-

Senior Member

Help me think through this new wet sump idea

I'm looking for a way to keep the wet sump system in my EZ36 H6 and still have it work well in road race conditions. I don't want to build a deeper / larger pan that would protrude down below the belly pan.

The following fixes don't appear to be viable for the EZ platform:

- Baffled oil pan (not enough room in the pan)

- Arc Tangent type oil plate (upper oil pan integrated into block, no way to mount)

- Flop tube type pan (not enough room in the pan)

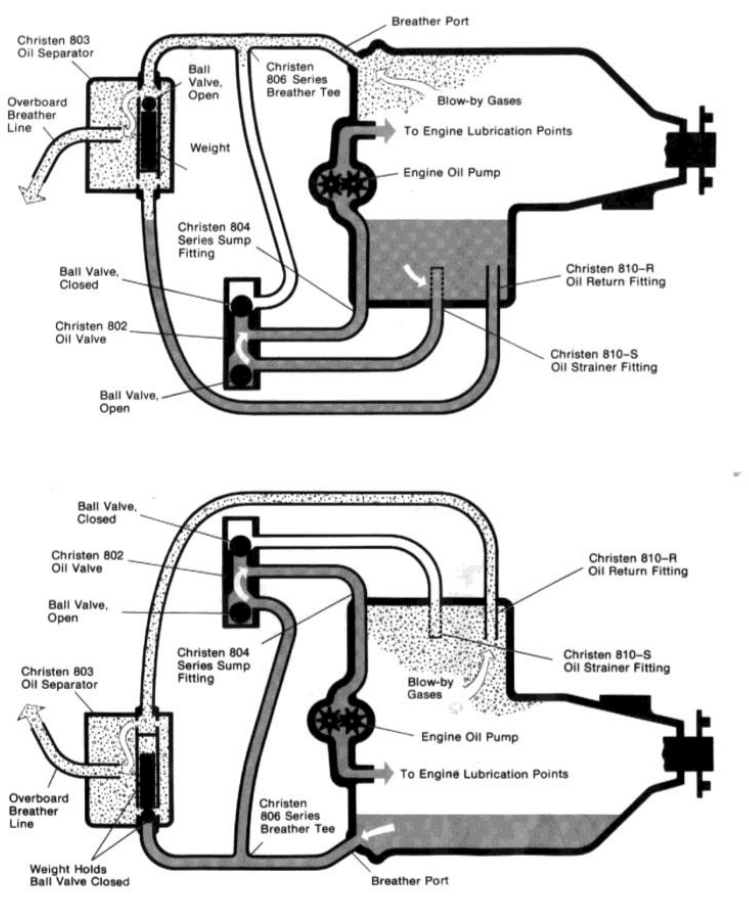

What if I make a pan with dual pickups, one in the far left and one in the far right sides of the pan. A device to block the pickup not submerged in oil during hard cornering would be needed. I'm thinking a Christen Oil Drain Valve type device. These are used in acrobatic aircraft that fly upside down. In this application it would be used horizontally instead of vertically.

In the picture below you see an airplane engine in normal and inverted operation. Focus on the Christen 802 valve part.

If viable, you could even use Killer B's Oil Control Valve as it's based on the same concept. I have an email into them to see if they think its a viable use of their device.

What are your thoughts?

Last edited by Hobby Racer; 01-09-2020 at 12:13 PM.

-

There are several ways to accomplish your objective. Some newer motorcycles have a flop tube, however it moves fore and aft only since a motorcycle leans into turns, negating the necessity for sideways movement. A wet sump is fine as long as you can keep the oil pick up tube in the oil. Dry sump systems in our application are problematic for several reasons. One is added weight. Another would be the added complexity, drive belts, possibility of leaks due to a myriad of hose connections. The main objective is to keep the oil pump from cavitating. I’m with you all the way on this. I think the Major flaws have been identified, the worst of which is the nose down attitude of the motor as FFR has the mounts made.

-

Senior Member

Killer B confirmed that the oil control valve would not work in this application. The ports are too small and the check valves would not operate correctly.

I ordered a Christen 802 Oil Valve this morning to experiment with. Very hopeful this could be a simple and robust solution to oil starvation!

Last edited by Hobby Racer; 01-09-2020 at 01:30 PM.

-

It would also be worth reaching out to Bill Walker toss around some ideas, he did a lot of testing with the Arc Tangent plate and has built a beautiful airplane at home. My KB pan was about 3/4 of and inch below the frame rail wasn't a concern to me, I have had many wet sump race cars with the pan below the frame. With all the track I had on my 818 which included a few 2 and 4 offs and straddling curbs and rumbles the pan wasn't touched. I wouldn't be afraid to have the pan below the frame rail, that just me.

Looks like you have some interesting options to explore and will be a fun project. I assume the engine has the same problem as all boxer engines with oil wanting to fill the heads. I think your on the right track with some sort of baffle/oil control plate and making sure the pick up always has oil. Your thought process my be way ahead of me on this, KB Oil control valve for the cam cover breathers (assuming they are the same as the EJ) and AOS and a pan with a captured pick-up with trap doors?

-

Senior Member

Originally Posted by

Mitch Wright

It would also be worth reaching out to Bill Walker toss around some ideas, he did a lot of testing with the Arc Tangent plate and has built a beautiful airplane at home.

I may try that to toss around some ideas and pick his brain about it. Hey, Bill you out there reading this thread?

Originally Posted by

Mitch Wright

I assume the engine has the same problem as all boxer engines with oil wanting to fill the heads.

The EZ platform does not seem to suffer from this like the EJ's do. The oil returns through the center of the front timing chain case and two baffled ports in the upper oil pan. There are two oil pans, an upper that's integrated with the block and a small stamped steel lower pan.

Originally Posted by

Mitch Wright

I think your on the right track with some sort of baffle/oil control plate and making sure the pick up always has oil. Your thought process my be way ahead of me on this, KB Oil control valve for the cam cover breathers (assuming they are the same as the EJ) and AOS and a pan with a captured pick-up with trap doors?

I think you miss interpreted my first post. I am NOT able to use a baffle/oil control plate or the Killer B oil control valve for the cam covers. I was thinking of using the Killer B valve connected directly to the oil pickups in the oil pan, using the valve to control which pickup in the pan was open to the oil pump. In any case its not feasible with that product.

I am going to experiment with an aviation Christen Oil Valve mounted horizontally and not vertically like you see in the picture in the first post..

-

No I understood and understand how much different the sump design is. I guess what I was thinking was if you had a deeper sump you could use something like this EJ Oil Pan Baffle.jpg sandwiched between the bottom steel pan and top aluminum portion to keep oil from climbing the walls of the sump. Not knowing how the crankcase or heads vent just throwing out ideas using the KB OCV. Looking forward to seeing what you come up with using the Christen valve. Seeing your engine photo's is the extent of my knowledge of the EZ. I will stop talking out of my a$$.

-

Senior Member

Originally Posted by

Mitch Wright

I guess what I was thinking was if you had a deeper sump you could use something like this

EJ Oil Pan Baffle.jpg sandwiched between the bottom steel pan and top aluminum portion to keep oil from climbing the walls of the sump. Not knowing how the crankcase or heads vent just throwing out ideas using the KB OCV.

Ok, I am following you now and your right, I could build a deeper pan with baffles and other typical control devices. But I want to try to come up with a solution that stays above the belly pan. On the EZ engines there is only one breather located on the left side cam cover. There are internal crossovers between the heads that route through the block, quite different than the EJ's. If the Christen valve idea fails then I will most likely build a deeper pan. I'm already at 10 qts of oil in the system, with a deeper pan its going to be crazy.

Originally Posted by

Mitch Wright

Looking forward to seeing what you come up with using the Christen valve. Seeing your engine photo's is the extent of my knowledge of the EZ. I will stop talking out of my a$$.

No worries, keep the comments coming. All input is welcome!

-

Senior Member

There is not much on the internet about the internals of the Christen valve. I did manage to find this disassembled pic.

I like the fact that both ends come out so I can inspect and clean everything when changing the oil. Very simple design, I like that, less to go wrong

-

Senior Member

That unit does look interesting in theory. I've never thought about how airplanes deal with such ranging conditions. If it's proven to work upside-down and in aircraft that's pretty impressive. Thanks for posting, and I look forward to your work with it.

The question I have, is why not dry-sump? I disagree with the idea that it's too complex/unreliable. It's well proven in racing (maybe just not Subaru?). The heavy part is a non-starter in these cars (IMO). I have run multiple DS engines from traditional multi-stage external pumps, to hybrid scavenge pump with the OEM pump for supply. Never had any particular issues, but there was some refinement of the pan on my hybrid system. I went straight to DS on my last car with a Yamaha R1 engine, and it worked great. During that time I witnessed a bunch of others' destroyed R1, then GRX-R and Kawi. engines while working through wet-sump and accusump ideas and solutions. Swinging pickups and doors were the current WS solution when I got out of it.

I too would keep it above the frame rails- learned the hard way what happens when the flywheel "touches" the track (because it's below the frame)... Oil pan contact could be ugly/costly too. *That car did have only a 1.75" rear ride height, though.

Good luck in your quest!

818S #332, EZ30R H6, California licensed 01/2019

-

Senior Member

The valve arrived today. Instead of an epoxy coated aluminum casting, the housing is CNC machined out of solid brass. Nice!!!

The 1.125" steel balls rest in 1.188" diameter passages, giving a bit more than 0.030" clearance around the ball. A bit more than I would want but I'm sure the engineers have worked out the best clearances given thermal expansion, oil thickness and viscosity. I'm not going to try and second guess them.

You can see a dark circle where the steel ball seats up against the brass, like a valve seat in a cylinder head.

IMG_20200114_162624232.jpg IMG_20200114_162701469.png

I used a digital angle gauge to test when the balls begin to move and when they become fully seated. They begin to move almost immediately when tilting. They do no fully seat until 30 degrees of tilt. That equates to 0.57 G of lateral acceleration.

I noticed the ball undergoes a slight step up to become fully seated. The seating surface is concentric to the outer chamber walls where the ball rests, but since the ball sits ~ 0.030" lower, due to the clearances, there is a slight step up to fully seat the ball. This concerned me at first but after thinking about it I believe it will be a good thing. Since the ball will not fully seat until 0.57 G, the oil pump will be able to pull oil from both the left and right pickups until that point. Since that level of lateral acceleration will not uncover either pickup, this is a good thing. Once I move past 0.57 G the inboard pickup will become fully sealed off, forcing the engine to pull only from the outboard pickup.

In a horizontal application like this, the ball will always be in contact with the bottom surface of the chamber unless fully seated, rolling back and fourth along its axis. When used in an airplane in the vertical position, its rattling around all over but there is never really a step up to seat the ball as the ball is falling straight down once you roll the plane over.

I wonder if I'm the first person to try this in a car?

Last edited by Hobby Racer; 01-14-2020 at 09:59 PM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

DSR-3

DSR-3 thanked for this post

-

Senior Member

Hobby,

It looks to me once a ball closes it will never reopen because of the suction of the pump. Then then the other side closes, kaboom.

Tell me why I'm wrong.

Bob

-

Who is giving those valves away?

-

It looks to me like that valve is designed to work in the vertical plane. I’d have serious doubts about using it in any other position.

-

Senior Member

Originally Posted by

Bob_n_Cincy

Hobby,

It looks to me once a ball closes it will never reopen because of the suction of the pump. Then then the other side closes, kaboom.

Tell me why I'm wrong.

Bob

If you look at the disassembled picture you will see a spring that is placed between the balls. The spring makes it impossible for both balls to be closed at the same time. Only one ball can be seated at a time while they can both be fully open at the same time. It really is an elegantly simple device.

Originally Posted by

lance corsi

Who is giving those valves away?

I wish they were giving them away! I purchased it from Aircraft Spruce airplane supply house.

Originally Posted by

lance corsi

It looks to me like that valve is designed to work in the vertical plane. I’d have serious doubts about using it in any other position.

It is designed to work in all positions, as aerial acrobatic planes fly in all positions, but I'm sure their main focus is inverted flight.

I'm thinking of building a quick test bed to validate the horizontal operation. I can rig up a simple pan with twin pickups and place it on an engine stand like Bill did with his oil control plate. That way I can tilt it easily. I'll drive an external oil pump with a hand drill to simulate the Subaru oil pump.

Last edited by Hobby Racer; 01-14-2020 at 10:02 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

I like this idea. I was thinking along the same lines when planning my oil system, decided to go with a dry sump. I think this setup can work. Will be interested in seeing more of your work on it.

-

Senior Member

Test Bed Ready

And for those of you following along at home, the tests will begin soon. I'm going to mount my digital angle gauge to the rig so I can track the angle / G force as I test. I'm using a high volume oil pump from a SB Ford 302 I had laying around. I'll drive it with my high torque Milwaukee drill.

I will video the test and post it up when complete.

IMG_20200118_174944977.jpg IMG_20200118_174955304.jpg

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

First Test

This is a lot harder than I thought without helpers. You need to run the drill, tilt the rig and get the camera in the right spot all at the same time. I think I need to try a GoPro mounted on a head band so you can see what I see during the tests. A single static camera position does not give the best perspective.

A description of the rig:

I found a container that is just about as wide and long as my stock oil pan. I fastened two clear pickup tubes in the bottom corners and connected them to the outer ports on the valve. The center port on the valve is connected to the suction port on the oil pump. The output of the pump is pumped back into the bucket through a black hose seen in back of the valve. There is a digital angle gauge mounted to the side of the valve.

The pickup tubes are not pointed down at the pan bottom like real pickups would be. They are simply hoses cut perpendicular to their length and clamped near the bottom of the bucket. Not trying to be super accurate here, just getting a feel for if this valve will work in the horizontal position. I am using the same oil I run in the car on track, 5W-40 Synthetic.

This first test was with only 1.75" of oil in the bucket. This would simulate a dangerously low oil condition. In fact the pickup tubes are only covered by about 1/2" of oil when the bucket is level. I did this intentionally so the pickups get uncovered easily so I can tell when the valve closes off one side and is feeding solely from the other side.

Anyway, here is what I've learned so far.

- Valve switches ports between 12 - 15 degrees of tilt (0.21 - 0.27G)

- Once closed the valve operates as expected (i.e. seals air tight)

- I only tested to ~51 degrees (1.27 G) so far

- Short answer, it works!

I need to get a better camera setup and maybe a helper to run the drill so I can focus on the tilt mechanism. Then I can fill the bucket more to simulate normal oil levels in the pan and run it at more extreme angles to simulate high G forces.

Last edited by Hobby Racer; 01-19-2020 at 09:48 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Excellent work! This looks to be a viable option.

-

Senior Member

Second Test - Disappointment

With the first test showing real promise I proceeded to the more realistic test and filled the pan with ~5" of oil to simulate a normal fill condition. Unfortunately the results were not what I expected. With the deeper depth of oil the port switch over point increased from 12-15 degrees of tilt to almost 30 degrees before the valve switched pickups.

What the heck is going on here!

After much pondering I believe that the switch over point is triggered when one of the pickups sucks air and breaks the suction allowing the steel balls to move freely and switch positions. So by filling the pan with more oil, the angle at which of the pickups gets uncovered increased to ~30 degrees. Once the pickup is uncovered the pump draws in air and the suction is broken and the balls move to block off the port drawing air. Problem is that is takes too long for this switch over to happen. If I'm running at 6,000 RPM in a fast sweeper, any amount of time with no oil pressure is critical!

Planes apparently do no mind a second or two with no oil pressure. Actually it makes sense. When you roll a plane over, it takes a second or two for all the oil to migrate from the pan to the top of the motor where it can now be scavenged by the breather and fed to this valve.

So unless I can think of a way to modify this valve to correct for this design problem, this idea is toast

-

Senior Member

However I just found this little number and ordered one. Its a swing arm a.k.a flop tube pickup. Apparently its for a 60's big block Chrysler or AMC, go figure! The swing looks to be about right and its height is very short so with some modification to the mount, it might fit inside the stock oil pan. Fingers crossed.

Lance, I might be joining your camp soon

Last edited by Hobby Racer; 01-21-2020 at 11:12 PM.

-

I was thinking of something similar to the swivel pickup you bought. My idea was flexible hose with a pickup attached, which had a roller magnet attached to the pickup. This would keep it stuck to the bottom but let it slide side to side with the G forces.... Easy to picture in my brain, hard to describe.

-

You’re coming around. My home made swinging pickup cost me less than $100, including the pan, added less than 2 lbs weight to my car, no external pumps or hoses. But I hope you come up with a better system. It’s not rocket science.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Dodge Vipers have come with swing arm oil pickups for years. Maybe you can mod one.

1fa529230271733fd7baf541e87e639c.JPGDodge Viper Swing Arm oil pickup.JPG

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Post Thanks / Like - 1 Thanks, 0 Likes

DSR-3

DSR-3 thanked for this post

-

Senior Member

Originally Posted by

Sgt.Gator

The swing arm part looks very much like the one I ordered.

-

Have you made any progress on this?

PBMS makes this for the EZ30, not sure if they will make them for the 36:

https://www.possumbournemotorsport.c...d-sump-ez30-h6

Last edited by Sgt.Gator; 08-14-2020 at 11:12 AM.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

-

Senior Member

Originally Posted by

Sgt.Gator

Have you made any progress on this?

Yes, as you know I made a custom swivel oil pickup. Its' here in my build thread.

I'll be testing it out with full sensor data on 8/24 & 8/25 at Watkins Glen. I'll post results back in my build thread.

The baffle plate would not work for the EZ36, completely different oiling system than the EZ30.

-

I forgot that part of the project was done. Now that I've reviewed your extended pan and the oil pickup I'm pretty certain that your system could be converted to a Aviad style hybrid dry sump easily. All you'd need to do is replace the swing arm with a solid tube or hose that goes up to a port in the side of the upper pan where you feed the dry sump tank return back to the engine's internal oil pump; and put a couple of scavenge ports in the lower pan that feed up to a Aviad DS pump on top. The pump replaces the air conditioning unit and uses the current drive belt setup. I'm not sure if there's enough room up there for a four stage scavenge pump to scavenge the heads too....so you could use a second pump in place of the power steering pump. It could draw one line from the right hand head and one line to the lower oil pan, and the air conditioning side pump would mirror one line to the head and one line to the pan. You'd definitely have lots of vacuum with with twin pumps and could probably even use a stock length serp belt, or very close to stock length.

I may have to get an EZ36 for a winter project.....but first I need to get my 818 running solid on it's EJ257. More on that very soon.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

2005 Subaru STI Race Car ICSCC ST and SPM

Palatov DP4 - ICSCC Sports Racer

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote