I've got a complete EJ20G broken down to it's individual parts:

- Block (Cylinder walls look great, but I want to do new rings so I think a light honing will be needed, closed deck)

- Heads look good

- Rods and Pistons looks good

- Crank is good but does have some minor surface rust so would need to be cleaned

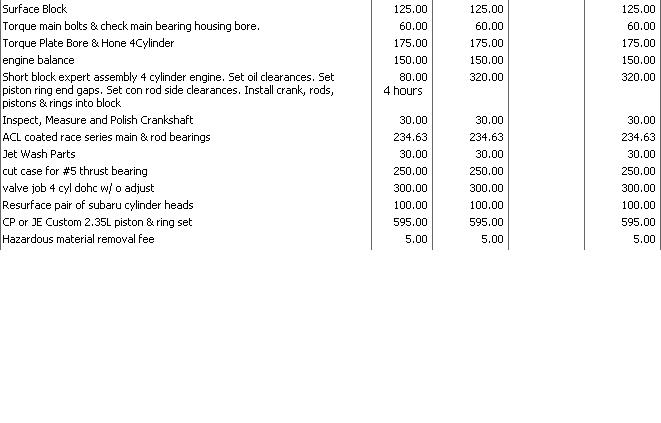

I'm going to have a go at doing this myself since I've got a lot of time until my delivery date, but if I decide not to re-assemble the engine myself (never done it before), does anyone know what I should expect to pay a competent shop for a the machining and re-assembly of the engine?

I'm trying to see if it's going to be worth it to build it or just buy a brand new 2.0 shortblock ($1900) and sell what I have.

Thanks!

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote