-

01-07-2024, 06:47 PM

#321

Senior Member

And a nice go-kart session today in the Florida sun:

https://youtu.be/K2mC-VPa-Gc

Sorry the audio sucks. I've gotta figure out a better microphone. This one is remote but cheap.

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-08-2024, 10:45 AM

#322

Depending on your physical build, you might want to sit in the seat and see how the dash button locations work out ergonomically. Things to the left and under the steering wheel are not the most accessible for me.

Good job on the trans.

20th Anniversary Mk IV, A50XS Coyote, TKO 600, Trunk Drop Box, Trunk Battery Box, Cubby Hole, Seat Heaters, Radiator hanger and shroud.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

01-08-2024, 12:39 PM

#323

Senior Member

Originally Posted by

Railroad

Depending on your physical build, you might want to sit in the seat and see how the dash button locations work out ergonomically. Things to the left and under the steering wheel are not the most accessible for me.

Good job on the trans.

Thank you. Since you mention it, I've chosen that location for the turn signal buttons because I'm used to using my left arm for turn signal action, and in manual cars I tend to keep my right hand on the shifter. BUT, do you think there's a chance the top of the door will be in the way for my left arm to comfortably access those switches?

Clearly I don't have the door installed so I wouldn't know the difference. Why was it an issue for you?

Matt

My build thread

here

-

01-09-2024, 12:04 PM

#324

I thought I would mount something on the left side of the steering wheel, forgot what it was.

I must have had the body and doors on, when I found out the reduction of area and access.

I ended up putting the horn button on the dash, to the right of the steering wheel.

My headlight dimmer is on the Russ Thompson turn signal lever.

I must not have a pic of the my dash. I do have a panel on the trans tunnel to dash support. I have a power outlet, 4 way flasher and wiper switch on it.

Too cold to go to barn for pic taking, today.

Maybe others will chime in.

good luck,

20th Anniversary Mk IV, A50XS Coyote, TKO 600, Trunk Drop Box, Trunk Battery Box, Cubby Hole, Seat Heaters, Radiator hanger and shroud.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

01-09-2024, 01:45 PM

#325

Not a waxer

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

01-12-2024, 11:09 AM

#326

Senior Member

I like the idea of putting them to the left of the tach, I just figured the curved nature of the dash wouldn't allow for a 19mm diameter momentary switch. I'll take a closer look. I also like the idea of putting a hi-lo toggle over there as well.

Matt

My build thread

here

-

01-15-2024, 08:53 AM

#327

Senior Member

Originally Posted by

Jeff Kleiner

I've built several cars using a self cancelling Signal Dynamics module (which uses momentary switches for activation) rather than a Russ Thompson style column mount and on all of those located the controls to the left of the wheel. It works and as you say seems more natural.

Jeff

Hey Jeff, I'm curious, but did you just use a jumper wire in place of the OEM flasher relay that goes into the fuse block? Since the Signal Dynamics module does the flashing, I'm guessing you'll have to feed it 12 VDC constant through that circuit.

Matt

My build thread

here

-

01-15-2024, 09:55 AM

#328

Not a waxer

I set them up with keyed and fused 12 volts, just like conventional turn signals. That can come from the turn signal feed or wherever else you care to grab it. I prefer keyed power rather than constant hot so that people can’t activate them while the car is parked.

Jeff

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

01-17-2024, 04:43 PM

#329

Senior Member

I'm too excited to not share this, but I just spent $700 at Spintech for all my low-profile exhaust components. I'll be sure to post pics of the fabrication and assembly, and definitely sound clips.

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-27-2024, 10:32 PM

#330

Senior Member

I installed a smaller clutch MC today. The last few times I went out I grew annoyed how touchy the clutch was. Wilwood sells a bunch of different sizes, so I did some quick math and went with a 15/16" MC. The clutch onset is so much smoother now, less grabby, and easier to leave the line and go backwards up my driveway.

Matt

My build thread

here

-

01-30-2024, 06:25 PM

#331

Senior Member

Gonna have a fun couple a weekends:

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

01-31-2024, 08:11 AM

#332

Wow that is definitely a different mod for the MK4. I will be interested in your install and see how it looks.

Roadster MK4 #10653 Date: 4-27-23; First Start: Oct 2023; Go Kart: Nov 2023; Body and Paint: To Kleiner EDD - April 2024; Graduated: TBD

SBF Boss 347, Edelbrock ProFlo 4, Milodon Road Race Oil Pan, Tremec TKX 2.87/0.81 OD, IRS Dakota Digital Dash, FFMetal Firewall Forward, BOIG Lower Cool Pipes, Forte's Mechanical Throttle Linkage and Hydraulic Clutch, Breeze Radiator Fan Shroud- Radiator Support Kit and Battery Forward

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

01-31-2024, 08:41 AM

#333

Senior Member

Originally Posted by

maclonchas

Wow that is definitely a different mod for the MK4. I will be interested in your install and see how it looks.

The design intent is to run the oval tubing and muffler right under the seats, then ditch out in front of the rear tires. I'm gonna put a 1/4" strip of wood on top of the mufflers and jack them up firmly before welding the hangers so they're actually hanging a bit, but up as high as possible. Then a buttload of insulation under the seat.

There's a fella on here who's done the same thing. The end game here is the "Gentleman's Cobra". Metallic BRG paint with an under exhaust, but since I'm solid axle doing tail pipes would be difficult.

Matt

My build thread

here

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-31-2024, 01:17 PM

#334

Originally Posted by

MB750

Gonna have a fun couple a weekends:

This may be of interest:

https://www.ffcars.com/forums/17-fac...t-halfway.html

I'm the current owner of the car shown in the thread above--exhaust was fabbed by the prior owner/builder.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

02-01-2024, 08:47 AM

#335

Senior Member

Originally Posted by

jab351w

Hand built headers? Amazing!

I went with the oval inlet/outlet 7000 series. My goal was the lowest profile mufflers available. These are only 2.5" thick.

Matt

My build thread

here

-

02-07-2024, 08:09 AM

#336

Senior Member

Drivers side. Went together pretty easily. Some custom cuts to adjust angle, but for the most part not bad. It's just tacked together with the Flux Core, but I'll TIG it for the finish welds. And I'll whip up a hanger on the back end. I got started on the passenger side but dinner was calling before I got to the J pipe.

It'll all get a coat of high temp paint, and header wrap from the O2 sensors down to the muffler to try keeping heat inside the pipe.

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-07-2024, 09:04 AM

#337

Senior Member

I find this interesting. On the original 260 & 289 Cobras the exhaust ran under the car and out the back. The 427SC had the sidepipes we all know. What you're doing is under the car but exiting at about the same place as the sidepipes. Is it just to eliminate the big sidepipe and clean up the lines of the car? I'm guessing with those mufflers it will be quieter than with the sidepipes.

I hope you're able to insulate well enough to keep from roasting your butt. When I was looking to buy a Viper I looked at a few Gen III that had the exhaust under the car and out the back. The heat from the exhaust in the cockpit was noticeable. I ended up buying a Gen IV where they went back to the sidepipes and no heat in the interior.

Looking good so far!

-

02-08-2024, 03:30 PM

#338

Senior Member

That's interesting Mike, I always thought the 427 had the full under exhaust and the 289 had the side pipes.

Regardless, my end game is the Gentlemen's Cobra. British Racing Green and no pipe to sting your lady's leg.

I'll definitely post a sound video when they're done

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-25-2024, 01:50 PM

#339

Senior Member

Spintech exhaust fabricated, but not yet painted and insulated:

https://youtu.be/59DJ5jZvCo0

I'll be painting, then wrapping the pipe up to the muffler, then partially wrapping the top and inside of each muffler with some aluminum backed fiberglass to keep heat off my bum and the fuel/brake lines.

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-13-2024, 03:43 PM

#340

Senior Member

From the "Took long enough..." department, exhaust is done and installed:

Header wrap down to the muffler, then fiberglass backed aluminum around the top and inside of each muffler. Hopefully that'll keep the heat at bay (somewhat).

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-21-2024, 08:10 PM

#341

Senior Member

After a few more miles go-karting around the hood I decided I wasn't much of a fan of the pedal positioning, so I made some modifications. Firstly, the brake needs to be further out, but there's a frame member in the way:

I didnt' want to push the seat forward because I like the positioning the way it is, so I made some adapters.

I finally got to use those Harbor Freight letter stamps too. Now it's perfect!

Next up, raise the gas pedal a scootch, and scoot the clutch over as far as possible, just to make the pedal flush with the Wilwood arm.

Matt

My build thread

here

-

04-09-2024, 05:34 PM

#342

Senior Member

I've had heartburn over that panel bend on the throttle side of the footbox because my toe kept hitting it, so I picked up some sheet aluminum and a metal brake from Harbor Freight and went to town. First with some cardboard, then the final product. Two pieces later:

I also scooted the clutch pedal over one hole space and used a metal plate to distribute the load. It looks a bit goofy but works great. Now I can wear normal shoes and not worry about my foot hitting anything unintended (like the gas when I'm hitting the brakes...)

Matt

My build thread

here

-

05-19-2024, 02:08 PM

#343

Senior Member

I know I had to shorten the driveshaft to work better with the SN-95 bellhousing and input shaft I used from the donor, but I've had heartburn about it since I did it. Yes, technically it worked, but I wanted it to be just a smidge longer, and not welded in the center. So, I took the universal joints out of the driveshaft, took some measurements to see what size yokes I'd need, and ordered some. I already had some 3" tubing lying around, so I got the correct yokes for a 3/32" tubing wall and got to cuttin'.

The process was pretty straightforward, until I got to the point where you have to have the yokes indexed correctly. This was my way of making sure they are perfectly in phase"

Then I used my 20T press to drive the loose yoke home.

I then checked roundness, which was less than .005"

The garage was plenty hot so I called it quits before firing up the TIG to finish the job. When it's all done I'll bring it in for balancing.

I also worked on the dash a bit. From go-karting, I know I'll want my left hand on the wheel all the time so my right hand could be busy with switches and shifting. I moved the turn signals over to the right, bought a larger horn button, and also bought the 16A "brights" button to toggle those on.

Matt

My build thread

here

-

05-19-2024, 02:09 PM

#344

Senior Member

FYI, they're size 1330 universal joints.

Matt

My build thread

here

-

08-26-2024, 02:21 PM

#345

Senior Member

From the "Unnecessary but neat stuff" department, I'm putting an electronic E-stop on. Difficulty: I'm building and fabricating the kit myself. No way that E-stopp kit is worth $570 when it's just some electronics and a linear actuator. Those linear actuators are only around $50.

First, I need to know the stroke minimum requirement, and the power required. Stroke length is easy. I held a ruler down by the mechanism and pulled the E-stop. 3/4", good, next.

Get out the luggage scale, hook it up to the handle and give it a yank:

And now that I know how much force is needed to fully set the parking brake, I've got some math to do. There's quite a large mechanical advantage on the brake handle. 8.3 times in fact. Since Work = Force X Distance, and with levers it's a ratio, it's just a little math. Knowing this:

So, I need an actuator that has 300 lbs of force (or 1334 Newtons if you swing metric).

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

08-26-2024, 03:58 PM

#346

Senior Member

My wife's luggage scale has a higher capacity

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

08-27-2024, 12:50 PM

#347

Hey, I think I may be able to assist! I did the same thing, as I was having a difficult time of getting enough leverage to engage the brakes mechanically. So, like you, looked at the E-stop, but could not understand or comprehend the total cost and well, I am always looking for a challenge. I wanted it to engage like my old e-brake by pulling the handle. Here is my parts list:

Actuator

https://www.amazon.com/dp/B00NM8H5TG...fed_asin_title

Relay

https://www.amazon.com/dp/B07T12WLMT...fed_asin_title

Switch

https://www.amazon.com/dp/B07DJ9NVMS...fed_asin_title

And wiring diagram (it was actually for a chicken coop door actuator!)wiring_diagram 2.jpg

I mounted and connected the switch to a spring and hooked that to my e-brake handle. Works really good, can hold on hill. I would say my only drawback, is that the stroke is 2 inches and it does not have any limit switches, so I have to wait for the entire until to release and then tighten up which takes approx 4 - 5 seconds. good luck!

Chris

-

08-28-2024, 07:14 AM

#348

Senior Member

Originally Posted by

Dash

Hey, I think I may be able to assist! I did the same thing, as I was having a difficult time of getting enough leverage to engage the brakes mechanically. So, like you, looked at the E-stop, but could not understand or comprehend the total cost and well, I am always looking for a challenge. I wanted it to engage like my old e-brake by pulling the handle. Here is my parts list:

Actuator

https://www.amazon.com/dp/B00NM8H5TG...fed_asin_title

Relay

https://www.amazon.com/dp/B07T12WLMT...fed_asin_title

Switch

https://www.amazon.com/dp/B07DJ9NVMS...fed_asin_title

And wiring diagram (it was actually for a chicken coop door actuator!)

wiring_diagram 2.jpg

I mounted and connected the switch to a spring and hooked that to my e-brake handle. Works really good, can hold on hill. I would say my only drawback, is that the stroke is 2 inches and it does not have any limit switches, so I have to wait for the entire until to release and then tighten up which takes approx 4 - 5 seconds. good luck!

Chris

Thanks for the feedback and links. I see you went the relay route. I'm just gonna keep it simple and go with the DPDT switch on the dash and omit the handle completely to clean up the transmission tunnel cover. I'm going with this actuator too, simply because it's claimed power is plenty high enough for my needs:

https://www.amazon.com/Justech-Actua...s%2C91&sr=8-16

Also, those actuators do have limit switches. They're just internal to that barrel that's around the pushrod, and you need some soldering skills to make it happen. Here's a video on it:

https://www.youtube.com/watch?v=ls4zv-nhBUU

Matt

My build thread

here

-

08-28-2024, 07:28 AM

#349

Senior Member

Originally Posted by

Dash

Hey...

Chris

One other question. Could you please share a pic of your mounting? I've got some ideas, but I'm always looking for further inspiration.

Matt

My build thread

here

-

09-05-2024, 03:19 PM

#350

Senior Member

Your exhaust is a work of art. I am both impressed and a little jealous. I was always skeptical of under frame exhaust on these and you have proven it can be done and be awesome.

Great job.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

10-15-2024, 07:18 PM

#351

Senior Member

Cooler garage, no cervical pain, no excuses, back to work!

Got the lighting wiring squared away and tested. Had to make a jumper for where the flasher relay goes to feed my special signal module constant 12 VDC.

Test lamp:

Rat's Nest:

Procedure:

And finished. The switch in the middle is for the E-parking brake:

Matt

My build thread

here

-

10-15-2024, 07:54 PM

#352

Looking good Matt. Cooler garage temps finally here!

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

10-16-2024, 06:42 AM

#353

Senior Member

Oh, and one other thing...

Someone at Ron Francis must have dropped the ball in the Quality department because my rear turn signal wires are swapped somewhere in the harness.

Fortunately I was able to just swap them at the switch. It still bugs me though. I mean they're clearly labeled, and color coded!

Matt

My build thread

here

-

10-16-2024, 10:26 AM

#354

Senior Member

Originally Posted by

MB750

Rat's Nest:

FYI, you can order the Billet Buttons without the pigtails, they will send you the connectors and housings loose so you don't have all those splices. That's what I did. Or after the fact they will sell you loose connectors and housings.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

10-17-2024, 08:23 AM

#355

Senior Member

Originally Posted by

Mike.Bray

FYI, you can order the Billet Buttons without the pigtails, they will send you the connectors and housings loose so you don't have all those splices. That's what I did. Or after the fact they will sell you loose connectors and housings.

Huh, that's good to know. I did end up swapping all those wire nuts out with butt splices, but the extra length would have been nice to get rid of.

A few of those terminations, like the grounds, and the bundle of wires for each turn signal path, had 5 conductors under each so I still would have had some bulk, but I still would have cleaned it up a bit.

Matt

My build thread

here

-

10-27-2024, 05:24 PM

#356

Senior Member

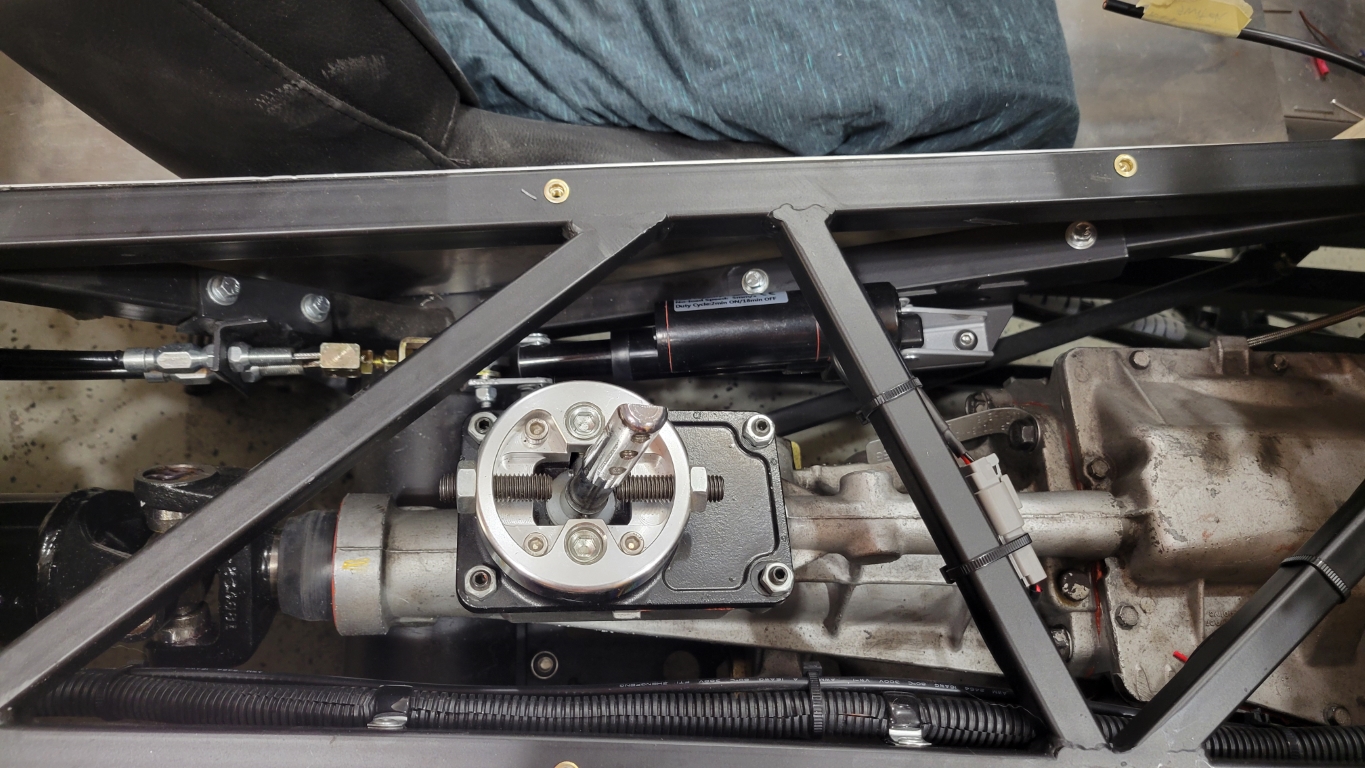

Got the mechanical and some of the electrical side for my DIY E-brake done:

I did have to reconfigure the internal limit switches to reduce the stroke from 2" to 1". The whole sweep is 3/4", that extra 1/4" will just be sag in the mechanism. I'll be driving it with a DPDT momentary switch in the dash. Up engages it, down releases it. You just gotta hold it for a few seconds. I can live with that.

Last edited by MB750; 10-27-2024 at 05:26 PM.

Matt

My build thread

here

-

11-06-2024, 07:48 PM

#357

Senior Member

Wrapped up the footbox and the glove box:

I didn't like the F5R way of just using epoxy to hold the glove box cover bits together so I added a few SS fasteners to hold things together better.

And from the looks of the manual, it's time to start fiddling with the body!

Matt

My build thread

here

-

11-11-2024, 06:37 PM

#358

Senior Member

Initial body installation.

And I've devised a way to get the body in and off myself.

Matt

My build thread

here

-

11-24-2024, 07:11 AM

#359

Senior Member

Changing it up a little in the wheel department:

There's a few reasons for this. Firstly, I just wasn't feeling the "busy-ness" of those other wheels. Second, the front wheels had too little backspacing and were too wide, which would have put the tire into the body pretty easily on bumps. Third, that one wheel had a dent. These are off a late model Mustang and half my current rubber spooned right onto them. I got some 225's on order for the front. I did have to buy some longer studs and a 3/8" spacer for the front spindles though. That caliper is too meaty for a clean swap.

Matt

My build thread

here

-

11-24-2024, 10:09 PM

#360

Senior Member

Some of you might remember my shenanigans to the roll bars. I though they stood just a bit too tall, so I shortened them and modified the 3rd leg accordingly. It all worked nicely, slid in and out, and was easily removable. In the back of my mind I always knew the challenge of getting a custom hole lined up for that 3rd leg would be a chore. Well.....

Nailed it! My trick was to hold a laser on the hoop end of the 3rd leg receiver at a few points around the diameter while marking the laser dot on the fiberglass. After an oval was created, I blasted a couple 1.75" holes right next to each other, then took a drum sander on my drill to smooth it out.

Color me surprised it worked perfectly with no extra fiberglass work needed from a screw up.

Matt

My build thread

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote