-

03-24-2024, 07:46 AM

#241

Senior Member

-

03-25-2024, 07:55 AM

#242

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-27-2024, 08:14 AM

#243

Senior Member

-

04-01-2024, 07:57 AM

#244

Senior Member

-

04-03-2024, 08:16 AM

#245

Senior Member

Cab roof ribs added

Quick update.

Striping the old, flaking LizardSkin product was easy in some spots and very difficult in others. I ended up using my pressure washers to strip the difficult areas.... worked well. As I was cleaning, I was also thinking about the final finish for the roof of the cab. I decided to add some wood strips (ferring strips) to attach the roof cover to.

I simply ripped 1/2" strips from a 1 x 4 pine board and glued them in place with 3M 5200 polyurethane and weighed the strip down to match the contour of the roof.

I'll then cover the wood ribs masking tape and respray the cab with the two LizardSkind sound and heat products.

More later on all this,

Mark

-

04-05-2024, 08:09 AM

#246

Senior Member

Cab interior covered with two products for sound, vibration and heat

After cleaning and scuffing the cab's interior, I changed my mind on the LizardSkin. I had other sound and heat options from other builds I've done. And to be very honest, after my bad experience with LizardSkin peeling off and my plan to glue my interior cover to the side walls.... well, I was very concerned about the interior side cover not staying in place because of my fear LizardSkin would fail over time.

I first cleaned all the interior surfaces again with Acetone. Then proceed with a Dynamat type butyl rubber backed by aluminum foil.

Then I covered most of the foil backed butyl rubber with this product.

This material is about 1/2" thick, heavy dense foam backed by a very sticky adhesive. Both the butyl rubber and foam will be great for sound, vibration and heat.

I also covered the back panels with the foam mats.

Lastly, I cut 1/4" lauan plywood to fit the roof that I'll cover with the diamond padded vinyl for the finish look and a fiber material for the sides. I'll add this after painting. Then I'll set the completed interior cab back on the chassis. It's much easier to do the interior while the cab is off the chassis.

Some of you may be wondering why the gap in front of the plywood. Well, you may recall from earlier posts I made an overhead gauge panel that fit tight to the cab's roof.... so, I had to leave room for the gauge panel to fit

Stay tuned,

Mark

-

04-08-2024, 07:15 AM

#247

Senior Member

Truck Cab base frame made and installed

Since I'm doing my Cab's body work and paint off the chassis, I had to build a frame system for the bottom of the cab to stiffen it up, with the cab to be up off the ground and be able to move it easily by myself.

Came up with the design below

I didn't want to drill holes in the cab's base, so I used fender washers to hold the cab to the wood frame

In the picks below, note the long front to back runners.... they are 30" apart, the same as the moving dolly I have. I simply clamp the dolly to the frame to hold in place while I roll the cab where I want it. Then, I can unclamp it, lift the front of the cab to tilt backwards and simply remove the dolly for a firm cab stance on the ground for sanding, etc.

When I'm done with body and paint, I'll place the cab on my lift's arms to complete the interior while comfortably standing inside the cab. I'll also use the lift to lower the cab back on the chassis.

More to follow,

Mark

-

04-15-2024, 07:50 AM

#248

Senior Member

Stack Pocket mounting to Bed Sides

During my body work on the bed side panels, I had to add some "parts". You might recall that I bought from FFR the Stake Pockets option. Well, by installing the pockets you hide the rear mounting area and, thereby, can't access the mounting button head screw. So, my fix was to install a couple rivnuts to each of the rear side panels so I can install the screws from the inside vs the outside.

Since the side panel has pretty thick fiberglass and the upper hole also had the ss wrap, the standard rivnut wouldn't work, i.e., not enough grip area was exposed for proper rivnut expansion..... so, I found this type of rivnut which worked out great.

In the next pic, I bonded the stake pocket to the bed side with 3M's High Strength Repair Filler (HSRF). I scuffed up the bed side and stake pocket mounting surfaces with 40 grit and applied the HSRF to the stake pocket and pressed on the pockets to the bedside. 30 min's later, I was cleaning up the HSRF that squeezed out. I'll show the finished panel later in another post.

More to follow,

Mark

-

06-04-2024, 06:36 AM

#249

Senior Member

Why no updates?

It's been awhile since my last update.... well, a lot is happening. We decided to cash in on the housing market in our town and downsize. Our house when for sale about 30 days ago. We're moving to NE Tennessee by Johnson City, TN. We found a great home with a shop for me. So I decided to but the build on hold and finish the truck in TN. I'll keep updating as appropriate.

Thx Mark

-

08-19-2024, 07:37 AM

#250

Senior Member

-

10-04-2024, 08:21 AM

#251

Hi Mark,

I'm finally getting around to installing my grill cowl. And I found large gaps at the sides after the top edge was fitted. Sounds like I have the same problem you had with it being aggressively trimmed at FFR. I'll email them today and see what they say.

But I have another question: Did you use that T shaped piece of aluminum that is supposed to mount the lower chin of the cowl to the frame?

Thx for taking the time to reply,

Last edited by DonImbimbo; 10-04-2024 at 08:55 AM.

Reason: ignore question on screws

1990 Mustang 5.0 5sp, 2021 Bronco Sport Badlands, 1935 Extended Cab Build, 347 & 4R70W

-

10-04-2024, 10:06 AM

#252

Senior Member

Hey Don.... I did use the T-Aluminum..... however, as I stated in my posts, I had to trim the lower fiberglass and make my own support to hold the lower cowl together.

Mark

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

11-03-2024, 09:58 AM

#253

Mark,

Did you have any issues getting the hood hinge to line up? I'm noticing that the hinge arm is perpendicular to the radiator but the hood bracket (that mounts to that hidden aluminum block) seems to be at a very different angle. Did you have to re-bend the bracket or hood arm?

Seems to be off by 13 degrees or so.

Or maybe I'm missing something.

1990 Mustang 5.0 5sp, 2021 Bronco Sport Badlands, 1935 Extended Cab Build, 347 & 4R70W

-

11-03-2024, 07:05 PM

#254

Don, send me your email and I’ll send you photos of how I dealt with this issue. DonS.

-

11-04-2024, 06:36 AM

#255

Senior Member

Don, I did have to bend and shape each hood hinge bracket/arms.... A few twists and bends. I took my time, test fit and off again as need to get each side perfect. A large bench vice will be your friend here.... I also use an adjustable wrench for the twisting. Happy to discuss if needed via a phone call.

Good luck, Mark

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

11-14-2024, 12:33 PM

#256

Originally Posted by

mkassab

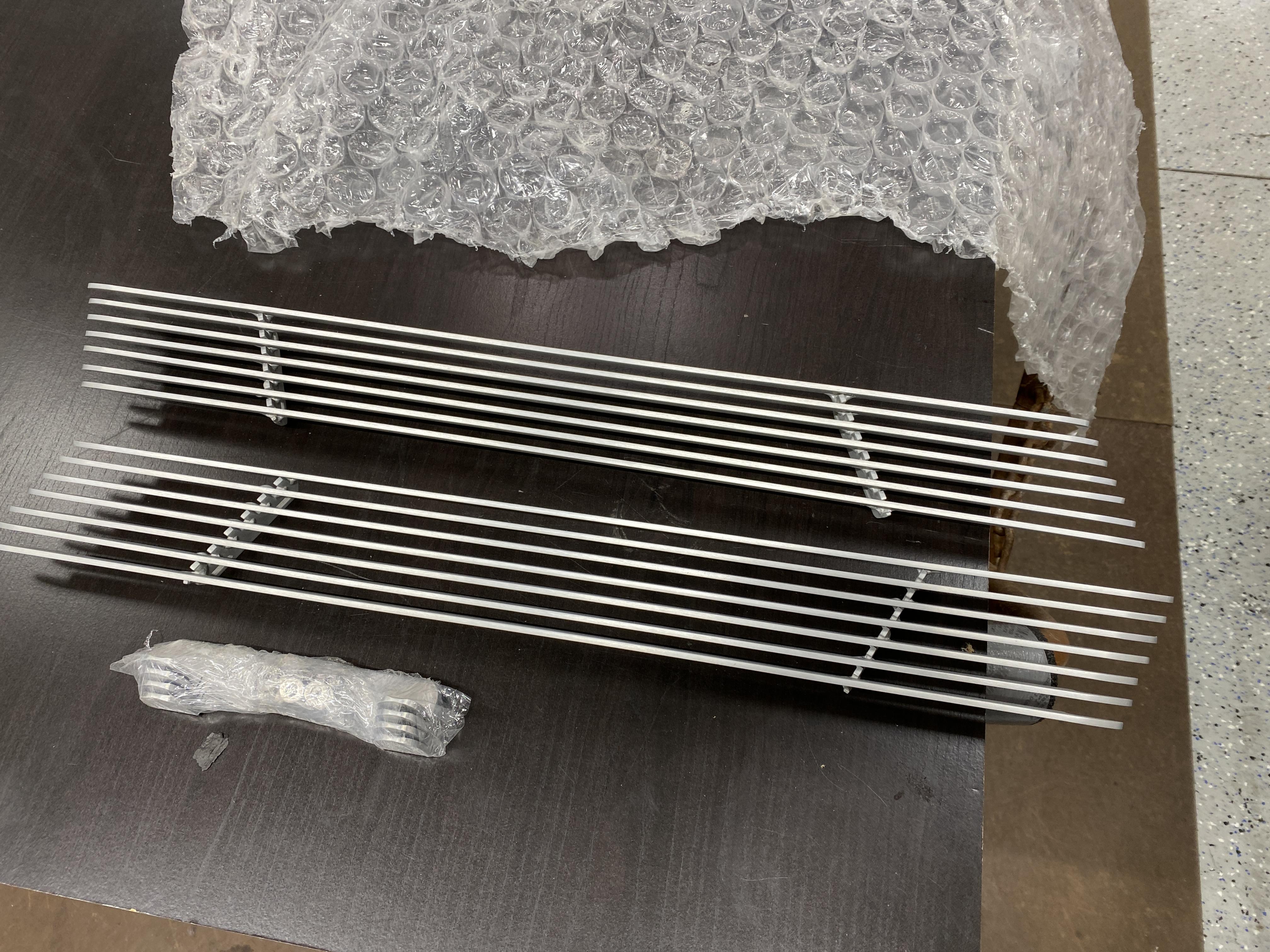

A few more items showed up yesterday.

First up, I received my engine side cover vents. I had then clear anodized which should help with preventing corrosion. These will allow the small engine compartment to dissipate some heat and I think they look good and period correct. I also plan on wrapping the headers/exhaust pipes and shields atop the mufflers (I have this stuff on order also).

This last pic shows two products, 1) Lizard Skin, a heat and sound proofing system with spray gun, and 2) Raptor protective coating and spray gun (like truck bed liner). I'll spray the Lizard Skin in the cab (e.g., cab body, floor, door interiors and firewall). I may also do the underside of the hood and engine side covers. For the Raptor product, I'll spray the underside of the 4 fenders and running boards. I'll most likely also spray the underside of both the floor pans and truck bed.

Stay tune, "stuff" coming in each day/week.

Mark

What was the sorce for your side vents? I am having heat issues and I think I need to add side hood vents to help in cooling the engine bay.

-

11-15-2024, 07:50 AM

#257

Senior Member

Grandpa... here's the link: http://www.streetdreamsbyross.com/vents.php I bought the same vent that Paul did for his '35 truck. I also had the grill vents "anodized" by Street Dreams.

Good luck,

Mark

-

01-14-2025, 08:20 AM

#258

Senior Member

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

01-15-2025, 10:55 AM

#259

-

01-15-2025, 11:29 AM

#260

Senior Member

Thanks Lewis. It your truck painted and complete yet?

Mark

-

01-26-2025, 08:40 AM

#261

Senior Member

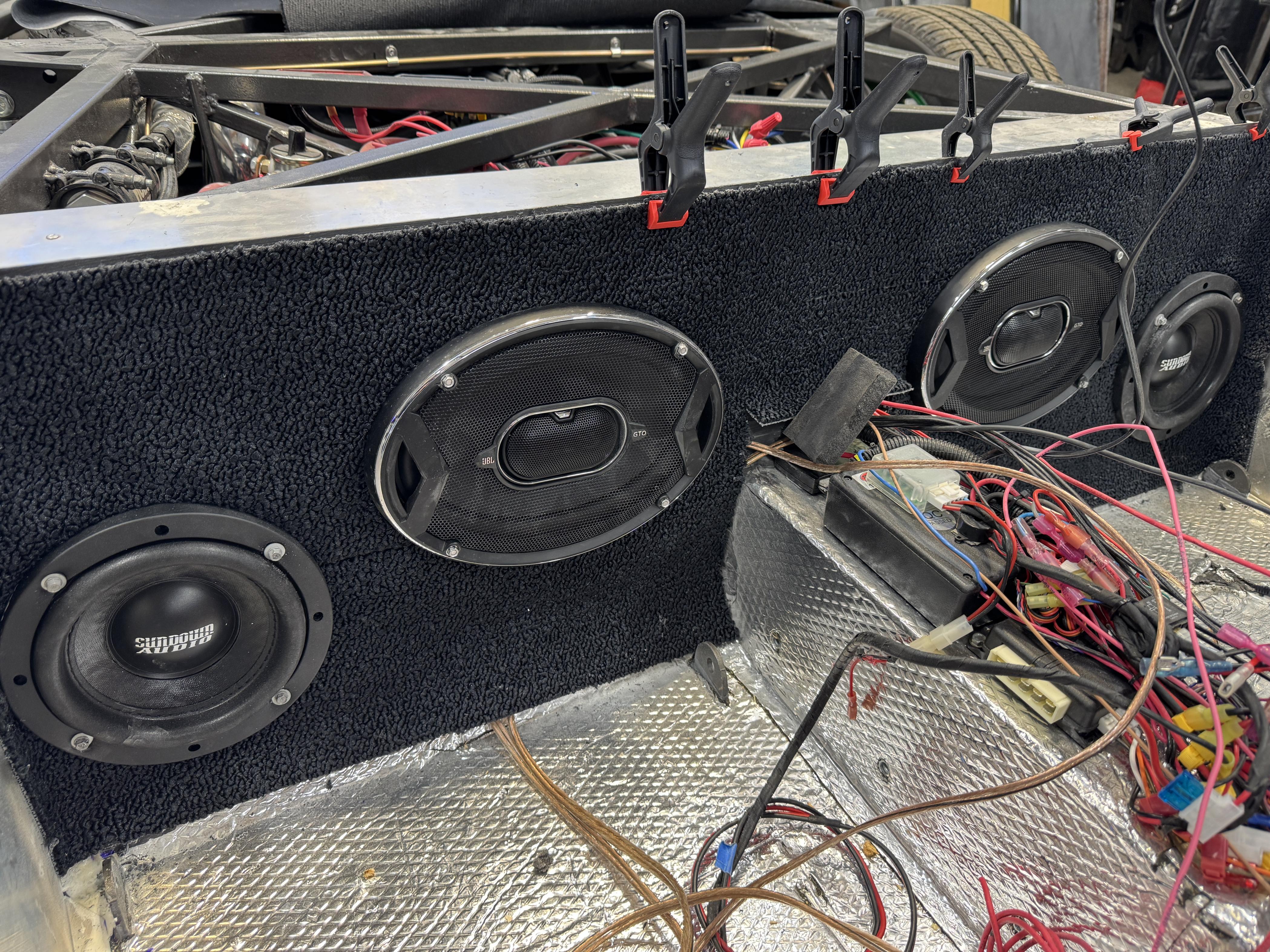

Interior start and cab preinstall questions??

To finish my build, I need to complete body and paint (along with my interior)..... but, I need the weather to be warmer to do all the prep/sanding outdoors so I don't "dust up" the entire shop. So, I'm focusing my "winter time" to wrap-up the interior as much as possible. I shared a few pics below of my start, i.e., Carpet and Speakers. I'm upgrading my carpet from FFR's supplied carpet (I'll use FFR carpet as a template, after I fit it, to cut the new carpet). It's better carpet and more "period correct". I started on the back panel where I have a pair of tri-axial speakers and a pair of subwoofers. I also have speakers for the cab front I'll show later.

However, I do have questions on what I can do before the CAB is put back on.... examples, can I install the dash, the seatbelts/shoulder belt brackets to the roll cage, etc. I'd like to also install the roof liner before the cab is put in place??

INPUT needed to the above questions. Any thoughts, cautions, got-yas most welcome!

Thx Mark

BACK PANEL:

Passenger Side floor:

Last edited by mkassab; 01-26-2025 at 10:19 AM.

-

01-26-2025, 10:18 AM

#262

Senior Member

No on Dash preinstall prior to cab install

OK, I just answered one of my questions..... you can't install dash before the cab as the dash bolts to the cab flange along the door opening and preventing the cab slipping behind the dash flange.

Mark

-

01-26-2025, 02:49 PM

#263

Senior Member

Howdy Mark.

Now it might be because my truck was an early build (sn# 0059) and it might be in part the mildly affected right hand from a stroke a few years prior to 2019 when I was building the ‘35….

All that aside I can recall terrible access to one of the upper door hinge bolts to frame…don’t recall now whether it was just LHS or both.

Can tell you if i were to do it all over again the temptation to drill holes in the doorframe and/or change assy instructions and weld a nut or two to the backside of the supporting structure (on the body frame) for the door and put a bolt in from the opposite side from recommendations…would be very tempting.

This as mentioned, could be my experience only…but it’s very little time for you to do a ‘dry run’ whilst the body is still off.

My 2 cents…hopefully helpful.

Cheers,

Pat

Once again with an 88 mm Turbo, Big Block Chevy powered, ‘35 Hot Rod Pickup

-

01-27-2025, 07:25 AM

#264

Senior Member

Thanks Pat.... you are correct, if the dash was in place, the upper inside hinge bolts would be impossible to get to..... so, no dash until the cab and doors are in place.

Thanks for your comments,

Mark

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-29-2025, 09:35 AM

#265

Senior Member

Front and rear dash prep install

While installing the interior, I had to complete all the wiring, e.g., speakers, security alarm and my front and rear dash cam.

The pic below is the unit being installed. The rear camera plugs into the main front camera. Both front and rear camera views are displayed on the color lcd monitor on the backside of the front camera. Also, the main mount has GPS and the GPS position is also recorded. This unit was highly rated during my research.

Mark

-

01-29-2025, 02:58 PM

#266

Senior Member

1935 Tenn Tag and Registration

I just wanted to share the end results of me registering and titling of my '35 Truck.

As the pic shows, my tag and registration, Tennessee registered and titled my truck as a 1935 Ford F5R. I bought the '35 License Plate/tag off eBay and they used it. And since it's an antique, it's a permanent tag with NO yearly registration fee. Also, they used FFR Ser # for my VIN. Lastly, no inspection in any way shape or form was required!

I couldn't have asked for anything better.

Mark

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-01-2025, 08:35 AM

#267

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

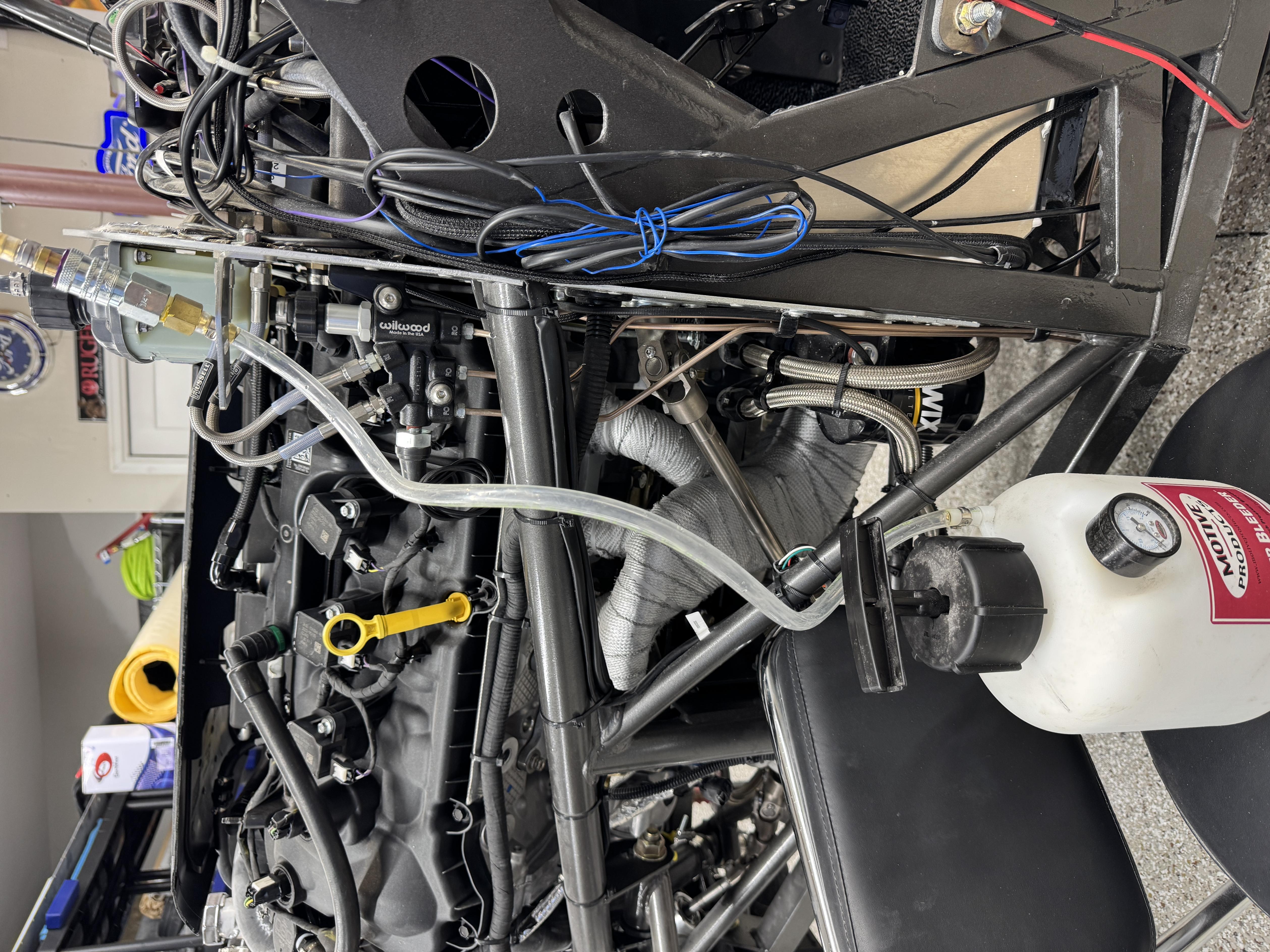

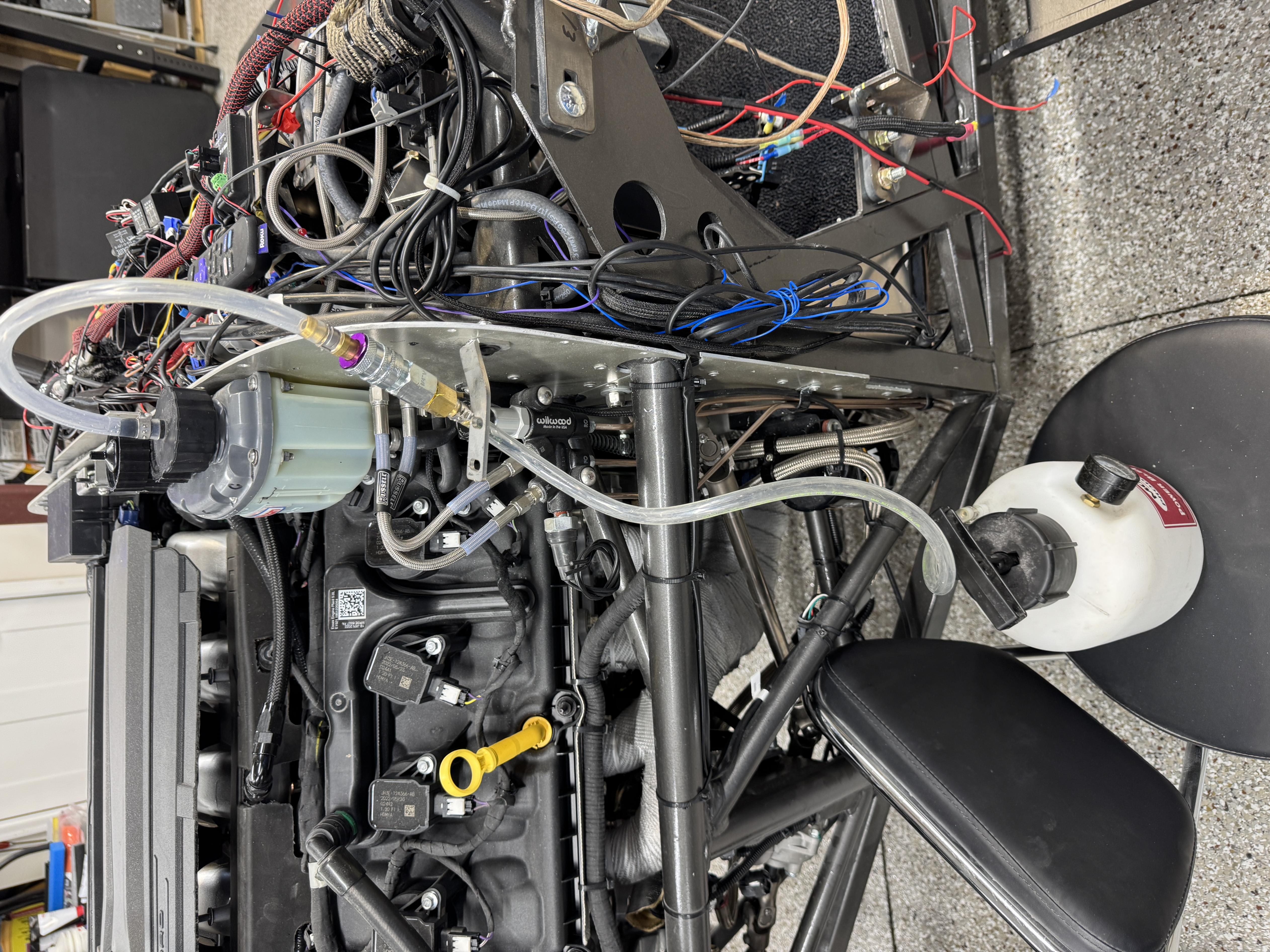

A great way to bleed brakes and hydro clutch

I'm sure many of you know and/or use this Motive Products device. For those that don't, you just select the cap that fits your brake fluid container(s), fill the Motive jug with brake fluid, pump to put positive air pressure in the jug to ~5-10psi. Then just open the bleed valve on each brake caliper or clutch throw-out bearing bleed hose. Keep open until all air bubbles are gone and you'll have perfect, 1-man, blead brakes.

Once you use this, you'll never go back to the "old" way to bleed brakes.

Mark

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote