Time to start the wire diet.

Since the 06 STI I bought had a pretty hacked up main wire harness I purchased a second complete wire harness from another wrecked 06 STI. As a result I have two of most of the major harnesses.

Here is how the shop floor looked starting out:

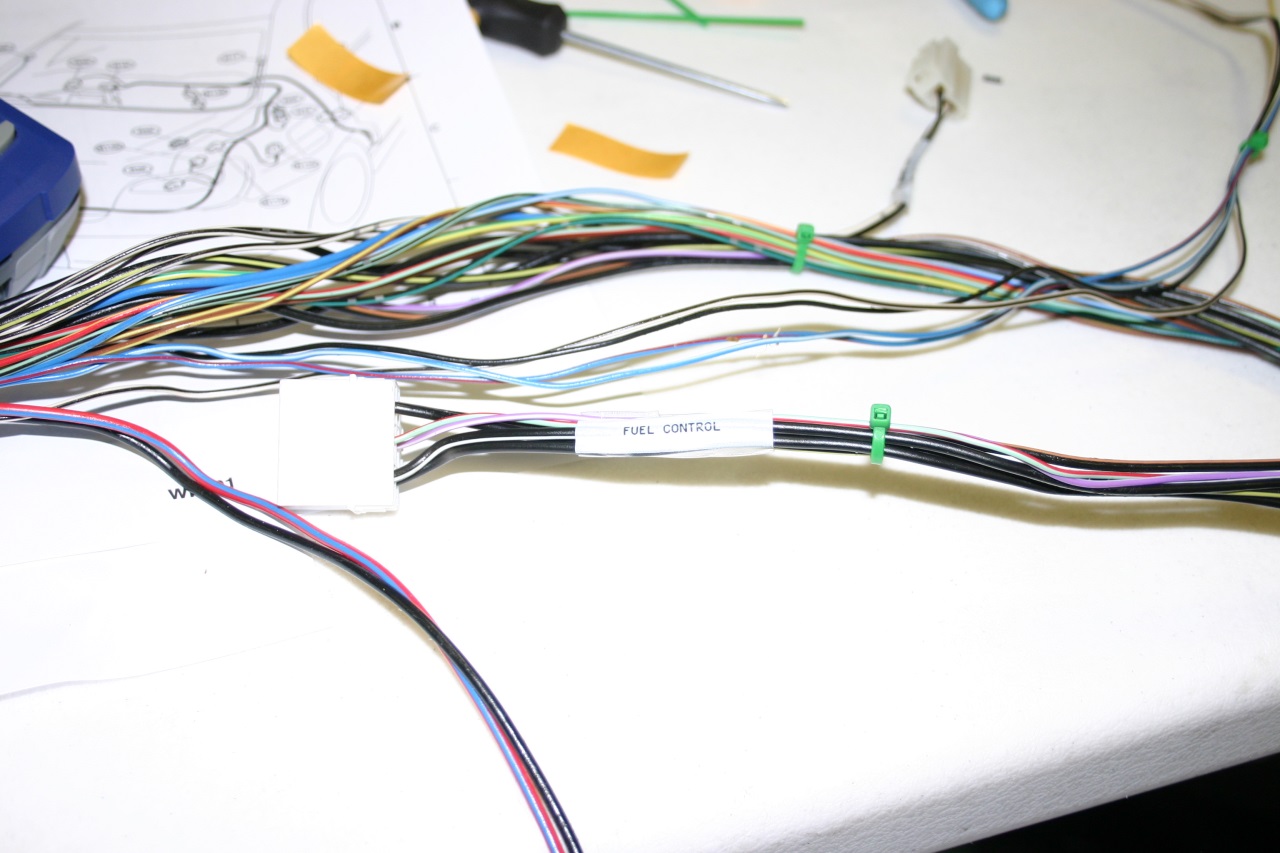

Here is a picture of the two main bulkhead harnesses. (Both are the same harness, once from my car and one from another car). This is the primary bulkhead harness that is really the backbone of the wiring.

In case you are curious as to what it plugs into, here is a small annotated picture:

Of the two main harnesses, one of them has a pretty hacked up ECU side, so I will be using the other main harness which has a very clean ECU connector.

You can see the hacked up one here:

Unfortunately this harness does have one problem, the ABS connector was cut off during removal:

The other harness doesn't have the problem so I can transfer over that connector. Since the ABS will probably be in the front, I would likely have to extend the wires anyways.

I also have two of the 'rear bulkhead' harnesses:

However I have only one dash harness:

I'll document the process for each harness, showing which connectors and wires I have removed how it is repackaged for installation.

Jeff

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote