-

what hydraulic release bearing is best?

greetings fellow builders! I'm going to give away my age (maybe) & admit that this is the first time I've ever posted. Anywhere. So if I do something stupid, you know why. My question is, having read numerous poor reviews on many concentric release bearings, I wonder if anybody has any useful input on the most reliable part available? I am leaning toward the Tilton.

-

Moderator

Great name, is your wife Pam?

Everyone will give you their favorite answer, this is like saying what's your favorite tire!

I'm using a RAM release bearing now (from Mike Forte, I recommend him highly for standing behind what he sells you) but I've used a Mcleod before. Unlike others, I've never had one fail even after 60,000 miles. But the one in my 33 (the RAM) has about.. 2 miles on it

James

FFR33 #997 (Gen1 chassis, Gen2 body), license plate DRIVE IT says it all!

build thread

My build: 350SBC, TKO600, hardtop, no fenders/hood, 32 grill, 3 link, sway bars, 355/30r19

Previous cars: GTD40, Cobra, tubeframe 55 Chevy, 66 Nova, 56 F100

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Seasoned Citizen

Have you considered other clutch actuating choices? The hydraulic T/O option works well in many applications but not all and is not without a few drawbacks. The real advantages are it displaces a smaller footprint than other styles and is easier to install in a clean sheet design with no current provisions for a mechanical release system. But they are the slowest to actuate (may not matter if you're building a street only car), won't work with all style pressure plates, are not forgiving if you fail to adjust them correctly or add a travel stop, and are much more difficult to R&R when they go bad.

As for which make hydraulic T/O is the best -- this is going to be like asking which oil filter is the best. They are a simple design so you're likely safe with whatever you choose from the name brand manufacturers. All the manufacturers are very proud of their designs as they are all priced about double what they should be.

Dart Little M 406" SBC 800 HP N/A & 1,100 HP on nitrous, 2-spd Powerglide with trans brake, 6,000 RPM stall converter, narrowed Moser 88 3.90:1 spool with 35-spline gun-drilled axles & Torino bearings, custom parallel four-link, custom tube chassis & roll cage NHRA certified for 8.5-sec (only two FFR Hot Rods have this cert).

33 Hot Rod Super Pro Drag Racer Build:

33 HR NHRA Cert Roll Cage Build

-

My intention for the car is just to play with. Turn heads, smoke the tires, go on trips with my wife (not Pam!) I ordered my kit with a hydraulic master cylinder (not arriving for a few more weeks) and I committed to a manual early on. I've researched a LOT on Summit's site, and there are many negative reviews on McCleod & Ram with most saying that they leak if not driven regularly. The fact that the are difficult to remove is why I'd like feedback from actual users as to the likelihood of having to pull a transmission regularly. I'm a forklift technician, so it won't be anything new to me, but why do it until you must? Anyway the whole clutch fork, pivot ball, etc. is bulky and from what I understand, these cars don't offer much room.

-

Seasoned Citizen

For your intended use, a hyd T/O will give you the ability to create more leg room if you choose to modify the doghouse.

Dart Little M 406" SBC 800 HP N/A & 1,100 HP on nitrous, 2-spd Powerglide with trans brake, 6,000 RPM stall converter, narrowed Moser 88 3.90:1 spool with 35-spline gun-drilled axles & Torino bearings, custom parallel four-link, custom tube chassis & roll cage NHRA certified for 8.5-sec (only two FFR Hot Rods have this cert).

33 Hot Rod Super Pro Drag Racer Build:

33 HR NHRA Cert Roll Cage Build

-

Senior Member

Have a RAM 78132 with a 347 and TKO600, can't speak to longevity yet but was easy to install and setup

Steve

Gen 1 '33 Hot Rod #1104

347 with Holley Sniper & Hyperspark, TKO600, IRS, 245/40R18 & 315/30R18, DRL, Digital Guard Dog keyless Ignition

-

Senior Member

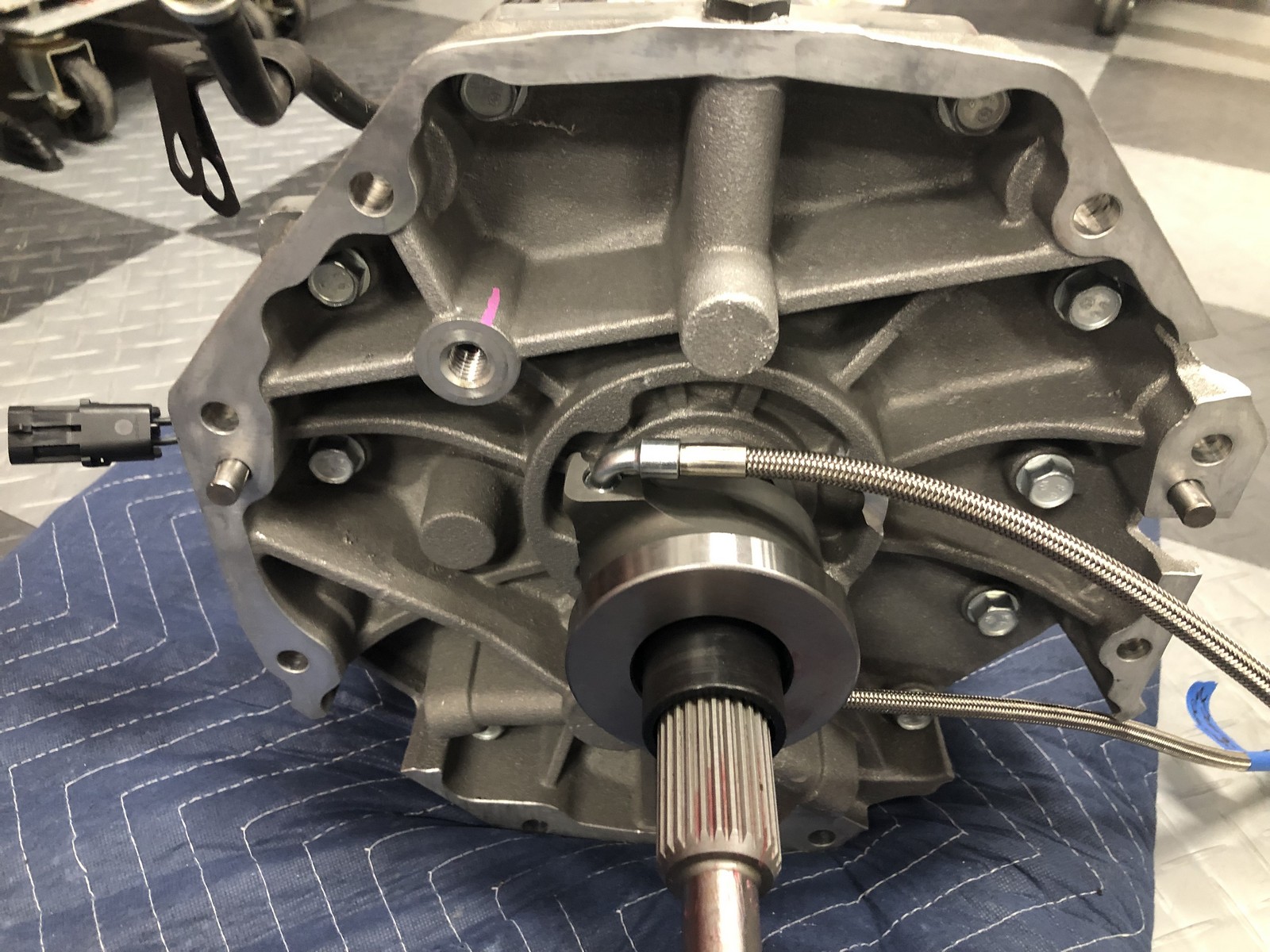

Installed a Tilton 6000-Series Hydraulic Release Bearing 60-6104 with a Coyote and T-56 trans in my Gen 3 Coupe build. Right out of the box I was impressed with the build quality. Did a lot of research and this one seems to get a lot of positive reviews. Was easy to install and works great. Wilwood pedal box and Wilwood 260-10373 13/16 inch MC. I have a Roadster with the exact engine/flywheel/clutch combination as the Coupe and a Forte hydraulic clutch setup on the usual clutch arm. The pedal effort on the Coupe is significantly less. I'm amazed at that and the first thing I notice every time I drive it. Approaching 1,000 miles (new this year) so hardly a long term test at this point. But I'm very happy with it so far. First I've heard an HRB is slower than the traditional clutch arm setup. But for my street driving, nothing I've noticed and don't expect to.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

A case can be made for sticking with an OEM setup - they tend to be pretty reliable. The reviews for many of the aftermarket set ups definitely seem to be hit or miss regarding longevity. Can't tell you which specific p/n but the kit that Silversport sells for the TKO claims to use an OEM hyd t/o bearing. I just installed that one and am pretty impressed so far as far as pedal effort although it remains to be seen how well it lasts. I can say it had been sitting on the shelf for over 8 years before I installed it (bought an unfinished kit) but so far works great.

Last edited by sread; 07-23-2020 at 11:20 PM.

-

Thanks Ed, that's encouraging news. My wife says she wants to drive it too (with 500 HP on tap, she may decide not to after her first drive), and she says she does NOT like a stiff clutch.

-

I had also considered going that route, since most manual (or all) cars now use them and they last a long time. I have a Hyundai Veloster with a 6 speed & 160,000 miles. Never an issue. I was unsure of the fitment. I plan to use a KO600 behind a Cleveland (engine is built & waiting)

-

Senior Member

AP HYDRAMAX Hydraulic Release Bearing Kit is what I used. TKO600 trans,SCIENCE FRICTION super street clutch. Smooth feel in the pedal. Easy to install,as long as the directions are followed exactly.

arrived July 18th 2019, first cart in Feb. 2020

BluePrint Engines 383CI TKO600 GM Street&Strip

Ridler wheels 17x 8 front 20 x 10 rear

Toyo Proxes 245/35-17 front

285/25-20 rear

0mm offset finished Jan 2022

-

Hey guys, Still waiting for my kit to arrive. After reading numerous threads, it appears that we are at the mercy of Stewart Transportation regarding the delivery after completion.

Anyway, another question on the release bearing issue. I've installed many clutches, but being a forklift technician, the release bearings are always mechanical.

When setup like this there is air gap between clutch fingers and bearing, this way the bearing isn't continuously rotated when engine is running. If I'm not mistaken,

some of the hydraulic concentric assemblies have the bearing in constant contact with the clutch fingers with a very slight pressure.

this keeps the release bearing in rotation any time the engine is running. Right?

Doesn't seem like a good idea to me, especially since my engine will see high RPM regularly. Not because I'm going to race it in competition (much!), but just because I can't

help myself. I love to hear the scream of a v8. So, the question is, are all concentric hydraulic release bearings deigned to spin constantly? Or will they relax enough when not actuated to provide the air gap I believe is necessary?

Thanks for any response.

-

Seasoned Citizen

As you would expect, there is an air gap spec that allows for clutch wear. Typically this is set with shims and requires precise measuring then calculating the shim stack needed to meet the air gap spec. There should be detailed instruction with your hydraulic T/O bearing.

There is typically more limit to the total available throw on a hydraulic release so pay close attention to detail when setting one up and make sure you calculate the amount of total throw your M/C will provide as over extending the hydraulic T/O will result in immediate failure causing you to pull the trans and repair the damage. Plan to incorporate an adjustable clutch pedal stop. These type clutch releases are not as forgiving as a mechanical release, and not nearly as robust. But when set-up properly prove reliable.

If using the slave cylinder type and mechanical T/O arm with conventional T/O bearing; there will likely be an adjustment on the slave cylinder and the adjustment procedure will be more like a fully mechanical release. However, there is little space saving advantage to this style release if foot box space is what you're after. The real advantage of the slave cylinder type is maintenance access vs the hyd T/O release type.

Last edited by NAZ; 08-23-2020 at 11:54 AM.

Dart Little M 406" SBC 800 HP N/A & 1,100 HP on nitrous, 2-spd Powerglide with trans brake, 6,000 RPM stall converter, narrowed Moser 88 3.90:1 spool with 35-spline gun-drilled axles & Torino bearings, custom parallel four-link, custom tube chassis & roll cage NHRA certified for 8.5-sec (only two FFR Hot Rods have this cert).

33 Hot Rod Super Pro Drag Racer Build:

33 HR NHRA Cert Roll Cage Build

-

Senior Member

I can only speak for the Tilton HRB I described and pictured in post #7. The instructions explain exactly how to install. There are no shims used and no mention of an air gap spec. There is a large threaded sleeve that's adjusted based on measurements taken during the installation. Once installed, I suspect the HRB is lightly touching the fingers on the clutch pressure plate. Enough to make it turn? I don't know. But I trust the setup and design from Tilton and am very comfortable recommending it. Agree a stop of some kind is important. The Tilton instructions emphasize this as well. It's early at only 1,100 miles on mine. But it's working perfectly.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

I think it varies by design. Mine is installed as you mentioned making continuous contact and requires a specific amount of pre-load which was new to me as it will always be spinning as you suspect, but others call for a gap. When all else fails - read the directions.

-

Seasoned Citizen

Originally Posted by

sread

I think it varies by design. Mine is installed as you mentioned making continuous contact and requires a specific amount of pre-load which was new to me as it will always be spinning as you suspect, but others call for a gap. When all else fails - read the directions.

My apologies for my misleading use of the term "air gap". These type releases are self adjusting so yes, the T/O bearing is always in contact with the clutch fingers. But there is virtually no force being applied.

When you initially set them up (before any lines are connected or fluid added) and the piston is fully retracted there will be a gap between the T/O bearing and the clutch fingers. That gap is to allow for clutch wear. But in normal operation there is no actual gap between the clutch fingers and the T/O bearing as there is no return spring. But don't fret about this contact, it will not affect the force the pressure plate applies to the clutch disc.

As sread stated, read the directions for your unit.

Dart Little M 406" SBC 800 HP N/A & 1,100 HP on nitrous, 2-spd Powerglide with trans brake, 6,000 RPM stall converter, narrowed Moser 88 3.90:1 spool with 35-spline gun-drilled axles & Torino bearings, custom parallel four-link, custom tube chassis & roll cage NHRA certified for 8.5-sec (only two FFR Hot Rods have this cert).

33 Hot Rod Super Pro Drag Racer Build:

33 HR NHRA Cert Roll Cage Build

-

I haven't purchased one yet. I am committed to a concentric design-just seems less complicated geometry wise, plus it takes up less space. I've pulled out plenty of clutches & throwout bearings that have scary amounts of wear on them from continuous contact. One even wore completely through the clutch fingers. Granted the T/O bearing was seized, but It seems to me the bearing will last longer if it isn't running all the time.

On a disc brake setup the brake piston(s)have no return spring, but the design allows the piston to relax slightly if no fluid pressure exists. that's what I want to satisfy in my mind. My idea of right in this case is one that doesn't quite touch until you begin to press the pedal. I've pretty well decided to use the Tilton unit, just thought I'd like that little peace of mind.

-

I ended up buying a Tilton 6000 series. The description said it was for a TKO in a Ford motorsport aluminum housing. I bought that housing as well, plus a Zoom 10.5" street single disc clutch. After dialing in the housing (took adjustable dowels), the measurement from mounting surface to clutch fingers was more than the adjustable threaded sleeve with the bearing could provide. Made a spacer sleeve out of a piece of tubing to slide on the guide sleeve behind the threaded adjustment sleeve. The spacer was .600". That provided the proper setup height with the threaded sleeve screwed in about .375". Also the instructions provided with the TOB said that the piston would relax just slightly after release providing a slight air gap, enough so that the bearing wasn't quite contacting the clutch fingers. They stressed the fact that a pedal stop would indeed be necessary to keep from popping the seal out of the bore. The TOB only provides .700" of travel, and they recommend .125" of initial clearance on assembly to make up for disc wear.

-

I’m sure you’ll be happy with your purchase. Just remember to make sure the bleed line is secured away from and will not rub against the spinning clutch inside the bell housing.

build thread:

http://thefactoryfiveforum.com/showt...-USRRC-vspeeds

Build School: July 14-16, 2017

Kit purchased: July 25, 2017

Kit delivered: September 13, 2017

First Start: December 22, 2018

Body painted and kit completed and drivable: July 2019 (but still not done)

CA SB100 Registration: January 2020

Mk4 - 289 USRRC Roadster kit, Roush 427SR with Schneider Racing custom camshaft, Fitech EFI, TKO600 (.64-5th gear), 15" wheels, stock brake calipers, under car exhaust with Spintech 7000 muffler, no roll bar, Russ Thompson turn signal, removable steering wheel, and many other small upgrades and modifications

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote