If it's going to be driven, consider custom 3M for the front (hood opening forward) and the front of the rear wheel wells. Get it done before the 1st mile and before the 1st stone chip. A relatively cheap investment in your project. I wouldn't bother with the paint defender system. I applied it on mine and the +10K paint job got hammered anyways.

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

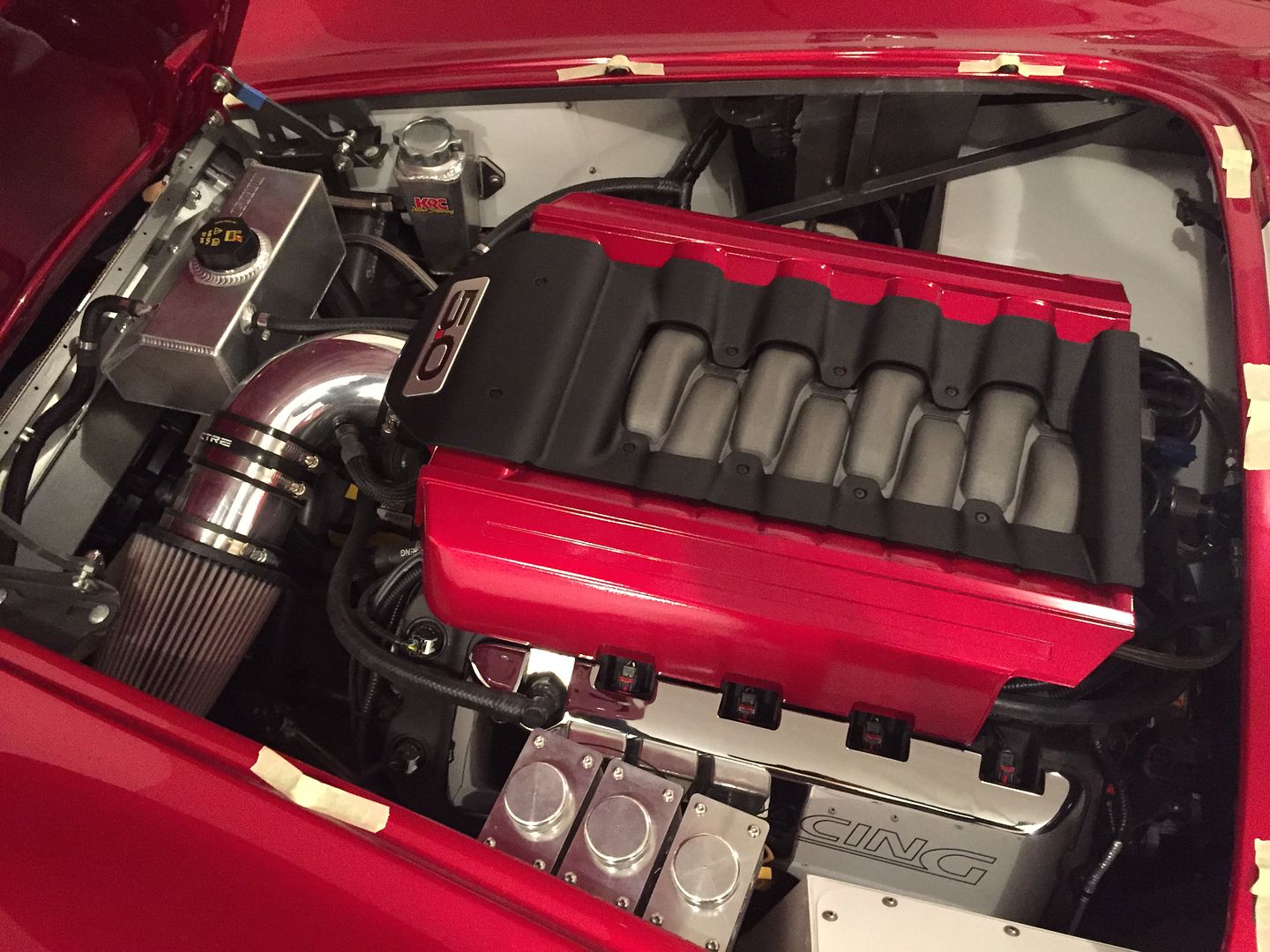

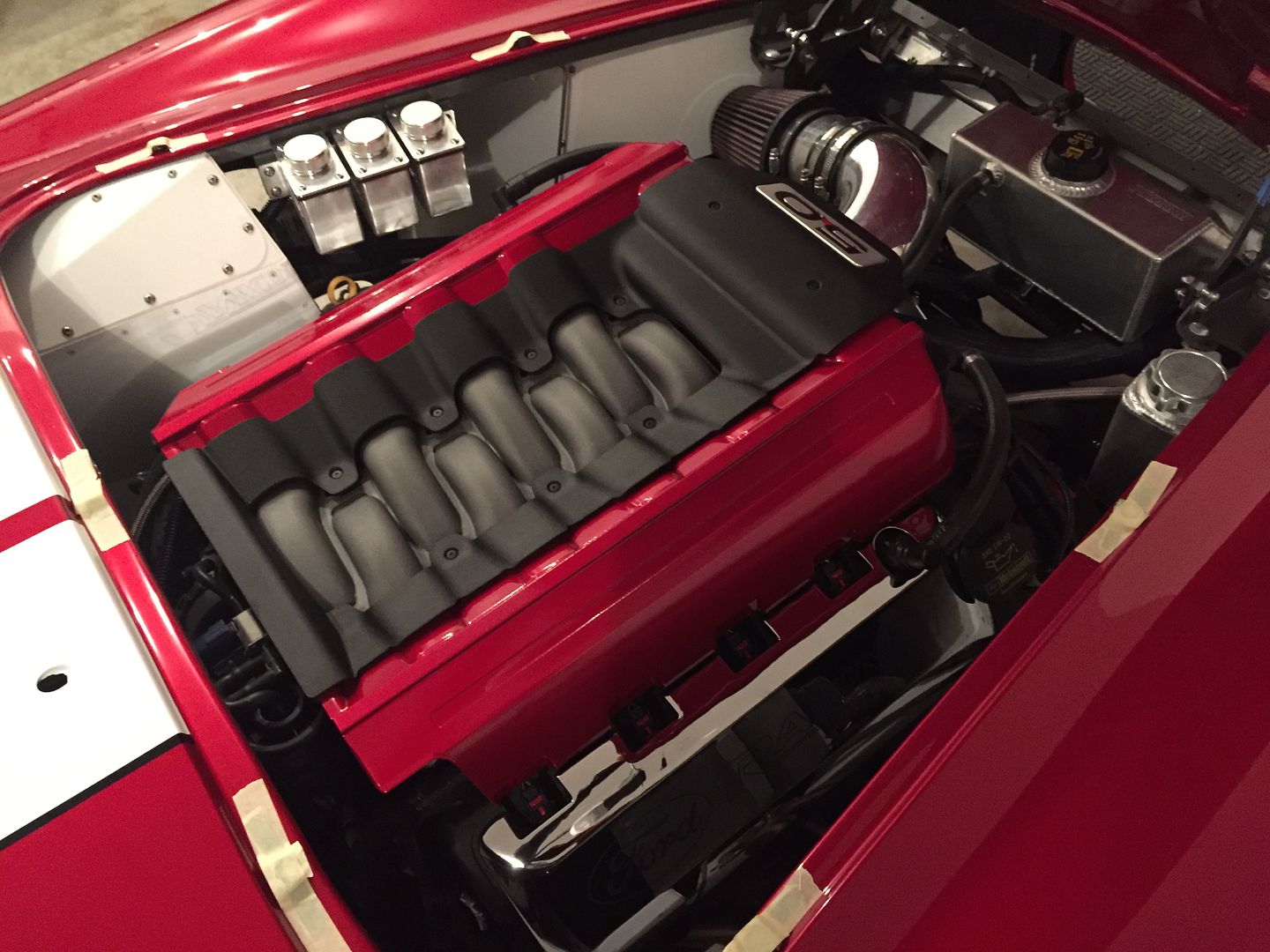

Enjoy the final assembly; for me that's always the icing on the cake!

Enjoy the final assembly; for me that's always the icing on the cake!