-

Senior Member

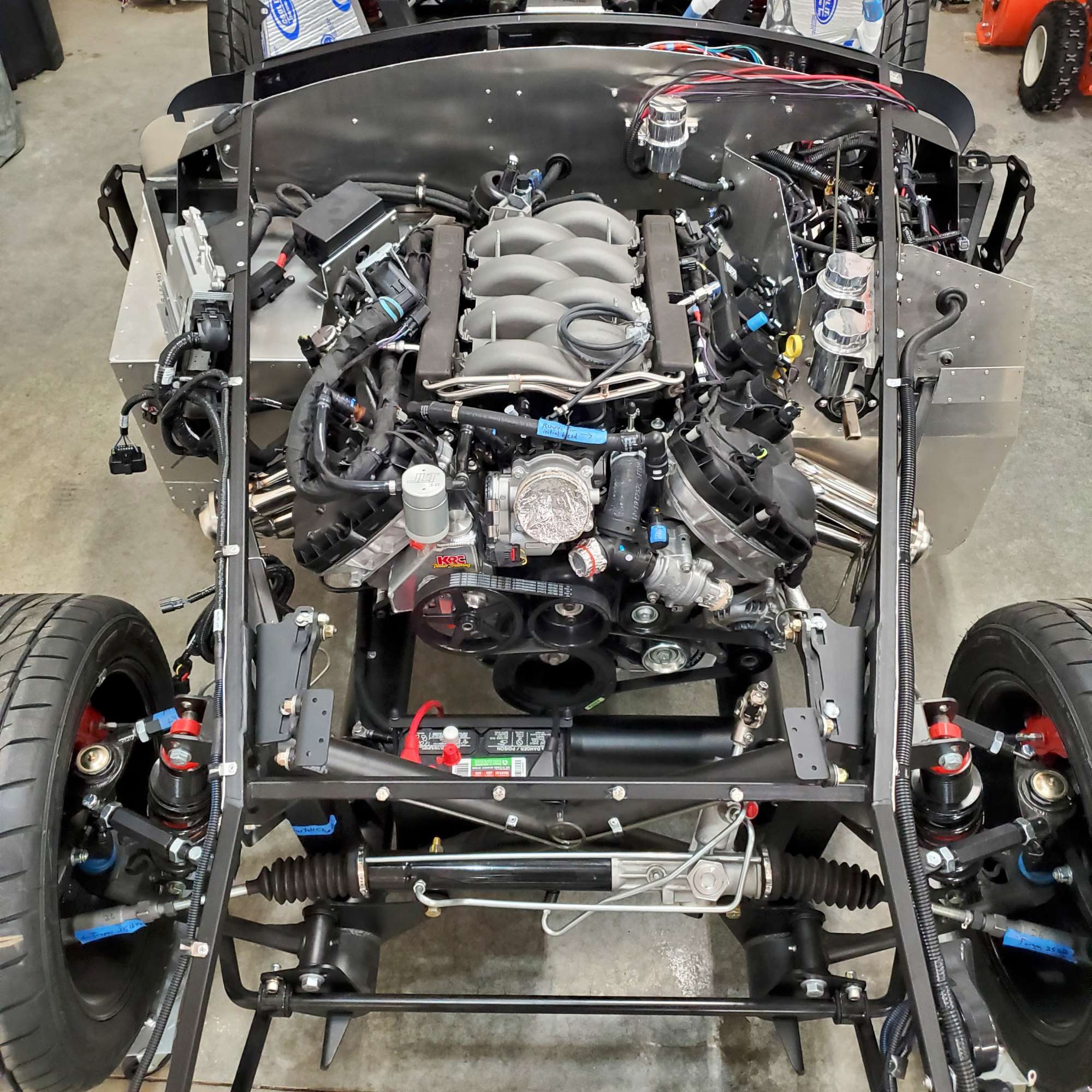

Coyote/TKO600 Installed! (Part 1)

Almost 18 months after getting the Gen 3 Coyote/TKO600 in my garage, they are now in my Roadster! It's easily been several hundreds of hours of build up to this point, and feels really good to see it nestled (ever so tightly!) in the chassis.

My wife gifted me the Harbor Freight two-ton engine crane and leveler for Christmas. I'm not sure if it was a Christmas Eve sale, but there was a $70 savings, and they threw in a year's membership. They still come with the red plastic handle many forum members have had issues with. I did too. I wasn't happy with the engine hoist attachments (I bought from Forte). No concerns with the quality, but they only attach to a single M10 header bolt on either side. I'm sure Forte wouldn't sell them if there was a strength issue. However, I found a set off of eBay for $40 shipped, and made in the USA! These attach to the bosses on the motor: two bolts secure each bracket to the motor--left side front, and on the rear-right. This approach inspired much more confidence when the drivetrain is suspended 4+ feet off the floor. Glad I tested the crane and hoist setup ahead of time to work out a few Gotchas!

Dry run the night before. Plenty of clearance above upper 3/4" tube, and a couple inches to spare between the crane legs and the 4" chassis. Bonus question: what additional items in this picture will become obstacles during the actual attempt?

Let the games begin! My daughter, Grace, keeps a close eye on the operations, perched high above for maximum optics.

Progress! Plenty of maneuvering left to go. Any rational person would be saying at this point, "It ain't gonna fit"! Thankfully, I have my German engineering consultant and fellow local builder, Jim, here for precision guidance! Jim is on the left, while I adjust the leveler for a change in roll?? of the engine (side-to-side).

Installation of the DS header underway. We're about 1 hour 45 minutes in at this point. The beast has been slain, so we transition to mop-up work like threading a bolt in to keep the driveshaft in place, install the transmission A-frame mount, etc. At this point Jim came up with the clever idea to raise the DS side of the motor up a little to give us a bit more finger space to thread in the DS header bolts. Thanks to a tip from JohnK I used a dab of Ultra Copper RTV on each header bolt.

Afterward it was time to celebrate our victory with a burger at Five Guys!

I can't thank Jim enough for his expertise and help. He was instrumental, and I couldn't have done it without him! Also, I really appreciate all the tips from the forum, and in particular from Coyote builders JohnK and Edwardb. Also, to Papa for the tip to remove the radiator. More on that in a minute.

Last edited by 460.465USMC; 05-08-2022 at 10:06 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote