Good day to everyone!

I've been putting this off long enough and I have come up with lots of questions so I suppose it's time to start my own build thread. I don't know how much time I will have to post updates, but I figure I need to do this so you good folks know who I am when I do.

A little background -- in June of last year I flew to Florida and picked up an '02 WRX that my buddy test drove/purchased for me, drove 800 miles back home, and started the tear down with my son and daughter then at 11 and 9 years old. My goal is for them to be able to turn a wrench when they get older, have build/troubleshooting skills, and know their way around a mechanical object larger than a lego set. I figure that if I can get 20 minutes at a time with them, it will be time well spent and they will have no problem taking ownership of it when we finish. "Look what my dad built with me!"

Here it is. It was a trooper for that long trek from Florida in June with NO A/C.

So far, our time together has been WAY more than 20 mins at a time. We had a blast dismantling it because it was fairly easy to just unscrew things and put them in piles.

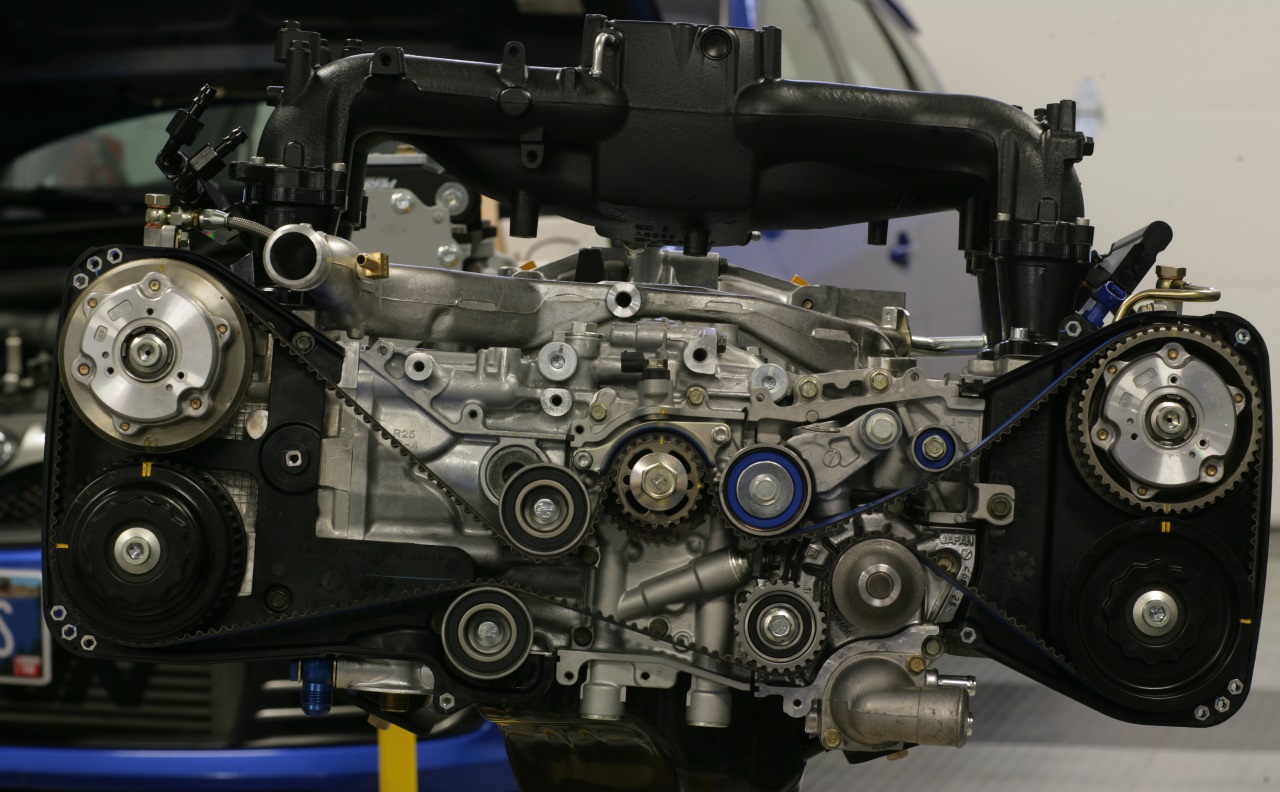

I received my kit about three weeks ago and we started the process. Needless to say putting it together brings up lots of questions. Many of those questions have been answered because of all you fine folks on this forum. Thank you all for your questions and answers. Because I have no experience save the occasional oil change/brake replacement, etc. this isn't as intuitive as one would imagine even following the manual. My engineering degree does help, but because I've never actually used my degree (thank God) the lack of practical experience leaves me scratching my head at times. Case in point, putting in the upper front ball joints requires you to orient the cotter pin holes PRIOR to tightening down the castle nut...just one of the lessons learned so far.

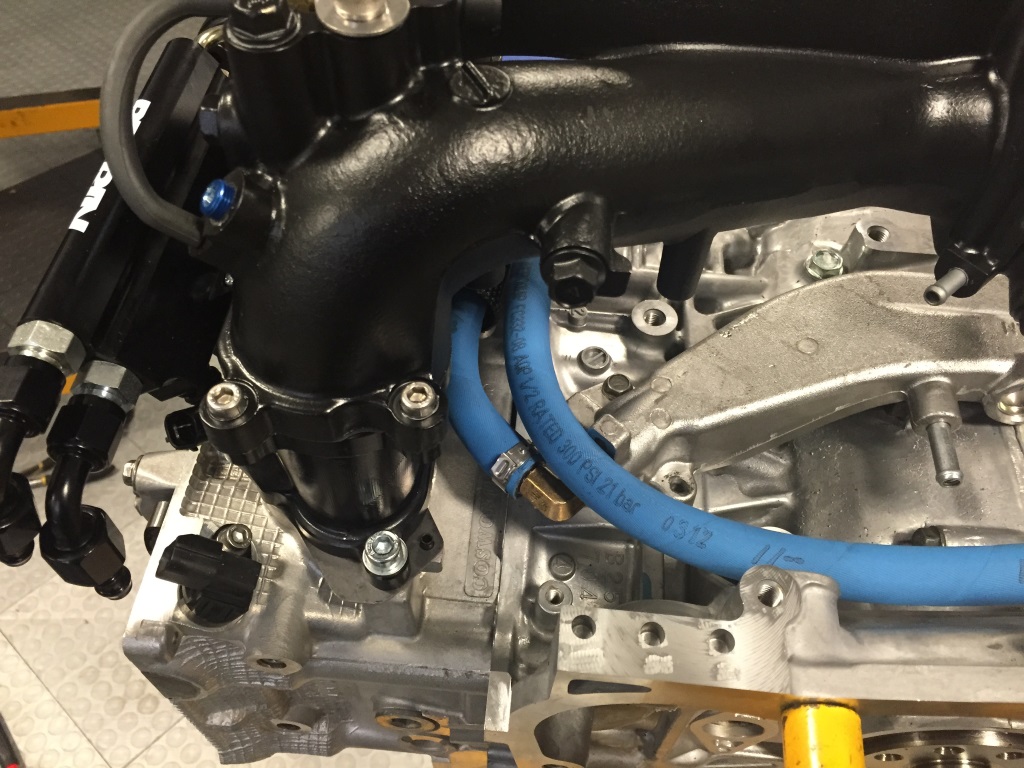

As the engine install isn't far away, I need to get things ready. My first question starts with Wayne's coolant system mod...⅛" NPT Barb nipple to burp the coolant system. I went to Home Depot to find one of these, and because I'm unfamiliar them I'm not sure if I'm looking at the correct thing.

What do you guys think? What exactly is 1/8 of an inch? Is it the threaded part OD, is it the barbed fitting ID? Would I be better off at a plumbing supply store? And now along those lines… because I've never tapped anything previously, what size tap and die set do I need?

Hopefully, this post will be the first of many

Thanks again all!

Rob

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote