-

Driveshaft Install

Happy Saturday to everyone! Working on driveshaft installation and what seems like a simple thing has been giving me some issues. I just can't seem to get the right angle for the slip yoke to slide right into the tail shaft. I have the 3/4" spacer from Forte installed. So thought that was the issue, so dropped the A-Frame and let the trans down as far as it will go against the 4" tube, but still having the same issues.

It's almost as if I have the wrong drive shaft. Does anyone have the measured length of the slip yoke? If it was about an inch shorter, I think it would work. Any tips would be appreciated.

Thanks!

-

David aka Ducky2009

Did you pull the donut out of the tailshaft? NOTE: I had difficulty trying to install the driveshaft with the donut in, so I ended up removing it.

This is from the Tremec instructions.

There is a rubber donut on the outputshaft that is used to prevent any remaining oil in the transmission from leaking during shipment. While you

may remove this donut, it is not necessary. It will simply slide forward on the shaft when the slip-yoke is

installed. If you do remove the donut, use extreme caution to avoid damaging the rear seal. The slip-yoke

must be able to stroke freely on the transmissions output shaft without bottoming out while maintaining

maximum spline contact. Therefore, proper driveshaft length is critical.

MK4 Build #9035 Delivered 2/17/17, First Start & Go-Kart 6/2/17, Licensed 9/1/17

Paint - Lightning Blue Metallic, No Hood Scoop, No Stripes

Gen 2 Coyote Engine & TKO-600. Solid Axle, 8.8-3.55, Power Steering, Power Brakes, Dual Roll Bars

Heater and Glove Box, Drop Trunk, Wipers, Radio, FFR Vintage Gauges, Custom Dash

Build Thread:

http://thefactoryfiveforum.com/showt...MK4-Build-9035

-

Senior Member

Not completely clear on where the problem is. Are you able to get the slip yoke to go all the way into the back of the trans? It should go in with the flange of the u-joint all the way against the seal. Normally you have to rotate the U-joints enough to get a sharp angle so there's room to fit it in. Once in that far, you should be able to swing it up in place against the diff flange. If the driveshaft is the right length it should fit. Maybe just barely. When pulled against the diff, usually 3/4 to 1 inch of the slip joint will be exposed at the trans.

Edit: Ducky2009's response is another good point that I didn't think off.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Thanks for the replies. I pulled the donut out before I installed the engine, so no issues there. The instructions say to come in from the drivers side with the slip yoke angled towards the tail shaft and flange angled opposite direction...kind of like a half way ‘U’ shape. I’m installing from underneath but the middle of the driveshaft is coming into contact with the driveshaft adaptor before I can get the slip yoke straight to install into the tail shaft. I’ve tried to finagle it a few different ways and always the same result. If it was 3/4” shorter, I could get it to fit.

-

Senior Member

So you are/are not able to get the slip yoke all the way into the trans with the u-joint flange against the seal? If not, something doesn't seem right. I've personally not had a problem finding a proper angle. Pretty sure it wouldn't be a good idea to have the slip joint shorter because it won't go in all the way. Maybe post a picture.

Last edited by edwardb; 03-30-2019 at 01:31 PM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Originally Posted by

edwardb

So you are/are not able to get the slip yoke all the way into the trans with the u-joint flange against the seal? If not, something doesn't seem right. I've personally not had a problem finding a proper angle. Pretty sure it wouldn't be a good idea to have the slip joint shorter because it won't go in all the way. Maybe post a picture.

Correct. I can’t get the slip yoke started into the tail shaft as the angle is just enough off so that the splines can’t align and engage.

-

Senior Member

Originally Posted by

cv2065

Correct. I can’t get the slip yoke started into the tail shaft as the angle is just enough off so that the splines can’t align and engage.

Have you tried turning the trans output shaft to see if that gives a better angle? Don’t know what else to add. Just haven’t had the problem you’re describing. Have had to fiddle around to find the right orientation. But always worked out. Maybe some others will have suggestions.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Originally Posted by

edwardb

Have you tried turning the trans output shaft to see if that gives a better angle? Don’t know what else to add. Just haven’t had the problem you’re describing. Have had to fiddle around to find the right orientation. But always worked out. Maybe some others will have suggestions.

Thanks for the troubleshooting Paul. I’ll try a few more things. Is it possible that I have an incorrect driveshaft? I was sent this one as a back order, so wasn’t sure how many variations there are.

-

Not sure if you have a 3 link or irs? If 3 link let the axle hang all the way down, put your trans back up where it’s supposed to be on the mount and try putting the driveshaft in from above.

I have a 3 link and that’s the only way I can get mine in or out.

If you have IRS I have no experience.

Good luck

-

Senior Member

Originally Posted by

cv2065

Thanks for the troubleshooting Paul. I’ll try a few more things. Is it possible that I have an incorrect driveshaft? I was sent this one as a back order, so wasn’t sure how many variations there are.

Yes there are different spline counts. It wouldn’t go in any amount if you had the wrong one.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Ok, so we have a touchdown! Was able to rotate the drive shaft until it went in and then struck gold. Thanks again for the replies.

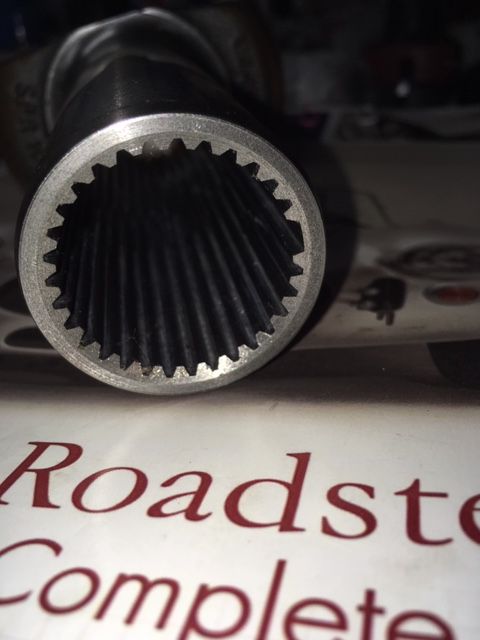

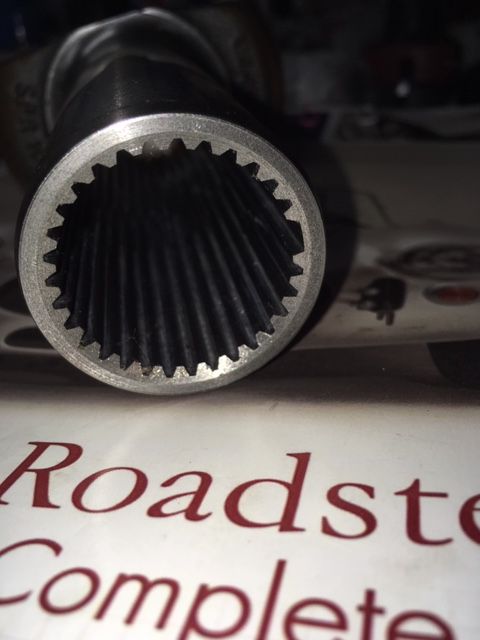

It brought up a couple of questions. The first is in regard to the slip yoke itself. It seems to have a key slotted into the splines. As I was rotating it, I felt it 'click', then it went in. Was that my imagination or does it need to be rotated to where it fits the slotted spline area? I didn't look inside the tail housing before to verify that there was a matching side, so thought I'd ask. Here's what it looks like (thanks to Badasp for his photo excellence!):

Also, I have two different sizes of bolts. One is 1" under head and the other 3/4". They are both the same thread size. Which is the correct one to use for the 4 bolts that secure the drive shaft flange? These were sent after the fact and can't recall which goes where.

Last edited by cv2065; 03-30-2019 at 05:36 PM.

-

Not a waxer

RE: The "missing spline" (or key as you called it) is simply so that the shaft doesn't air lock as it is inserted. The slip yoke does not have to key into the output shaft.

Jeff

-

Originally Posted by

Jeff Kleiner

RE: The "missing spline" (or key as you called it) is simply so that the shaft doesn't air lock as it is inserted. The slip yoke does not have to key into the output shaft.

Jeff

Makes sense. Thanks Jeff!

-

Senior Member

Two thoughts. 1- I was guessing through reading this as to what rear suspension you have. Since you mention drive shaft adapter I guess IRS. Can you put more car details in you signature line please? 2- It's been 2 years since I did my IRS upgrade but I remember removing the trans mount bolts and jacking the trans up as far as it would go to get the shaft in. Glad you got it to fit.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

It seems I remember some of the bolts went through the pinion flange and hit the carrier housing, bolts too long. Depending upon your pinion flange, one of the lengths will be right. The bolt should provide the most thread engagement without coming out the back and hitting the housing when rotated. No loctite on this trial fit.

20th Anniversary Mk IV, A50XS Coyote, TKO 600, Trunk Drop Box, Trunk Battery Box, Cubby Hole, Seat Heaters, Radiator hanger and shroud.

-

Updated my profile. Thanks for the feedback around the bolts. I think you are right Railroad, in that the longer bolts hit ever so slightly to where they can't be tightened up without some slop. Badasp also noted this and I may just grind the longer ones down a bit like he did.

-

Originally Posted by

Ducky2009

The bolts you are showing are not correct. See pic. Should be 12 point, hardened bolts, and they have a locking feature on the threads. Don't clear it off.

FYI... Same bolts for a solid axle and IRS, according to the manual pics.

Thanks Ducky. Thought those were just for the solid axle. I’ll have to call FFR tomorrow as I don’t have anything that resembles those 12 points.

-

Senior Member

Originally Posted by

cv2065

Also, I have two different sizes of bolts. One is 1" under head and the other 3/4". They are both the same thread size. Which is the correct one to use for the 4 bolts that secure the drive shaft flange? These were sent after the fact and can't recall which goes where.

Actually, those are the style bolts Factory Five supplies for the IRS setup with the adapter. Also what they show in their instructions. Just make sure you have the right lengths, e.g. fully engaged in threads but not bottoming out. Instructions say to use blue Loctite, which I have done as well. Visible in this picture from my Coupe build.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

David aka Ducky2009

Originally Posted by

cv2065

Thanks Ducky. Thought those were just for the solid axle. I’ll have to call FFR tomorrow as I don’t have anything that resembles those 12 points.

Deleted post as to not confuse anyone. I have a straight axle and the (full car assembly) manual shows the bolts I originally posted pic of for both installations. Paul's post appears to be from IRS instructions.... which I don't have.

Thanks Paul for the correction.

MK4 Build #9035 Delivered 2/17/17, First Start & Go-Kart 6/2/17, Licensed 9/1/17

Paint - Lightning Blue Metallic, No Hood Scoop, No Stripes

Gen 2 Coyote Engine & TKO-600. Solid Axle, 8.8-3.55, Power Steering, Power Brakes, Dual Roll Bars

Heater and Glove Box, Drop Trunk, Wipers, Radio, FFR Vintage Gauges, Custom Dash

Build Thread:

http://thefactoryfiveforum.com/showt...MK4-Build-9035

-

There are 2 styles of drive shaft flanges, one aluminum and one steel. The aluminum is thicker and the longer bolts are for it.

I had several drive shafts sent to me until I got the correct combination flange bolt pattern (IRS bolt pattern is different from the 8.8 axle) and spline so I had both versions. In Paul's picture he has the aluminum version

David W

Last edited by David Williamson; 03-31-2019 at 02:36 PM.

Mkll 4874 built in 2004

Gen 3 coupe #16 registered 2018 painted 2019

-

Originally Posted by

David Williamson

There are 2 styles of drive shaft flanges, one aluminum and one steel. The aluminum is thicker and the longer bolts are for it.

I had several drive shafts sent to me until I got the correct combination flange bolt pattern (IRS bolt pattern is different from the 8.8 axle) and spline so I had both versions. In Paul's picture he has the aluminum version

David W

Thanks for the clarification there Dave. I haven't seen that mentioned before. I have the steel flange, so I'll go with the shorter bolts as the longer ones bottom out about 1/32" from flush.

Last edited by cv2065; 03-31-2019 at 09:44 PM.

-

Senior Member

Maybe things have changed but 2 yrs ago they were both steel. The OD was slightly different. Notes about the adapter from FFR in the parts section;

""Note: For use with 2015-2017 manual transmission center section. Requires a 2-2-489 driveshaft flange.""

I don't see a listing for the adapter for a diff from an auto trans car.

FFR MkII, 408W, Tremec TKO 500, 2015 IRS, DA QA1s, Forte front bar, APE hardtop.

-

Hey CV2065,

How'd you finally get the driveshaft installed? I have the same setup with a Blueprint 427, TKO600 and IRS and seem to be having the same issue. I can't get the slip yoke started into the tail shaft because the angle is slightly off (doesn't look like it will go unless they are perfectly aligned). I can't raise the driveshaft high enough to get the right angle because the differential gets in the way. I have the transmission as low as it can go, resting on the frame, and still no joy. I'm worried that I am going to have to unbolt the engine and raise it up to angle the transmission down further. The splines are correct. See below where the driveshaft hits the differential as I try to raise it to parallel.

-

Hey Dncharo. After about 5 times trying, it went in by surprise. It really is like a combo lock...you have to have it in the exact spot for it to install. I went in from the driver side with both ends pointing out, kind of like a U shape. After some struggle, it just slid in. I’d hate for you to have to unbolt the engine to install. Can’t say it didn’t cross my mind a time or two. Keep trying...it will go in.

-

Was the slip yoke on the driveshaft perfectly parallel to the tail shaft of the transmission, or was there a slight angle? I can’t get it parallel... thanks!

-

Originally Posted by

dncharo

Was the slip yoke on the driveshaft perfectly parallel to the tail shaft of the transmission, or was there a slight angle? I can’t get it parallel... thanks!

There is a very slight angle initially, but don’t force anything. When you’re at that ‘right’ state of alignment, it will go in without a lot of effort. Doesn’t hurt to lightly lube up the yoke with some trans fluid either.

-

could someone verify for me that the ffr part number for the 6 bolts to attach the driveshaft adapter is 15961

thanks

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

I can only get my driveshaft in/out when the rear of it is above the differential flange. All other locations have some sort of interference that won't let it move back far enough.

-

Senior Member

Originally Posted by

dwheeler

I can only get my driveshaft in/out when the rear of it is above the differential flange. All other locations have some sort of interference that won't let it move back far enough.

Yep, loosen the trany mount, jack the backend of it up, then put the rear of the shaft above the differential.

-

Senior Member

Originally Posted by

Ducky2009

Did you pull the donut out of the tailshaft? NOTE: I had difficulty trying to install the driveshaft with the donut in, so I ended up removing it.

This is from the Tremec instructions.

There is a rubber donut on the outputshaft that is used to prevent any remaining oil in the transmission from leaking during shipment. While you

may remove this donut, it is not necessary. It will simply slide forward on the shaft when the slip-yoke is

installed. If you do remove the donut, use extreme caution to avoid damaging the rear seal. The slip-yoke

must be able to stroke freely on the transmissions output shaft without bottoming out while maintaining

maximum spline contact. Therefore, proper driveshaft length is critical.

I'm having difficulty installing my drive shaft into the transmission as well. What does the removable donut look like? is it the piece with the spline like groves in it? That piece seems to be separate from the smooth outer rubber. I have included a photo. Sorry for the poor quality of the photo.

Thanks for any help here.

TimIMG_2460.JPG

DRIVESHAFT INSTALLED.... Thanks anyway.

Last edited by tbl100; 10-11-2019 at 01:55 AM.

Reason: I got my drive shaft installed.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote