-

Senior Member

Trailer Strapping Question

Iím coming near the end of my build. Iíve trailered the go cart version without any issues using the front loop locations on the frame and wrapping the rear straps around the axle. My question is can I get to those locations when the body is on since the roadster is so low?

Curious how others use their straps?

Below are the straps I have.

https://www.macscustomtiedowns.com/c...32334634647626

MK IV - #9586, Gen 2 Coyote, TKO 600

-

Not a waxer

You can but you kind of have to lay down and do the worm

Jeff

-

Steve >> aka: GoDadGo

I use Tire Lassos from Vulcan and I feed them through the rim and they work well so the setup you are looking at should work well too.

I just stick a shop towel between the rim and the strap to avoid possible damage to the wheel finish since my straps are not padded.

https://www.truckntow.com/vulcan-car...king-load.html

You may be able to find both strap sets on Amazon for a few dollars less.

They work to haul other stuff too as long as you can get the lasso through something that won't cut the strap.

NOTE:..I became a Cobra Trailering Champ last summer when my car was less than legal and I had to move it to higher ground 5 or 6 times during Hurricane Season.

Last edited by GoDadGo; 02-22-2021 at 08:26 AM.

-

Senior Member

I am not sure where you could get these made but a friend w/ a 14ft trailer w/ big aluminum diamond plate wind breaker on front did this. He had a shop make a custom strap. It had hooks near the center to connect to the tow eyes on the FFR frame. It also had hooks on the ends to connect to eyes on his trailer. Hooks like this but heavier duty.

https://www.uscargocontrol.com/1-Hea...eper-2-000-lbs

He pulled onto the trailer and stopped about a foot back from full forward. Snapped the center hooks to the car and then pulled forward. It was a little difficult getting to the ends but grab them, pull across in front of the tire, and hook to his rings. Then he used a couple heavy ratchet straps at the rear to pull the car back a little until the front strap was tight. The advantage is that at the front there is no clunky ratchet to try to adjust. No ratchet rubbing on the body, just smooth 1.5 or 2inch webbing near the body edge. Since the front satrap isn't adjustable he did put a mark on the trailer so he could position the LF tire correctly left to right.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Always a good idea to cross strap the car...da Bat

-

I use wheel straps aka bonnet straps aka basket straps.

With fat tires, they never touch the rim.

-

I never trailered my previous cars much but did strap to the lower control arms on the dyno. Yup on the cross strapping.

Jim

-

Senior Member

A professional car hauler told me not to cross the tie down straps. He said that if one breaks or comes loose for some reason, the diagonal angle of the remaining strap will allow the car to move forward (or backward). It would also allow the car to slide toward the remaining straps trailer side. Pull them straight back (or forward). He also said not to put an automatic trans in park, that any rocking back and forth could potentially damage the trans.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

In Massachusetts (we always have our share of little known laws) any wheeled vehicle on a trailer MUST be cross strapped. I was strongly informed of this by a State Trooper as I was stopped on the side of the road just checking the tension. I use axle straps on the rear and straps through the wheels although I have anchors in the trailer bed that allow for a good angle. I drive on, stop where the anchors are, pass the strap through both wheels and tighten. Then cross strap the rear and tighten down. Trailered cars from here to Phoenix without any trouble.

-

-

I welded some 5000lb rated rings to the 4" tubes and I do the worm to hook my Vulcan straps.

-

Seasoned Citizen

There seems to be as many opinions on how to secure a car on a trailer as there are people doing it. Some cross the straps, some don’t – and both offer reasons for their choices. Then there’s the two camps on what you attach the tie down to on the car. Some are adamant that you tie down the wheels or axles and allow the suspension to do its job. Others swear by cinching down the chassis and loading the springs.

I’ve been hauling motorcycles and race cars around since I was 16. Was taught to tie down by truckers and racers when I was a young pup. And later I drove those 18-wheels for my brother-in-law and had the gray-haired truckers teach me the tricks of the trade.

There’s an old saying by racers that more shocks are worn out riding in trailers than on the track. Have you ever noticed how hot the shocks get on a trailered car after a few hundred miles bouncing around the interstate? Yup, I tie the chassis down and cinch those springs so the shocks don’t bounce around. That’s the way the auto manufacturers intended them to be transported and the chassis has holes strategically placed for chain tie downs the transporters use. When I worked at a Ford dealership, every one of those new cars being delivered by the Hadley driver was chained down by the chassis.

I will cross tie or straight tie depending on the load rating of the straps, trailer, vehicle, and tie down spots available. No need to cross tie a short tie down and I prefer to keep mine short as possible.

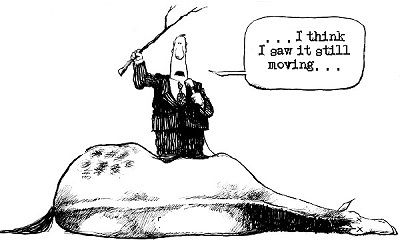

My race car in my race trailer gets cross tied in the rear only because of the chassis design and it gets straight tied in the front. As a Millwright who was taught rigging, I know that cross tying is not as strong as straight tying. The more the angle, the less load the tie strap can carry. The tie down’s working load rating is for a straight line pull, a cross tie is not a straight line pull. Here's a cartoon that shows the relationship of load and strap angles:

sling-to-load-angle-illustration.jpg

I have five trailers, all set-up for different uses. I don’t understand how people can live without a trailer, a truck, and a tractor. I have more than one of each.

Last edited by NAZ; 02-22-2021 at 11:28 PM.

Dart Little M 406" SBC 800 HP N/A & 1,100 HP on nitrous, 2-spd Powerglide with trans brake, 6,000 RPM stall converter, narrowed Moser 88 3.90:1 spool with 35-spline gun-drilled axles & Torino bearings, custom parallel four-link, custom tube chassis & roll cage NHRA certified for 8.5-sec (only two FFR Hot Rods have this cert).

33 Hot Rod Super Pro Drag Racer Build:

33 HR NHRA Cert Roll Cage Build

-

Post Thanks / Like - 1 Thanks, 4 Likes

WIS89

WIS89 thanked for this post

-

Originally Posted by

NAZ

I don’t understand how people can live without a trailer, a truck, and a tractor. I have more than one of each.

I've had my trailer for 30 years and agree. One of the best purchases I've ever made. Trees, trash, lumber and construction materials, a Bobcat that ruined my ramps, moving and of course a car trailer. Right now, it is a storage container, soon to be emptied for trailering the car to body and paint work. Originally a flat bed car trailer, I have added, easily removable, 4' sides all around and have added a top to fully enclose it. Those sides and top I totally rebuilt in 2008.

George

-

Originally Posted by

NAZ

1: There’s an old saying by racers that more shocks are worn out riding in trailers than on the track.

2: As a Millwright who was taught rigging, I know that cross tying is not as strong as straight tying. The more the angle, the less load the tie strap can carry. The tie down’s working load rating is for a straight line pull, a cross tie is not a straight line pull. Here's a cartoon that shows the relationship of load and strap angles:

sling-to-load-angle-illustration.jpg

3: I don’t understand how people can live without a trailer, a truck, and a tractor. I have more than one of each.

1- Another old saying is that more race cars get wrecked falling off the trailer than on the racetrack.

2- As a former Navy nuclear weapons handling supervisor (+ rigger), the straight across chain GWL pictured front + back desperately needs a different setup - even if it is only a secondary tiedown.

3- Agreed completely.

Last edited by mike223; 02-23-2021 at 09:35 AM.

-

Originally Posted by

mike223

2- As a former Navy nuclear weapons handling supervisor (+ rigger), the straight across chain GWL pictured front + back desperately needs a different setup - even if it is only a secondary tiedown.

Mike,

The chains are a secondary tiedown, both front and back. The primary straps that cross each other connect to the chassis both front and back. The rear ones use Breeze's (vendor) IRS rings mounted to the suspension. So, I've got both cross for primary and straight for secondary.

I am taking note about crossing, as explained earlier that it lowers the working load limits, I did not realize that.

What would you suggest, otherwise?

Thanks, George

Edit: PS-been doing a bit of research and thinking and I see what you mean as the chain runs right to left. I'm guessing I should have it run straight from my 'D' rings to the chassis and not across and attach to the center of the chain. GWL

Last edited by GWL; 02-23-2021 at 12:11 PM.

-

If the straight chain ever gets much of a load on it - all it's doing is pulling the tie down points toward each other - and putting a whole lot of stress on the chain + tie down points for what it's accomplishing.

Probably not a failure mode with your trailer due to the welded tie down points + steel construction - but not good practice.

I'd rather see either a tie down point in the middle (for a single strap like you're running fore + aft), or just run another pair of straps on each end straight.

Your diagonal straps are also crossed up further (greater angle) than I like to see them, which I'm guessing is why you wanted to add secondary tie downs.

I like to see the X's taller - shorter and wider is bad practice.

Tying similar (priceless) stuff down on a ship we would typically make very tall X's on the sides - tie down from the deck LR to the object LF - deck LF to object LR - deck RR to RF, deck RF to RR - not very practical for a car in an enclosed trailer, but just to give the example of making tall X's.

All for the purpose of getting "tall" X's so we didn't significantly derate the strength of the tie downs.

Hope that makes sense - the shorter you make your X's the worse you've derated them - tying onto the straight chain in the middle as pictured is practically a 100% derate and never done (unless you want to be keel hauled, lol).

-

Post Thanks / Like - 1 Thanks, 0 Likes

GWL

GWL thanked for this post

-

Last edited by acmikee; 02-23-2021 at 03:04 PM.

-

Seasoned Citizen

Mike, I also worked with nukes. US Army Nuclear Warhead Technician (back when the Army had tactical nukes) I worked on every warhead type the Army deployed, from the small demo charges a crazy airborne type jumped with to howitzer rounds to the largest theater nuke missile delivery system deployed in the field to project a nuclear presence protecting our allies. Not as big as the Navy and Air Force had but if you drop a wrench inside the warhead it would still make a very large crater and be on the six o'clock news. I used to laugh at the security guys hiding behind the wall when we would open the warheads to work on them.

Dart Little M 406" SBC 800 HP N/A & 1,100 HP on nitrous, 2-spd Powerglide with trans brake, 6,000 RPM stall converter, narrowed Moser 88 3.90:1 spool with 35-spline gun-drilled axles & Torino bearings, custom parallel four-link, custom tube chassis & roll cage NHRA certified for 8.5-sec (only two FFR Hot Rods have this cert).

33 Hot Rod Super Pro Drag Racer Build:

33 HR NHRA Cert Roll Cage Build

-

Post Thanks / Like - 0 Thanks, 1 Likes

GWL

GWL liked this post

-

Senior Member

Originally Posted by

NAZ

Mike, I also worked with nukes. US Army Nuclear Warhead Technician (back when the Army had tactical nukes) I worked on every warhead type the Army deployed, from the small demo charges a crazy airborne type jumped with to howitzer rounds to the largest theater nuke missile delivery system deployed in the field to project a nuclear presence protecting our allies. Not as big as the Navy and Air Force had but if you drop a wrench inside the warhead it would still make a very large crater and be on the six o'clock news. I used to laugh at the security guys hiding behind the wall when we would open the warheads to work on them.

BUT that's why they where called 'blast doors'.

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Ammunition ship here - during the heyday of tactical nukes (a long, long time ago).

Had to stay certified for ~38 different weapons systems.

All the air drop bombs came on castered carriages and had to be strapped down - with crossed straps LR/LF LF/LR RR/RF RF/RR - no other options were authorized.

We also had special wrenches for crossing up and locking the casters (required).

Notice the locking pin on the front of the right front caster here:

NINTCHDBPICT000530959115.jpg

Originally Posted by

NAZ

but if you drop a wrench inside the warhead it would still make a very large crater and be on the six o'clock news. I used to laugh at the security guys hiding behind the wall when we would open the warheads to work on them.

Heh - that's one option for use denial...

-

Post Thanks / Like - 0 Thanks, 1 Likes

GWL

GWL liked this post

-

Originally Posted by

mike223

Hope that makes sense - the shorter you make your X's the worse you've derated them - tying onto the straight chain in the middle as pictured is practically a 100% derate and never done (unless you want to be keel hauled, lol).

Yes, it does make sense. Thanks for taking the time to help me get it better.

George

-

Senior Member

I picked up a car hauler recently and am learning about strapping only have about three tows with the car in the trailer. So far, so good (knock on wood)... I did pick up 4 wheel chocks for the front wheels just to add as a backup in case of a strap failure. I am not sure how much this would actually help but I figured it could not hurt having some type of secondary holding power other than the e-brake. I also installed a wireless camera in the trailer so I can keep an eye on the car while driving, this definitely seems to help visually seeing what is going on inside the car hauler.

-

-

Originally Posted by

acmikee

That's a very good video.

I absolutely agree that losing one strap in a four way cross strap is catastrophic failure - you absolutely can not let that happen, for exactly the reasons he demonstrates.

But tying it down with four straight straps does not secure the vehicle nearly as well side to side, and depending on the exact angles involved (varying with tie down points) - can be near exactly the same sort of catastrophic failure if you lose one strap.

Overall it's a video with a great deal of solid advice especially getting into the hooks + tiedown points.

-

Senior Member

OK, who has the 'beating a dead horse' photo

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Senior Member

Originally Posted by

rich grsc

OK, who has the 'beating a dead horse' photo

Here you go.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Senior Member

thanks

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

You can call it beating a dead horse.

But all these years (30+), that video is the first well reasoned objection to cross strapping I've ever seen.

It has me thinking that anything worth four straps is probably worth eight straps.

Four crossed and four straight.

Maybe it's ocd - maybe it's a dead horse - maybe I spent too much of my youth dealing with nerve wracking stuff...

-

Senior Member

Originally Posted by

NAZ

There seems to be as many opinions on how to secure a car on a trailer as there are people doing it. Some cross the straps, some don’t – and both offer reasons for their choices. Then there’s the two camps on what you attach the tie down to on the car. Some are adamant that you tie down the wheels or axles and allow the suspension to do its job. Others swear by cinching down the chassis and loading the springs.

I’ve been hauling motorcycles and race cars around since I was 16. Was taught to tie down by truckers and racers when I was a young pup. And later I drove those 18-wheels for my brother-in-law and had the gray-haired truckers teach me the tricks of the trade.

There’s an old saying by racers that more shocks are worn out riding in trailers than on the track. Have you ever noticed how hot the shocks get on a trailered car after a few hundred miles bouncing around the interstate? Yup, I tie the chassis down and cinch those springs so the shocks don’t bounce around.

That’s the way the auto manufacturers intended them to be transported and the chassis has holes strategically placed for chain tie downs the transporters use. When I worked at a Ford dealership, every one of those new cars being delivered by the Hadley driver was chained down by the chassis.

I will cross tie or straight tie depending on the load rating of the straps, trailer, vehicle, and tie down spots available. No need to cross tie a short tie down and I prefer to keep mine short as possible.

My race car in my race trailer gets cross tied in the rear only because of the chassis design and it gets straight tied in the front. As a Millwright who was taught rigging, I know that cross tying is not as strong as straight tying. The more the angle, the less load the tie strap can carry. The tie down’s working load rating is for a straight line pull, a cross tie is not a straight line pull. Here's a cartoon that shows the relationship of load and strap angles:

sling-to-load-angle-illustration.jpg

I have five trailers, all set-up for different uses. I don’t understand how people can live without a trailer, a truck, and a tractor. I have more than one of each.

You need to review auto transport procedures. No cars shipped today are tied to the frame, all are strapped over the tire. I just did a 600 mile run to and from Chicago, NOT one single transport was strapped on the frame, even the load of full sized pickups had over the tire straps.

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Post Thanks / Like - 1 Thanks, 1 Likes

NAZ

NAZ thanked for this post

-

You drive around all day without the license plate being covered, yet you cover it so your friends can't read it. Lol. Just kind of funny.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote