-

Senior Member

What goes above my axle?

I'm at a point in my build where I'm doing my best to follow the assembly manual, but there's some design criteria where I'm marching to the beat of my own drum, not FFR's. Case in point, my fuel system.

I'm going carb'd, but I want to set up everything so a switch to FI will only require a pump and regulator swap, and maybe rerouting some short lengths of fuel lines.

For now I've got the hard 5/16" fuel line run but just terminated close to the filter, and in the engine bay around the angled side of the passenger footbox. I'll be running the 1/4" return line as well the same way but terminating closer to the fuel tank pickup.

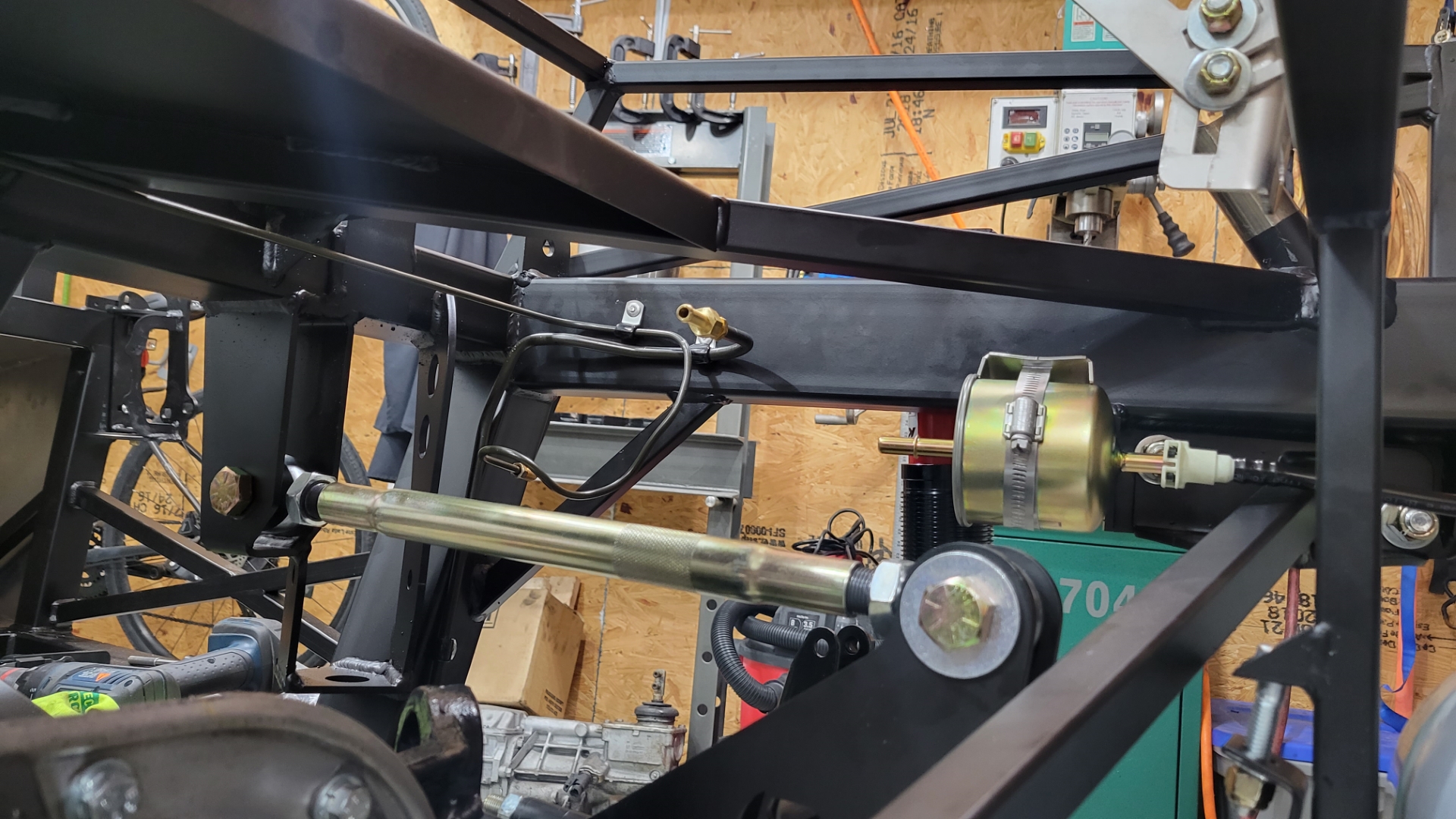

Since I'm carb'd I'll be putting a Holley Mighty Mite down by the main 4" frame rail on the passenger side. No need for a regulator because they're self-regulating, and can provide enough for 400hp. My plan was to just run some soft 5/16" line from the filter, down to the Holley, then back up to the hard 5/16" line to feed fuel forward. I'd just cap off the return line since it's not used. Here's a pic:

But going forward, if I go EFI I'll most likely end up using an external pump and filter affair. What I'd like to do is build an isolated plate where the pump and filter mounts to this plate that's fixed to the chassis above the axle on rubber isolation posts to keep noise and vibration down. I'm dealing with this location:

You can see the outlet of the filter and the inlet of the 5/16" hard line going to the engine bay. There's about 6" of clearance above the upper control arm, with little vertical travel towards the front and full suspension travel towards the back of it. I feel like I can fabricate this fuel pump/filter plate and stash it above the front of the upper control arm hanging down from rigid members of the chassis. Is anything going in this vicinity, based on a typical MK4 build of course?

I'm also putting my battery in the engine bay.

Last edited by MB750; 01-10-2023 at 09:47 AM.

-

Not a waxer

Fuel filter needs to be on the pressurized side of the pump, not the suction side as you are showing.

Jeff

-

Senior Member

What goes above my axle?

If I had a nickle every time I heard a lady tell me that!

FFR Roadster Delivered 9/16/21

Forte 427 Fuel Injected with TKX Transmission

Forte's Axle

-

Post Thanks / Like - 1 Thanks, 2 Likes

-

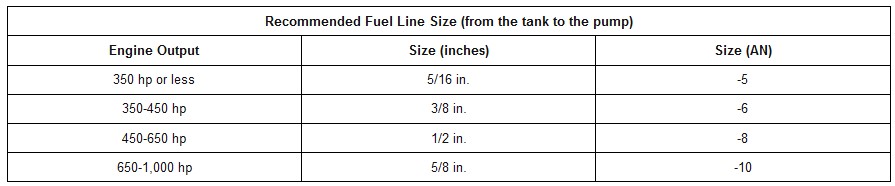

Id start by running 3/8 lines instead of the 1/4" and 5/16" lines. 5/16" is probably enough for 400 hp fuel injected with a big enough pump but 1/4" is really small

-

Senior Member

Originally Posted by

Jeff Kleiner

Fuel filter needs to be on the pressurized side of the pump, not the suction side as you are showing.

Jeff

Listen to Jeff, don't put a filter on the suction side of a pump.

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Jeff, I just installed a Sniper and they tell you to put a filter before the pump and one after the pump.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

On a roll

Wherever you place your filter and pump, think ahead. Think about how easy it will be to access them from underneath when everything (wheels, hoses, wires, etc.) is in place. The filter placement from the manual is OK, but you can probably do better. I just swapped mine out and it was "messy". Chuck and I got our share of gas sprayed all over us, even though we took steps to prevent that.

Hoooper suggested swapping your lines for bigger ones. That's another PITA once you've done the initial install. If you do decide to go that route, consider that you'll need to swap everything, not just the lines. If you have a 5/16 filter and a 5/16 tank hanger, you still have 5/16 capacity, not 3/8. (hopefully that made sense) I replaced my 5/16 and 1/4 lines with 3/8 flexible lines because I had too many issues with the hard lines. I did that before the body was on and it was still a PITA. I did that swap from the filter forward. If I ever decide to do the rest, it's all more or less accessible, but it would have been easier if I did it that way from the outset.

The bottom line is that it's your build. Do what you want (as long as Kleiner approves). Nevertheless, now is the time to make changes while you can easily get at everything.

Mk IV Roadster - #8650 - delivered 7-17-2015 - first start 7-28-2018 - first go-kart 10-13-2018 - licensed and on the road 9-9-19: body/paint completed 3-17-2020.

Complete kit / 2015 Coyote / TKO600 / IRS / Wilwood brakes / Mid-Shift mod / Power Steering / Heater and Seat Heaters / RT turn signal / Breeze radiator shroud and mount

-

Senior Member

Originally Posted by

first time builder

Jeff, I just installed a Sniper and they tell you to put a filter before the pump and one after the pump.

Maybe that's why they have issues?? You can run a screen(course mess filter) before the pump and filter after

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Senior Member

It is always recommended to run a 100 micron pre-filter or greater prior to an exterior pump. Maintains pump longevity. Now the filter that you have in the picture is about 55 microns that is too small pre fuel pump. As jeff said move that one further down the line. I ended up replacing mine with a 40 micron post fuel pump and used a 100 micron pre-pump. With that being said I believe the holley sniper kit comes with both filters if you go with the master kit so you will be replacing the one in the picture anyways down the line when you make the switch.

Last edited by rthomas98; 01-10-2023 at 02:15 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Ok, I'll rerun my plumbing. The illustration above was more for semantics than anything. I like the location of my filter, and black fuel line is easy to route so I'll make it work. I was just trying to get the fuel pump below the location of the tank like most carb'd pumps seem to appreciate.

-

Not a waxer

Originally Posted by

rthomas98

It is always recommended to run a 100 micron pre-filter or greater prior to an exterior pump. Maintains pump longevity. Now the filter that you have in the picture is about 55 microns that is too small pre fuel pump. As jeff said move that one further down the line. I ended up replacing mine with a 40 micron post fuel pump and used a 100 micron pre-pump. With that being said I believe the holley sniper kit comes with both filters if you go with the master kit so you will be replacing the one in the picture anyways down the line when you make the switch.

Thanks, you saved me from a lot of typing! Yes, typically the pre pump filter/trap/strainer (also the "sock" at the fuel pickup in the tank) will be in the 100 micron range... the idea is to catch debris large enough to stop the pump but not so small that they would easily clog the filter since the pump can't suck as hard as it can blow (be careful how you use that phrase  ) Post pump filters will be 40 microns for a carb and typically 20 or lower for EFI. The Ford Motorcraft FG1060 or equivalent filter shown in MB750's photo is rated at 20.

) Post pump filters will be 40 microns for a carb and typically 20 or lower for EFI. The Ford Motorcraft FG1060 or equivalent filter shown in MB750's photo is rated at 20.

Jeff

-

Senior Member

Originally Posted by

Al_C

Hoooper suggested swapping your lines for bigger ones. That's another PITA once you've done the initial install. If you do decide to go that route, consider that you'll need to swap everything, not just the lines. If you have a 5/16 filter and a 5/16 tank hanger, you still have 5/16 capacity, not 3/8. (hopefully that made sense) I replaced my 5/16 and 1/4 lines with 3/8 flexible lines because I had too many issues with the hard lines. I did that before the body was on and it was still a PITA. I did that swap from the filter forward. If I ever decide to do the rest, it's all more or less accessible, but it would have been easier if I did it that way from the outset.

I see your point, but fluid flow is not as black and white as the smallest diameter in a line.

For instance, if you have a 3/8" like that's 20' long with a bunch of bends all around the frame it could have more restriction in it than a 1/4" line that's straight as an arrow and only 1' long. It all boils down to whatever causes a flow restrictions in the tubing. Like you said, filter and pickup diameter plays a role too. That D'Arcy-Weisbach Friction Coefficient is the factor in the whole equation for flow and there's a LOT that goes into it besides diameter.

This calculator gets you in the ballpark:

https://lmengines.com/pages/fuel-line-calculator

And according to Summit:

Hmmmmm, I might be pulling my hard line after all, and regrouping on my fuel needs. I'm anticipating 400hp at the crank, and I don't want fuel to be a choking factor.

-

On a roll

Originally Posted by

MB750

I see your point, but fluid flow is not as black and white as the smallest diameter in a line.

For instance, if you have a 3/8" like that's 20' long with a bunch of bends all around the frame it could have more restriction in it than a 1/4" line that's straight as an arrow and only 1' long. It all boils down to whatever causes a flow restrictions in the tubing. Like you said, filter and pickup diameter plays a role too. That D'Arcy-Weisbach Friction Coefficient is the factor in the whole equation for flow and there's a LOT that goes into it besides diameter.

This calculator gets you in the ballpark:

https://lmengines.com/pages/fuel-line-calculator

Hmmmmm, I might be pulling my hard line after all, and regrouping on my fuel needs. I'm anticipating 400hp at the crank, and I don't want fuel to be a choking factor.

Yes! Now you're really getting into it! This is what makes building one of these cars so much fun! Each of us takes it to another level of detail and analysis that gets our juices flowing! I started thinking about friction loss and other basic hydraulics stuff when I swapped out my fuel pump, but decided that was more than I wanted to deal with. Go with the approach you like best!

Mk IV Roadster - #8650 - delivered 7-17-2015 - first start 7-28-2018 - first go-kart 10-13-2018 - licensed and on the road 9-9-19: body/paint completed 3-17-2020.

Complete kit / 2015 Coyote / TKO600 / IRS / Wilwood brakes / Mid-Shift mod / Power Steering / Heater and Seat Heaters / RT turn signal / Breeze radiator shroud and mount

-

Not a waxer

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Senior Member

Jeff can you order a few T-shirts like that. I'd like one, or maybe some hats.

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Not a waxer

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

Senior Member

I know that what you and I ALWAYS do..

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Senior Member

Group buy.

I'll take a Large.

-

Senior Member

It may not matter now but the area above the 3rd link at it'a front end is empty. The trunk floor aluminum sits on top at the lengthwise 2x3 rectangle tube and on top of the 1x1 diagonals.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

CraigS

It may not matter now but the area above the 3rd link at it'a front end is empty. The trunk floor aluminum sits on top at the lengthwise 2x3 rectangle tube and on top of the 1x1 diagonals.

Thanks Craig, good to know. That real estate may also harbor an Estopp in the future, which will take up a LOT more room than fuel bits.

-

For future proofing and possible upgrade to EFI. You may want to have both a send and return line in place and upgrade to 3/8 if possible. You could also go with an in tank EFI pump that also works with carb. If you had both lines and an in tank pump, you may only have to swap out the filter and regulator, to go to EFI.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

Gizmosrcool

For future proofing and possible upgrade to EFI. You may want to have both a send and return line in place and upgrade to 3/8 if possible. You could also go with an in tank EFI pump that also works with carb. If you had both lines and an in tank pump, you may only have to swap out the filter and regulator, to go to EFI.

That's actually exactly what I'm thinking about now. Summit sells 25' rolls of the 3/8" copper/nickel fuel line for $57 (which is enough for supply and return), and they have an assortment of in-tank fuel pumps that are universal. Graft one onto the FFR tank pickup with an intake sock and there's my fuel supply, and not to mention quieter. Get a good regulator up front for carb level psi and I'm done. Holley even makes a regulator that just takes a spring change and now it's an EFI regulator.

-

Senior Member

I used the standard FFR supplied lines on my build and when we dynoed the car there is less than 5 PSI fuel pressure drop fully loaded at 6000 RPM. (Dash mounted, calibrated fuel pressure gauge). Fuel pressure didn't drop below 60psi setpoint until over 5000rpm.

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Here is video showing fuel pressure (top left gauge) 0-100psi, set point 60psi.

Hope this helps with you decision on fuel line size. At lower (carburettor pressures) the losses are more likely to be an issue. Also depends on position of regulator (mine is on firewall).

Cheers,

Nigel

Last edited by Nigel Allen; 01-12-2023 at 08:23 AM.

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

You may be able to find an in-tank pump that puts out the usual 6# or so and no need for a regulator. Going from a real old memory here but I 'think' I remember someone saying that an early year Fox Mustang had an in-tank pump when they were still running a carb. Hopefully someone else knows more than I.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Post Thanks / Like - 1 Thanks, 0 Likes

MB750

MB750 thanked for this post

-

Senior Member

Originally Posted by

CraigS

You may be able to find an in-tank pump that puts out the usual 6# or so and no need for a regulator. Going from a real old memory here but I 'think' I remember someone saying that an early year Fox Mustang had an in-tank pump when they were still running a carb. Hopefully someone else knows more than I.

That's true. The fox body didn't go FI until 1986. I can just hit up Rockauto for parts to see what's available. They are great for showing pictures of everything too

-

Originally Posted by

Nigel Allen

I used the standard FFR supplied lines on my build and when we dynoed the car there is less than 5 PSI fuel pressure drop fully loaded at 6000 RPM. (Dash mounted, calibrated fuel pressure gauge). Fuel pressure didn't drop below 60psi setpoint until over 5000rpm.

That means you almost have enough pump to overcome the undersized lines. I say almost because if you have a static set pressure you shouldnt be losing any pressure as RPM rises if the lines and pump are sized right. With a big enough pump though you could make 1000 hp through a 1/4" line, its just not the right way to do it and its going to heat your fuel up way more than if the lines were the right size. There is really very little reason not to upsize the lines at this point if they may be too small unless the added cost of new lines just cant be absorbed.

Last edited by Hoooper; 01-12-2023 at 11:13 AM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Originally Posted by

CraigS

You may be able to find an in-tank pump that puts out the usual 6# or so and no need for a regulator. Going from a real old memory here but I 'think' I remember someone saying that an early year Fox Mustang had an in-tank pump when they were still running a carb. Hopefully someone else knows more than I.

Check with Mike Fortes on a Holley intank pump with 6an. I received one from him. I do not have the part number as I am out of the home area for a bit.

-

Senior Member

MB750, like you, I originally built my car to run with a carb but to be easily upgraded to fuel injection. My research at the time resulted in me running 3/8 inch feed and return lines and an EFI rated in tank fuel pump. A Mister Gasket fuel pressure regulator mounted on the firewall dropped the pressure to 6 psi for the carb.

All that was required for the upgrade to the Sniper unit was to remove the regulator and connect the feed and return lines to the Sniper.

HTH

Norm

Mk4 base kit 7721, 331 Stroker, Holley Sniper EFI, Wipers, Heater, Whitby Soft Top, Drop trunk mod and more

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Originally Posted by

Norm B

MB750, like you, I originally built my car to run with a carb but to be easily upgraded to fuel injection. My research at the time resulted in me running 3/8 inch feed and return lines and an EFI rated in tank fuel pump. A Mister Gasket fuel pressure regulator mounted on the firewall dropped the pressure to 6 psi for the carb.

All that was required for the upgrade to the Sniper unit was to remove the regulator and connect the feed and return lines to the Sniper.

HTH

Norm

That seems to be the consensus from the internet in this regard. You can use an EFI fuel pump on a carb application, you just need the correct pressure regulator, and make sure it has a return line.

-

Originally Posted by

Norm B

MB750, like you, I originally built my car to run with a carb but to be easily upgraded to fuel injection. My research at the time resulted in me running 3/8 inch feed and return lines and an EFI rated in tank fuel pump. A Mister Gasket fuel pressure regulator mounted on the firewall dropped the pressure to 6 psi for the carb.

All that was required for the upgrade to the Sniper unit was to remove the regulator and connect the feed and return lines to the Sniper.

HTH

Norm

Hear Hear, make that three. I currently am running a carb but wanted to keep the option open to upgrade to EFI in the future. Ran 3/8" stainless hard lines to and from (with '6AN braided PTFE soft ends). System uses a Holley in-tank fuel pump (not sure exact specs but can surely look it up) and a Aeromotive return-style regulator in the engine compartment. Also ran a Aeromotive 10 micron canister style fuel filter downstream of the pump at the rear of the car. So far so good but my build is still in its infancy.

BUILD THREAD:

The Brew City Cobra

Current Build: MK4 Complete Kit, Delivered December 2021; First Start November 9, 2022; Go-Cart November 23, 2022; Carbureted 427W, TKX, IRS

-

Senior Member

Originally Posted by

Hoooper

That means you almost have enough pump to overcome the undersized lines. I say almost because if you have a static set pressure you shouldnt be losing any pressure as RPM rises if the lines and pump are sized right. With a big enough pump though you could make 1000 hp through a 1/4" line, its just not the right way to do it and its going to heat your fuel up way more than if the lines were the right size. There is really very little reason not to up-size the lines at this point if they may be too small unless the added cost of new lines just cant be absorbed.

G'day Hoooper, you make a sound argument for upgrading the lines. I certainly had not figured heating of the fuel into the equation. In normal driving I have never seen fuel pressure drop, even under hard acceleration, so I guess I cant seem to load the engine as hard as the dyno and I am usually not exceeding 5,500RPM.

Our summer has just arrived, so will be a good winter project.

Cheers,

Nigel

Last edited by Nigel Allen; 01-14-2023 at 07:38 PM.

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

) Post pump filters will be 40 microns for a carb and typically 20 or lower for EFI. The Ford Motorcraft FG1060 or equivalent filter shown in MB750's photo is rated at 20.

) Post pump filters will be 40 microns for a carb and typically 20 or lower for EFI. The Ford Motorcraft FG1060 or equivalent filter shown in MB750's photo is rated at 20.