Completed the first start and hopefully my issues help someone else with the new pack. Video here

https://www.youtube.com/watch?v=0OPzhN7-nbo

Issue 1. Throttle (electronic drive by wire) didn't work on first start. The reason, absence mindedness. If you have already hooked up your battery to your system (PCM/PDB sees power) and then plug in the connection to your throttle, your throttle may not work. It worked on my second start

Issue 2. Following the Ford control pack instructions for Setup B, referencing Edwards post (#3) Blunt Lead 16 - Key On 12V/10A (Yellow) was not needed for me. When I completed the first start and went to shut the motor down, it would not shut down until I went from On, CCW past off and finally would kill the engine when I was in the farthest CCW ACC spot on the ignition switch.

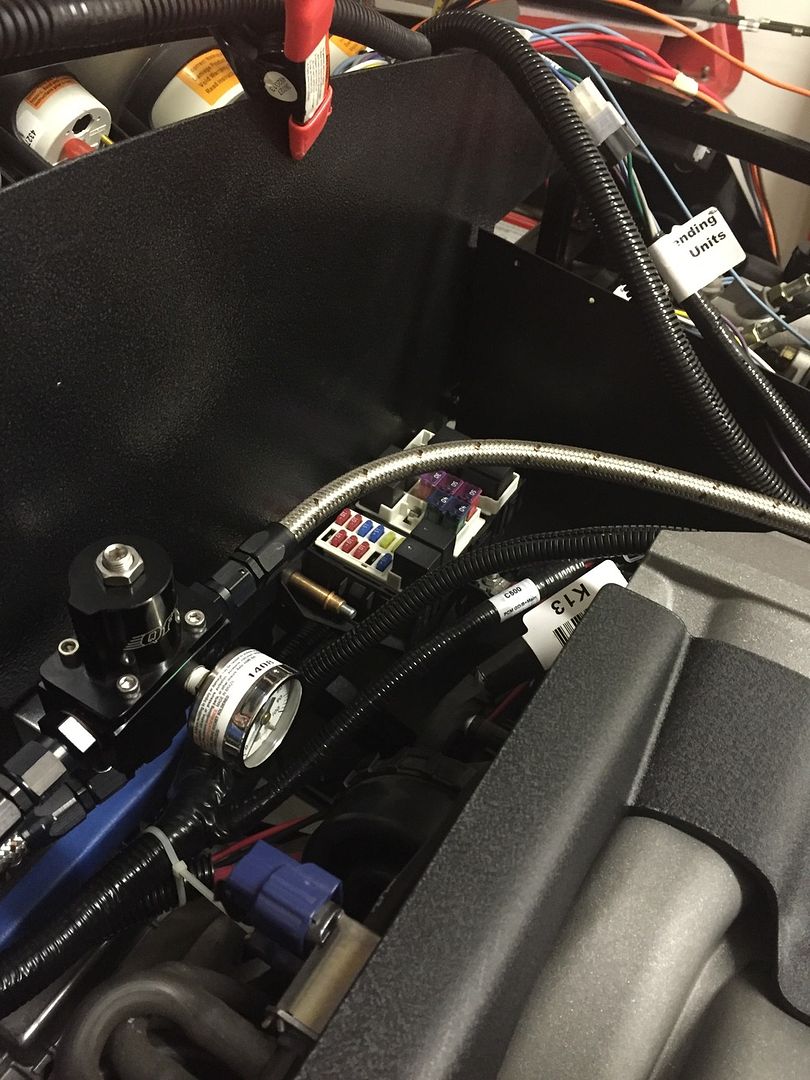

Got out the multimeter and started to test again. What was weird is the ignition switch checked out by itself (no continuity between +12V and off position) and would check out again with leads attached before reconnecting the battery. As soon as I hooked up the battery and rotated the ignition switch to On, the PDB relays would energize and the Blunt Lead 16 - Key On 12V/10A (Yellow) would have power regardless of whether the ignition switch was in On or ACC. This was after several hours of testing leads, disconnecting harness connections and validating the RF fuse box. Literally pulling my hair out. The kicker, I was only checking the connection at the ignition switch not where the Blunt Lead 16 - Key On 12V/10A (Yellow) tied in.

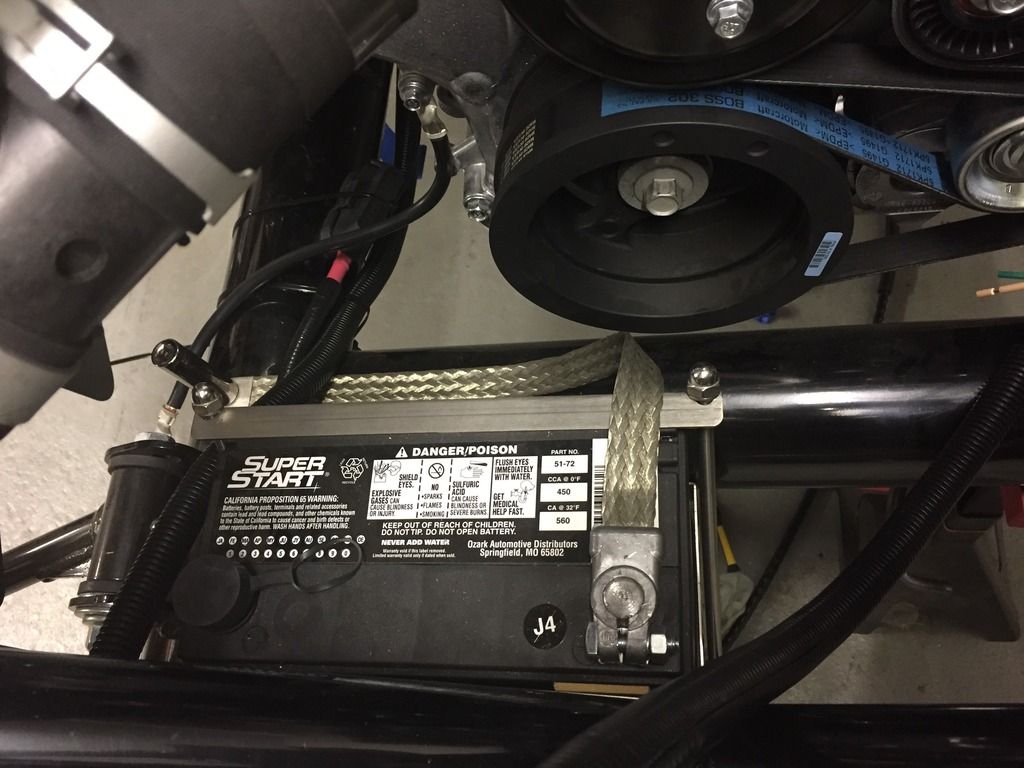

I even went as far as trying to hookup the Blunt Lead 16 - Key On 12V/10A (Yellow) to both the RF orange and brown wires (ACC and On connections) just to validate what was going on. Since both of these see +12v, there was little risk of damaging anything as the PCM/PDB would just think it was either in ACC or On. You experienced guys are probably cringing right now. Yep the motor would not shut off! Disconnecting the battery didn't help as now the alternator was providing enough juice at idle to keep the motor running. I had to physically cut the Blunt Lead 16 - Key On 12V/10A (Yellow) to kill the motor. But that was the point that I realized that the Blunt Lead 16 - Key On 12V/10A (Yellow) had power regardless of which lead (Acc or On) I connected it to. And since both of these see power through the ignition switch I was never able to isolate it or THOUGHT about isolating it.

Summary and your results may vary. For Setup B (using an ignition switch), I do not need the Blunt Lead 16 - Key On 12V/10A (Yellow) at all.

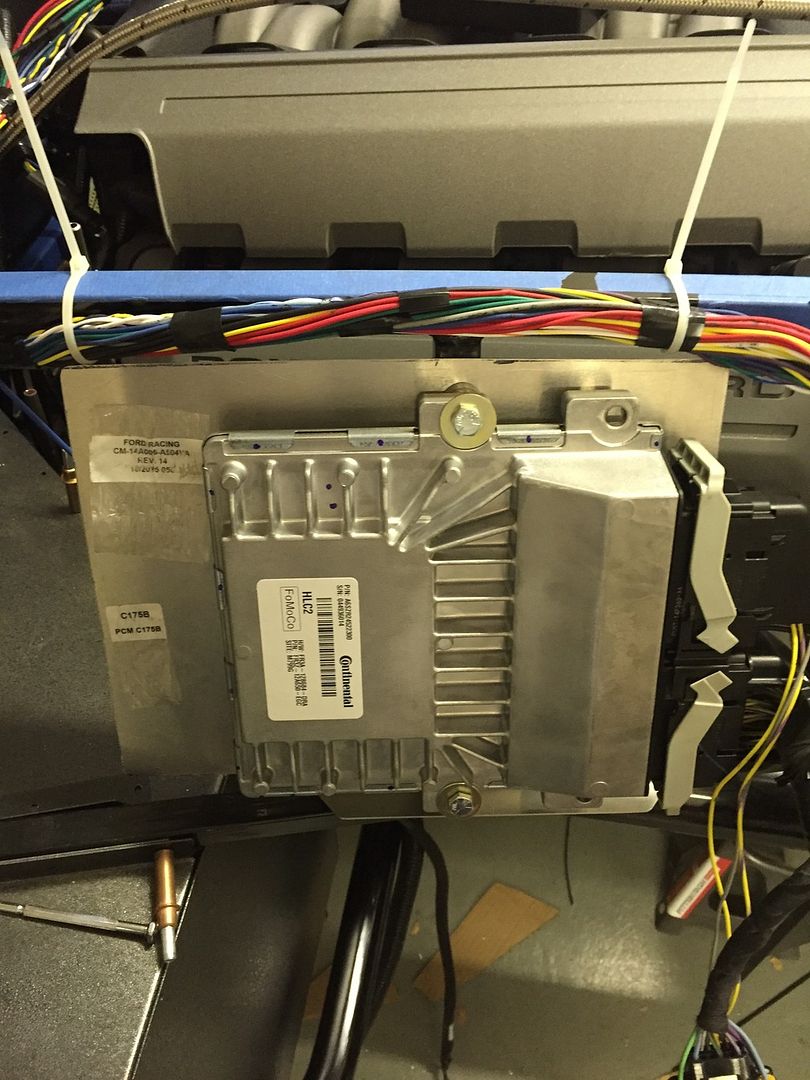

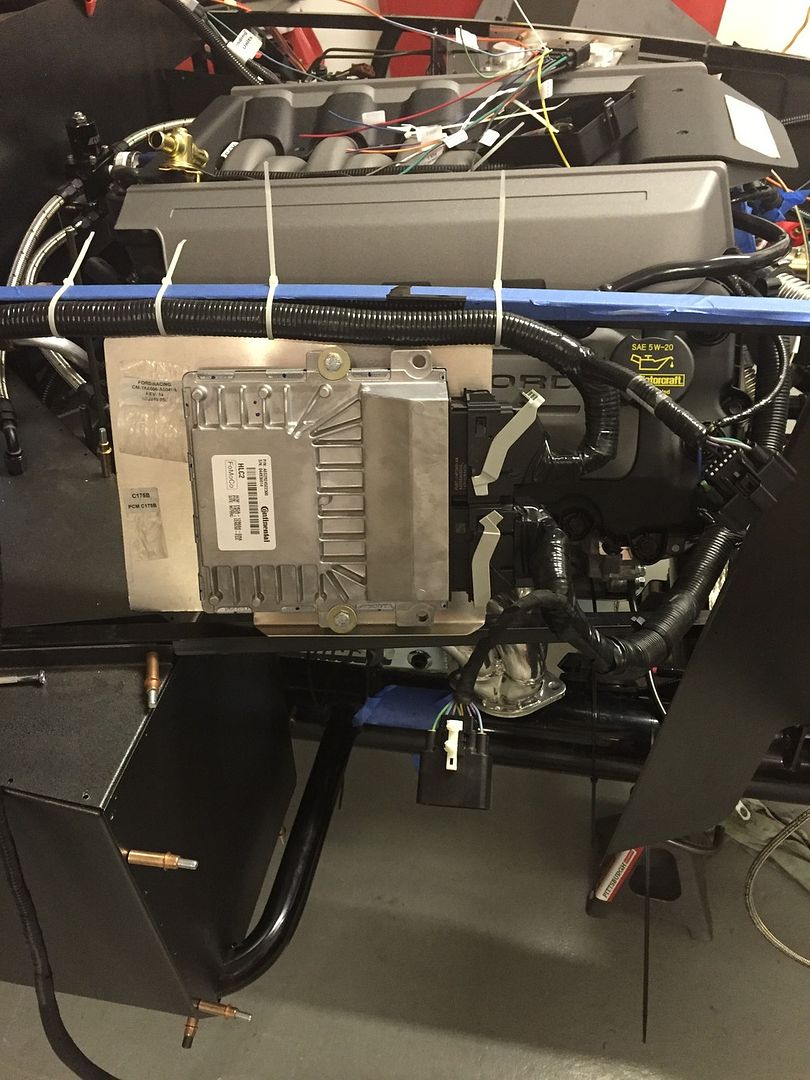

I will likely go back, pull the PDB so I can get to the back side (bottom side) so I can find out why the Blunt Lead 16 - Key On 12V/10A (Yellow) has power whenever the ignition switch is on On or ACC and has power while the engine is running. But for now, trying to get everything buttoned up so I can go kart it!

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote