-

04-07-2019, 05:31 PM

#241

-

04-11-2019, 06:37 PM

#242

Looking nice.... I can easily answer your first question about the lights... there is no Pos/Neg, either will do both. On my build, I used jumper wires between the turn signal switch and the hazard switch to get the power where it needed to go... CLICK HERE for the page I have on my build and in one of the photos you can see the two switches on the left side of the photo. You have a different turn signal switch than I do so not sure if my system would work for yours. Bottom line, I just followed the wiring on the schematic for the wiring harness and you should be able to follow how to hook them up. I know this is not a text book explanation, but it makes sense once you follow the schematic. The Speed/clock/mem wire is your always hot wire to keep your clock running even when the key is off. It will also keep your radio memory sets (if you have one) and on the GPS spedo it will allow for a fast boot up and satellite connection. Hope this is at least a little help.

Last edited by BadAsp427; 04-11-2019 at 06:41 PM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-11-2019, 08:31 PM

#243

Senior Member

Looks like you're using the standard kit switches, e.g. dash mounted toggle for turn signals, hazards, and low/high beam headlights. That makes it easy. Well, easy to say. Just follow the Ron Francis dash wiring schematic exactly and it will work. Specific responses to your questions:

1. BadAsp427 is right. The kit supplied incandescent indicator lights will work with +12V and ground on either lead. No worries there. If they were LED, that wouldn't be the case.

2. You're not quite understanding the circuit. There isn't a separate indicator for the hazards. There are two turn signal indicators. One for each direction which will flash along with the turn signals on each side. When the hazard switch is turned on, both turn signal indicators will flash along with the lights on all four corners. Same as every DD I've ever owned or seen.

3. Again, wire it just like it shows. You're right. The front and rear turn signals are different colors for each side. But they are joined at the turn signal switch.

4. Don't see a clock in your dash, so you don't need it for that. Also with those Autometer gauges no GPS, so don't need it for that either. Looks like you don't need it. Make sure it's capped since it's always powered. You can't pull the fuse since there are other things on that circuit you need, e.g. headlight switch and courtesy lights (if you're using them).

Last edited by edwardb; 04-11-2019 at 08:33 PM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-11-2019, 08:34 PM

#244

Originally Posted by

BadAsp427

Looking nice.... I can easily answer your first question about the lights... there is no Pos/Neg, either will do both. On my build, I used jumper wires between the turn signal switch and the hazard switch to get the power where it needed to go...

CLICK HERE for the page I have on my build and in one of the photos you can see the two switches on the left side of the photo. You have a different turn signal switch than I do so not sure if my system would work for yours. Bottom line, I just followed the wiring on the schematic for the wiring harness and you should be able to follow how to hook them up. I know this is not a text book explanation, but it makes sense once you follow the schematic. The Speed/clock/mem wire is your always hot wire to keep your clock running even when the key is off. It will also keep your radio memory sets (if you have one) and on the GPS spedo it will allow for a fast boot up and satellite connection. Hope this is at least a little help.

Thank you, Carl! That all makes sense and is very helpful!

-

04-11-2019, 08:39 PM

#245

Originally Posted by

edwardb

Looks like you're using the standard kit switches, e.g. dash mounted toggle for turn signals, hazards, and low/high beam headlights. That makes it easy. Well, easy to say. Just follow the Ron Francis dash wiring schematic exactly and it will work. Specific responses to your questions:

1. BadAsp427 is right. The kit supplied incandescent indicator lights will work with +12V and ground on either lead. No worries there. If they were LED, that wouldn't be the case.

2. You're not quite understanding the circuit. There isn't a separate indicator for the hazards. There are two turn signal indicators. One for each direction which will flash along with the turn signals on each side. When the hazard switch is turned on, both turn signal indicators will flash along with the lights on all four corners. Same as every DD I've ever owned or seen.

3. Again, wire it just like it shows. You're right. The front and rear turn signals are different colors for each side. But they are joined at the turn signal switch.

4. Don't see a clock in your dash, so you don't need it for that. Also with those Autometer gauges no GPS, so don't need it for that either. Looks like you don't need it. Make sure it's capped since it's always powered. You can't pull the fuse since there are other things on that circuit you need, e.g. headlight switch and courtesy lights (if you're using them).

That's great - very clear. Thank you, Paul! I think I understand what we need to do now. I certainly don't know what we'd do without all your great help!

-

04-15-2019, 08:48 PM

#246

-

04-15-2019, 10:02 PM

#247

I start working on the dash pretty soon. Maybe as early as next week. I'll be following this pretty close since I have the stock gauges as well.

"Doddmoore," Mitchell Moore on facebook, Follow Tonks347Cobra on Instagram

MK IV Complete kit, SB Ford 347, Holley Sniper EFI, TKO 500, Moser 8.8 Solid axle, Wilwoods, Power Steering

My Build Thread:

Tonks347, The Baker's Build

Slow and steady wins the race.

-

04-21-2019, 08:58 PM

#248

Brake Balance

We tried to set up our brake balance today to get at least an acceptable starting point. I think we shouldn't worry about this too much before we go kart but still wanted to see if you guys had any comments or advice. Here's a link to a video showing us depressing the brake:

https://youtu.be/U9Sy8o13rHM

We tried to balance it out such that each cylinder depressed about equally. It seemed ok - however the initial positioning looks a little off-kilter. Here's a picture:

Love to hear your advice - especially on something as important as brakes! Thanks, guys!

-

04-21-2019, 09:16 PM

#249

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

04-22-2019, 07:13 PM

#250

Looking good! I actually had the shorty headers installed outside the car - made it a little tighter but still installed with not real issues. Sure looks nice with the mill in place, right?

Mk4 #8861 Complete kit. Delivered: 27 Apr 2016, currently a roller.

Gen-2 Coyote, clutch, TKO600, midshift, and solid axle from Forte. Many pieces from Breeze and Replicarparts.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-22-2019, 09:19 PM

#251

Originally Posted by

initiator

Looking good! I actually had the shorty headers installed outside the car - made it a little tighter but still installed with not real issues. Sure looks nice with the mill in place, right?

Yeah! It does look good with the engine in there - really feels like a big step forward!

-

04-27-2019, 06:17 PM

#252

Senior Member

Great Progress... Isn't it cool to go through that "It ain't gonna fit... no way... too big... Holy Crap! It's in there!"

John D. - Minneapolis 'Burbs

1965 El Camino - LT-1, 4L60e, 4wh discs, SC&C susp.

2013 F-150 Platinum - Twin Turbo 3.5

2018 Mk4 Roadster w/ Coyote - #9365 - Build Thread Delivery 7/3/18, 1st Start 1/4/19, 1st Road Mile 5/5/19, Legal 6/18/19, In Paint 2/25/21, Done (?) 4/2021

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-28-2019, 08:58 PM

#253

Originally Posted by

Fixit

Great Progress... Isn't it cool to go through that "It ain't gonna fit... no way... too big... Holy Crap! It's in there!"

Ha! Yeah, you're exactly right!  Thanks, John.

Thanks, John.

-

05-04-2019, 05:41 PM

#254

Connecting Fuel Lines to Fuel Regulator

Hi guys. This weekend, we are trying to connect the rigid fuel lines to the fuel regulator using the flexible fuel lines supplied with the kit. These flexible lines seem to fit well going into the regulator, but they don't seem to fit the rigid fuel lines at all - on the fuel intake line, the flexible line is too large and on the one for the fuel return, the flex line is too small. Has anyone else run into this issue? Did you go buy different fittings for the rigid lines? Here's a look at what we're doing. Here are the fittings on the rigid lines:

Here are the fittings on the flex lines we're trying to fit to the rigid lines.

We are unscrewing and taking off the ends of the fittings on the flex lines as well as that little plastic ring.

Any help on what to do to connect those flexible lines to the rigid lines would be greatly appreciated! Thanks, guys!

-

05-05-2019, 12:05 PM

#255

Senior Member

Hey Pete, great to see you got it in there! It’ll be running in no time. It’s nice to have a fellow Coyote builder at nearly the same stage. I started mine last weekend and let me tell ya, car nutz come out of the woodwork when they hear it! It’s the best part. Neighbors rarely talk around here, but if the weather is good and there’s a project like this?...Well, it’s just a lot of fun. I’m even contemplating starting a car gathering at the pool for our neighborhood.

Bradley

Build thread - Mk4, Coyote, IRS, Wilwood brakes, old-style soft top and accessories.

The distance between "finished" and finished is literally infinite.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

05-22-2019, 08:47 PM

#256

Transmission and Driveshaft

We tried installing our driveshaft but the transmission was too far down for the driveshaft to spin unimpeded. This seems to be a common problem and we found an easy fix via a set of spacers from summit racing. We installed them to lift the transmission up a bit. The arrow below points to the spacer.

Then we were able to install the driveshaft:

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

05-24-2019, 03:44 PM

#257

Hi Pete - I think most folks use 1.5" of lift at the TKO600 supports. I used 1/4" thick Aluminum from Home Depot and made a stack of 6. Haven't had the chance to see how well that aligns with the differential yet, but that's the lift I've seen others use for Coyote/TKO600/3-link.

How much lift did your Summit spacers give?

Mk4 #8861 Complete kit. Delivered: 27 Apr 2016, currently a roller.

Gen-2 Coyote, clutch, TKO600, midshift, and solid axle from Forte. Many pieces from Breeze and Replicarparts.

-

05-25-2019, 01:54 PM

#258

Originally Posted by

initiator

Hi Pete - I think most folks use 1.5" of lift at the TKO600 supports. I used 1/4" thick Aluminum from Home Depot and made a stack of 6. Haven't had the chance to see how well that aligns with the differential yet, but that's the lift I've seen others use for Coyote/TKO600/3-link.

How much lift did your Summit spacers give?

Hi Initiator,

Happy memorial day weekend! The summit spacers don't give as much lift as your 6 aluminum spacers - they give the transmission about 3/4 of an inch of lift. It seems to be enough clearance for us as far as i can tell so far. You're solution sounds like a good one as well. Here's a link to the summit ones in case anyone is interested:

https://www.summitracing.com/parts/i...-tko/overview/

-

05-25-2019, 02:30 PM

#259

Senior Member

Originally Posted by

PeteMeindl

Hi Initiator,

Happy memorial day weekend! The summit spacers don't give as much lift as your 6 aluminum spacers - they give the transmission about 3/4 of an inch of lift. It seems to be enough clearance for us as far as i can tell so far. You're solution sounds like a good one as well. Here's a link to the summit ones in case anyone is interested:

https://www.summitracing.com/parts/i...-tko/overview/

That should be about right. I've found 3/4-inch is the right amount for the TKO. Both solid axle and IRS.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

05-28-2019, 04:42 PM

#260

Originally Posted by

edwardb

That should be about right. I've found 3/4-inch is the right amount for the TKO. Both solid axle and IRS.

Gack! Teach me to rely on memory at this age. Sorry, Pete - sure didn't mean to mislead you. I'll have to go back and check my sources, but the proof is in the driveline alignment (and u-joint angles).

EDIT - My mistake was that I used 1/8" Aluminum instead of 1/4". Six of these makes 0.75" height, which matches the experience of others. Sorry about that.

Last edited by initiator; 05-28-2019 at 10:43 PM.

Mk4 #8861 Complete kit. Delivered: 27 Apr 2016, currently a roller.

Gen-2 Coyote, clutch, TKO600, midshift, and solid axle from Forte. Many pieces from Breeze and Replicarparts.

-

05-28-2019, 08:58 PM

#261

Originally Posted by

initiator

Gack! Teach me to rely on memory at this age. Sorry, Pete - sure didn't mean to mislead you. I'll have to go back and check my sources, but the proof is in the driveline alignment (and u-joint angles).

Ha!  You weren't misleading at all! I always appreciate your thoughts and advice!

You weren't misleading at all! I always appreciate your thoughts and advice!

-

05-28-2019, 09:16 PM

#262

-

06-01-2019, 09:05 PM

#263

-

06-01-2019, 09:13 PM

#264

Clutch cable issue

One thing we noticed recently was that the clutch cable mount on the front of the drivers footbox has come a little loose. In fact, the pressure of the bending cable actually cracked the head off of the screw we used to attached the clutch cable to the footbox. Here's a picture where you can see the mount being pulled a little bit away from the footbox wall:

I think what we'll do is get a stronger bolt and use that instead of the screw we had in there before. Unfortunately, the mount itself isn't too big so we won't be able to get something that much bigger and stronger. We could try a stronger material for the hardware too.

Does this seem like a good solution? Feel free to suggest any better ideas - thanks!

-

06-02-2019, 09:21 PM

#265

Senior Member

Hey Pete, good progress. I don’t know if this will help, but I wonder what your clutch cable route is? I ran mine under the engine mount and it seems to be free of undo pressure. I also put that mount screw at the top on the foot box.

If you can see in this picture, the first arrow is the route of the cable and the second arrow is where I tapped a bolt and mounted a cable guide to the frame. The cable then continues under the engine mount and has a straight line to the bell housing.

Bradley

Build thread - Mk4, Coyote, IRS, Wilwood brakes, old-style soft top and accessories.

The distance between "finished" and finished is literally infinite.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

06-02-2019, 09:36 PM

#266

Senior Member

Originally Posted by

PeteMeindl

This weekend we made some progress on the radiator, both attaching the top part of the radiator to the chassis, as well as hooking up some of the hoses between the engine and the radiator. Man, it took all of my strength to get those steel tubes into the rubber hoses! Whew! I wasn't sure if we were going to get them to fit... but i think it worked out in the end.

Here's the hose going to the upper opening on the radiator:

And 2 shots of the lower hose. The lower hose is just touching the steering shaft which concerns me. You can see in the picture, we put some cardboard in between the hose and the shaft and we're hoping that this pressure bends the hose a little bit over time. I could try to force it to curve more sharply too, if this doesn't work.

Bend it away from the steering shaft, I did. I also tapped a bolt into the cross member and added a snug-fit vibration dampening loop clamp from McMaster, part number 3177T59. It holds the radiator hose where I want it and keeps from moving around.

Bradley

Build thread - Mk4, Coyote, IRS, Wilwood brakes, old-style soft top and accessories.

The distance between "finished" and finished is literally infinite.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

06-02-2019, 09:47 PM

#267

Senior Member

Pete, a word of caution. I’ve read that these stainless radiator hoses can come lose and blow off. Some go so far as to modify things to make sure it doesn’t happen. I have about two miles on the odometer now and a bunch of warm ups at idle. I checked the hose clamps after a bit of running it up to temp and sure enough, the clamps were needing to be retightened.

Bradley

Build thread - Mk4, Coyote, IRS, Wilwood brakes, old-style soft top and accessories.

The distance between "finished" and finished is literally infinite.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

06-03-2019, 08:48 AM

#268

Senior Member

Originally Posted by

GTBradley

Pete, a word of caution. I’ve read that these stainless radiator hoses can come lose and blow off. Some go so far as to modify things to make sure it doesn’t happen. I have about two miles on the odometer now and a bunch of warm ups at idle. I checked the hose clamps after a bit of running it up to temp and sure enough, the clamps were needing to be retightened.

What hoses did you use. Do you have part numbers?

-

06-03-2019, 02:13 PM

#269

I've seen folks install rivets around the radius of the metal hose to give the rubber hose and clamp something to grab onto.

Mk4 #8861 Complete kit. Delivered: 27 Apr 2016, currently a roller.

Gen-2 Coyote, clutch, TKO600, midshift, and solid axle from Forte. Many pieces from Breeze and Replicarparts.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

06-03-2019, 07:12 PM

#270

Senior Member

Originally Posted by

D02G

What hoses did you use. Do you have part numbers?

My full-kit parts list only says "3/8" coolant hose cut 5ft" part number 16575. I'm sure that's the stainless hose I used, but it doesn't say it in the part name.

Bradley

Build thread - Mk4, Coyote, IRS, Wilwood brakes, old-style soft top and accessories.

The distance between "finished" and finished is literally infinite.

-

06-03-2019, 09:22 PM

#271

Originally Posted by

GTBradley

Hey Pete, good progress. I don’t know if this will help, but I wonder what your clutch cable route is? I ran mine under the engine mount and it seems to be free of undo pressure. I also put that mount screw at the top on the foot box.

If you can see in this picture, the first arrow is the route of the cable and the second arrow is where I tapped a bolt and mounted a cable guide to the frame. The cable then continues under the engine mount and has a straight line to the bell housing.

Thanks a lot, GT! I think we have a similar routing but i didn't mount any sort of cable guide. And like you said, maybe mounting the screw on the top helps. The clutch cable had a natural bend to it and it seemed to have less pressure with the screw on the bottom for me but i'll check it out and see if making the change solves the problem.

Thank you for the good advice!

-

06-03-2019, 09:25 PM

#272

Originally Posted by

GTBradley

Pete, a word of caution. I’ve read that these stainless radiator hoses can come lose and blow off. Some go so far as to modify things to make sure it doesn’t happen. I have about two miles on the odometer now and a bunch of warm ups at idle. I checked the hose clamps after a bit of running it up to temp and sure enough, the clamps were needing to be retightened.

I'll remember to check those hose clamps after we get the engine running for a bit. I'll write it down too as i'm sure in the excitement of the first start (whenever that may be... ), we are likely to forget things like checking the clamps!

), we are likely to forget things like checking the clamps!

-

06-05-2019, 08:23 AM

#273

Senior Member

Originally Posted by

PeteMeindl

I'll remember to check those hose clamps after we get the engine running for a bit. I'll write it down too as i'm sure in the excitement of the first start (whenever that may be...

), we are likely to forget things like checking the clamps!

That’s the truth. I was so excited on first start I didn’t even realize that the oil pressure I thought was coming up was actually reading on the water temp gauge. I had my connections reversed on water/oil sensors at the engine.

Bradley

Build thread - Mk4, Coyote, IRS, Wilwood brakes, old-style soft top and accessories.

The distance between "finished" and finished is literally infinite.

-

06-14-2019, 08:24 PM

#274

tach wiring question

Lately we've been continuing to work on the wiring. Here's a picture of some of the fan wiring we did today.

We do have a question on the tach wiring.

Question: In the coyote fitment manual p82, it talks about taking the purple tach line out of the sending unit harness (which runs along the top of the engine) to attach to the 4th cylinder. However, I don't have a purple tach line in the sending unit harness like they show in the manual. Instead, I have a purple tach line in the coil crank bundle pointed out by the red arrow below. It seems like this purple line should be going in the sending unit harness (shown in green). Should i just take this purple wire by itself and run it out onto the engine to connect with the cylinder?

Thank you so much, guys!

-

06-15-2019, 05:35 AM

#275

Senior Member

Originally Posted by

PeteMeindl

We do have a question on the tach wiring.

Question: In the coyote fitment manual p82, it talks about taking the purple tach line out of the sending unit harness (which runs along the top of the engine) to attach to the 4th cylinder. However, I don't have a purple tach line in the sending unit harness like they show in the manual. Instead, I have a purple tach line in the coil crank bundle pointed out by the red arrow below. It seems like this purple line should be going in the sending unit harness (shown in green). Should i just take this purple wire by itself and run it out onto the engine to connect with the cylinder?

What you're seeing there is a difference between versions of the Ron Francis harness. Earlier versions did have the purple tach wire in the sending unit harness. The current version has the tach wire in a bundle along with the orange EFI, speed sensor, etc. Unfortunately looks like the Coyote installation instructions don't reflect the change. But not a big deal. Route the purple tach wire however it makes sense.

One other observation though. Based on your earlier pics and descriptions, you have Autometer gauges. Right? Although I personally haven't used Autometer gauges, I'm nearly certain you can't connect the Autometer tach directly to the coil over plug (COP) signal wire like many of us have done with the Speedhut gauges and the Coyote. The Speedhut tach can calibrate to the COP signal directly.

Autometer I believe requires a tach adapter like this. https://www.autometer.com/tach-adapter.html. Don't take my word for it. Do some further research and confirm. But pretty sure that's what you need to do.

Last edited by edwardb; 06-15-2019 at 05:55 AM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

06-15-2019, 12:39 PM

#276

Originally Posted by

edwardb

What you're seeing there is a difference between versions of the Ron Francis harness. Earlier versions did have the purple tach wire in the sending unit harness. The current version has the tach wire in a bundle along with the orange EFI, speed sensor, etc. Unfortunately looks like the Coyote installation instructions don't reflect the change. But not a big deal. Route the purple tach wire however it makes sense.

One other observation though. Based on your earlier pics and descriptions, you have Autometer gauges. Right? Although I personally haven't used Autometer gauges, I'm nearly certain you can't connect the Autometer tach directly to the coil over plug (COP) signal wire like many of us have done with the Speedhut gauges and the Coyote. The Speedhut tach can calibrate to the COP signal directly.

Autometer I believe requires a tach adapter like this.

https://www.autometer.com/tach-adapter.html. Don't take my word for it. Do some further research and confirm. But pretty sure that's what you need to do.

Thanks a lot, Paul! Sounds good on just rerouting the tach wire. Also, thank you very much for pointing out the potential need for the tach adapter. Yup, I'm using the basic autometer gauges - I didn't know about the need for an adapter at all and I'm sure I wouldn't have figured that out on my own! Thanks for the link, too!

-

06-15-2019, 12:55 PM

#277

Fuel pump wiring question

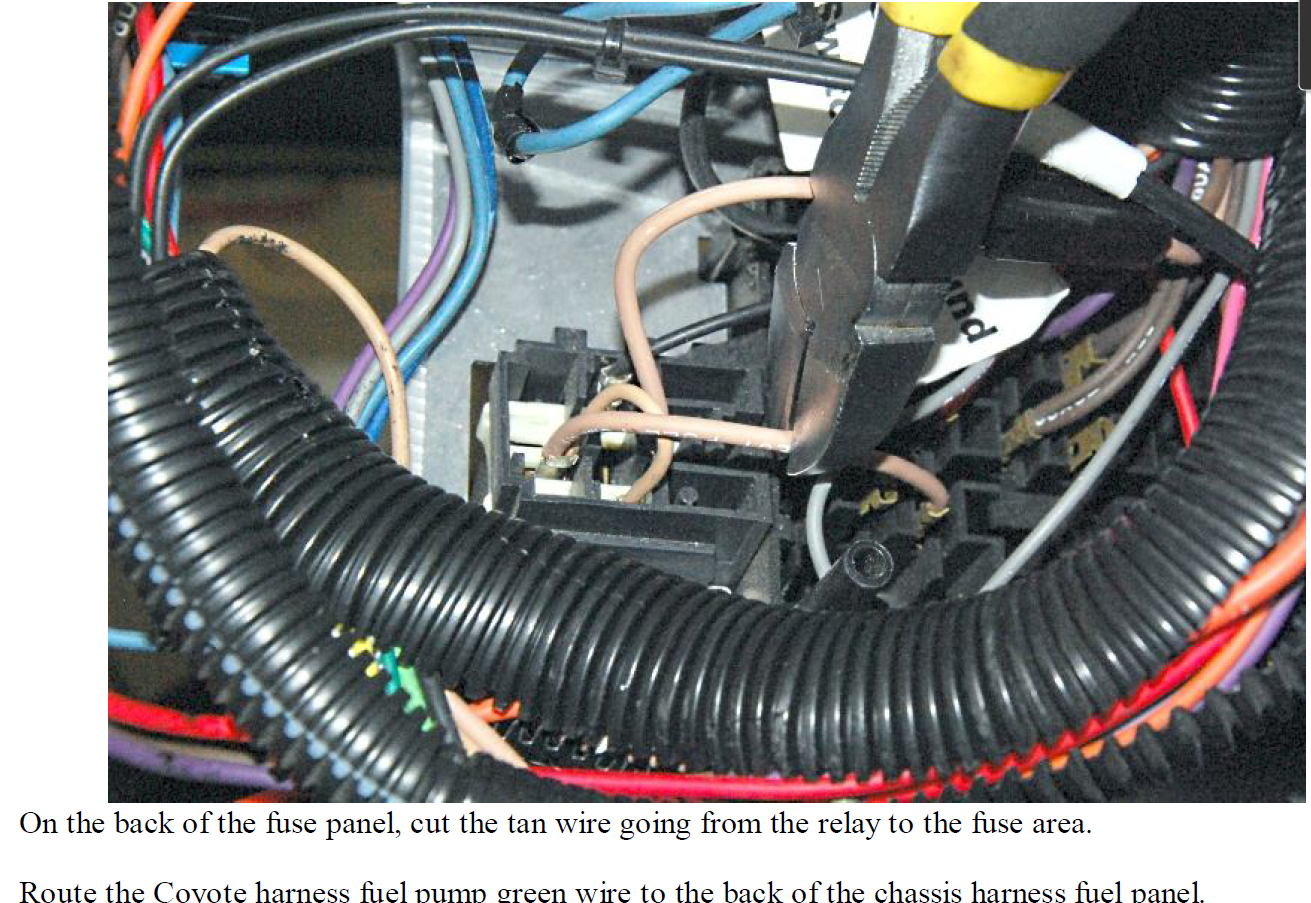

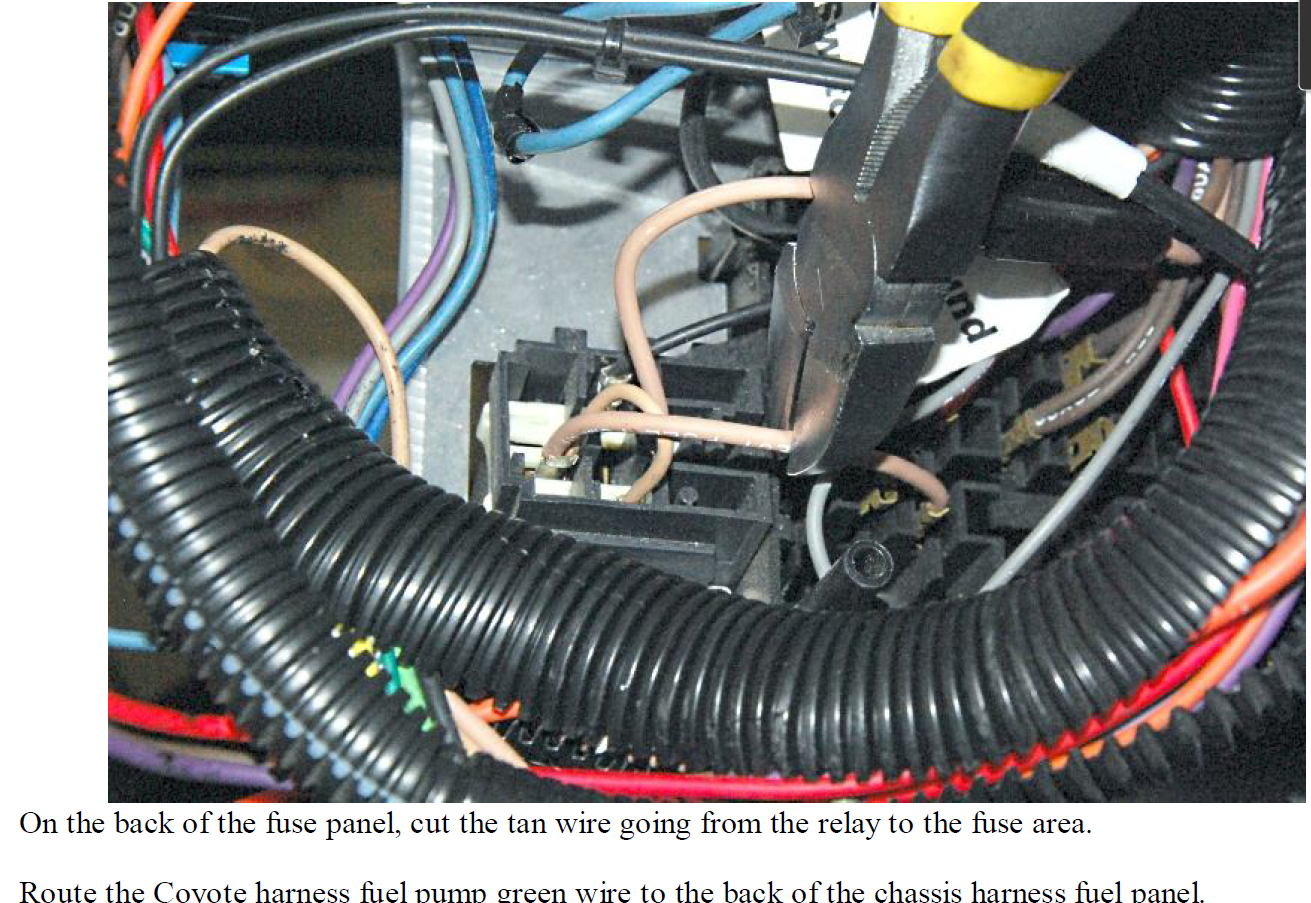

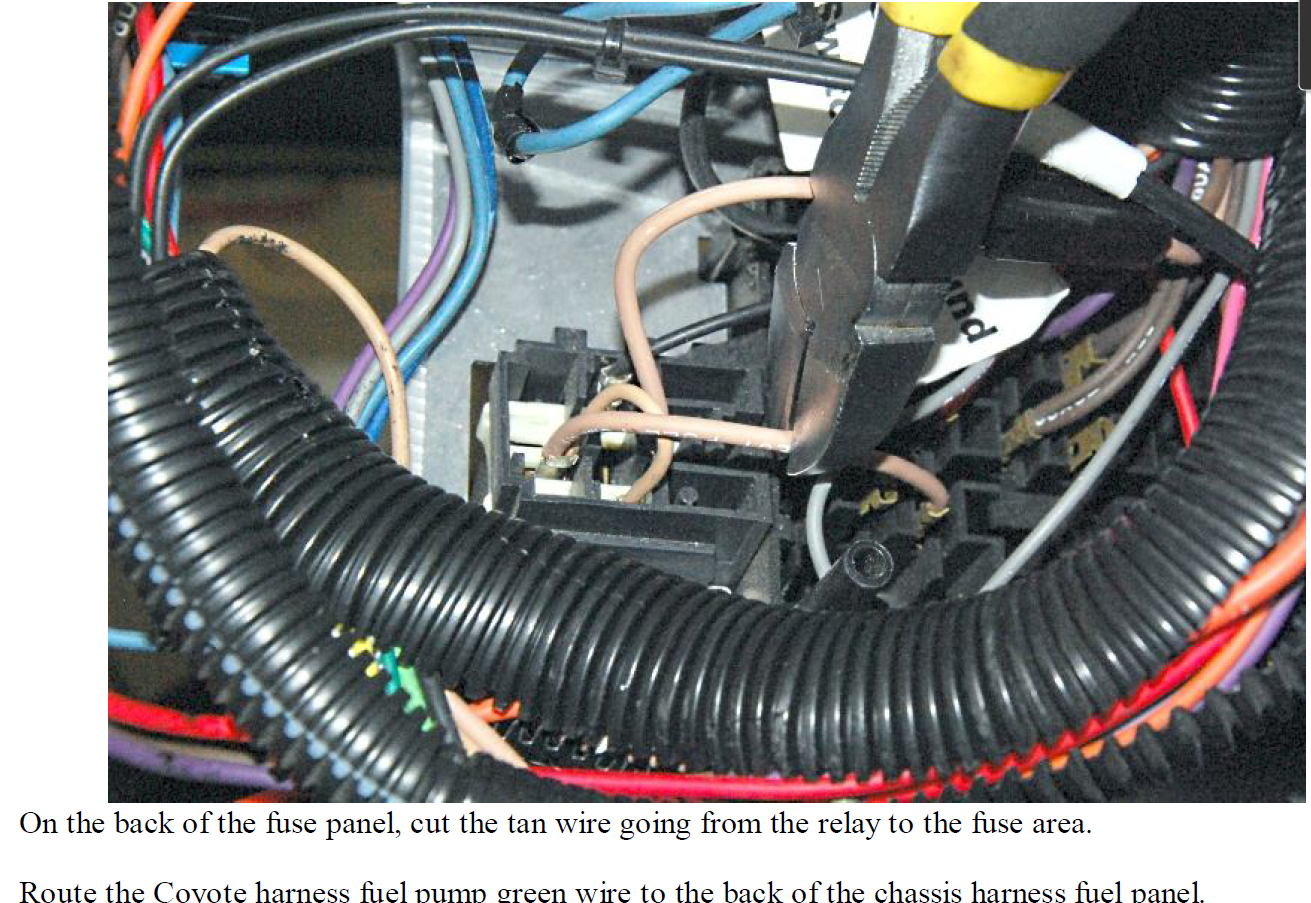

Hi guys, As most of you know, we're installing a coyote engine in our mk iv. We've got a question about how to connect the green fuel pump wire from the wiring harness to the fuse box right by the pedal box. In the coyote fitment manual (9/5/18) on p 75, it says to cut a wire on the fuse box and connect the green fuel pump wire to one of the cut wires. Here's a picture of the instructions.

Question: Which part of the now cut tan wire do i connect the green fuel pump wire to? I think it's the one that's more towards the top of the picture but i am not sure so i wanted to check with you guys. Thanks a lot for your help! Hope you're all enjoying the weekend.

-

06-15-2019, 04:48 PM

#278

Senior Member

Originally Posted by

PeteMeindl

Question: Which part of the now cut tan wire do i connect the green fuel pump wire to? I think it's the one that's more towards the top of the picture but i am not sure so i wanted to check with you guys. Thanks a lot for your help! Hope you're all enjoying the weekend.

Using those instructions, you would cut the wire exactly where the red arrow is pointing. Then connect that loose end to the Coyote green fuel pump wire. As the instructions say, that will cause the Coyote PCM, via the green fuel pump wire, to energize the relay and run the fuel pump. But the actual power from the RF panel is what will be supplying the +12V to the fuel pump. That's via the larger wire coming from the RF fuse location. That means that both the Coyote PDB and the RF harness are providing power for your fuel pump setup, and both fuses are in play. I've scratched me head trying to figure out the advantage of wiring it this way, and to be honest can't come up with anything. Earlier versions of the instructions looked like the linked pic below. (I saved it because this question comes up frequently)

Here you can see they're saying to cut the main power wire from the fuse location and attach the Coyote fuel pump wire to the end going to the relay. This takes the RF fuel pump circuit completely out of play. In fact the RF fuel pump fuse can be removed. The relay and the fuel pump are now powered by the Coyote PDB, which has the necessary fuse, etc. I've wired both of my Coyote builds this way. In the end, either will work. I just prefer to have one place to look for a blown fuse and source of power.

Last edited by edwardb; 06-15-2019 at 04:51 PM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

06-15-2019, 08:06 PM

#279

Originally Posted by

edwardb

Using those instructions, you would cut the wire exactly where the red arrow is pointing. Then connect that loose end to the Coyote green fuel pump wire. As the instructions say, that will cause the Coyote PCM, via the green fuel pump wire, to energize the relay and run the fuel pump. But the actual power from the RF panel is what will be supplying the +12V to the fuel pump. That's via the larger wire coming from the RF fuse location. That means that

both the Coyote PDB and the RF harness are providing power for your fuel pump setup, and both fuses are in play. I've scratched me head trying to figure out the advantage of wiring it this way, and to be honest can't come up with anything. Earlier versions of the instructions looked like the linked pic below. (I saved it because this question comes up frequently)

Here you can see they're saying to cut the

main power wire from the fuse location and attach the Coyote fuel pump wire to the end going to the relay. This takes the RF fuel pump circuit completely out of play. In fact the RF fuel pump fuse can be removed. The relay

and the fuel pump are now powered by the Coyote PDB, which has the necessary fuse, etc. I've wired both of my Coyote builds this way. In the end, either will work. I just prefer to have one place to look for a blown fuse and source of power.

Thanks, Paul! That is really helpful. I owe you a lot! Thank you very much.

-

06-15-2019, 08:29 PM

#280

Parking Brake install

We put together the parking brake today. Things went pretty smoothly, in general. We had to dremel out the hole in the silver handle to get the button to fit inside of it but that was pretty easy to fix and things went together well after that. The parking brake handle does slightly rub the aluminum panel, unfortunately, but we've been reading about some your solutions to this as it sounds like this is often a problem. We're now working on connecting the cables to the rear brakes.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

), we are likely to forget things like checking the clamps!

), we are likely to forget things like checking the clamps!