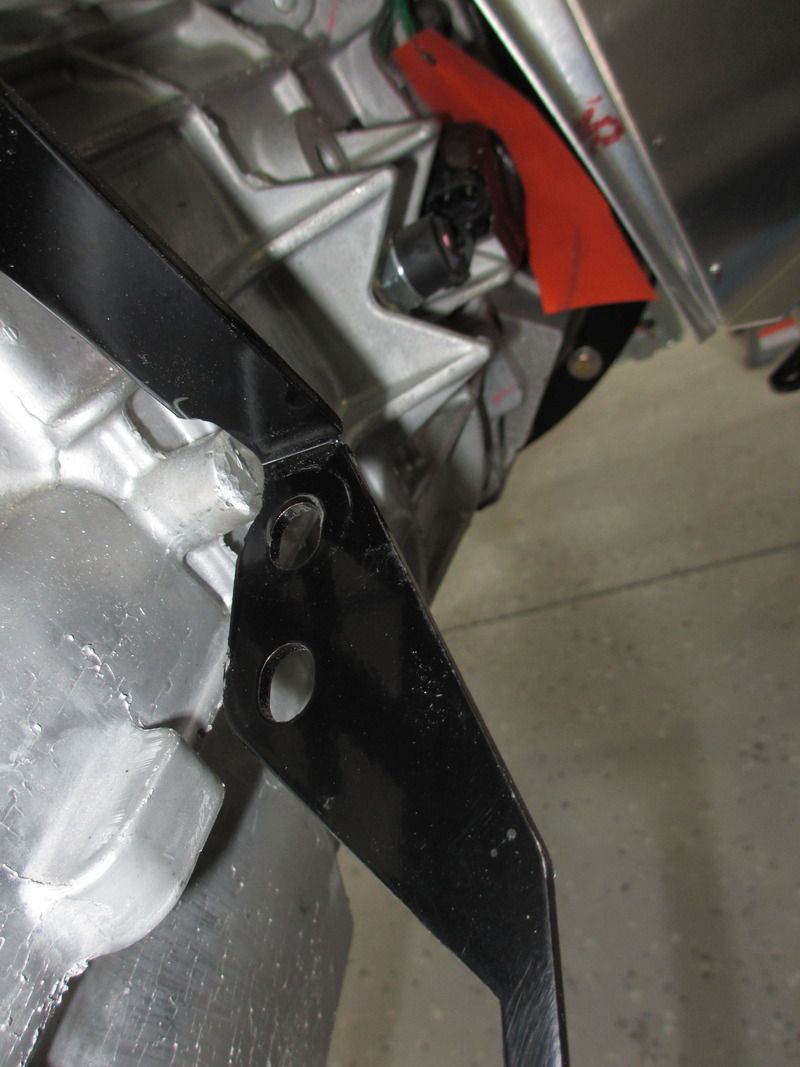

It fits! This is for my 2015 Coyote, T56 Magnum transmission, with 2015 IRS transmission. A few things to note if you are crazy enough to try this at home. The transmission mount bracket needs to be modified (see pictures below). There is a small spot on the parking brake bracket that needs to be ground down for clearance, and a custom driveshaft is needed. Nate at Michell Drivetrain in Shrewsbury MA (who happens to be one of the vendors who supplies FFR with their drive shafts) did an amazing job machining down two joints before welding them up and running it through the balancing machine. Joint to joint it measures 4" and has 3/4" split play into the transmission (31 spline). Three drive line shops I called first said it couldn't be done. To get it in you must put it while you are installing the motor and trans though. The joint doesn't have enough flex to clear if you try and install it after the motor/trans are in.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote