Hi Tino. You could definitely weld a plate under the floor pan, but its much harder to weld over your head, and you only lose an 1/8 of an inch with the plate on the inside. I am using a six point system from Schroth Racing.

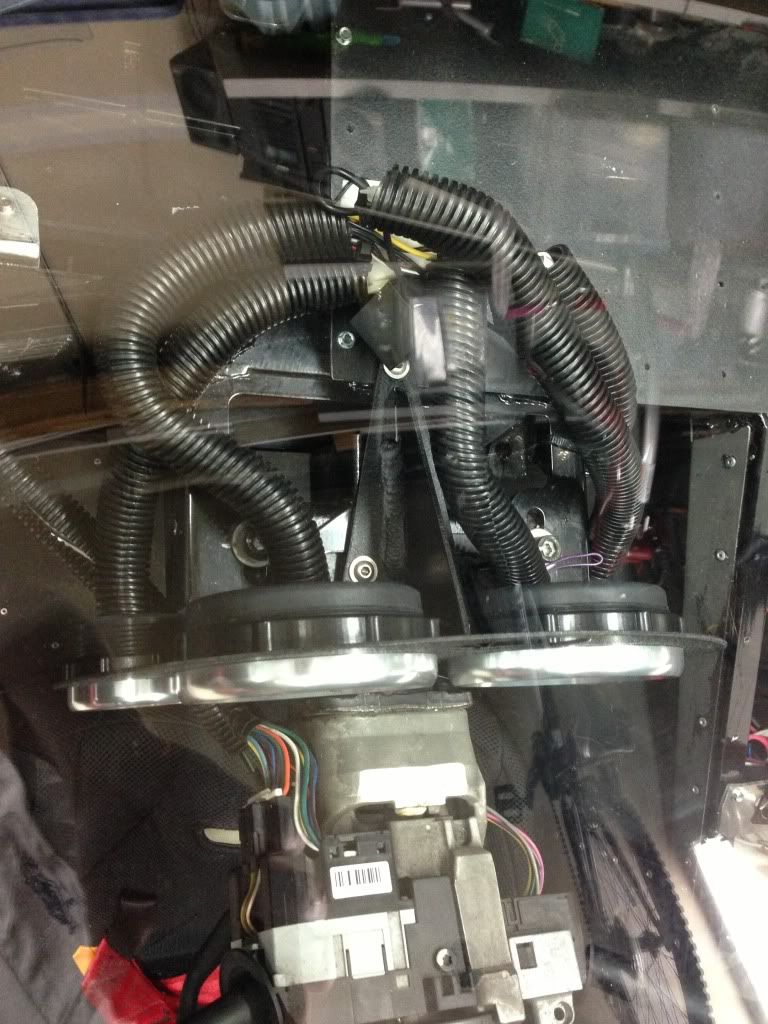

Yes I did need to add mounting points for the harness. It took a little trial and error to get all the mounting points in good locations where all the adjustments worked as designed. With the seat only a half inch off the floor pan the anti submarine belts were more difficult to install. Normal cars have he seat at least a few inches higher off the pan and as a result have easier belt routing options. Also note that the top mounts on my setup wrap around the harness bar I made. I did not use clips on the top, but I could have. I thought the bars looked nicer.

Thanks Gene. BTW no doubt the individual carbs on your sons car are more work, but you don't see them every day. I personally like that. And they look and sound so cool.

Hey Mendo, some racing organizations require additional bracing to mount the upper part of the seat to the cage. or body structure of the car.

Something like this.

I don't like the idea of a pole pointed at my spine, and every forum has some horror story of a guy who was injured because his seat failed for some reason. I figure there might be a solution out there that we could borrow or modify to fit the GTM.

Maybe I will just brace the seat along the lines of many of the full containment seats out there and not add any additional mount. It does need something. I'm unsure what the right thing to do is so was looking to see if anybody has seen or experienced a solution that works.

John

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote