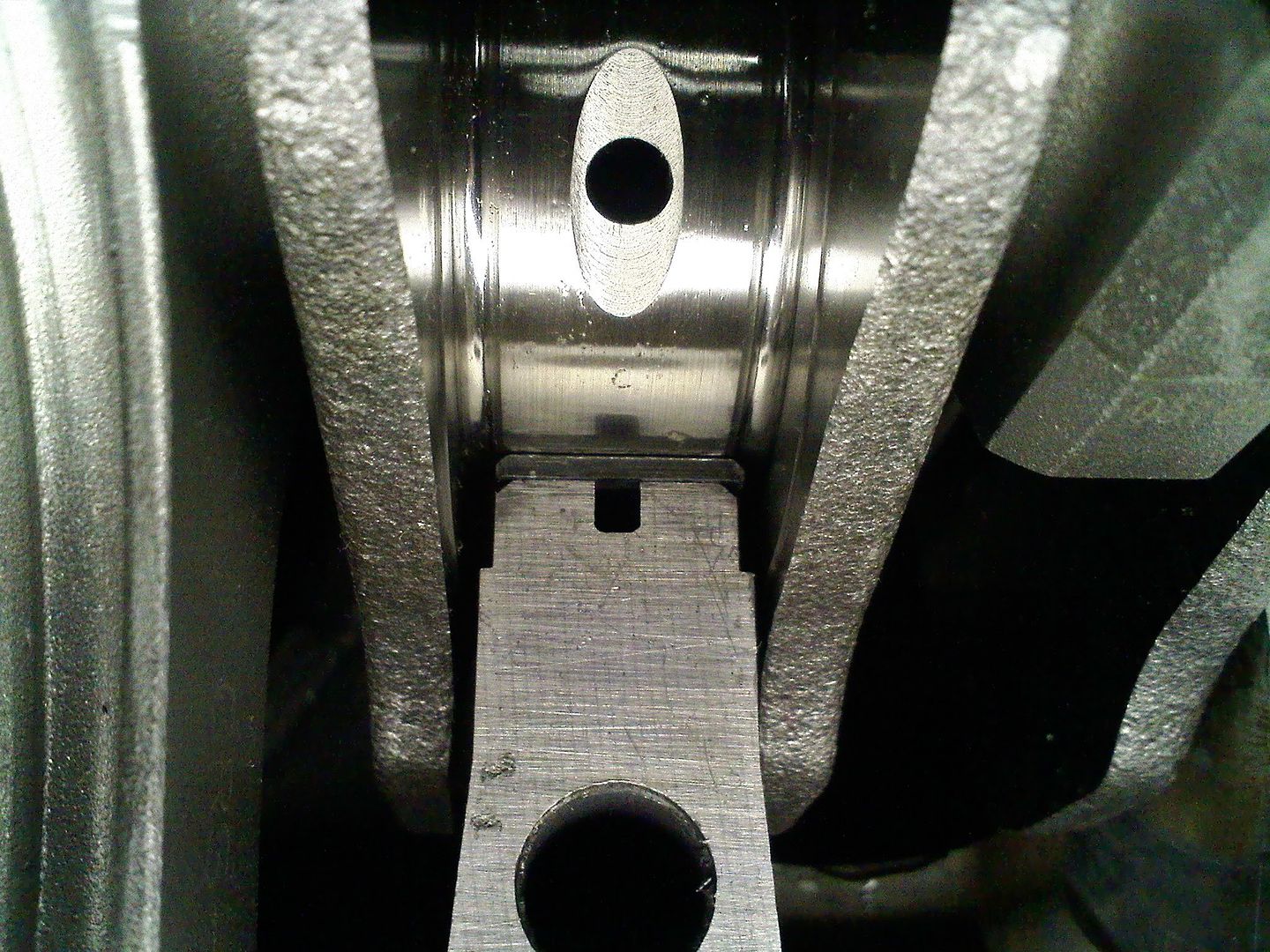

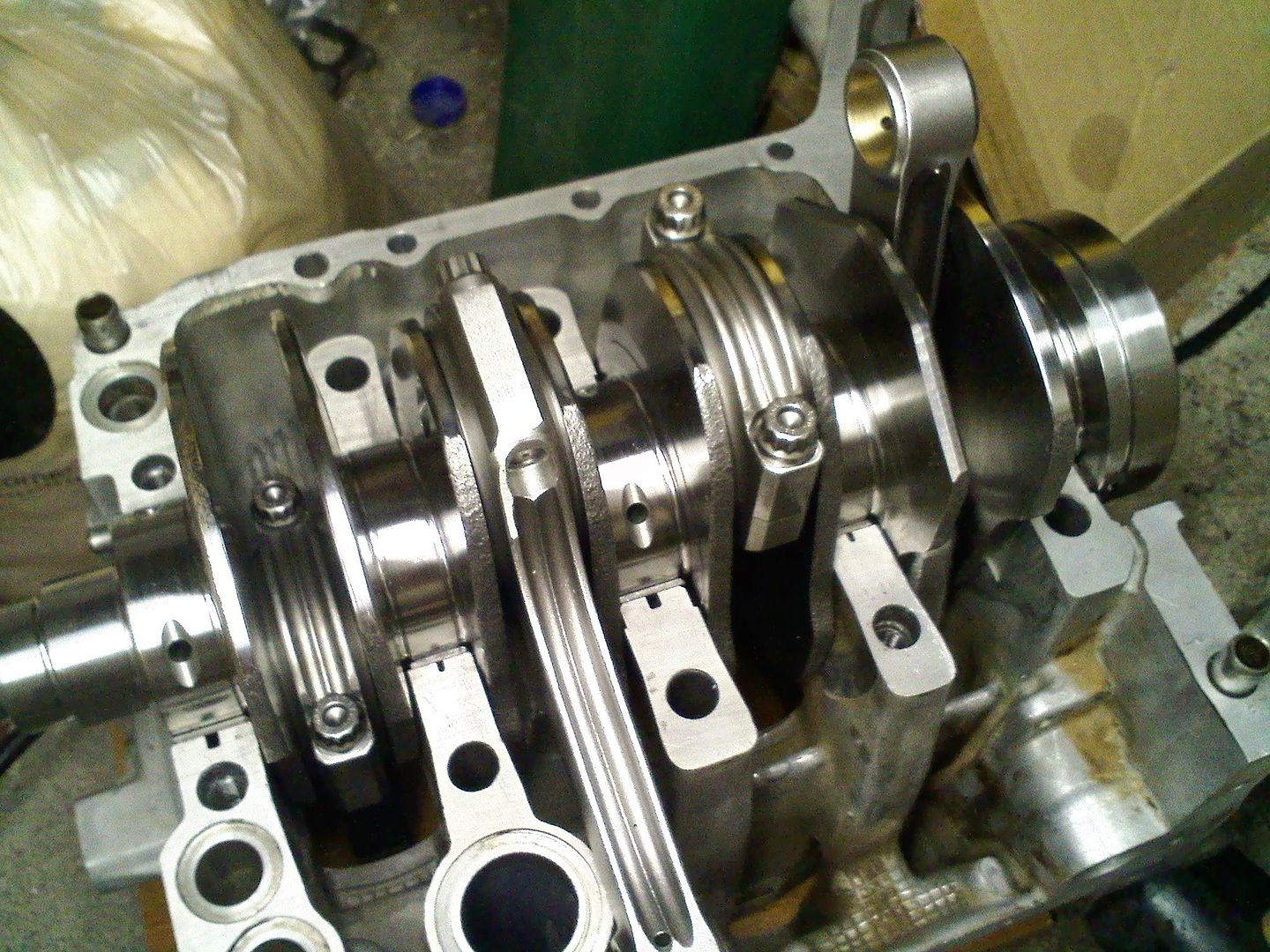

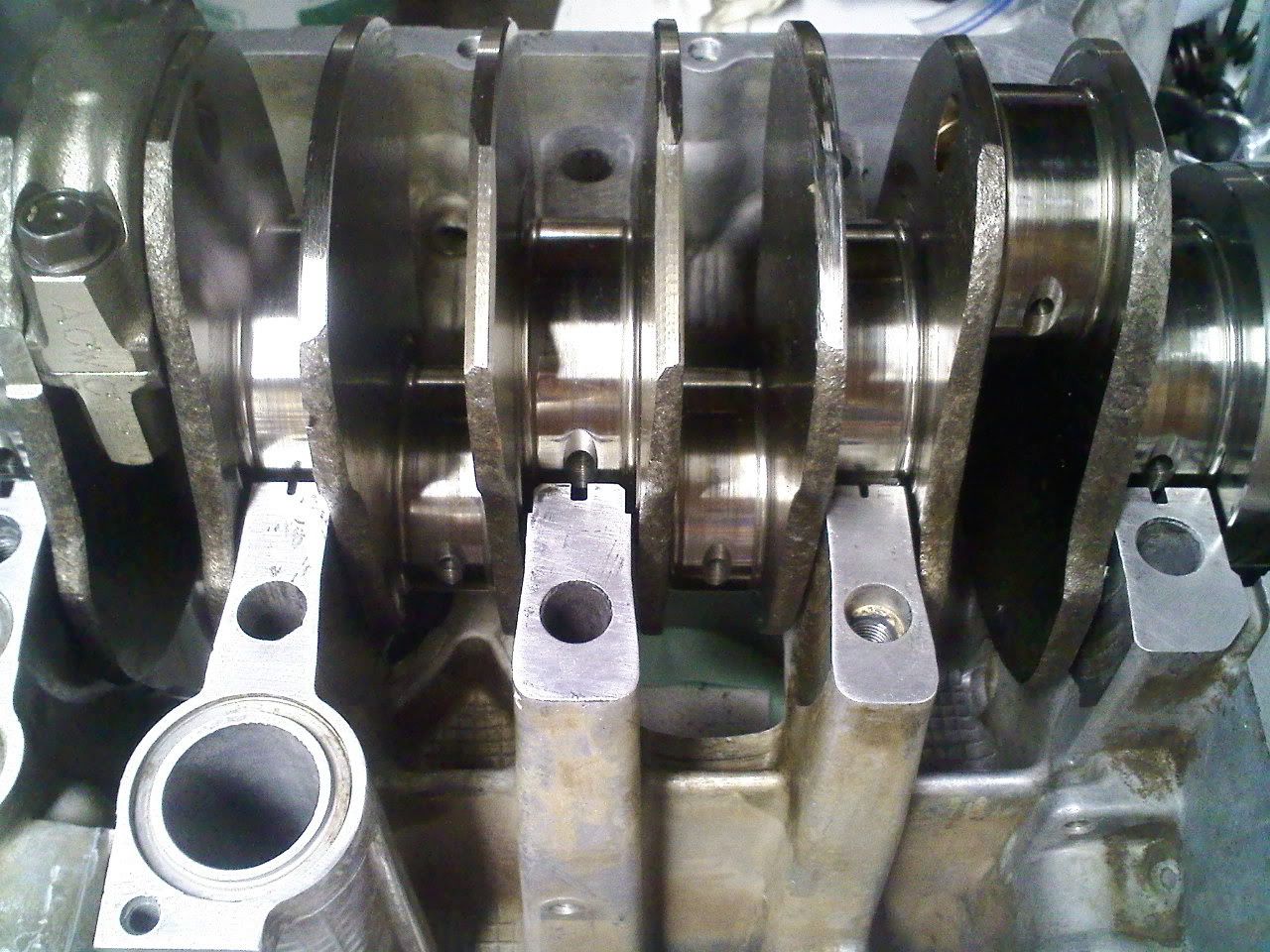

The thrust bearing on the crankshaft is located on main bearing #3 on the phase1 block, which is the middle of the five mains. This thrust bearing as you may know keeps the crank from moving forward and backwards when you disengage the clutch. Other differences are the exterior casting of the block and varies in casting bracing and ribs as it progress through the years. Phase2 has its thrust bearing on #5 main bearing, which is the last main bearing on the crankshaft. However they both use the same #3 main crank journal to feed connecting rods #2 and #3 where as connecting rods #1 and #4 get their own individual oil feed.

The internals vary in journal sizes and strokes for both phases depending on the engine size. Phase1 EJ20 and EJ22 uses the same crankshaft dimensions. They both run a 75mm stroke and have the same rod journals of 52mm. The phase1 EJ25 however uses a 79mm stroke, but with a 48mm rod journal to compensate for the longer stroke. Phase2 EJ-series crankshafts all use the same 52mm rod journals but vary in strokes of 75mm and 79mm. Overseas Subaru has crankshafts with much smaller strokes such as a 65.8mm on the EJ15/EJ16. The rod lengths are the same length for phase1/2 EJ20 and EJ22, as well as the phase2 EJ255/EJ257 and '05+ EJ25 NA models. Rod length for the phase1 EJ25 is different from the rest of the EJ-series for US models.

Now lets get to the fun part. Now which ever crank and bore size you choose will determine how your power-band will look like with your whole setup. The base EJ20 tends to be a higher RPM engine. The EJ22 gives you some more mid range. The EJ25 gives you more mid range and low end grunt.

Knowing what phase block you have, you can swap cranks around and even use connecting rods that may have not been made for your engine to begin with. Now you can only use the crankshaft with the correct thrust bearing on which ever phase block you have. To alter this you will have to have the block's main bearing machined to fit the thrust bearing in which the crank calls for. Usually this applies to phase1 blocks wanting to use phase2 cranks so #5 main gets machined on the block to fit the new thrust bearing and #3 main gets notched to fit the tab of the phase2 bearings. This is the best way to go about it to be able to use the different thrust bearing location cranks.

Now that you have that done you can choose your rods. All the turbo rods now are made the same because they all share the same rod length. If you have a EJ25 phase1, your rod will be different because of the 48mm rod journal. There are few companies that still make the 48mm rod journal connecting rod but will cost you some to get customs ones made if you need it. Pauter may still have these rods if you are wondering.

Now the pistons are what you have to get now. The piston goes with the block you have. EJ20 means you have to get the piston to fit that bore. Same goes for EJ22 and EJ25. Now depending which crank you choose, you may have to change the wrist pin location. You run a EJ20/EJ22 with the OEM 75mm crank and you do not have to worry about wrist pin location. However when you change that crank to a 79mm crank, the added 4mm pushes the piston up and extra 2mm up top and pulls it down and extra 2mm at the bottom. To counter this you have to raise the wrist pin higher, thus dropping your compression height dimension by 2mm. The same would be for a EJ25 engine using a 75mm crank having to lower the wrist pin, thus adding 2mm more to the compression height dimension. You can also counter this by using a connecting rod that is longer by 2mm to make up the difference and keep the wrist pin at its original location. NOTE: Phase1 pistons tend to come out of the block and over the deck. You may want to use phase2 piston compression height dimensions.

The head gasket now is what we are wondering. You want to use the HG to is the same thickness as stock. It will keep the overall width from cam gear to cam gear. This keeps the timing within the correct range. When you change the thickness this changes the timing degree. You do not want to use the thickness of the head gasket to alter compression ratio. You should change compression ratio with pistons. The coolant passages may be altered or covered up a little depending what block you are using. You can have them modded or have the one made for you. Cometic may be able to help you with that.

Now that you have the major part finished, you can add on top of that different compression ratios by altering the pistons either by off the shelf pistons or custom. You can also set the specs to make the car produce more off boost grunt. You can add bigger cams if you built the engine for more RPMs. Now go and build that engine!

Other changes you can make are by altering the short block much more. You can add sleeves to it. You can change to a much larger or smaller stroke. You can add rod length to it. You can change piston dish design. You can increase bore size. All of this will alter the engine's power-band. How about a 65.8mm crank with +6mm rods on a 2.0L bore NA build with ported heads and long duration cams? Maybe 14,000rpms? Or how about a built 79mm stroked EJ22 with +2mm rods and 9000rpms boosted? Or say a simple sleeved EJ25 79mm with +2mm rods and high boost with 9000rpms? Maybe an EJ20 with +4mm rods and 10,000rpms might be fun with the right turbo? Fun comes with a wide power-band.

Please read the sticky to get yourself familiar with the engine parts.

Nasioc Sticky of Engine Parts

-

-

-

-

-

Along with all of this, reading the Wikipedia post of Subaru EJ Engine Is probably a good idea if you are newer to the subaru game, or completely lost with all this barrage of info.

-

Senior Member

Hey Iron, this is good stuff! You've contributed a LOT here, and I would personally like to say "Thanks!"

-

It's not my information, As much as I would LIKE to think i have contributed, i've really just collected info.

the real thanks to this thread goes to FuJi K on Nasioc (as much as i dislike that forum, it has a LOT of good info)

-

I've been doing some calculations on a block I want to build. and in short. read below

EJ22T block Halves (fully Closed Deck, Piston oil Squirters)

83mm Aftermarket crank (Manley, cosworth also makes one)

EJ25 Rods (eagle Replacement)

Cometic Head gasket (can get in a wide array of Thicknesses to offset Compression Ratio)

Wiseco Pistons (ej22T Stroker pistons) advertized to give the EJ22T with an EJ25 crank a 8.xx Compression Ratio

EJ207 Heads, complete with Variable Intake cam utilized

Custom ground Cam profiles (TBD, not sure if I can get my desired lift and ramp rate with the high compression i'm going to be running)

in the end i'm going for a 2.4Liter (almost 2.5) NA (maybe in the distant future superchared) 10.5:1 Compression Ratio (i can go high as 11.2 if my calculations are correct).

it will be fun. though, nobody i've ever had the chance to converse with has put these components together, so this is uncharted territory, and i'm willing to go out there for the power.

-

fasterer and furiouser

No mentioned of the 2.5 crank in a 2.0? The 2.1 is getting pretty popular.

A well stocked beverage fridge is the key to any successful project.

-

Originally Posted by

longislandwrx

No mentioned of the 2.5 crank in a 2.0? The 2.1 is getting pretty popular.

2.35 Stroked 2.2L (applies for 2.0L as well)

Post #5, in the middle.

-

Last edited by David Hodgkins; 02-24-2015 at 02:09 PM.

Reason: Infraction given for New User SPAM

-

I'm looking into using different possible engines.

Does anyone know the dimensions of the engine bay?

-

Tazio Nuvolari wannabe

EJ25 Series oiling system design and modification notes

EJ25 Series oiling system design and modification notes:

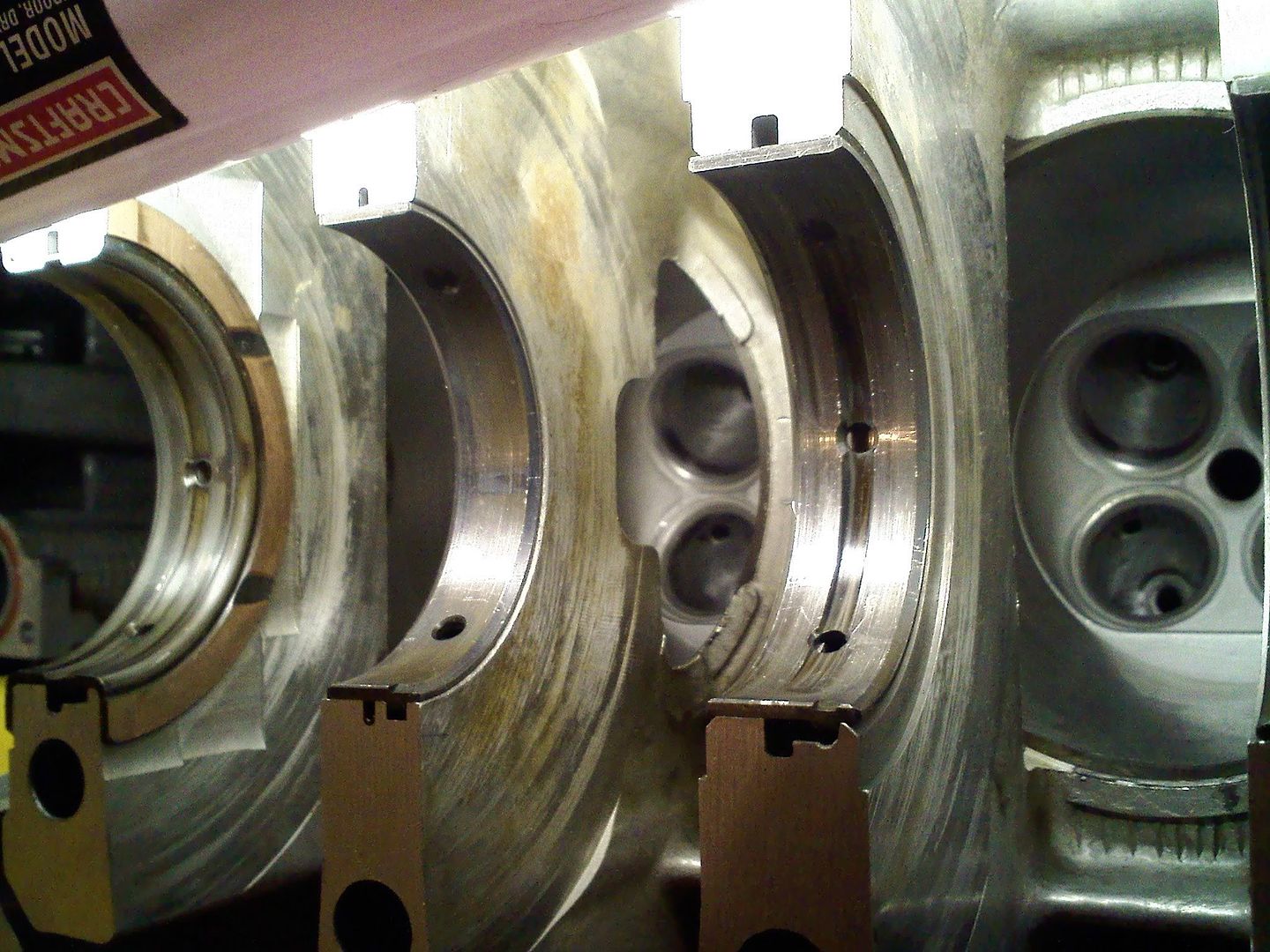

I am going to speak to the EJ25 engine because it’s what I know. I want to make the caveat that the enlargements are untested for the moment. A lot of what I'm doing will be applicable to other, earlier engines, like the 2.0.

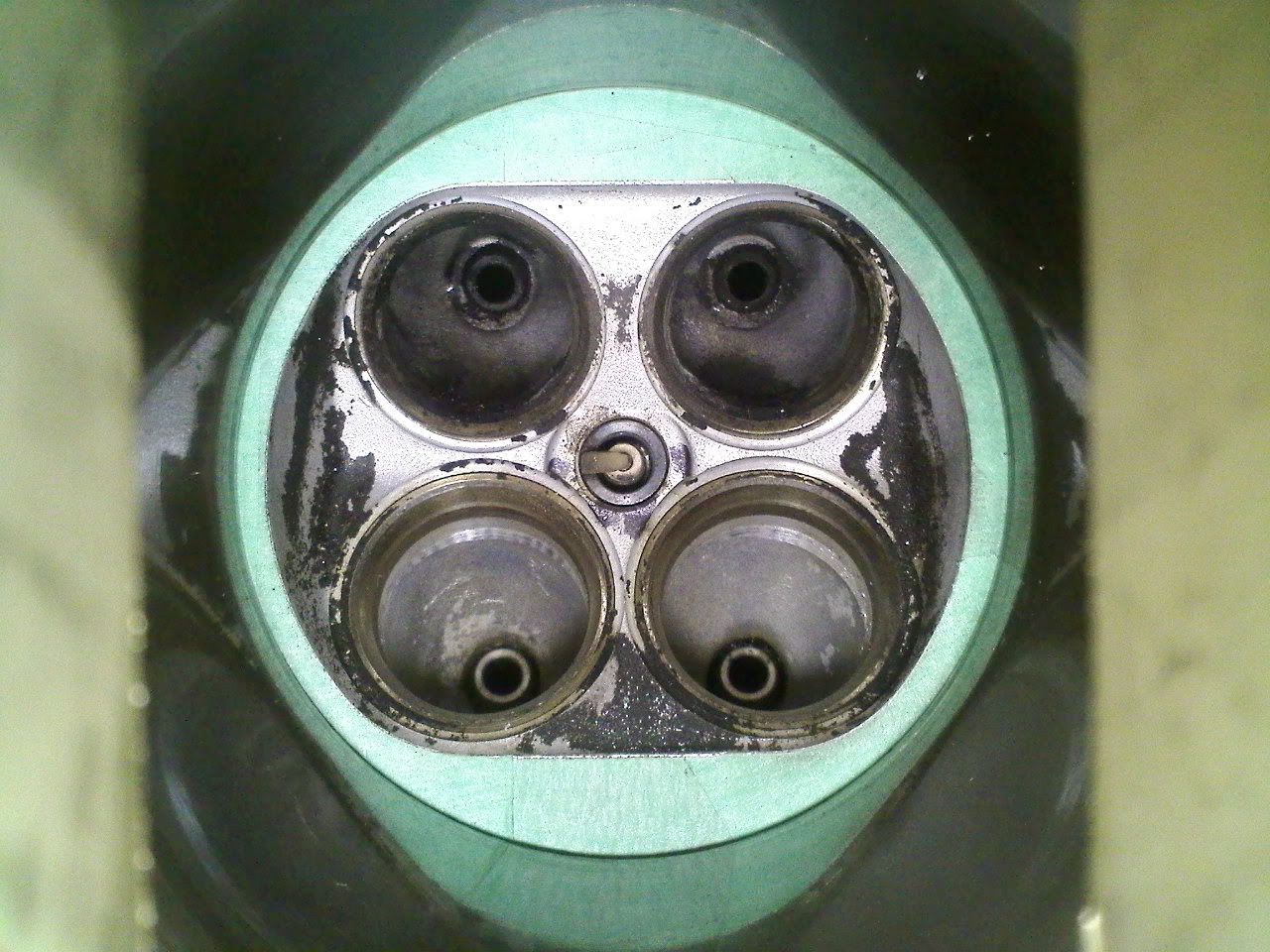

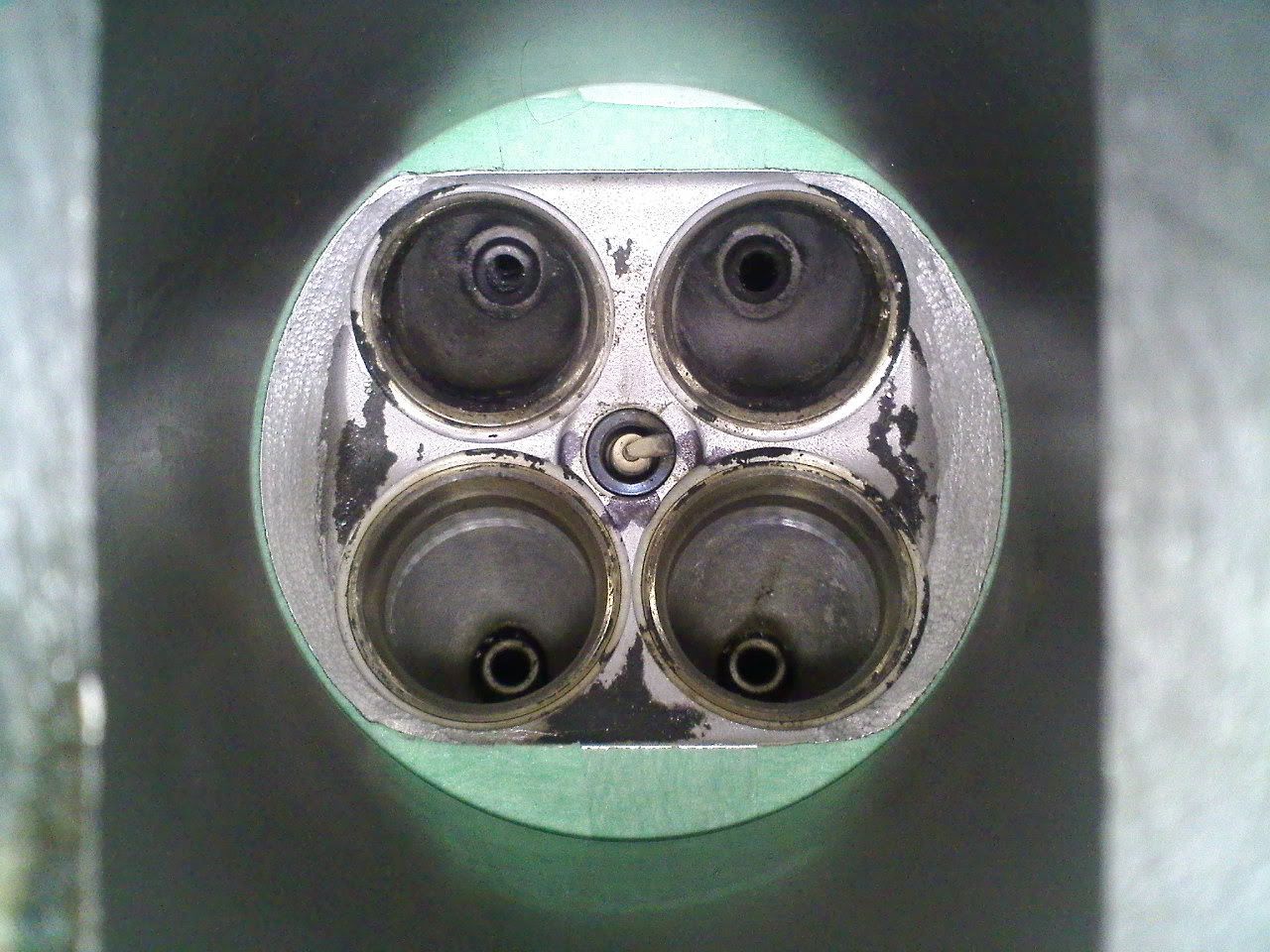

The majority of passages and orifices in the case do not exceed 13mm inside diameter (ID). Almost all passages in the case halves are cast-in using tapered core pins. Passages from the oil pump to oil filter and the return barely exceed 13mm and neck down to 12MM ID. Once oil reaches its highest point in the right-hand side of the case and branches off at 90° angles to the main oil galleys it is reduced to 12mm and tapers down to approximately 8mm at the end of the galleys. As the runners go from the left and right galleys to the heads they taper from 12mm to 7mm.

The single oil feed into the head’s galleys is 6mm ID. Internally the heads are drilled to 8mm ID. The external feed tubes for the AVCS Control Valve is 6.5mm ID (8mm OD). There is a large reduction to 2 mm ID at the right, rear head banjo (where oil comes out of the head for feeding the turbo and the AVCS, *if you have the late model heads.

Other sizes of importance and summary:

Oil Pump feed to filter: tapered from 16mm to 12mm ID

Oil filter to upper galleys: this passage tapers from 12mm to 14mm ID and reduces down to 10mm as it transitions horizontally to the left side of the case.

Left side case oil galley only goes half way to the rear of the case (tapers from 13mm to 8mm ID)

Right side case oil galley (tapers from 13mm to 8mm ID, from each end of the case)

Turbo CHRA (bearing cartridge) Oil Feed (late model heads): 2mm ID*

Note: on many turbos there is another reduced ID orifice fitting to which you connect the SS braided hose.

Right Head Oil Feed Line (tapers from 12mm to 7mm ID)

Left Head Oil Feed Line (tapers from 12mm to 7mm ID)

Heads entrance for oil: 6mm ID (drilled)

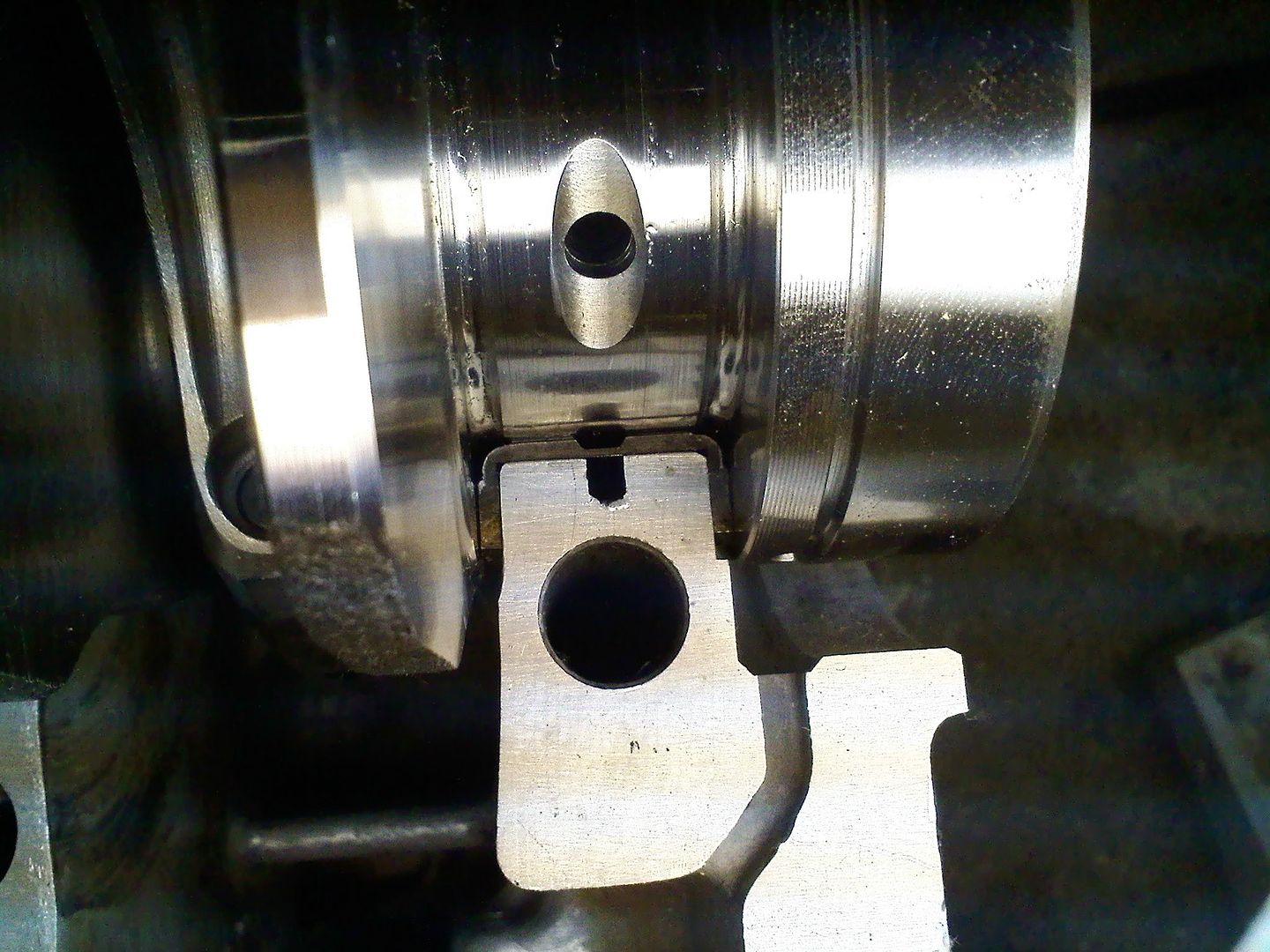

#5 Main bearing and rear thrust bearing (6mm ID feeds #4 rod journal through crankshaft journal without reduction)

#4 Cylinder, rod bearing feed line (from #5 main/thrust bearing through crankshaft)

#4 Main bearing oil feed line (feeds only this main bearing)

#4 Main bearing feed line diameter reduction (passage reduces from 6mm minimum inside diameter to a 3.5mm orifice, like #2 main)

#3 Main bearing feed line reduces to 7mm minimum ID (feeds both #2 & #3 rod bearings through this one crankshaft journal)

#2 Main bearing feed line, feeds only this bearing (6mm minimum inside diameter passage reduces down to a 3.5mm orifice)

#1 Main bearing, with reduction to 5.5mm diameter (feeds from/beginning at the front of the right galley)

#1 Cylinder, Rod Bearing feeds from #1 Main Journal through crankshaft journal)

Crank main oil holes are 5.5mm and rod journal holes are 4.5mm.

Summary: I eliminated the tapers in the galleys and cast passages. I made them 14.3mm (9/16”) on the right side galley. On the left galley I made it 14.3mm till I hit the feed for #2 Main Bearing. I reduced it to 13mm (1/2”) for the balance of the distance to the #3 Main Bearing runner. Feeds from the oil pump to the filter and back to the vertical runner up to the galleys were all enlarged to 14.3mm. I drilled the cast runners so they were a consistent 7mm to the journal.

All bends were radiused and blended. Feed runners to the heads were opened to 13mm ID. The receiving orifice in the head was radiused and tapered to be funnel-like.

Until I am convinced that the #2 and #4 Main bearing orifices can be enlarged I will leave them alone.

All this work was done with the express intent of running an 11 or 12 mm oil pump that is ported and shimmed to achieve 85PSI hot, with bearing clearances of Mains .0015” and Rods .002”. I will use what has worked in the past for me and that is -10AN hose and fittings going to an external cooler and remote, oversized racing filter. Since -10AN is nominally .480”ID or 12.2mm and galleys and primary passages reduce down to 8mm or 10mm in stock form, I feel I now have the hose and fittings as my bottleneck. -10AN has worked successfully for me in undrilled cases to 7,200 RPM and 395 AWDHP.

This latest full case mod is for an anticipated 8,000 RPM red line and up to 500 CHP or 400AWDHP. My pistons weight 530 grams (complete) and the Manley rods 592 grams. Together, this is 14% less than stock.

I can’t see a problem with what I’m doing but I will again throw in the caveat that some of these enlargement mods are untested.

lubrication engine copy.png

UPDATE: One engine builder said he does not touch the orifices in the passages of main bearing 2 and 4. He did say he did much the same as the things I have done for 400+ WHP engines and that it helps.

Last edited by Scargo; 10-29-2017 at 09:46 AM.

Reason: clarification

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Visit our community sponsor

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote