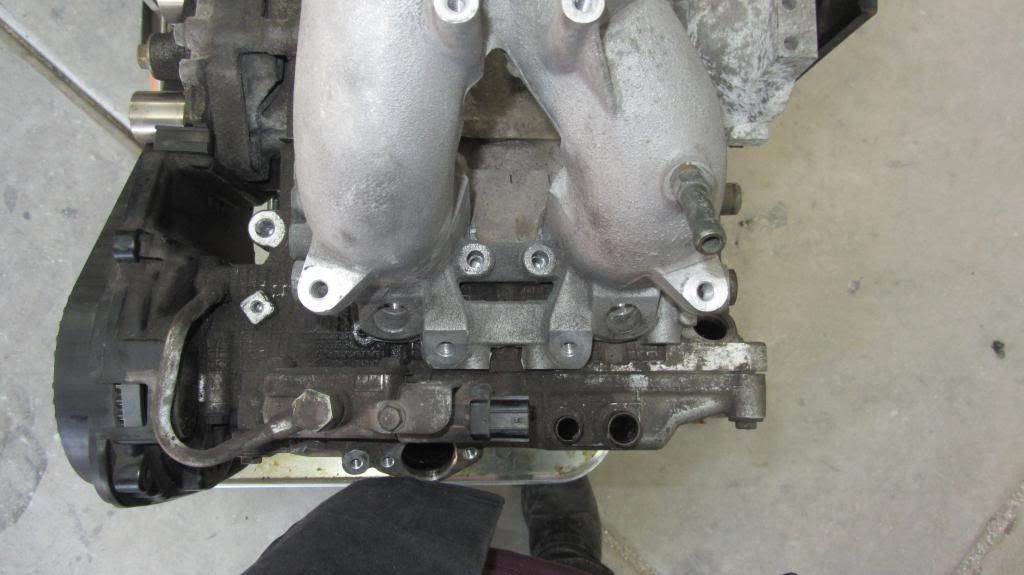

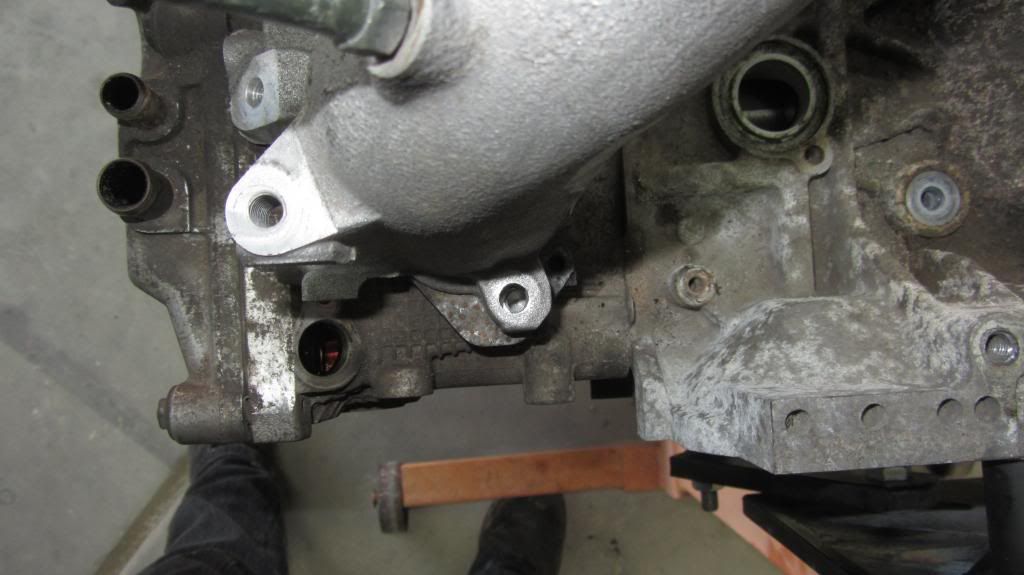

OEM EJ205 75mm stoke P/N 12200AA240. Yep it's a de-stroker. Comes OE with the good crossdrilling for better oiling at high rpm.

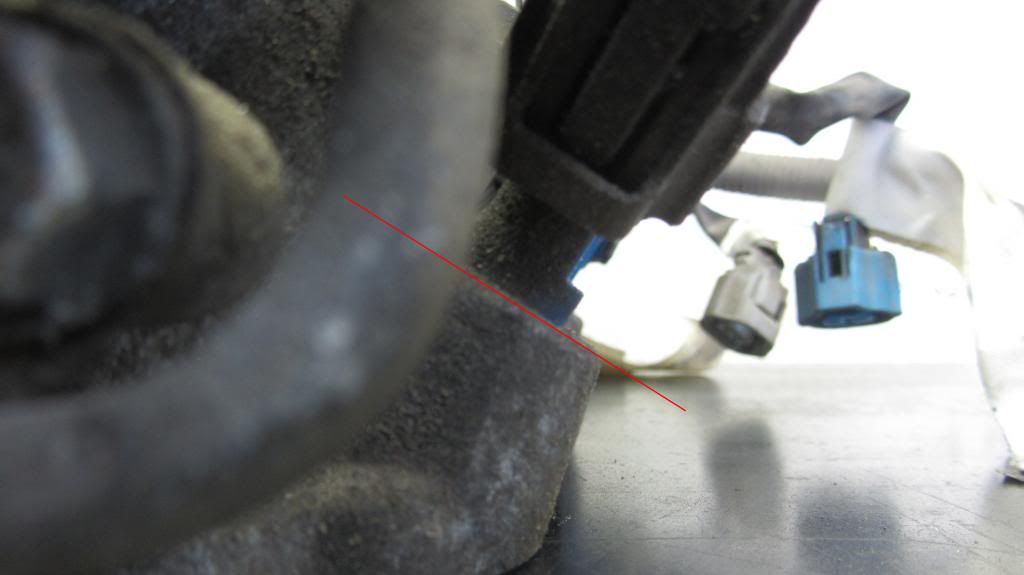

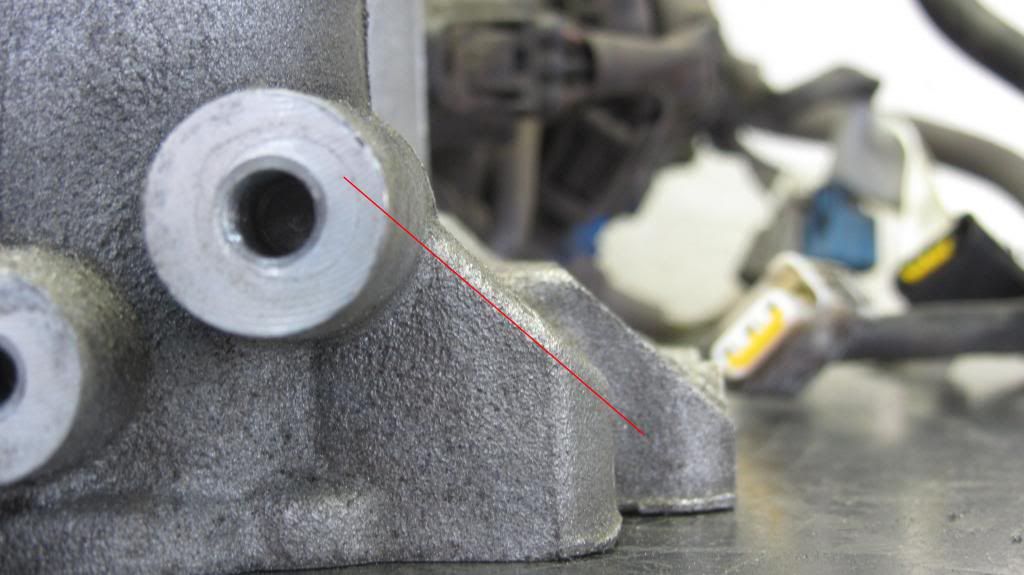

Weird coloring is from the nitriding process 3MI Racing had done to it.

It's a beauty, too.

And as promised. A Subaru EJ205 75mm stroke crankshaft next to a Cadillac 500, 4.304" stroke (~109.3mm) crankshaft. Banana for scale.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote