Hi Mike,

That was a while back when I decided to make that switch. There was quite a discussion on the ffr cars forum, led by a couple of people who's oppinions I trust. It started when a couple of people noted that the clutch stroke was a little long and the "ears" that hold the pin for the clucth release are were cracking due to the pressure of being over extended.

If I recall correctly, that discussion led to the master cylinders to use with the big brake kits, where the solution was to move to the 5/8" bore MCs for front and rear. I'm not an expert in fluid dynamics, but the way it was presented made a lot of sense to me. And as you mentioned, there were calls made to Wilwood, who at the time recommended the 5/8" mc for the larger calipers. Go Figure.

With that said, the brakes feel good to me; but then I'm building a car that may see the the race track only once or twice. As well, I've only driven the car around my neighborhood, so I've not gotten up to any significant speed with it yet; (25-30 maybe). But from what I can feel in the pedal, I am not concerned that I'll have any trouble. They feel fine, and give me the confidence that I need that they will stop the car easily.

Take Care,

Mike

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

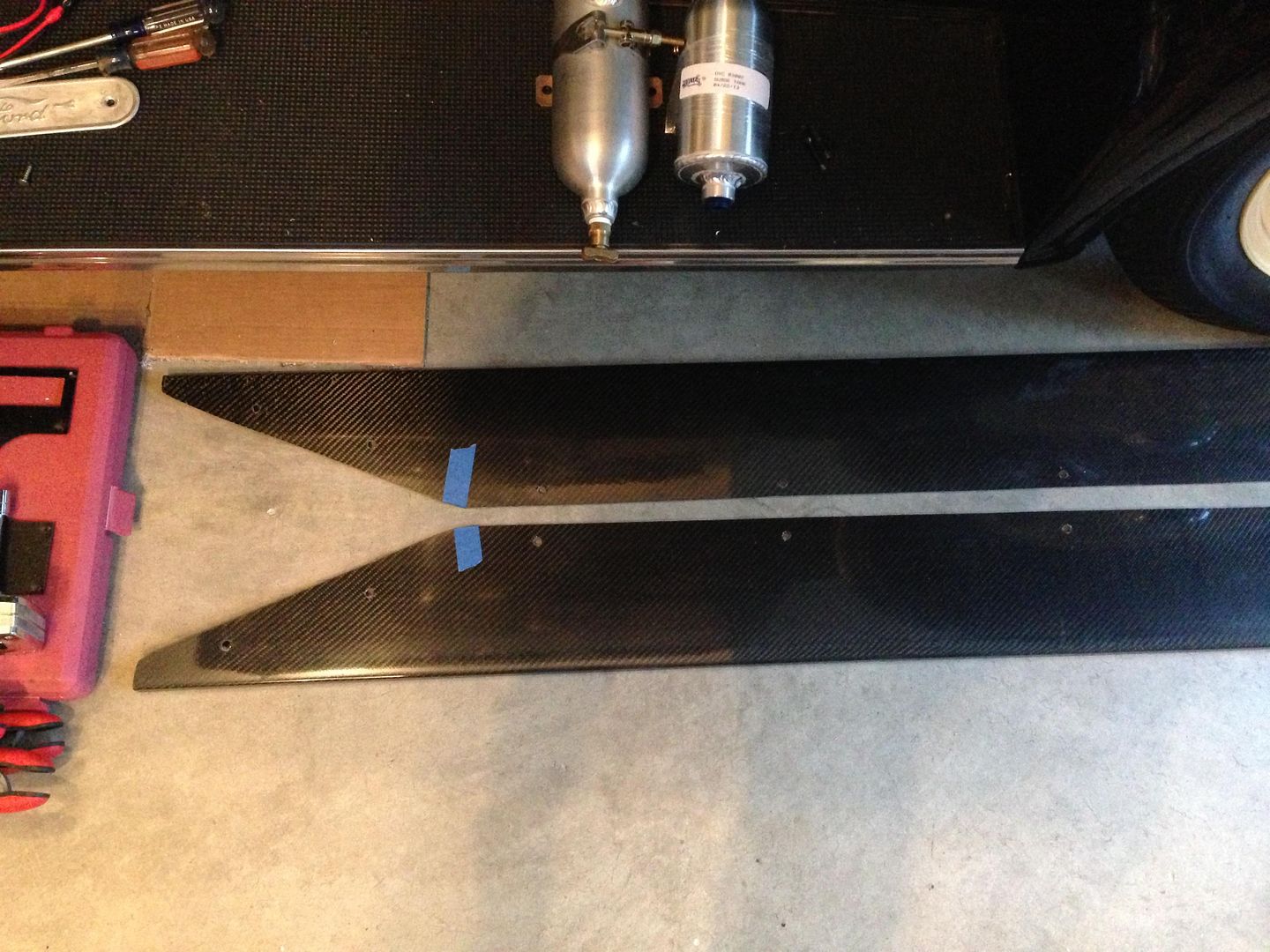

Just curious to know if yours are free from cosmetic issues or not.

Just curious to know if yours are free from cosmetic issues or not.