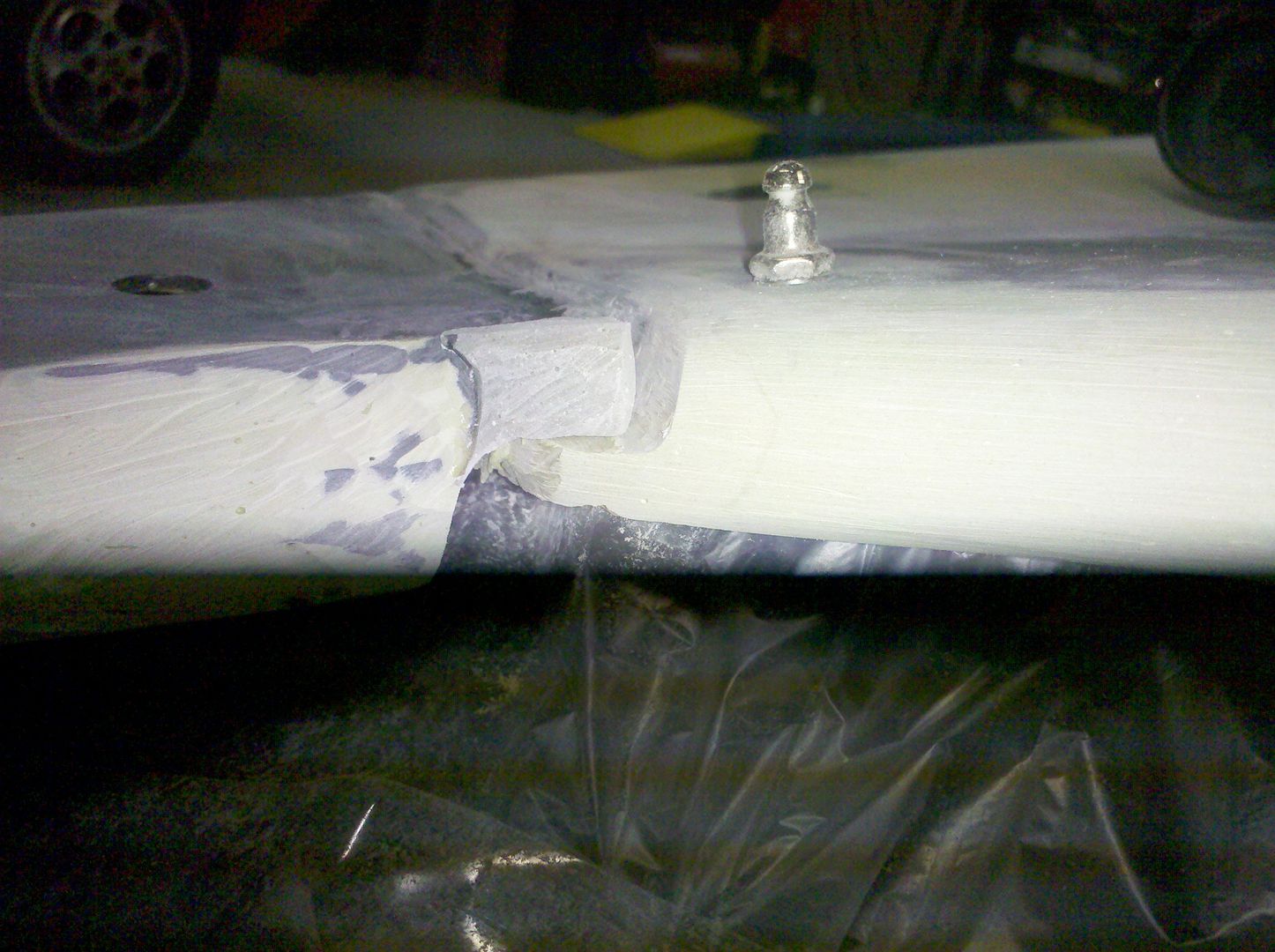

I did back-up the tail light area as part of patching over the holes that FFR cut. My body came with two circular holes in each pad for the round tail lamps and, wouldn't you know it, those were right where the mounting studs for the rectangular lamps needed to go. I cut some 6" circles of fiberglass cloth, then cut those in half to patch the top and bottom - see post #18 for details. I built that up about 3/16" - 1/4" thick on the inside, so that I wouldn't have issues with thinning the body when I did the resculpting, so it sort of killed two birds with one stone.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote