-

12-06-2024, 10:37 AM

#121

Senior Member

Originally Posted by

topherchrisb

so I'm hoping I can maybe get arranged for a test fitment this weekend.

If you need an extra hand shoot me a note. I’m 20 minutes from you…

-

12-06-2024, 10:58 AM

#122

Great build! What part/model did you use for the third brake/reverse light? I've been considering options here...bought a few different reverse lights from Amazon, but not really happy with anything so far. -Joel

----------------

Ordered Aug 2023; Delivery Dec 2023.

MK IV Complete Kit w/ IRS, Forte SBF 427W w/Edelbrock ProFlo 4, TKX, Wilwood 12.88, Willwood EPB.

Power steering, manual clutch

-

12-06-2024, 12:16 PM

#123

Originally Posted by

jklapp

Great build! What part/model did you use for the third brake/reverse light? I've been considering options here...bought a few different reverse lights from Amazon, but not really happy with anything so far. -Joel

I'm using this at the moment for that third brake light. It doesn't fit flush with the body at the moment though. The profile of the curve is nearly identical but there is a counter sunk portion to the light you'd either have to cut a larger whole into the body... or build up a form to match the outer profile. I haven't decided which way I'm going to go yet. If you look at the picture of the back of the light with the wiring... the portion with the foam gasket is the section I'm talking about. It'd be a rather large hole. Because of that I'm leaning towards building up the body instead. I could probably see about modifying the light casing as well but just not a priority for now.

https://www.amazon.com/gp/product/B0...e?ie=UTF8&th=1

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-06-2024, 12:27 PM

#124

Originally Posted by

danmas

If you need an extra hand shoot me a note. I’m 20 minutes from you…

Thanks for the offer. There are at least four people in the area that have roadsters in flight or just driving that I know of. It's hard for me to schedule any of my progress. It's usually a "I don't have anything to do for an hour, I'm headed to the shop" situation. I could be out there with my lunch, or with my computer while I'm waiting on work, or in the middle of the night when I can't sleep. I have been thinking about hosting a gathering of those people though. We don't necessarily need to work on a car or anything but have some snacks and drinks and just talk shop.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-06-2024, 03:23 PM

#125

Senior Member

Originally Posted by

topherchrisb

Thanks for the offer. There are at least four people in the area that have roadsters in flight or just driving that I know of. It's hard for me to schedule any of my progress. It's usually a "I don't have anything to do for an hour, I'm headed to the shop" situation. I could be out there with my lunch, or with my computer while I'm waiting on work, or in the middle of the night when I can't sleep. I have been thinking about hosting a gathering of those people though. We don't necessarily need to work on a car or anything but have some snacks and drinks and just talk shop.

I had many offers to help shove my engine in the chassis, but it ended up being a spur of the moment, 'hey, I've got an hour' activity. Plus, I think I kind of wanted to do it on my own. Can't really explain why. I will say, though...my 427/TKX, while doable by myself, would have been much easier with a 2nd pair of hands, even with the engine leveler in play. Could've saved a lot of wiggling/shoehorning if I had someone to push the tranny snout down a few inches to clear the frame near the firewall. I can imagine the Coyote is even more of a challenge without any helping hands. Good luck, though, and post up some pics! I love seeing pics of folks dropping in their engines. It's an exciting event.

Greg

Built an early MkIII years ago, sold years ago. Back after 18 years to build a MkIV

Build Thread Here Partners: Levy Racing, Summit Racing, LMR, Breeze, Forte's Parts, Speedhut, ReplicaParts

MkIV Complete Kit Ordered 4/18/23, Delivered 7/11/23, Boss 427W, Edelbrock Pro Flo 4, TKX (.68 5th), IRS, Wilwood Brakes, 18" Halibrands, Toyo R888R Tires, Custom Speedhut Gauges

-

12-09-2024, 05:49 PM

#126

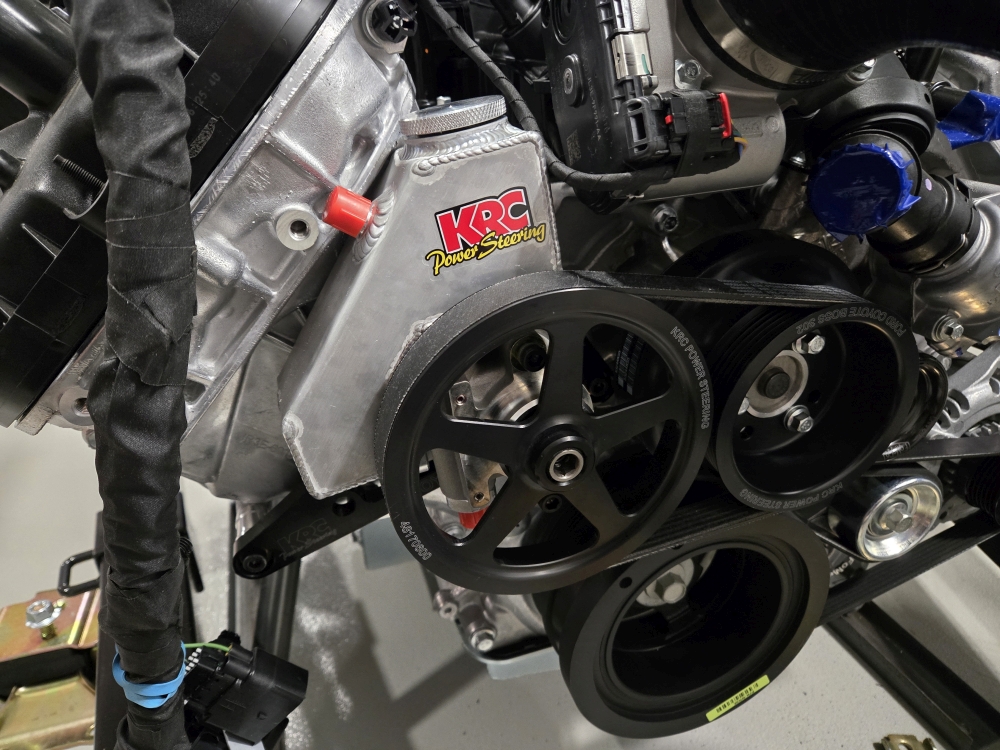

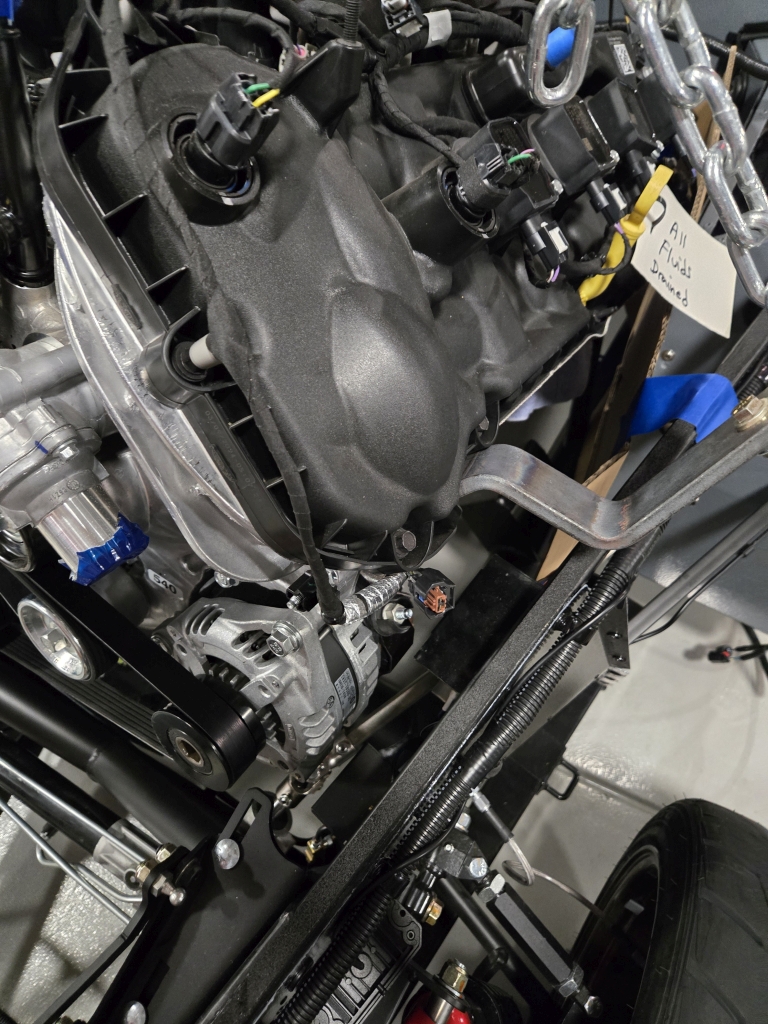

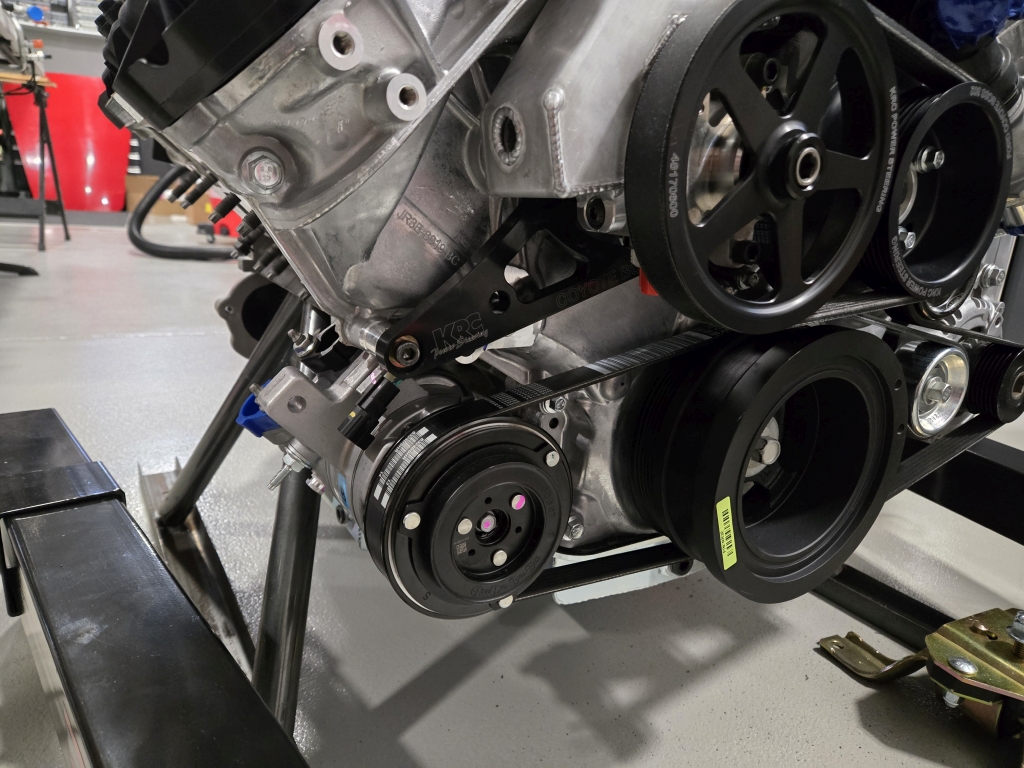

Power steering

Well I was no where near a position where I could do a test fitment of the engine in the car. My original plan was just to push it in as is to do some fitment marks and checks for firewall mounted items like fuel pressure regulator, AC evaporator, brackets for hood pins and such. The amount of effort to even get to that point seemed like I may not want to pull it out once I have it in place. So I decided to start prepping it for a permanent placement. Maybe I'll be ready to do that next weekend... but probably the weekend after that if I'm realistic.

First the power steering. I went with the KRC option from FFR. There are two pools of people with that pump placement: 1. everything fits nicely and although it's tight... it fits. 2. There is interference on the upper corner of the reservoir with the head and it's nearly impossible to get the belt on with the amount of travel the interference allows you. I was in camp 2.  I took the angle grinder and ground a little on the head and the reservoir to be able to get the thing on. What's funny is with the pump and pulleys sitting on the bench I couldn't get the belt to get around them gracefully. The belt could be just bit longer in my opinion. It was obvious it would be a pain with the pulleys on the engine. I ended up getting it to fit by doing things in this order: mount the pump, pre route the serpentine belt as much as I could without tension, get the steering belt on both pulleys, mount/torque the water pump pulley, tension the serpentine belt, then adjust the steering pulley tension. I didn't even mention the time cover bolt that had some extra stand off threads on it I had to grind down to get the bracket to fit... or that one of the spacers is no longer the right depth so I replaced with a stack of washers for correct depth. Early adopter problems.

I took the angle grinder and ground a little on the head and the reservoir to be able to get the thing on. What's funny is with the pump and pulleys sitting on the bench I couldn't get the belt to get around them gracefully. The belt could be just bit longer in my opinion. It was obvious it would be a pain with the pulleys on the engine. I ended up getting it to fit by doing things in this order: mount the pump, pre route the serpentine belt as much as I could without tension, get the steering belt on both pulleys, mount/torque the water pump pulley, tension the serpentine belt, then adjust the steering pulley tension. I didn't even mention the time cover bolt that had some extra stand off threads on it I had to grind down to get the bracket to fit... or that one of the spacers is no longer the right depth so I replaced with a stack of washers for correct depth. Early adopter problems.

Final form:

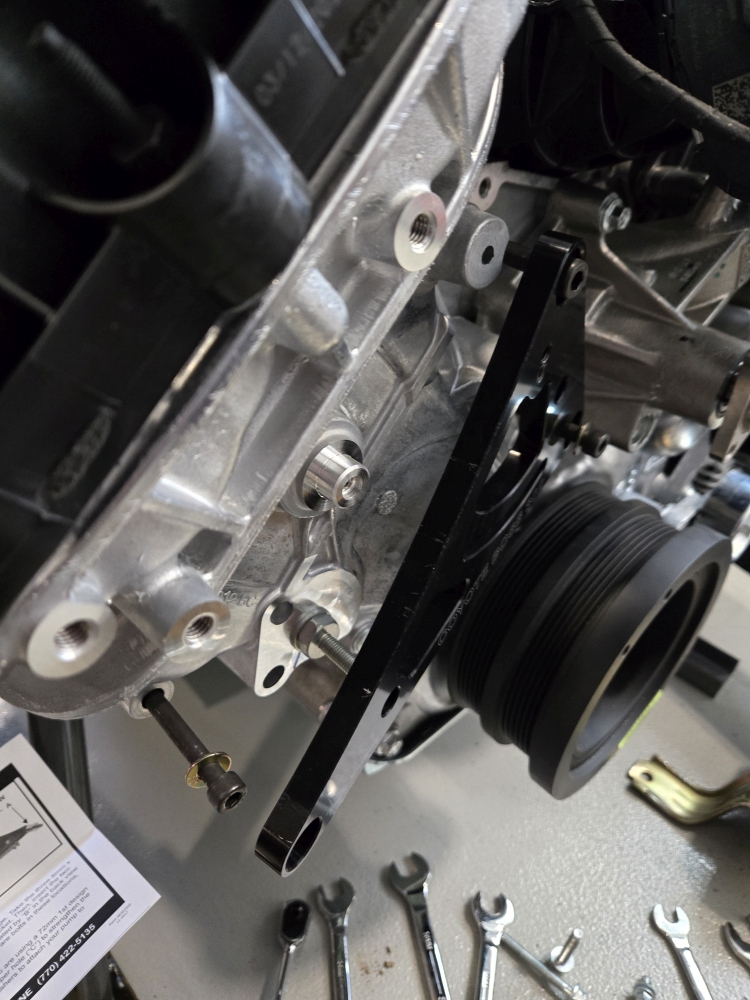

Initial interference (Looks like it should fit that bracket hole... but it doesn't):

Stand off that I ground down:

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-09-2024, 06:00 PM

#127

Senders

Then I tackled the senders. This went just as the FFR documentation says it should. On the gen4 there is a false hole and mount you can see just behind the third party oil sender in the picture below. I'm sure it's a parts efficiency thing... but it's weird to have non functional castings of that nature. It definitely looks like some sort of fluid will come shooting out when the engine is running. I almost got the bore scope out to verify the documentation that it's not machined through. I was feeling too lazy for that kind of action at that point though. I did opt to get a 3/4 to 1/8 npt adapter instead of going with the daisy chain set of three you get in the FFR kit. Just a little cleaner... couldn't find a tee with direct sizing for the oil side of things. So that went as the FFR package is intended.

Senders:

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-09-2024, 06:08 PM

#128

Timing cover gasket anomolies

One thing I forgot to mention that feels bad is the gasket around the timing cover. More specifically there are a few spots where the gasket is protruding from the valley it supposed to reside in. I looked up images of the gaskets for the gen3 and it doesn't seem like there are locations for overflow like this. It's hard to believe that if this was a problem it wouldn't have been noticed till now though. I think ford runs all these engines for a bit before shipment... right? There were three places that I found of a similar nature to the one pictured below. I think I might send the pictures to Forte and see what they think.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-09-2024, 06:29 PM

#129

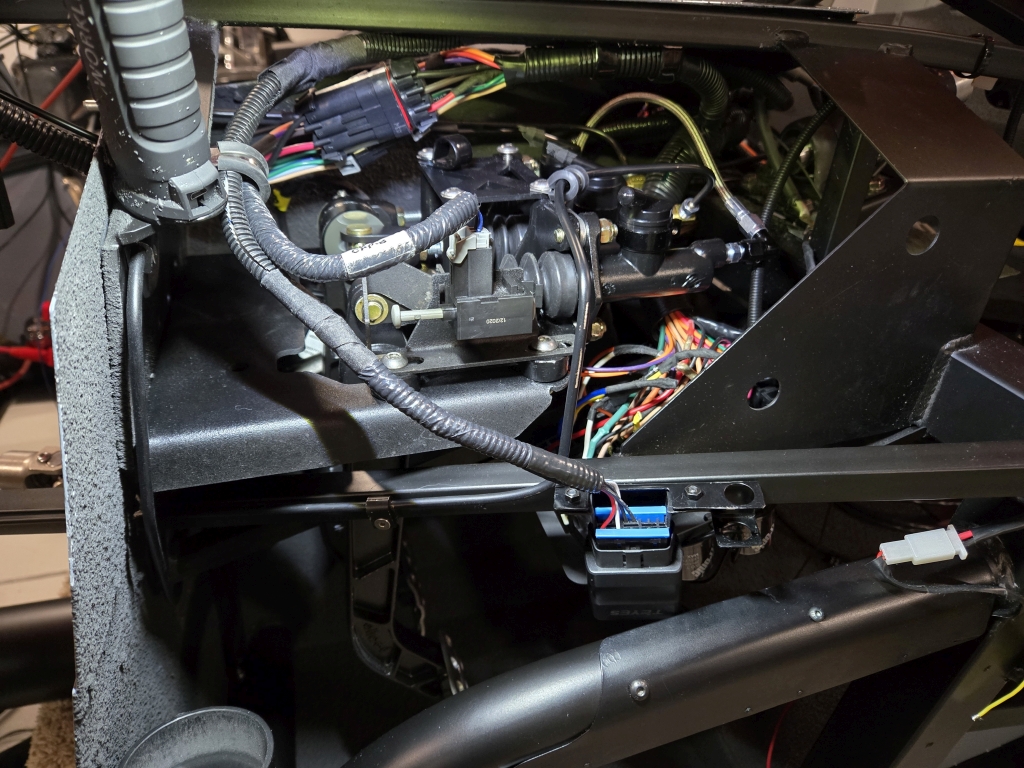

Engine fuse box/harness

Well... ford is definitely not taking this harness back. I've already mutilated it quote a bit. So much bloat... another one of those manufacturing efficiency things. This part is not as straight forward with FFRs instructions anymore. It seems to be making sense to me so far though. An example being... one of the first things the FFR instructions mentions when getting to wiring in the coyote instructions is handle connector C400 for the intercooler pump. Well in the new version of the wire harness there are two intercooler connectors C1217 and C1743. So now you handle both of those in the same way. Also there is no mention of dealing with a PATS module connector in the instructions(FFR or Ford)... but I'm hesitant diet that out till I have a successful start and can verify I don't need any of that. There isn't anything in the connector that seems scary... ground, key on, HAAT, and can bus.

Diet out some wires and leave labeled. Will probably diet them out completely after first start.

Then tear the whole thing apart anyway so you can reroute the fan feed into the cockpit cleanly for the relay/PWM fan contoller.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-23-2024, 06:11 PM

#130

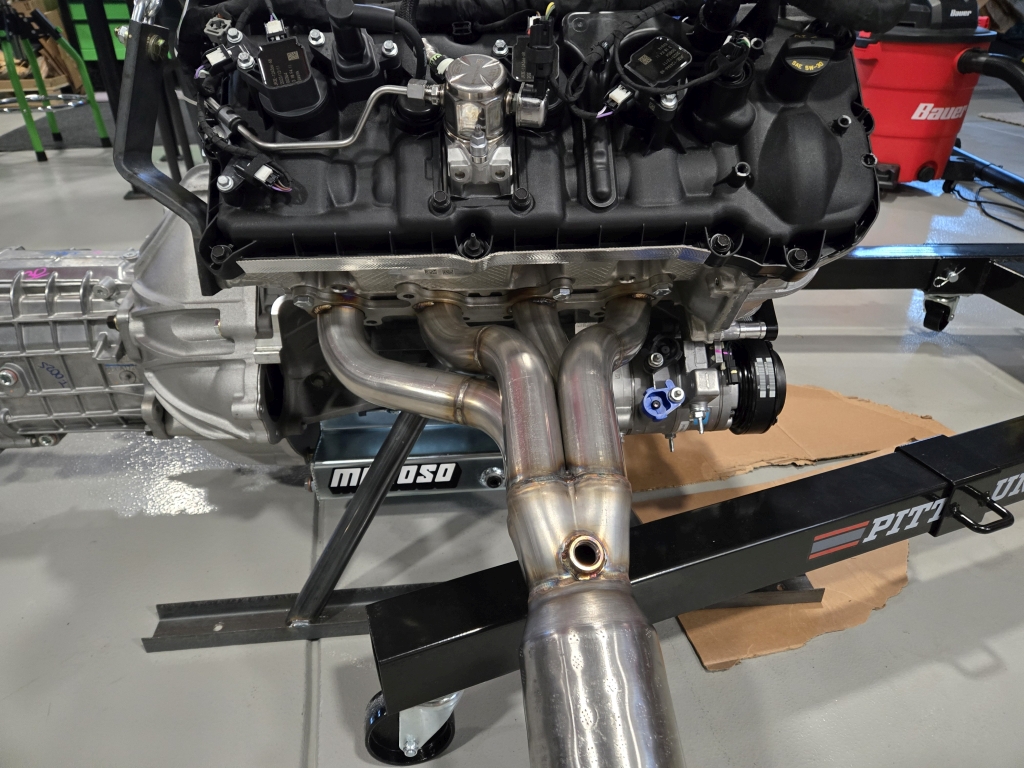

Exhaust flange

So an eventful number of days has passed as I've been prepping to drop the engine in. I have this thread on the roadster forums about adapting the gen3 left side header to the new gen4 bolt pattern using Forte's new offering. I don't want to rehash all of that here but here are the end results of test fitting the headers and how they look inside the engine bay. I'll do an engine install post next for more detail as to how I got there.

Left side with adapter:

Right side no adapter needed:

From the rear:

Left side in the bay:

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-23-2024, 06:30 PM

#131

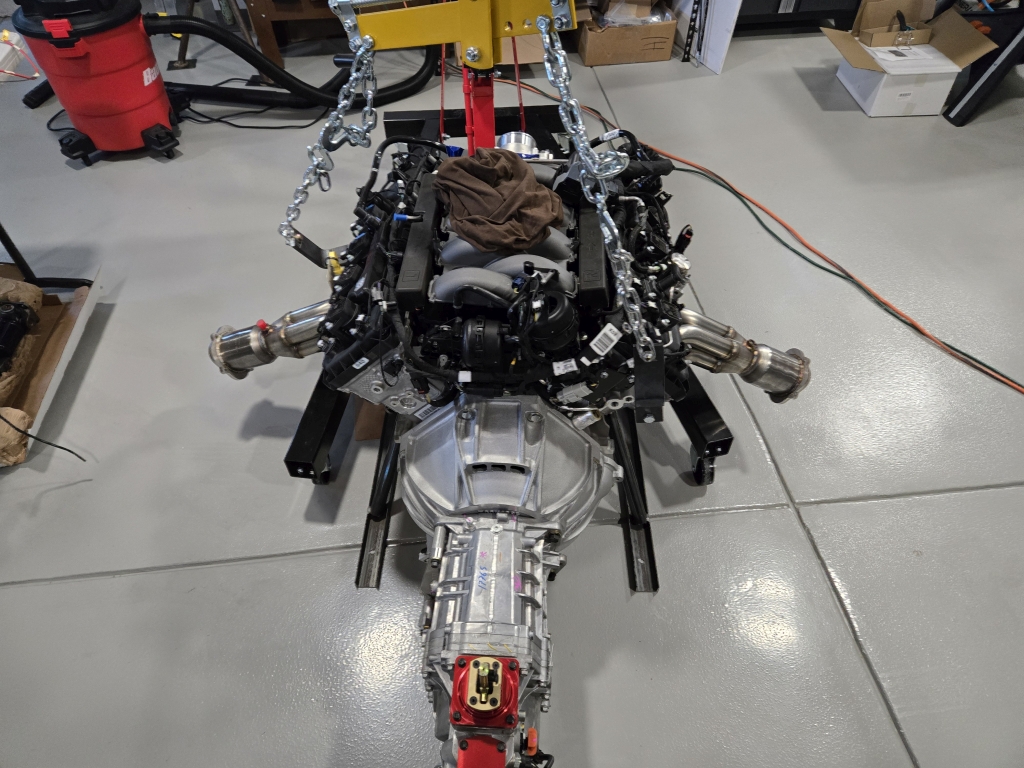

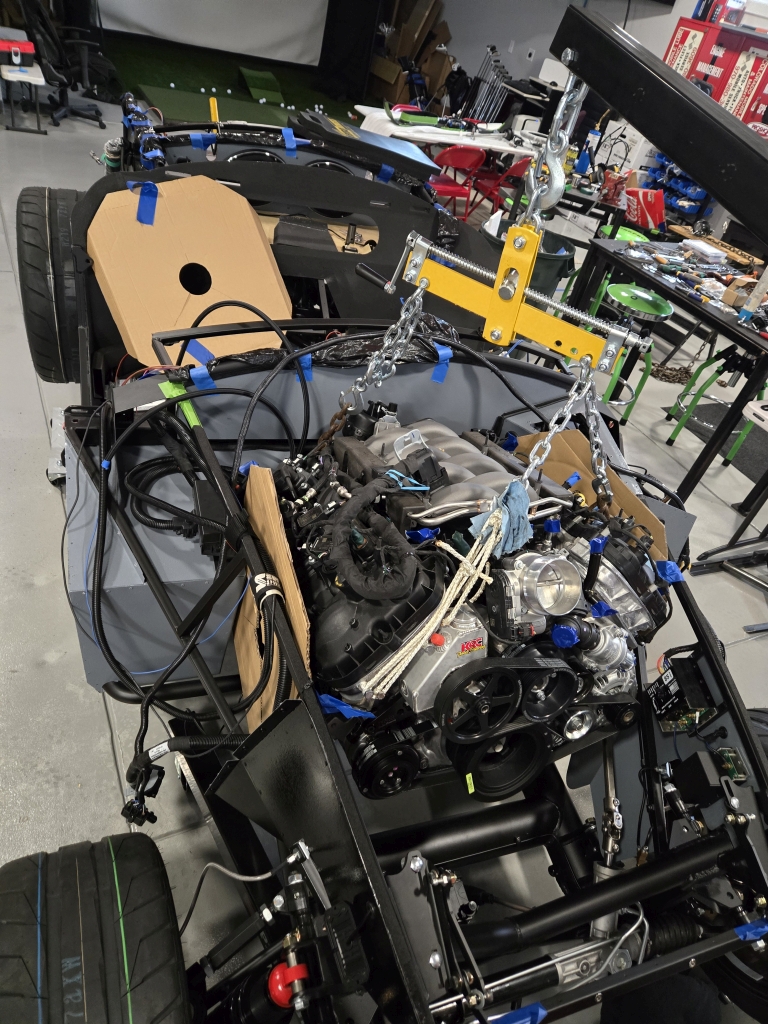

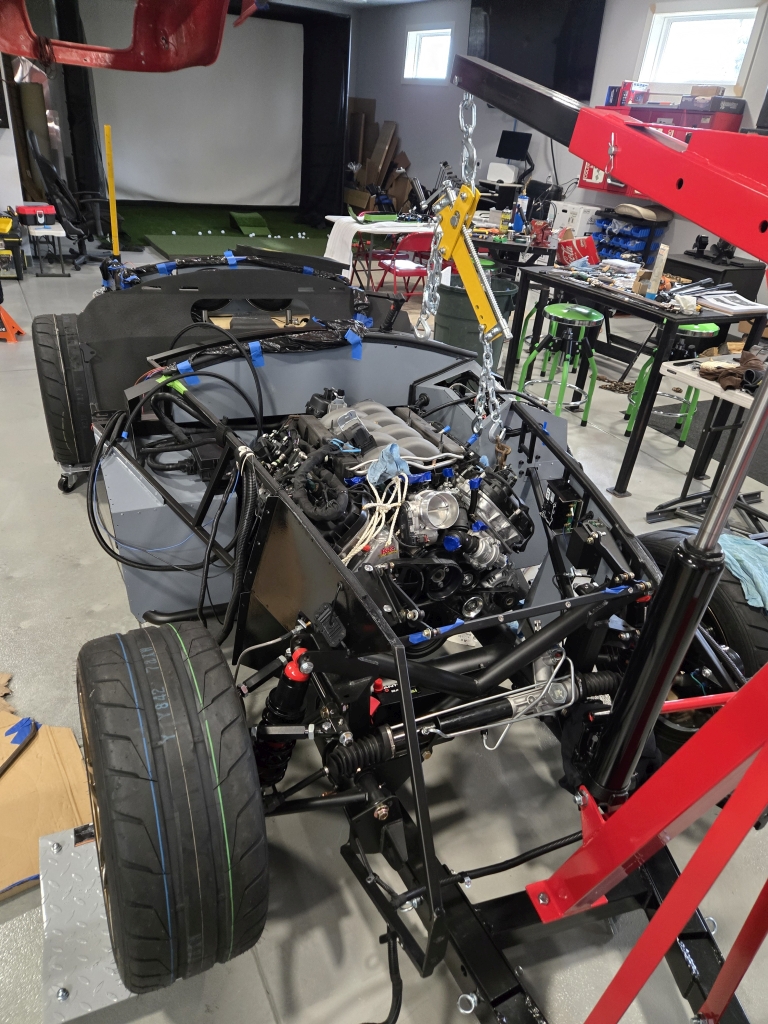

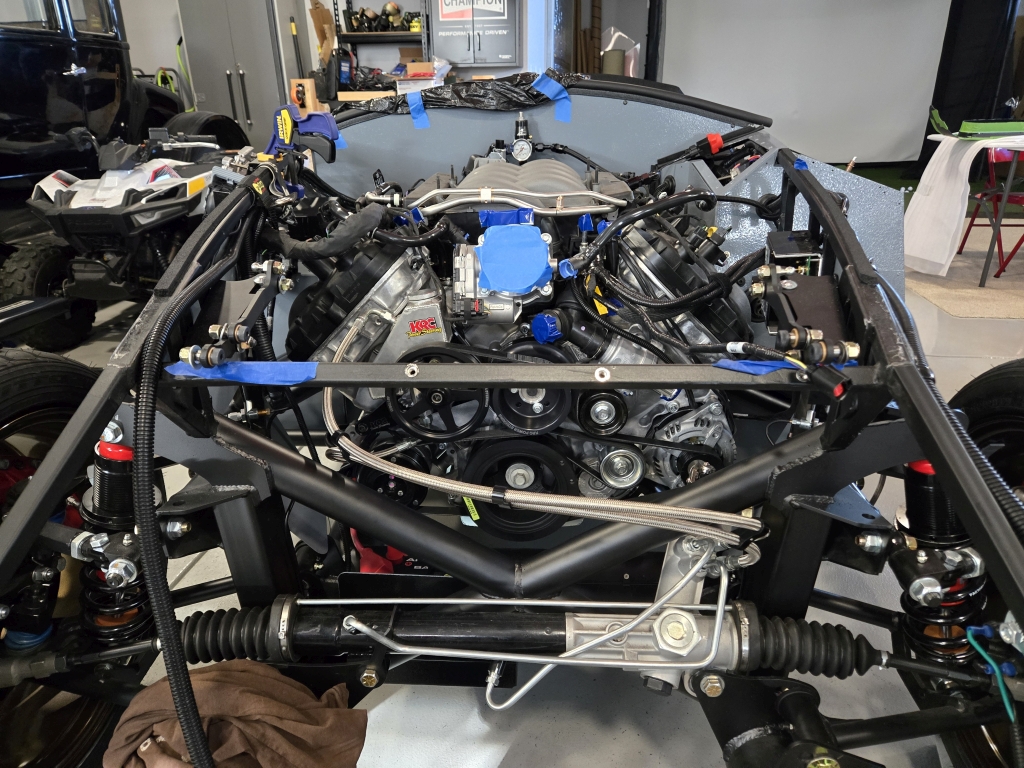

Engine fitment

I know I've read so many posts about how tight the fitment of the coyote is for this roadster setup... I don't think you can actually verbalize how tight it is. My best way to describe it is... I had to remove a piece of cardboard I was using as protection between the left side valve cover and the foot well to get it to slide in properly. When I was rocking the engine back and forth to adjust the height on the ends of the header collectors I scratched the foot well wall with a bolt stand off on top of the valve cover. It's the only scratch I got from the install... but jeesh there is no extra room at all in this setup.

I definitely want to give everyone on the forum props for all the info provided. There were definitely things I knew about ahead of time, but there were also things I had to adapt to that had some form of motivation from info received here. Like I was having a hard time mating both mounts into the plates on the frame at the same time. It was SO much easier just detaching one of them, placing it in the mount plate loosely and then attaching it as the engine came down. I would like to say it only took me a half hour like most... but two attempts and the tight squeeze made it about three hours for me. But you couldn't have smacked the smile off my face after it was done. I can still say I've done all of this work by myself. Paint and body work is the only thing on my list that is questionable on keeping the integrity on that statement.

My first attempt I setting up everything perfect...

Stage the engine:

Lift the engine and roll the car under on casters(it was easier to move the car than the engine crane under load):

Tilt the car, the engine and lower into place:

And then hit your engine hoist bracket on the top rail cause the damn engine is soooooo wide:

Then cut up some old tow chains and some rip chord for less profile and your golden:

And it's in!!!:

Last edited by topherchrisb; 12-23-2024 at 06:32 PM.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

12-23-2024, 06:54 PM

#132

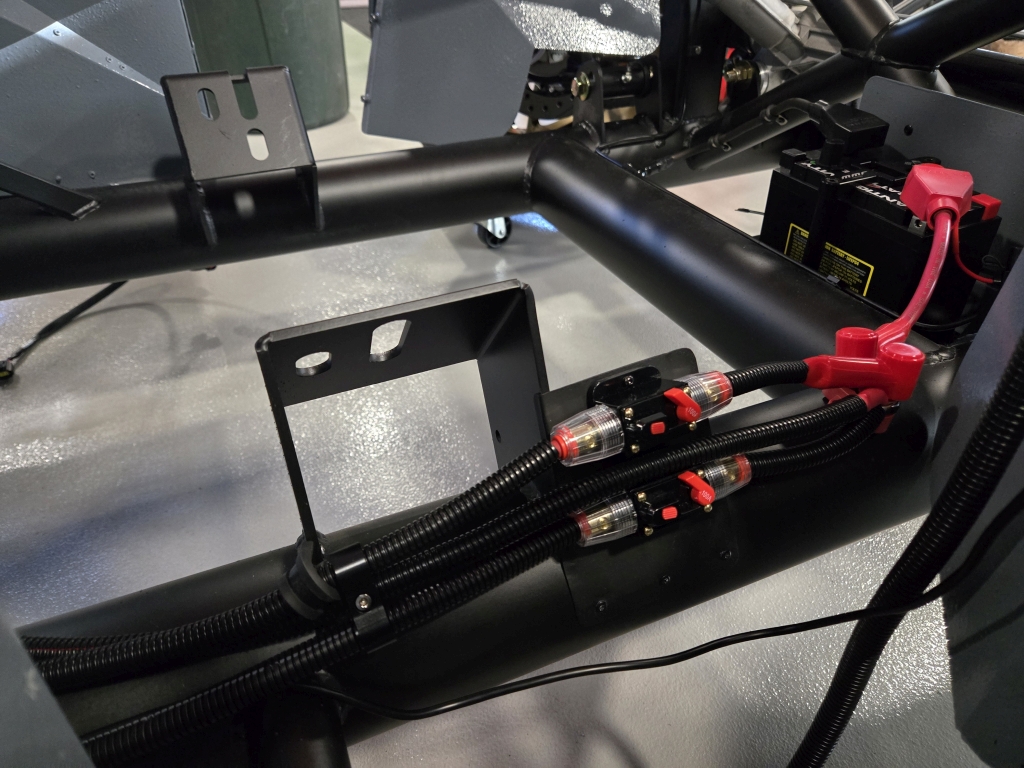

Some primary wiring

I may be doing things a little out of order but a lot has been done and I'm not good for attention when it comes to producing content. A couple wiring things I did before the engine install. I did end up getting the OEM AC compressor setup. Ford performance had a 20% off sale this month so I ordered from them for an extra $200 off. I also had it two days after I ordered. Pretty impressive. I still hate installing those stretch belt setups though. After struggling on that install for a while I ended up using the slide the belt behind the crank pulley with the zip tie technique. Way easy that way... just took me a lot of struggling before I was deflated enough to try it. Wasn't comfortable putting the belt behind the pulley... doesn't feel good when you're doing it, but it's a hidden gem for sure.

OEM AC compressor:

I decided to wire up my OBD2 setup near the clutch wiring so I didn't have to mess with changing the harness from that regard. I placed it so I can barely get my bluetooth reader in it. The reader connects to my stereo so I can use any android app from the screen to get diagnostics on the road. I did modify the check engine wiring to use the light I installed in the dash previously. That's why you don't see it in the bracket.

This one may not get very well received but I actually like the setup. I'm using a two post distribution near the battery to split off all my main power lines. I made a plate that is attached to the 4" frame and the engine mount as a bracket to hold a couple breakers and also used it for wire management. The top breaker goes into the cabin for the main power there, the bottom goes to the trunk fuse box for use there. They are 100amp breakers but I think I can reduce them more. My fan runs off it's own fused circuit (small wire on the battery termination), my lights are LED using WAY less power, and my other components use capacitors and batteries as buffers to reduce large load spikes. The rear runs two speaker amps and the seat heaters however... might have to increase that one after some real life sea trials. The line down the middle runs to the starter position.

My coyote fuse block I slid out away from the firewall as much as possible while still being able to route the cables up the edge and down the top frame rail. I wanted to have as much room as possible for my future AC upgrade while still being able to route the wiring cleanly out of the way once the body is on. You can also see I pre-ran the flex fuel lines as I thought I wouldn't have enough room to tighten those when the engine was in place.

Last edited by topherchrisb; 12-23-2024 at 06:58 PM.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-30-2024, 03:12 PM

#133

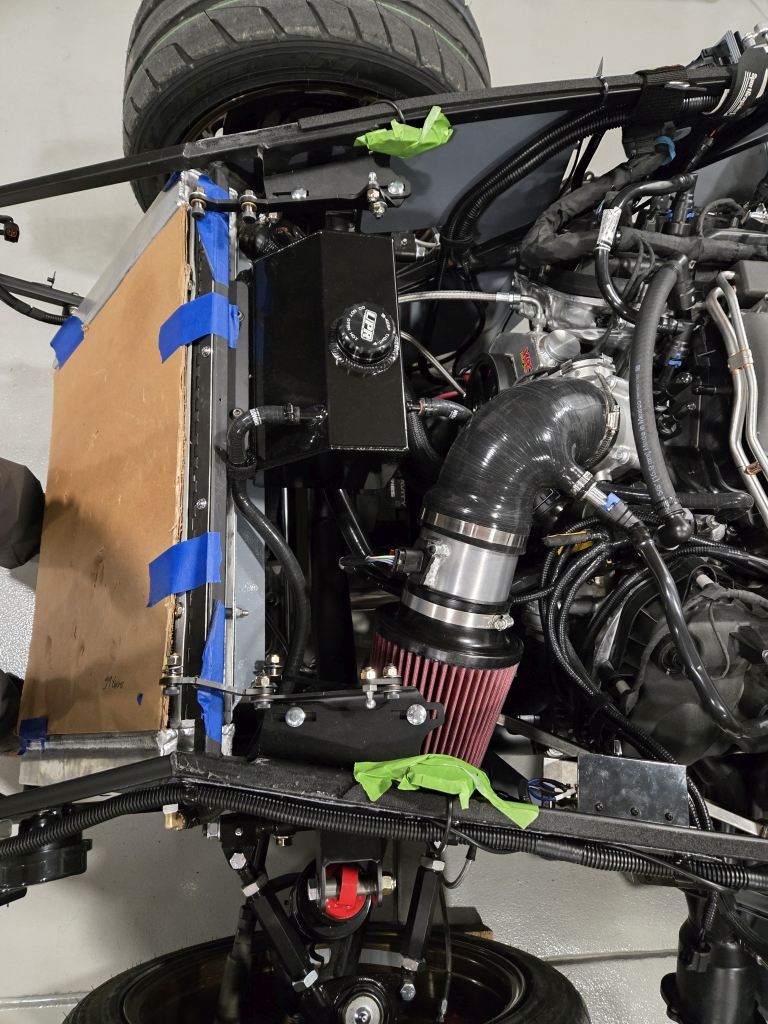

Prepping for first start

Well I'm about a week past when I would have expected to have a first start attempt. I hadn't planned as well as I thought I did. My major shortcomings were for the coolant plumbing. I'm using a UPR expansion tank... and I didn't get any of my plumbing pre-planned. I am currently just awaiting one hose for the top of the radiator to engine route and I should be good to go. I ordered the f150 hose (KM5114) that seems to have a better fitment by popular opinion but none were in stock at the parts stores around me. Things I have been working on to get that first start... power steering plumbing, air cleaner fitment, starter wiring, ecu mounted/wired, and fuel plumbing/testing. One thing I can do with that delay though is get ready for a first go cart instead of just a start. So on top of start preps... I also primed/bled the brakes, filled the transmission/rear end, mounted the seat belts, installed a temp shifter handle, and rearranged the shop for an easy roll out the door.

I used the power steering hoses that came from FFR. They seem to work just fine for what I need. You can see I mounted the fuel pressure regulator in the middle of the firewall. I'm hoping to cover as much of it as possible with the gen4 engine cover. I like the look of the new covers and have one on the way from ford now. It seems impossible to have set of coil covers right now... it's busy on top of those heads.

Nothing special... just better shot of the fuel line routing.

On the air cleaner fitment I ended up having to take out my buzz box for the fan controller. I wasn't really impressed with it's performance nor will I likely hear the fan buzz from the PWM. So the loss is not consequential I believe. I did have to seat the filter much closer to the MAF sensor than the hard tube intended. Might have to tweak some things a bit once we can see how it runs.

I deviated from the plan with the computer mount. I made a bracket that is a little further forward and stands off a bit more than the FFR plan. I also flipped the computer over and added a couple more holes in the bracket for a less flimsy fit. The way the harnesses flow this felt like a more natural layout for them. I could also tuck the wires between the frame and the bracket for hopefully a less cluttered look once the body is on.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

01-02-2025, 02:09 PM

#134

First start has happened.

I finally had got the last cooling hose on New years eve... but I was at a kids party when it showed up and for most the afternoon. So I didn't get to have a new year's eve first attempt... but I didn't party too hard and was able to get up early to have everything ready for a new years day lunch attempt. We had success but it didn't go without a hitch... the problems were self induced.

Issue #1 fuel pump circuit:

I had decided to attempt to prime the fuel system before the start to be able to check for leaks and such. Well I figured I could go through a couple ignition cycles of the PCM to have it do it's normal system on routine which includes the fuel pump run for a bit. No go. I tested as far back in the circuit as I could go even taking out the fuse in the PDM and jumping it with a HAAT wire I've been leaving handy for all these tests. Fuel pump ran fine... so must be the ECU right? I had an extra button I wasn't using on my panel anyway so I decided to splice it into the circuit behind the dash so I could just have a manual pump ready to go. You'll see me messing with things in the video before the start attempt and that was one of them. What I didn't realize till later though is after the initial start... I never used the button again and the engine was starting instantly. So probably a lot of worrying and work for nothing.

Issue #2 understanding the start request condition:

The first time I hit the button the starter barely kicked, same with the second time. Crap... I did something wrong? I took the starter out and bench tested it with a jumping battery I had laying around. Smooth as butter. So I took the battery I had in the car out and tried it with that... same thing smooth as butter. Put the starter back in wired it back up and same result. I'm using the digital dawg ignition system so in order to turn things off completely you need to hold the button down for a period. When I attempted to shut things off I was in a state where it would attempt to start and low and behold the starter just kept going as long as I held the button.... wow I'm an idiot. I made the assumption that the coyote ECU would just take a momentary signal and it would control the starter until it sensed the engine was running like the stock mustang configuration. Again.... a lot or work for nothing.

Then was first real start attempt now that I know everything is working correctly. I didn't plan on making it available to the forum but only to buddies over phone messages. I played the damn video and sent it to so many people I decided it was probably worth it to create a you tube account. It cranks for a while in this video but every time you hit the button after that first start it fires up instantly and furiously. Almost 3 years apart from delivery to actually being able to drive it.

https://youtube.com/shorts/iNtYUhvSnHU?feature=share

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

01-06-2025, 10:21 PM

#135

Coyote/TKX things to note

I wanted to make sure I took some time to highlight things that were things I wish I was more confident about or knew before installing the engine. Like I said... I was excited to get it in and rolling as quickly as I could but a little more thought earlier in the process and I could have probably saved a weeks worth of time.

Coolant plumbing:

This was way easier than I made it out to be. I tried to look at all the popular build threads, youtube build videos, specific coolant forum threads and I didn't recognize for a while I was really seeing the same parts called out. They all just had slight variations of part numbers and vendor opinions of the same pieces. The list of items I specifically used were: a upr coolant expansion tank, a mishimoto hose kit for said tank, a 3/8" hose barb to 1/4" NPT fitting for the radiator, a 90 degree hard tube, a bracket to support said hard tube, and a more easily fitting upper radiator hose. I used the FFR provided lower hose cut into a couple sections with the 90 hard line for the bottom.

Wiring fun:

There are a number of portions of the wire harness I am not using. I'll edit this post in the near future with a list of their actual termination labels off the harness when I'm back in the shop. The important one I want to stress right away is the alternator control 3 wire plug. I had see this one mentioned in posts to unplug if you're having high voltage issues. I had to do the same thing. I swear I saw the voltmeter jump up to 18 volts at one point and the engine idle was all over the place. I unplugged that and everything stuck at a consistent 13.8 volts and the idle remained a solid 750rpm. I would suggest everyone just start with that unplugged. I actually got my first minor snake bite trying to unplug it when my hand slipped and I grazed the catalytic converter. The paint was still warming up to cure and it melted right onto my hand. I'm five days out and the dead skin is just now starting to break open and show the raw skin underneath. Can't wait to get the big one on the calf. Generically there were a bunch of terminations I haven't used... super charger related connections, extra O2 sensor items, and a few I don't even know what they are for yet.

I did buy a set of 16" O2 sensor extensions to allow for the stretch I needed between the collectors.

The MIL is ground triggered! I had originally wired this with a constant ground and only hooked up the positive. The light originally didn't come on and some simple test showed a constant continuity on 12v and the line. Also testing the pinout on the ECU connection showed continuity to the ground wire for the MIL. So had to redo that wiring a bit.

The finicky fuel pump circuit. I just did an ignition cycle this morning and verified after five days sitting the fuel circuit initiates a prime as expected now. My best guess is the initial attempts were either seeing a high enough pressure from my manual priming it didn't think it needed to prime itself... or the oil pressure wasn't high enough and it decided to hold off till a few cranks could get it up before kick on? I may call ford performance to see if they have a take but it's working as expected now.

Engine drop in:

There were two things in particular I wish I had realized before dropping the engine in. The first was the clearance issues with any hardware used for the crane hookup which I previously mentioned in my thread. The other is dealing with a standoff on the left hand side right behind the oil dipstick. That standoff is the only thing that scratched my finished panels on drop in. Had I known I would have cut it off before hand and I'm recommending anyone with a gen4 do the same before the drop. The clearance is so tight I think the scratches are actually from trying to level the engine side to side when getting final placement in the mounts.

Transmission:

Pinion angle was something I've seen stressed over on the forum but it wasn't a big deal. The coyote/tkx/irs package has been proven to be pretty consistent with needing a slight shaft lift to be in tolerance. I just went with the recommended three shims from forte out the gate. When I measured I calculated about 1.3 degrees which is about what you'd want. It's been a bit but I think I was -.5 on the crank and +.8 at the rear. So I'd repeat what I've heard... three shims from forte is the money spot.

The reverse sensor wiring is further forward than I expected so I have to do a little rearranging there. I was thinking it was going to be closer to the tail of the transmission when it is closer to the front. Not a big deal just something to note for others whom are going to use it. I bought a pigtail for it as the studs are so close together I couldn't find a reliable ring connector that wasn't capable of shorting to the other stud.

Gen4 engine cover:

I think it looks good but doesn't hide very much. I was optimistically hoping this would fit the gen4x as well but it doesn't. It's likely the 4x intake shares the same arrangement for the engine cover as the gen 3. I'll still try to figure out a way to adapt the gen4 cover to what I have before it's done. I want to find some subtle coil covers when said and done too.

First gokart:

Don't drive with your shop slippers on. It's nearly impossible to hit the brake without touching the accelerator with wide shoes. I ordered a pair of puma speedcats before I take it out again. Treadwear 200 tires are sticky even when cold. You can see my breath at one point in the start video as I think the temp was about 30f here in CO that day. Well that didn't mitigate the tires from picking up every pebble on the road and tossing them in every direction. I didn't expect to have to vacuum out the car the first time I took it around the block. I'm sure glad I got the vraptor wheel wells for it's final form.

Last edited by topherchrisb; 01-06-2025 at 10:28 PM.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

01-07-2025, 12:07 PM

#136

Senior Member

Originally Posted by

topherchrisb

The MIL is ground triggered! I had originally wired this with a constant ground and only hooked up the positive. The light originally didn't come on and some simple test showed a constant continuity on 12v and the line. Also testing the pinout on the ECU connection showed continuity to the ground wire for the MIL. So had to redo that wiring a bit.

Can you expand on this? The MIL is contained in the control pack and harness that comes with the coyote. As far as I understand it there is not external input required to make it work. What did you originally do and what did you need to change?

-

01-07-2025, 01:16 PM

#137

Originally Posted by

Blitzboy54

Can you expand on this? The MIL is contained in the control pack and harness that comes with the coyote. As far as I understand it there is not external input required to make it work. What did you originally do and what did you need to change?

I incorporated a MIL (engine logo) light in my pilot light cluster previously. So I wanted to use that instead of the one built into the harness. I had created the wiring terminations for that a long time ago with a common ground amongst most of the pilot lights planning on only needing to feed them the 12v signal to activate any of them. I have turn signals, brights, check engine and a parking brake light. I previously found out the same type of thing for the parking brake where the wilwood switch has 12v hot all the time and the ground is closed for the light to come on. So I had to take that ground out of the common ground in the pilot cluster previously.

The coyote mil is the same but in order to test it you have to tap into the wire or cut it off. You can see that it has 12v live even when the ECU isn't plugged in if your PDM is already live. Then if you go to the FFR instructions for the coyote control pack page 28 you can see pin 34 is the MIL lamp trigger. If you test that you'll find that it as continuity with the ground wire on the built in MIL instead of the 12v line. So the ECU is shorting that pin to ground in order to trigger the light on.

What I had to do to fix it is simple but was rework like a lot of things I've done. I removed the ground for the dash light from the common pilot light ground and hooked it up to the ground wire that is coming from the ECU for the stock MIL and I had already had the ECU 12v on the light because I originally thought that was the trigger. So no change from what I had done on the 12v side.

The long explanation can be shortened to... just use or tap into both wires provided for the stock MIL if you're going to use an external indicator. Don't try to share the 12v or ground with any other circuits.

Last edited by topherchrisb; 01-07-2025 at 01:21 PM.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

01-07-2025, 01:38 PM

#138

Senior Member

Oh I got it. That makes sense, I did something similar but just tied power and ground to the new light with the wires from the MIL. I see what you were thinking and why it didnít work.

All is well that ends well.

Can you do me another favor and add a picture of your transmission in the tunnel? I am also using a TKX Coyote and would like to see where my shifter is going to end up. Also I would like to get ahead of the tail light wiring you mentioned.

PS. Your car looks great. The interior is really sharp. Iím enjoying your thread for sure.

-

01-07-2025, 03:38 PM

#139

Originally Posted by

Blitzboy54

Oh I got it. That makes sense, I did something similar but just tied power and ground to the new light with the wires from the MIL. I see what you were thinking and why it didn’t work.

All is well that ends well.

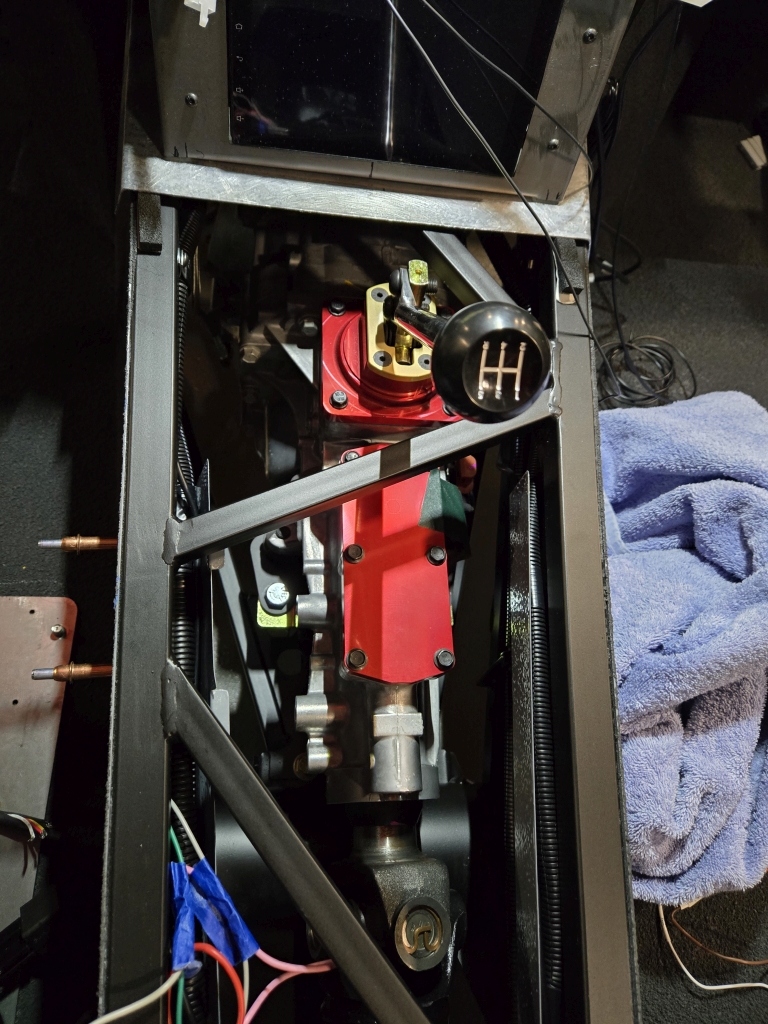

Can you do me another favor and add a picture of your transmission in the tunnel? I am also using a TKX Coyote and would like to see where my shifter is going to end up. Also I would like to get ahead of the tail light wiring you mentioned.

PS. Your car looks great. The interior is really sharp. I’m enjoying your thread for sure.

That interior is just lizard skin at the moment. I have an upholster local to me I'm going to work with but was waiting till I could drive it before I got it to him. He's only about 1/4 mile up the road but winter finally showed up on the CO front range once I could start this thing up. So have to wait for some more consistent nice days but I'm glad the snow could wait till I could drive it at least once. I have a few more wiring things to polish and finalize anyway. You can see the wiring hanging in the trans tunnel picture here. That is the reverse light/camera trigger wiring and I polished all that up this morning. The shifter is just like that for temporary use. I have an offset adapter from MGW going in as soon as I get the shorty shifter handle turned down about 1/16" before I can finish that. Still have to figure out an AC/Heater solution but I think I read somewhere FFR has a new solution for the MK5 that I can hopefully retro fit to the 4. The reverse sensor connection is laterally under that cable clamp barely sticking out on the left forward side of the tunnel if you're interested. I ended up removing the wiring from the loom and just tapping into it instead of trying to stretch the wiring I had pre-run. Couldn't find a wire stretcher on amazon.

MK4 #10255 project: "Mako"

Coyote Gen 3, TKX, IRS, Wilwood brakes, power steering

Order date: 6/24/21, Received date: 1/12/22, First Gocart date: 1/1/25, Registration date: TBD

Build thread

-

Post Thanks / Like - 1 Thanks, 0 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

I took the angle grinder and ground a little on the head and the reservoir to be able to get the thing on. What's funny is with the pump and pulleys sitting on the bench I couldn't get the belt to get around them gracefully. The belt could be just bit longer in my opinion. It was obvious it would be a pain with the pulleys on the engine. I ended up getting it to fit by doing things in this order: mount the pump, pre route the serpentine belt as much as I could without tension, get the steering belt on both pulleys, mount/torque the water pump pulley, tension the serpentine belt, then adjust the steering pulley tension. I didn't even mention the time cover bolt that had some extra stand off threads on it I had to grind down to get the bracket to fit... or that one of the spacers is no longer the right depth so I replaced with a stack of washers for correct depth. Early adopter problems.

I took the angle grinder and ground a little on the head and the reservoir to be able to get the thing on. What's funny is with the pump and pulleys sitting on the bench I couldn't get the belt to get around them gracefully. The belt could be just bit longer in my opinion. It was obvious it would be a pain with the pulleys on the engine. I ended up getting it to fit by doing things in this order: mount the pump, pre route the serpentine belt as much as I could without tension, get the steering belt on both pulleys, mount/torque the water pump pulley, tension the serpentine belt, then adjust the steering pulley tension. I didn't even mention the time cover bolt that had some extra stand off threads on it I had to grind down to get the bracket to fit... or that one of the spacers is no longer the right depth so I replaced with a stack of washers for correct depth. Early adopter problems.