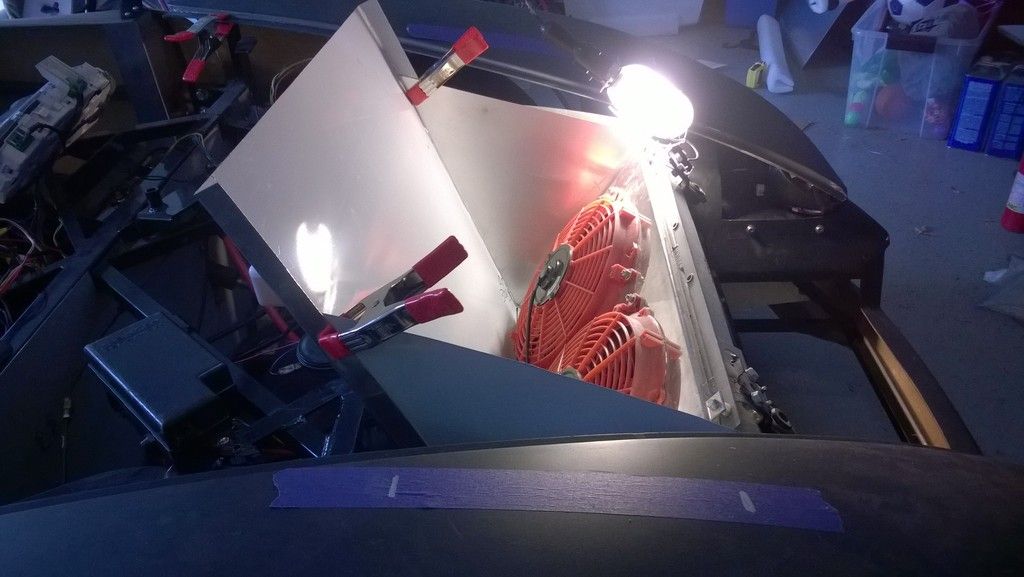

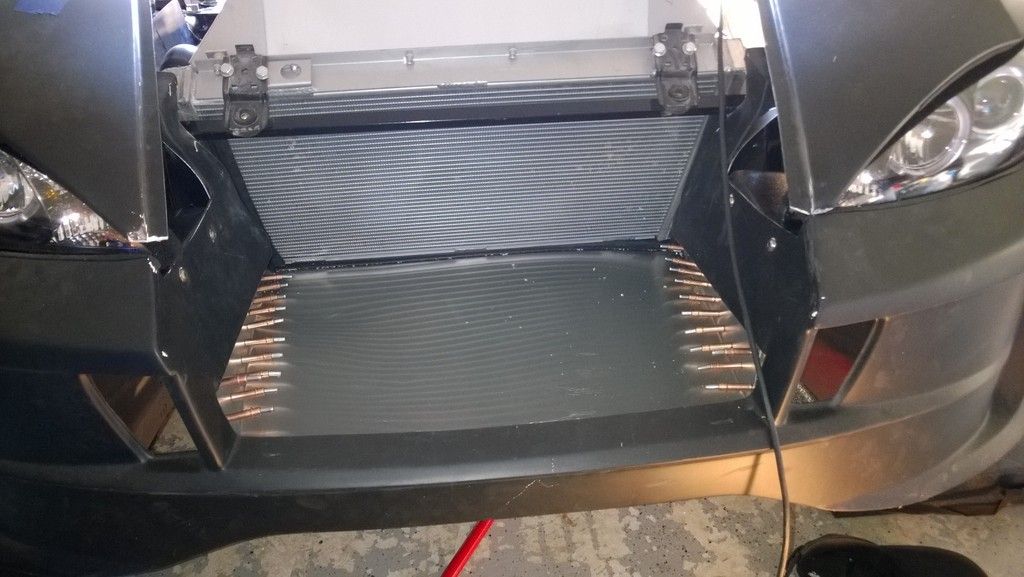

Still missing a bunch of things to complete this phase of the build. It isn’t going to get done in time to get on the track this year… pretty much knew that in August. So, I’m waiting on some things that are going to push this build past an ‘S’. Until they arrive I’m kinda shooting in the dark, but some radiator ducting was called for. It’s nowhere as nice as the work RetroRacing just posted, but it should do for now.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

. Actually I'll be using an ebay flock-it-your-self kit (go figure), which consists of acrylic paint, the actual flocking material, and a squeeze bottle for depositing. If it works out properly I'll post the information up.

. Actually I'll be using an ebay flock-it-your-self kit (go figure), which consists of acrylic paint, the actual flocking material, and a squeeze bottle for depositing. If it works out properly I'll post the information up.

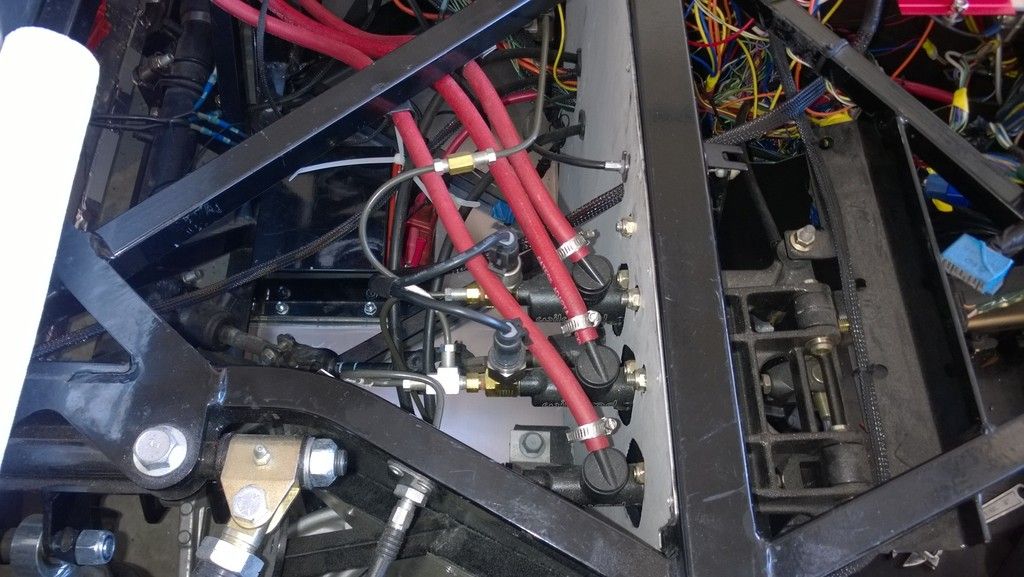

) I went ahead and ordered a pair of 2500 PSI transducers this afternoon

) I went ahead and ordered a pair of 2500 PSI transducers this afternoon