-

Senior Member

Help needed - Gen2 Coyote + T56 + IRS install - trans mount and clearance questions

Yesterday I got the engine/trans installed (per my build thread post #169 & #170. However, I have a couple of questions for those with the same drivetrain combo as I have (MK4 w/ Gen2 Coyote + T56 + IRS). Here's a list of my questions and concerns - would love some feedback/suggestions on this. I don't fully understand the driveline angles that are needed and admittedly need to read up on this to help me understand the angles needed between the trans, driveshaft, and pumpkin.

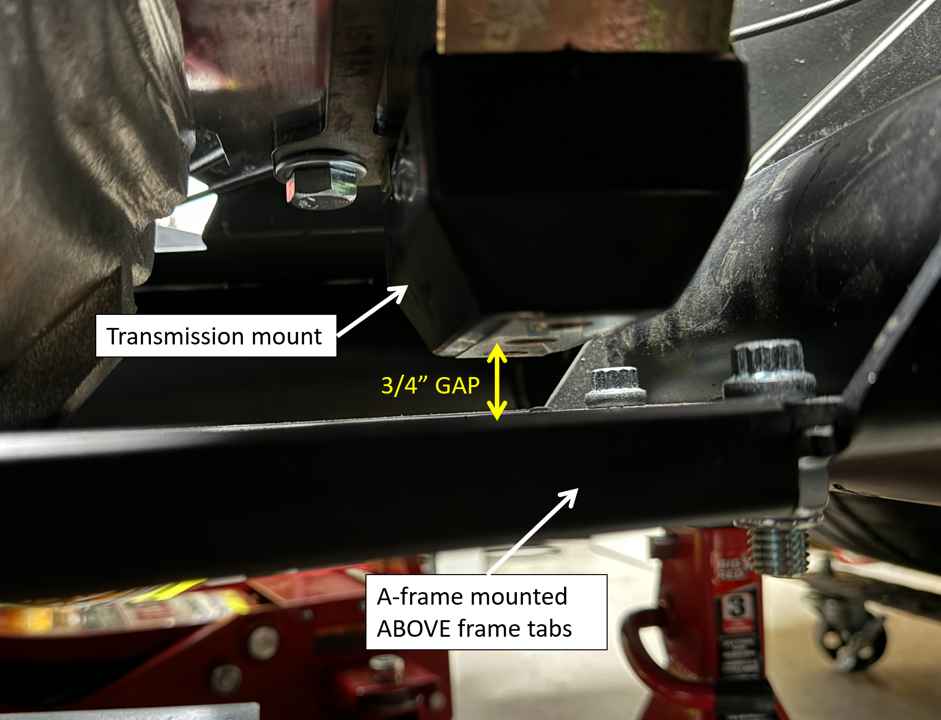

1) With this drivetrain combo, is it better to mount the A-frame above or below the frame tabs? I currently have it mounted on top of the tabs. Asking this question because of the gap I have between the trans mount and the A-frame bracket after installation (see bullet #3 below).

2) I wasn't sure if I needed to use the transmission mount spacers with the Tremec T56. The FFR Complete Kit instructions show using the spacers, but the Coyote Fitment instructions do NOT show them. Which is correct for this combo? Or is the answer, "your pinion angle will determine what spacers you might need between the trans mount and the A-frame"?

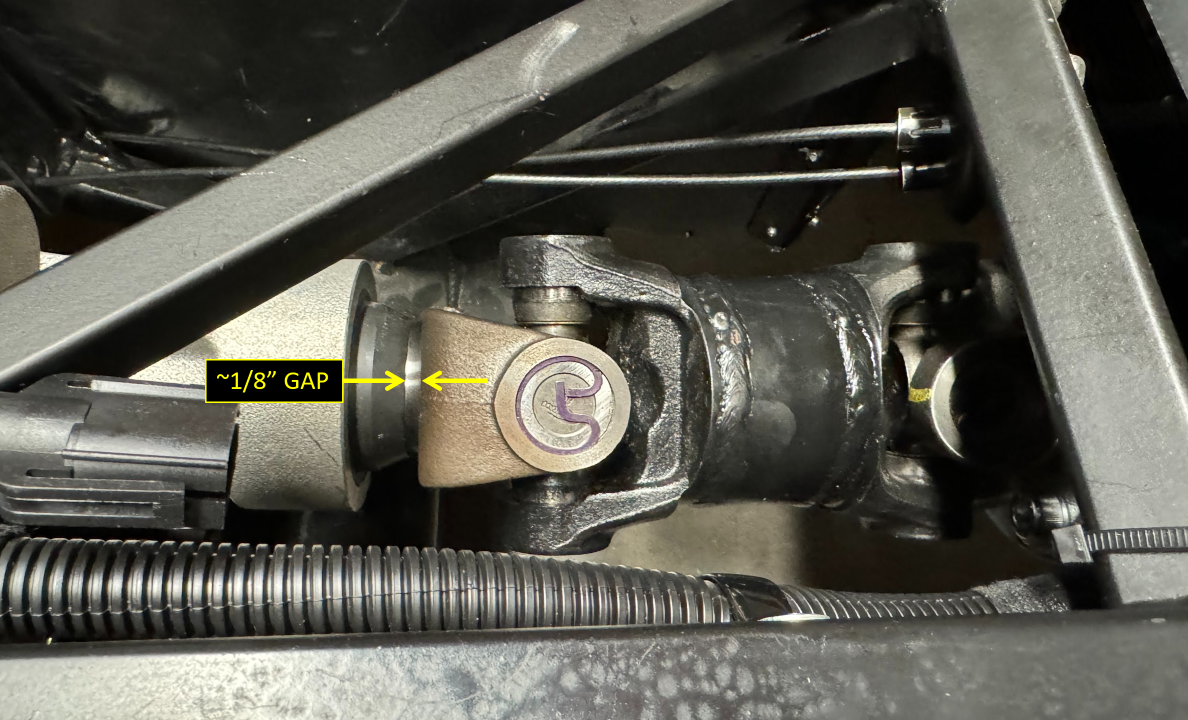

3) Issue: After installing the drivetrain (and inserting the driveshaft during the install), the transmission mount ends up about 3/4" above the A-frame. Did I do something wrong here or is this a result of how I have the driveshaft installed? The driveshaft is almost completely straight inline with the IRS pumpkin and the transmission output. I don't think it's supposed to be that way, but that's how it ended up when I pushed the engine rearward to get the mount studs into the engine mount slots. During the install I inserted the driveshaft slip yoke into the trans, then bolted the other end to the IRS adapter plate. Then pushed the engine rearwards to get the engine mount studs through the frame bracket slots, and this is how it ended up. Almost like the driveshaft is sandwiched between the trans and pumpkin in a straight line. There's only about 1/8" of the slip yoke exposed --> Is that about right or should more be visible? Is it better to get the engine/trans positioned, then install the driveshaft? For reference, the driveshaft I'm using is FFR p/n 16038 (ROADSTER 31 SPLINE 8.375" DRIVESHAFT FOR 2015 IRS) which I'm pretty confident is correct for this driveline combo. Here are some reference pictures:

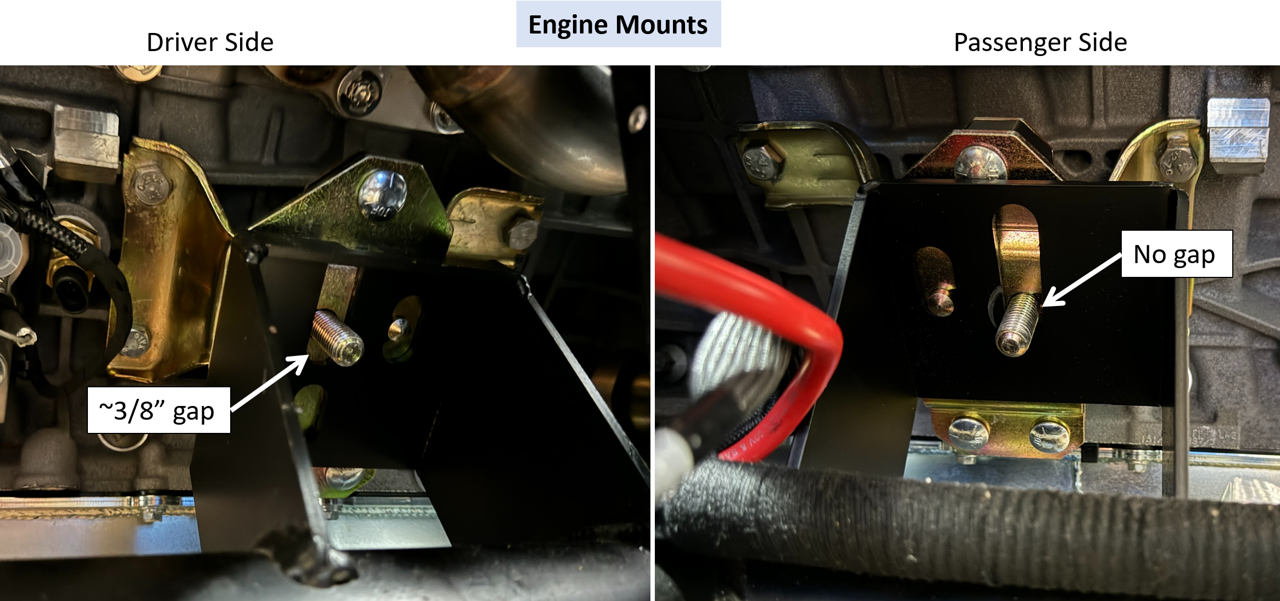

4) Currently, my engine mounts look like this, with a 3/8" gap on the DS and no gap on the PS between the stud and the slot. Should both be sitting flush with the bottom of the slot? Is my engine sitting too high? Again, this might be because the driveshaft is basically sandwiched between the trans and pumpkin. If I removed the driveshaft, maybe the engine could slide down all the way in the mounts. Looking for feedback on how it "should be" sitting.

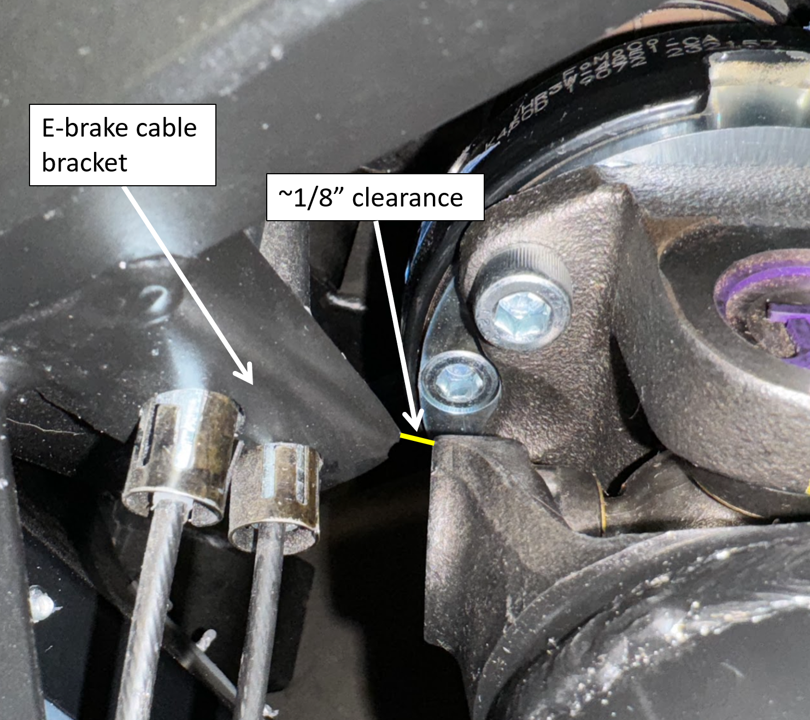

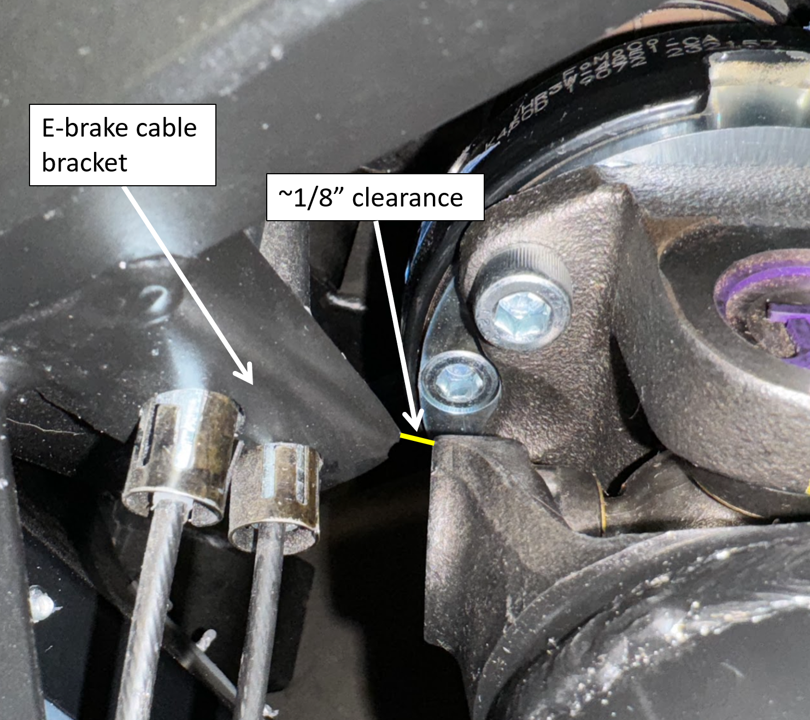

5) Issue: Is this enough clearance between the e-brake cable routing bracket on the PS and the driveshaft? Right now it's about 1/8" which seems really small. I was hoping to not have to cut that bracket off, but I'm wondering if this is just too close. The gap may grow or shrink depending on where the final transmission mounting position ends up, but looking for feedback on what kind of clearance is needed/expected with this drivetrain combo, or if I just need to cut the bracket and figure out different routing for the e-brake cables. I could also just trim the corner off the bracket to gain a few more millimeters of clearance.

Last edited by dbo_texas; 02-06-2024 at 12:54 PM.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

Anybody have some suggestions?

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

For the ebrake cable bracket mine was actually touching and I had to cut the corner of the bracket to allow clearance. I bought a partially completed kit so cannot comment on the other items.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Darryl,

My setup is a little different but not that much. Gen3 coyote, TKX and IRS. My thoughts below.

1) I also mounted the A-Frame on top of the tabs. Just make sense to me that the tabs and bolts are holding things up rather than hanging from the bolts.

2) I have a TKX and used three 1/4” inch spacers from Mike Forte. Ended up working out perfect.

3 & 4) I recommend pulling the drive shaft, letting your motor mount pins settle in the frame motor mounts. Then fitting your drive shaft, measuring for trans spacers and pinion angles. I’d want the engine seated as best as possible before messing with the drive shaft and trans spacers. Also, my drive shaft has about 1” showing at the yoke slip gap. Again, I have a different trans so that could be why.

5) The e-brake brake bracket makes me nervous as well. I have a little more space than yours, but I plan to shave off that most proud corner to give me a little more comfort it’s not going to touch the drive shaft. In reality neither the driveshaft or the bracket should move/flex or shift but any additional space is a relief.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Originally Posted by

Junbug

3 & 4) I recommend pulling the drive shaft, letting your motor mount pins settle in the frame motor mounts. Then fitting your drive shaft, measuring for trans spacers and pinion angles. I’d want the engine seated as best as possible before messing with the drive shaft and trans spacers. Also, my drive shaft has about 1” showing at the yoke slip gap. Again, I have a different trans so that could be why.

I think the issue is that from all the builds I've read up on using the Coyote/T56, I don't think I've seen one where they were able to get the driveshaft in with the engine fully seated. They've all indicated they had to get the driveshaft in during the engine install so that was on my list of "TO DO" items when installing the engine. Maybe it's possible - I may see if I can remove it and I do think I'm going to hook up the hoist and see if I can get the engine to settle at the bottom of both mounts. I'm pretty sure the TKX is shorter than the T56 by a little bit too.

One thing I did check tonight based on some feedback from Mike Everson was to confirm that the slip yoke shaft isn't bottoming out inside the transmission. I loosened the 4 bolts to the IRS adapter and I am able to push the driveshaft forward and close up that 1/8" gap at the front side. So it isn't bottoming out which is good. I would love to see some pictures of others with the Coyote/T56 setup and how much of the slip yoke is visible after installing and what the final spacers and driveline angles are. I can't really find any good pics of this, and especially how the transmission mount looks with the spacers.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

So if the driveshaft isn't bottomed out, what's holding up the transmission? the joint angle? can you rotate the driveshaft in neutral?

Mike

-

Senior Member

Originally Posted by

michael everson

So if the driveshaft isn't bottomed out, what's holding up the transmission? the joint angle? can you rotate the driveshaft in neutral?

Mike

I'm not sure what's holding it up. Even when I loosened the 4 bolts on the driveshaft flange yoke I still couldn't push the transmission downwards. I made a quick video - towards the end I can spin the rear tires and the driveshaft turns with the transmission in neutral no problem.

https://photos.app.goo.gl/ZWu5wFeqauySYQor6

The only 2 things I can think of to try next are to see if the transmission tail can move upwards if I put a jack under it (may need to raise the tail anyways to get parallel with the IRS pinion, and try to get the driveshaft completely removed and then see if that allows the transmission to move more freely (up or down). I need to do this anyways so I can take some accurate measurements on the IRS pinion flange angle.....hard to do with the driveshaft attached and since it doesn't move anyways I should just have to measure it once.

Last edited by dbo_texas; 02-08-2024 at 11:00 AM.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Are you sure the trans is not interfering in the parking brake area? How old is your kit?

Mike

-

Senior Member

Originally Posted by

michael everson

Are you sure the trans is not interfering in the parking brake area? How old is your kit?

Mike

My kit is from Summer 2019. I don't see anywhere that it's interfering. I did already cut off the e-brake mounting bracket on the passenger side of the tunnel (see pic below), so that isn't a problem. When I had the engine/trans sitting on the mounts previously (before the reinstalling recently), the transmission was sitting fully on the cross-tube. So the only thing I can think of now is the driveshaft is holding it up. I'll try my best to remove that and see if it has more freedom of movement.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

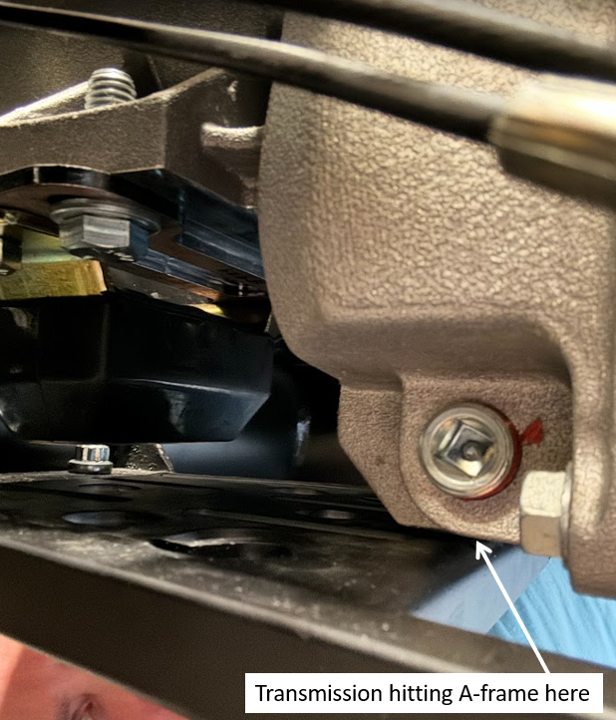

I removed the bolts from the driveshaft flange to the IRS pinion to disconnect the driveshaft, but the transmission still wouldn't drop any. When I got underneath the car I realized the transmission body is hitting the A-frame plate preventing it from dropping any further - so that mystery is solved at least. I'm going to remove the A-frame and mount it underneath the frame tabs (I currently have it mounted on top of the tabs). That will give me a little bit a clearance, but not much.

Since I had the driveshaft disconnected, I was able to take a better measurement of the IRS pinion flange. I made the following measurements:

- Frame 4" tube: tilted 1.7° down towards the front

- IRS pinion flange: tilted 1.1° down towards the front (i.e. if the frame was level, it would be 0.6° pointing upwards)

Perhaps my understanding of the angles is not correct, by I was under the impression that with a typical setup, the IRS pinion flange should slope downward (toward the front). Mine seems like it is pointing upward toward the front. Can anyone confirm if this is correct? I don't think there's any way to change that angle is there?

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Call factory five and have them ship you the updated one. don't mount it on the bottom. They changed them when the TKX came out.

Mike

-

Senior Member

Originally Posted by

michael everson

Call factory five and have them ship you the updated one. don't mount it on the bottom. They changed them when the TKX came out.

Mike

They changed the A-frame? Or the transmission mount?

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

the A frame. I suppose you could modify the one you have though.

Mike

-

Senior Member

Originally Posted by

michael everson

the A frame. I suppose you could modify the one you have though.

Mike

Got a response from Factory Five team. The pictures of the A-frame they sell seems to match with the version I have so I think I have the latest one. Can anyone comment on the angle of the IRS flange? Mine looks to be pointing up at 0.6° (if the frame is level). I thought it was supposed to point downwards....

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

OK I'm at the point where I've confused myself. As mentioned on post #10, it looks like my IRS pinion has a negative slope of 0.6° when the frame is level (i.e. the front is higher than the rear). That seems wrong to me - in all the threads about pinion angle, it seems everyone indicates their IRS flange has a positive slope (i.e. lower in the front, higher in the rear). I don't think there is any way to change this on the IRS setup is there? My concern is that if the IRS has a negative slope, then my trans would also need a negative slope (to achieve close to parallelism). But because my T56 housing hits the A-frame, it isn't possible for me to slope the transmission downwards. I can only achieve a positive slope (by shimming).

Another question - lots of folks mention using about 1/2" - 3/4" of spacers on the trans mount --> do those spacers go between the trans body and poly mount, or between the poly mount and A-frame? Or does it not matter which side you add the spacers?

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

I still say you have the wrong A frame for that transmission. Spacers can go in either or both. Don't worry about the IRS, You cannot change it and FFR did not weld it wrong.

Put 3/4 spacers under the mount or the A frame and if its still hitting, call FFR and get the new A frame.

Mike

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Originally Posted by

michael everson

I still say you have the wrong A frame for that transmission. Spacers can go in either or both. Don't worry about the IRS, You cannot change it and FFR did not weld it wrong.

Put 3/4 spacers under the mount or the A frame and if its still hitting, call FFR and get the new A frame.

Mike

Mike thanks for the feedback (here and on the FB page). I think you are correct - I took some measurements of my A-frame and it looks like the mounting plate is about 1" longer vs. the image FFR sent me of their latest design. So I think I will need to get the new one....thanks for helping me track this down.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

Or get really cute and modify your own A frame...

DSCN1797.jpg

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Senior Member

Originally Posted by

Its Bruce

Or get really cute and modify your own A frame...

DSCN1797.jpg

Did you weld on a flange after cutting out the clearance notch? I wonder if I could get away without reinforcing it. Seems like all the load is toward the mounting flange so maybe it would be OK.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

Originally Posted by

dbo_texas

Did you weld on a flange after cutting out the clearance notch? I wonder if I could get away without reinforcing it. Seems like all the load is toward the mounting flange so maybe it would be OK.

That's a photo from someone else. I did not weld on a flange, simply cut it out and mounted accordingly. I agree with your load assessment and believe it's structurally adequate.

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

I would mod the A-frame myself and weld in a new flange. I have plenty of cutting tool options and a Tig welder and be done in 30-40 minutes. But since FFR has an updated A-frame I think you should get the new one. I would not worry about the pinion angle. It could actually be helpful in that your trans may need less than the usual 3/4 to 1 inch spacers to match angles. RE; slots in your engine mounts. Usually you can fudge the position my jacking up the low side until it slides a bit and the engine rotates slightly looking from the front. But I wouldn't worry about it until you have the body on and are working on the sidepipes vs body opening. I haven't worked on any Coyotes but used to be we were always fudging the engine position to help make the body opening heights closer to equal.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

I think I'm going to modify my current A-frame and make it work. I have a neighbor who can help me weld in a reinforcement flange - probably not needed but won't hurt. I'll report back on this thread after I'm all done. Thanks for all the suggestions!

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

A-frame modified, pinion angle check!

Thanks to Mike Everson's suggestion that perhaps I had an older A-frame, I checked with Factory Five tech team and sure enough sometime after 2019 they changed the A-frame to shorted the plate which was causing the interference with the T56/Coyote combo. Instead of buying a new A-frame, I decided to cut away about 2 inches of the support plate, then cut a rib off the section I removed and weld it back in for reinforcement. Here are some pics - turned out great and now fully clears the T56 body.

Cutting the flange off the trimmed piece to re-use as a reinforcement rib:

Here is is with the section removed and rib added back in:

And the welded piece prior to cleaning it up and repainting with some epoxy paint:

And here is the before & after:

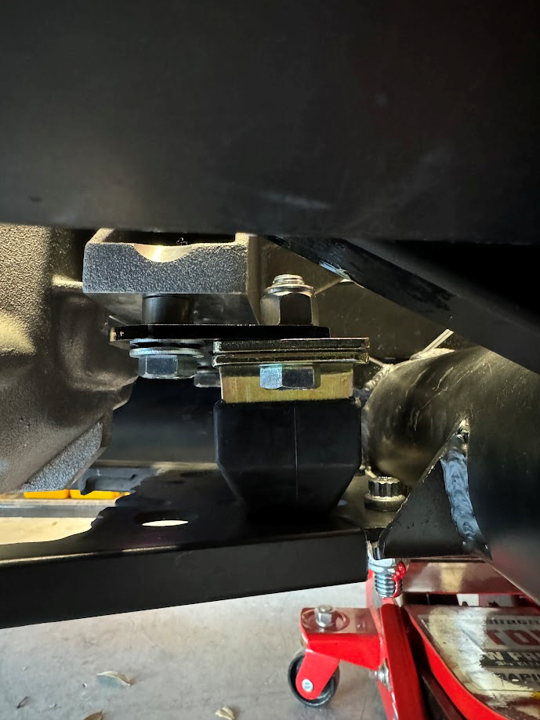

Next up I went ahead and reassembled the FFR poly-mount with the spacers per the instructions. Now, I'm able to fully rest the transmission mount down onto the A-frame.

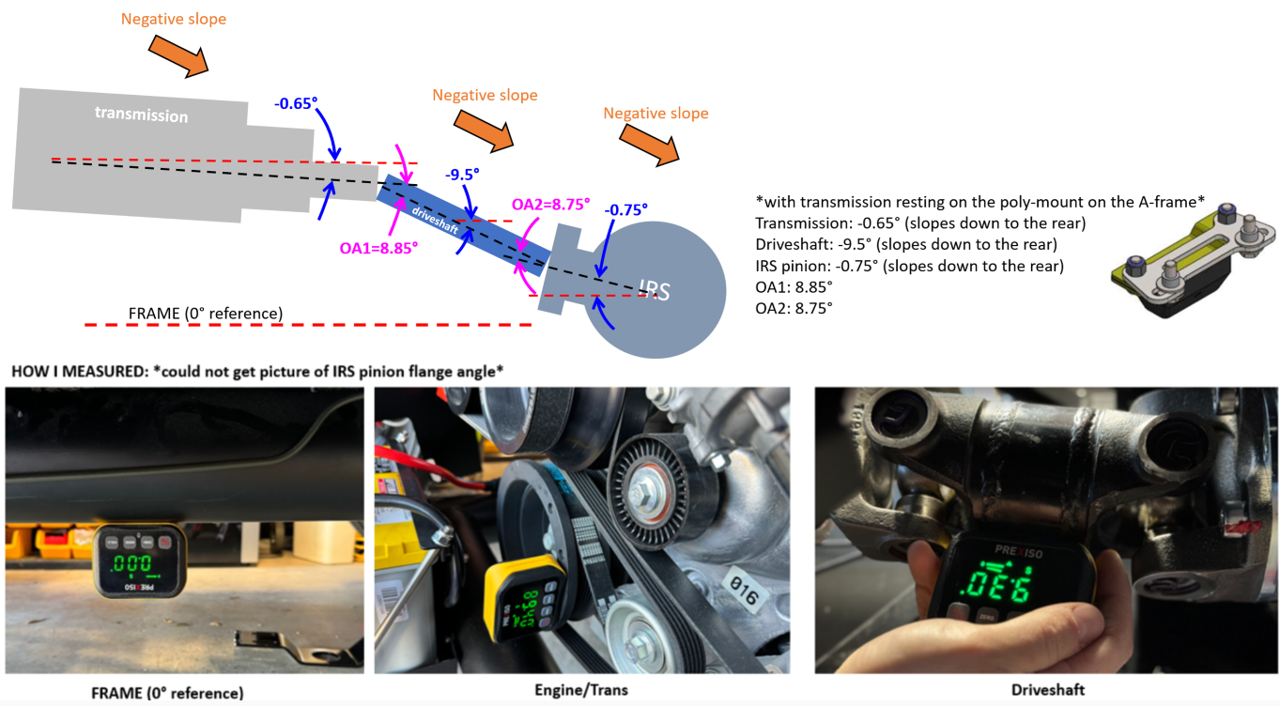

And finally, I went ahead and remeasured all my driveline angles and this is what I currently have. On the plus side the transmission output and IRS pinion flange are within 1° of each other. All 3 members of my driveline slope downwards (i.e. the front is higher than the rear), including my IRS pinion. I think my angle measurements are fairly accurate, and the values below are relative to the frame (which is my 0° reference).

So my question for the group: Are these angles OK or are the two operating angles of 8.85° and 8.75° too severe? - from what I've read the OA's should be within 1° of each other (mine are), and also have a 3° max OA (mine are way over that!).

The only variable I can really adjust is the transmission angle. I could remove some of the FFR spacers from the poly-mount and that would increase the negative slope of the transmission but make the driveshaft angle less severe. I'm looking for some feedback here - thanks in advance.

Last edited by dbo_texas; 02-20-2024 at 10:41 AM.

Reason: fixed driveline angle diagram

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

I think you are probably ok but...you have about 1/2" spacers under the trans correct? If you removed or reduced them your trans -.65 angle would increase and probably go beyond your -.75 diff angle right? That would also decrease your OA1 and OA2 angles? IE; if trans and diff are going to differ by .1 or .2 it doesn't matter which is larger than the other. So for discussion, if changing the trans to -.85 reduces your driveshaft angle a bit why not do it? BTW that is a really, really nice illustration.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

CraigS

I think you are probably ok but...you have about 1/2" spacers under the trans correct? If you removed or reduced them your trans -.65 angle would increase and probably go beyond your -.75 diff angle right? That would also decrease your OA1 and OA2 angles? IE; if trans and diff are going to differ by .1 or .2 it doesn't matter which is larger than the other. So for discussion, if changing the trans to -.85 reduces your driveshaft angle a bit why not do it? BTW that is a really, really nice illustration.

Yes I do have the FFR provided spacer which is 0.43" plus whatever the washer thickness is, so probably about 0.5" total. You can see it in the picture below. I think that's a good idea to remove that spacer and see where the new angles end up. As you mention, it would increase the angle on the trans (probably surpassing the -.75° of the IRS pinion but that's OK as long as they are within 1° right)? And both operating angles should decrease as well which is good. I'll try it out and report back. If it's too big of a change I can always stack some washers up and find something in between.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

Your numbers suggest there may be vibration and a reduced u joint life. Ref. https://spicerparts.com/calculators/...alculator#more

Is there any way to lower the engine?

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Senior Member

Originally Posted by

Its Bruce

Not that I'm aware. I need to go back and re-check how the engine is sitting in the mounts since I modified the A-frame and the trans can now sit lower, but in the first post you can see how the engine WAS sitting in the mounts on the frame when I started. There was a 3/8" gap on the DS where the engine could maybe be lowered slightly - I tried messing with it and prying on it to get it to drop fulling into the mount but ultimately couldn't get it to fully sit down all the way. On the PS, it's all the way down in the mount. Beyond using different mounts (which is far beyond my capability) I think I'm stuck with where it is now.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

You just need to STOP. Everything you are worrying about is pointless. You have IRS and the differential doesn't move and doesn't change any of the u-joint angles. Worrying about the engine not level side to side is pointless has it has nothing to do with anything. ALL of your angles are just fine, LEAVE it alone go find something else to stew over.

Mrk III, 331 stroker, Borla stack injection, T5, 3:55 IRS, Power steering and brakes. Kleiner body & paint

-

Senior Member

Originally Posted by

rich grsc

You just need to STOP. Everything you are worrying about is pointless. You have IRS and the differential doesn't move and doesn't change any of the u-joint angles. Worrying about the engine not level side to side is pointless has it has nothing to do with anything. ALL of your angles are just fine, LEAVE it alone go find something else to stew over.

As always rich you are a value to this community. Thanks for the non-condescending response. If only we could all be as knowledgeable as you.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Senior Member

OK I think I'm in business. I removed the two 0.4" cylindrical spacers plus the washers FFR provides, then remeasured all the angles. Removing that 0.5" of shims only changed the transmission angle by 0.45° (went from -.65° to -1.1°) but it made a hug impact on the driveshaft and operating angles (for the better). I end up with:

- pinion angle = 0.35°

- operating angle 1 = 0.75°

- operating angle 2 = 1.1°

This meets all 3 of the general criteria for driveline angles from everything I've read. I'm going to call this setup good to go. Thanks everyone for the troubleshooting tips. Here are the final numbers with my updated diagram:

MK4, Gen2 Coyote + T56 (TUET11010 FD) + IRS - removed FFR spacers from transmission poly-mount. I did end up putting a small piece of .25" steel on the driveshaft to take the angle measurement because I was worried the welds were throwing off the readings since the angle finger is longer than the shaft itself. I rotated it several times and got the same measurement within 0.1° so I'm confident it's accurate. Also got a pic of how I measure the IRS pinion flange angle.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Senior Member

Excellent outcome. I saw that you had your measuring technique figured out so I didn't mention this but I will now for others reading here. Sometimes it is easier to drop the front of the car so frame is at maybe 5-8 deg. That way all your angles are on the plus side. Makes it easier to figure through if your angles range from say 1deg to 8deg and don't flip back and forth from + to -.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Senior Member

Originally Posted by

CraigS

Excellent outcome. I saw that you had your measuring technique figured out so I didn't mention this but I will now for others reading here. Sometimes it is easier to drop the front of the car so frame is at maybe 5-8 deg. That way all your angles are on the plus side. Makes it easier to figure through if your angles range from say 1deg to 8deg and don't flip back and forth from + to -.

That's a good technique when measuring the angles. I had mine up on 4 jack stands then zeroed out the angle finder. When I took each measurement, after getting the reading I would tilt the angle finder more severely in the direction of the reading to make sure I had the correct slope (+ or -). Then I found that drawing it out helped a lot.

Darryl [dbo_texas]

MKIV #9644 (build thread) (Index)

MK4 Complete Kit | Gen2 crate Coyote | Tremec T56, 3.55 IRS | power steering | hydroboost | dual roll bars | FFR carbon fiber dash | 18" Halibrands + Wilwoods | RT drop trunk kit & turn signal | front battery mount | saddle leather Intatrim Stoneleigh seats + interior accents

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote