-

05-29-2019, 06:12 PM

#601

Senior Member

Originally Posted by

subysouth

I am amazed at the incredible fabrication work being applied to these cars. I guess I should not be surprised though, its a great package so it is going to attract some very talented people. Awesome work Hobby.

ss

I seem to be working on the car more that driving it

-

05-30-2019, 04:41 PM

#602

Originally Posted by

Hobby Racer

I seem to be working on the car more that driving it

I hear but sometimes it seems like that is where you want to be if it is a real give and take. You working on the car and the car giving back results. What wears you down is chasing demons 75% of time at least IMO.

ss

-

10-21-2019, 10:02 PM

#603

Senior Member

First Video w/ Data Overlay

Finally got around to syncing up my first track video with GPS telemetry and engine ECU data. After watching the oil pressure drop in the brake zones and hard corners, I'll be fabrication a dry sump system for the EZ36R this winter! This is a long session at Watkins Glen International from back on 9/18/2019.

This is with the bone stock H6 on street tires (Dunlop Direzza ZII Star Spec). Sorry about the wind noise, the camera is in the air stream and this is as good as I could get it.

Last edited by Hobby Racer; 10-23-2019 at 01:39 PM.

Reason: Updated video with better overlays

-

Post Thanks / Like - 1 Thanks, 7 Likes

-

10-22-2019, 07:29 PM

#604

Senior Member

Damn it! That's nice!!!

How do you keep 88psi of oil at all time and all rpms?

Frank

818 chassis #181 powered by a '93 VW VR6 Turbo GT3582R

Go-karted Aug 5, 2016 - Then May 19+21, 2017

Tracked May 27/July 26, 2017

Build time before being driveable on Sep 27, 2019: over 6000h

Build Completed Winter 2021

-

10-22-2019, 08:31 PM

#605

Senior Member

Originally Posted by

Frank818

Damn it! That's nice!!!

How do you keep 88psi of oil at all time and all rpms?

That's the stock Subaru oil system! It has a huge oil pump. For comparison the EJ25 4 cylinders have a 10mm thick pump gear, the EZ36 has a 30mm thick gear. Yeah that's roughly 3 times the volume flow compared to the EJ25 motors. Must have something to do with the keeping the pressure up for the 4 variable valve timing cams this motor has.

In any case, it does drop into the 30's under heavy braking and high G corners (like over 1.3G). Still not bad for a completely stock oil system with no baffles or nothing!

Next year when I switch to slicks though I think it will be too many G's for the stock system. I'm going dry sump this winter.

Last edited by Hobby Racer; 03-10-2021 at 09:31 PM.

-

10-22-2019, 08:35 PM

#606

Senior Member

Hmmm... Is it that the accusump can't recharge fast enough to keep up with demand, or not enough capacity to make it thru the curves or braking.

-

10-22-2019, 09:04 PM

#607

Senior Member

Originally Posted by

flynntuna

Hmmm... Is it that the accusump can't recharge fast enough to keep up with demand, or not enough capacity to make it thru the curves or braking.

It's a 3 quart unit (the largest Canton Racing makes) so its not a capacity issue. I've found that the Accusump does not keep the pressure up. It does provide additional flow if the pump drops out altogether, but it does not provide high pressure. I log oil pressure both before and after the accumulator and have not found it to be very helpful.

-

10-23-2019, 09:00 AM

#608

Something you could make and install over the winter which is a simpler version of Bill Walters Arctangent oil control plate which works great with oil pressure at a consistent PSI. I copied this from a race Subaru team in Europe. I didn't use a Accusump just a 6qt KB pan. EJ Oil Pan Baffle.jpg I made one for my EJ but didn't try it, using Bills plate instead.

Last edited by Mitch Wright; 10-23-2019 at 09:05 AM.

-

10-23-2019, 09:30 AM

#609

Senior Member

Originally Posted by

Mitch Wright

Something you could make and install over the winter which is a simpler version of Bill Walters Arctangent oil control plate which works great with oil pressure at a consistent PSI.

Unfortunately that is not possible with the design of the EZ36 two piece oil pan. Its very weird!

oil pump.png

-

10-23-2019, 11:41 AM

#610

Tazio Nuvolari wannabe

I agree that with slicks and/or any more power you will need a DS system. How do you feel the steering and handling is? Did it understeer at all?

Where is the gas tank? Are you ultimately looking at a racing class, like ST2?

-

10-23-2019, 01:29 PM

#611

Senior Member

Originally Posted by

Scargo

How do you feel the steering and handling is? Did it understeer at all?

The car is very neutral, no push and you have to do something very dumb to get it to oversteer. And when you do it comes back in line with a quick steering correction. I think the Quaife TBD does a great job of getting the power down.

Originally Posted by

Scargo

Where is the gas tank?

The stock tank is in the stock location (behind the seats). The hydro-mat does an amazing job. I have run this down to about 1/2 gallon on track and had no fuel starve issues! In fact it was the session I posted in the previous video.

Originally Posted by

Scargo

Are you ultimately looking at a racing class, like ST2?

Not going for wheel to wheel racing. I just enjoy doing open track events.

-

10-23-2019, 01:45 PM

#612

Senior Member

I just updated the previous video with better data overlays for laps, oil pressure, and max G's in the corners. Helps to see the oil pressure issues in the corners.

-

10-23-2019, 02:37 PM

#613

Interesting, yes it is a bunch different than the EJ. So is that the oil pump/pickup that bolts that is bolted to the bottom of the block? Could additional baffles be welded to the pan? Can the pan and pick up be extended to allow for more oil capacity in the sump?

Last edited by Mitch Wright; 10-23-2019 at 02:43 PM.

-

10-23-2019, 03:14 PM

#614

Senior Member

Originally Posted by

Mitch Wright

Interesting, yes it is a bunch different than the EJ. So is that the oil pump/pickup that bolts that is bolted to the bottom of the block? Could additional baffles be welded to the pan? Can the pan and pick up be extended to allow for more oil capacity in the sump?

Yes, that is the oil pump bolted to the bottom, there is no real pickup to speak of. The lower steel pan is like only 1" deep so no mods would be effective. The capacity could be increased with a deeper lower pan and extended pick but that would push it below the frame and screw up the aero of the rear diffusor. Capacity is not an issue as I already run 10 quarts not counting the Accusump! The issue is the large integrated aluminum upper oil pan which is part of the block assembly and has lots of passages for coolant and such. You can not even remove it without taking the heads off! Here is a couple of pics in progression showing disassembly.

oil pan.png oil pump.png lower_1.png Lower_2.png lower_3.png Block_bottom.png

This winter I will examine it in greater detail when I pull the motor out. Maybe some convoluted control plate can be fabricated but I'm not real hopeful.

Last edited by Hobby Racer; 10-23-2019 at 05:00 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

10-25-2019, 09:22 AM

#615

Ok now I have a better understanding. As far as extending the sump personally I would opt for the additional capacity in the sump over the very slight disruption under the car. I am of the opinion the hole cut in the panel for the pan will have little effect on the aero.

Last edited by Mitch Wright; 10-25-2019 at 01:24 PM.

-

10-30-2019, 02:15 AM

#616

I hope you find a way to dry sump it!

You probably have this already, but for others that are interested: the Technician Reference Booklet 6 Cylinder Boxer Engine Series: https://1drv.ms/b/s!AjtLSJvxEnlPlmEF7hC6eTL5FPkb

Note the EZ30 and EZ36 oil systems are different. The EZ30 may be easier to dry sump if one were to use the Aviad style pumps most of us are using and modify the stock upper oil pan with a connection on the outside for the dry sump return and on the inside of the pan up to the oil pump intake. Similar to what we do now with the ARE pan.

EZ30 oil system:

Last edited by Sgt.Gator; 10-30-2019 at 02:21 AM.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

Palatov DP4 - ICSCC Sports Racer

-

10-30-2019, 07:56 AM

#617

Senior Member

Originally Posted by

Sgt.Gator

Yes, I have all the H6 tech manuals for both the EZ30 and the EZ36. You are right in that the EZ30 would be easier to dry sump. But I enjoy the challenge! I am planning on using a hybrid system like what every one else has done on the EJ motors. I will by using twin scavenge stages with 1.40" spur gears and the stock oil pump for the pressure side. The EZ series of motors displace way more oil than the EJ motors so I need much larger scavenge stages.

-

10-30-2019, 12:16 PM

#618

Originally Posted by

Hobby Racer

Yes, I have all the H6 tech manuals for both the EZ30 and the EZ36. You are right in that the EZ30 would be easier to dry sump. But I enjoy the challenge! I am planning on using a hybrid system like what every one else has done on the EJ motors. I will by using twin scavenge stages with 1.40" spur gears and the stock oil pump for the pressure side. The EZ series of motors displace way more oil than the EJ motors so I need much larger scavenge stages.

I was surprised when you said the EZ36 had a 30 cm pump ( I think you meant mm). The EZ30 has a 13 mm pump, just slightly larger than the 10,11,12 mm pumps used on EJ motors. I'm wondering if the EZ36 spins the pump at a much lower speed because of the way it connects to the drive shaft, so it's actually pumping the same volume? I've never seen specs on the EZ36 pump.

Here's the specs on the EJs:

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

Palatov DP4 - ICSCC Sports Racer

-

10-30-2019, 12:27 PM

#619

Senior Member

Originally Posted by

Sgt.Gator

I was surprised when you said the EZ36 had a 30 cm pump ( I think you meant mm).

Oops, yes I meant mm.

Originally Posted by

Sgt.Gator

I'm wondering if the EZ36 spins the pump at a much lower speed because of the way it connects to the drive shaft, so it's actually pumping the same volume? I've never seen specs on the EZ36 pump.

The EJ's and the EZ30 pump at crank speed. The EZ36 pumps at cam speed (or very close), so about 1/2 crank speed. Even so the flow specs are way higher than the EJ's

Here are the oil flow specs from FSM. Check out the flow rate at 6,000 RPM (which is only ~3,000 revs at the pump). Its 87.5 quarts per minute!

H6_Oil_Pump_Specs.png

Last edited by Hobby Racer; 10-30-2019 at 05:14 PM.

-

10-30-2019, 01:45 PM

#620

Originally Posted by

Hobby Racer

Oops, yes I meant mm.

The EJ's and the EZ30 pump at crank speed. The EZ36 pumps at cam speed (or very close), so about 1/2 crank speed. Even so the flow specs are way higher then the EJ's

Here is the oil flow specs form FSM. Check out the flow rate at 6,000 RPM (which is only ~3,000 revs at the pump). Its 87.5 quarts per minute!

H6_Oil_Pump_Specs.png

There's why your Accusump can't keep up! 3 quarts is gone in 2 seconds... and after 1 qt of the 3 is gone the Accusump pressure drops rapidly as the air side expands. So you really have about 3/4 of one second of good pressure from your Accusump. Or maybe my math is challenged......

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

Palatov DP4 - ICSCC Sports Racer

-

10-30-2019, 05:21 PM

#621

Senior Member

Originally Posted by

Sgt.Gator

There's why your Accusump can't keep up! 3 quarts is gone in 2 seconds... and after 1 qt of the 3 is gone the Accusump pressure drops rapidly as the air side expands. So you really have about 3/4 of one second of good pressure from your Accusump. Or maybe my math is challenged......

Yes, its clear that the Accusump is not well suited to a motor that needs high pressure / high volume oil.

I am surprised at how well the stock oil system works though. In a street setup you would never need to upgrade. Even tracking it hard like I'm doing, you never lose oil pressure completely, it just drops into the 30's briefly. But I will feel much better when I can get it to have constant oil pressure

Last edited by Hobby Racer; 10-30-2019 at 09:19 PM.

-

11-04-2019, 02:27 AM

#622

2009 Porsche 911 | Engine Oil Sump Test Rig |

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

Palatov DP4 - ICSCC Sports Racer

-

12-11-2019, 06:45 PM

#623

Senior Member

Frame mods for the 6 speed install

Winter is here, and now its time to get working on the 818R upgrades! First on my list is getting the frame modified to accept my Subaru 6 speed. I cut out the rear X brace to allow the transmission to fit properly. I added back some 1" tubing to triangulate the rear suspension pickup points and tie the left and right side together. I spaced the bracing to allow full access to both drain plugs.

I may cut out a shallow scallop in the rear most brace where the tail housing touches to further lower the transmission; you can see were it touches in the 3rd picture below.

IMG_20191210_120514463.jpg IMG_20191210_120421388.jpg IMG_20191210_120409074.jpg IMG_20191210_120359785.jpg IMG_20191210_142654572.jpg

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-11-2019, 06:55 PM

#624

Senior Member

I ended up getting a 2005 JDM 6 speed out of a Legacy Spec B car. The 06 /07 STI 6 speeds that are supported by the FFR 2WD conversion are very expensive and getting hard to come by. It is very easy to convert a non-DCCD 6 speed to 2WD.

I plan on doing a detailed write up in a future post on how I selected and converted my 6 speed for those wanting to install a 6 speed that is not supported by FFR. I will probably post it in the engine & transmission section so it will be easier to find for future builders.

Last edited by Hobby Racer; 01-04-2020 at 02:31 PM.

Reason: added link to conversion post

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

12-11-2019, 07:04 PM

#625

Senior Member

Thanks racer

I'll be looking for your how to on this conversion

Jet

-

12-12-2019, 07:01 AM

#626

Tazio Nuvolari wannabe

Originally Posted by

Hobby Racer

I ended up getting a 2005 JDM 6 speed out of a Legacy Spec B car. The 06 /07 STI 6 speeds that are supported by the FFR 2WD conversion are very expensive and getting hard to come by. It is very easy to convert a non-DCCD 6 speed to 2WD.

I plan on doing a detailed write up in a future post on how I selected and converted my 6 speed for those wanting to install a 6 speed that is not supported by FFR. I will probably post it in the engine & transmission section so it will be easier to find for future builders.

Are you just playing on the track with your 818? It's interesting that I fit a 6MT in mine and did the upgrades, including close-ratio fifth and sixth then decided to go with a Rallispec hardened 5MT built for an 818 and racing! I am just playing, but I forsee eventually selling it as a viable race car and wanted to save the 100 pound difference.

What did you pay for that Spec C tranny? Will look forward to seeing what you do and how.

-

12-12-2019, 07:41 AM

#627

Senior Member

Originally Posted by

Scargo

Are you just playing on the track with your 818? It's interesting that I fit a 6MT in mine and did the upgrades, including close-ratio fifth and sixth then decided to go with a Rallispec hardened 5MT built for an 818 and racing! I am just playing, but I forsee eventually selling it as a viable race car and wanted to save the 100 pound difference.

What did you pay for that Spec C tranny? Will look forward to seeing what you do and how.

I just "play" on track, doing HPDE's and open track lapping days at various tracks in the northeast. If you recall I custom built my 5MT with a close ratio 5th gear and a Quaife TBD diff and I love it, but my plans include forced induction in the future and the 5MT would never hold up to the increased power levels so I am biting the bullet early and building the drive train to handle the power even though I am not there yet.

The extra weight is big detractor, but its unavoidable if you want the extra strength the 6 speed offers.

I payed $1,000 for the transmission from a JDM importer in NYC. The non-DCCD aka viscous center diff transmissions go for a lot less because the Subaru guys don't want them. For our purposes they are the best units to get! Plus they are usually in excellent shape since they have lived calm and peaceful lives in Legacy's and Outback's and are generally not raced or modified like the STI units are.

More to come as I tear down and rebuild my 6MT. I plan to lighten the unit as much as possible and change 5th & 6th gears to longer ratios.

Last edited by Hobby Racer; 12-16-2019 at 09:48 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-12-2019, 09:34 AM

#628

Yes, I love Technology

Originally Posted by

Jetfuel

Thanks racer

I'll be looking for your how to on this conversion

Jet

Me too - thank you

-

12-16-2019, 09:46 PM

#629

Senior Member

Just a quick update, I compared the weight of my 5 speed against the 6 speed and was quite surprised. Both were weighed bare, without fluid.

6MT 155 lbs

5MT 115 lbs

Only a 40 lb difference, much less than expected! I was able to remove nearly 20 lbs from the 6MT by removing both rear transfer gears and the entire center diff. I have figured out 2 different ways to convert this unit to FWD and will outline each in a future post. I will be going with the most time intensive but lightest variant. And yes, all of them involve some degree of welding, with the lightest also involving some machine work.

Last edited by Hobby Racer; 01-04-2020 at 10:27 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-21-2019, 10:00 AM

#630

Senior Member

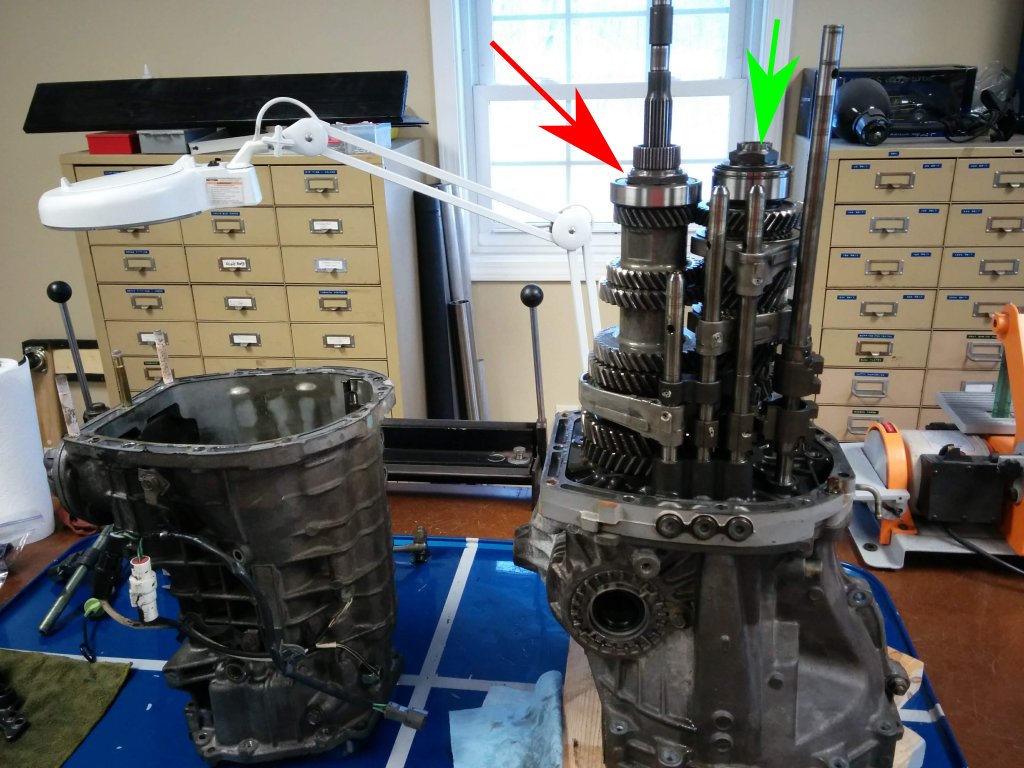

6MT Tear Down

Starting the tear-down of the 6 speed. The gears, shafts etc in the 6 speed are super heavy duty! I can see why these can take a lot of torque and abuse. From my initial evaluation, I think I can swap out the 5th & 6th gears without disassembling the ring & pinion section. That will save me from having to redo the backlash settings.

I have to fabricate some special tools to disassemble and reassemble the main shafts. The 55 mm nut (red arrow) that holds the main shaft gears is torqued to 420 ft lbs and you can't get a socket on it! The other shaft (green arrow) has a 38 mm nut that is torqued to 289 ft lbs.

The two special tools I need to fabricate are show below. The black base plate with the splined holes is a special tool Subaru sells for $900! The funky 55mm wrench just behind it sells for around $300! I'll be making my own.

special_tools.jpg

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-21-2019, 01:26 PM

#631

Tazio Nuvolari wannabe

I have to scratch my head and try and remember... I did at least one 5th & 6th close-ratio upgrade without any special fixturing. I did buy a 3/4" drive impact wrench from Harbor Freight for the job. I believe I was able to have an assistant hold onto the cluster (somehow) and I was able to impact it off and back on.

You must use an extra pair of hands to get the case back over the gears when reassembling.

-

12-26-2019, 04:39 PM

#632

Senior Member

So the factory service manual says you need to remove both the main shaft gear assembly and the drive shaft gear assembly, the 3 shift rails/forks and the reverse shift rail/fork and gear set all at the same time! They do mention that a second person is needed to help hold everything together while you lift everything up and out. Well I work alone and the wife is not keen on getting greasy in the garage

Here is my method for doing it by yourself. I wrapped the entire assembly in thin plastic film, think saran wrap but larger and stronger. It is used mostly in moving applications. Got it at Walmart in the packing section where you find boxes and packing peanuts.

This made it easy to keep everything aligned and tight together while I lifted everything out.

IMG_20191226_103702.jpg

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

12-26-2019, 04:51 PM

#633

Senior Member

My special fixture and service tool worked great. I made a torque extension for my torque wrench that allows my 3/4" drive 300 ft lb torque wrench to reach the 420 ft lb required to remove / install the nut on the driven shaft gear assembly. I cut out a 15" long section of 1/4" flat stock and welded a 3/4" to 1/2" impact drive adapter to one end. This allows me to connect my torque wrench securely to one end. On the other end I carefully cut out and filed a 55 mm hexagon to fit over the nut.

IMG_20191224_142829664.jpg IMG_20191224_142846372.jpg

To hold the shaft assembly securely while applying that much torque, I welded the gutted out center differential to a large piece of angle iron scrap I had laying around and fastened that to my large work table. The center diff has the splined hole that fits over the splines on the end of the drive shaft gear assembly, ensuring it can not move. Here are pics of it in action.

IMG_20191226_114615.jpg IMG_20191226_114621.jpg IMG_20191226_114642.jpg

Now I have the new 5th & 6th gear set on the shaft, but I'm waiting for Subaru to get the 55 mm nut shipped in so I can finish up and move on to the other gear set.

Last edited by Hobby Racer; 12-26-2019 at 09:39 PM.

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

12-27-2019, 07:28 PM

#634

Tazio Nuvolari wannabe

Nice fixture. Taking it apart is easy. Assembly requires a helper. Still not sure how I torqued mine other than the impact and putting the nut back to the same spot I marked when I disassembled it.

-

12-27-2019, 09:22 PM

#635

Senior Member

Originally Posted by

Scargo

Taking it apart is easy. Assembly requires a helper.

Yes, still trying to figure that part out

Dying to get the new parts in so I finish this up and get on to the FWD conversion. I can't cut up the center diff section until I re-torque the main shaft nut, which is welded to my fixture at the moment.

Last edited by Hobby Racer; 12-27-2019 at 09:25 PM.

-

12-27-2019, 10:13 PM

#636

Yes, I love Technology

We see eye to eye - I believe in making special tools too. Nice work!

-

12-30-2019, 09:58 AM

#637

Nice work, I too really enjoy making special tools as needed.

-

01-01-2020, 02:51 PM

#638

Senior Member

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

01-01-2020, 03:12 PM

#639

Senior Member

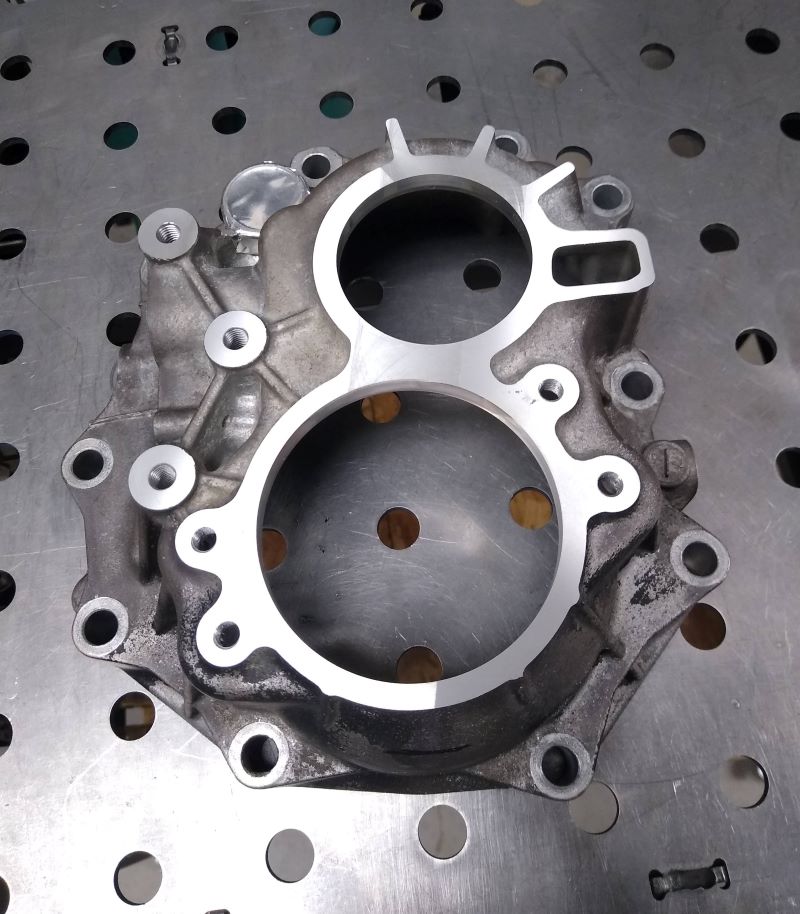

Converting to FWD (locking the main and pinion shafts together)

I will be doing a separate detailed write up on converting a 6 speed to FWD without using the FFR adapter later. For now here is a quick update on my progress.

I used a plasma cutter to cut out the outer splined section of the center differential. The rest of the center differential is not used. After grinding and trimming the outer splined section is ready to be welded to the inner splined section. It's important to tack weld the inner and outer splined sections together on the transmission shaft to ensure they line up perfectly. Any misalignment and the adapter will not slide onto the shaft after welding. After tacking, remove from the shaft and fully weld the circumference were the two parts meet. To finish it up I need to use my brother in-laws Bridgeport to put in a set screw or two to keep the adapter from walking back off the shaft.

IMG_20200101_101308243.jpg IMG_20200101_103747845.jpg IMG_20200101_103828926.jpg IMG_20200101_111723036.jpg IMG_20200101_124329811.jpg IMG_20200101_125903172.jpg

Last edited by Hobby Racer; 01-04-2020 at 02:33 PM.

Reason: Added link to conversion thread

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

01-02-2020, 06:29 PM

#640

Senior Member

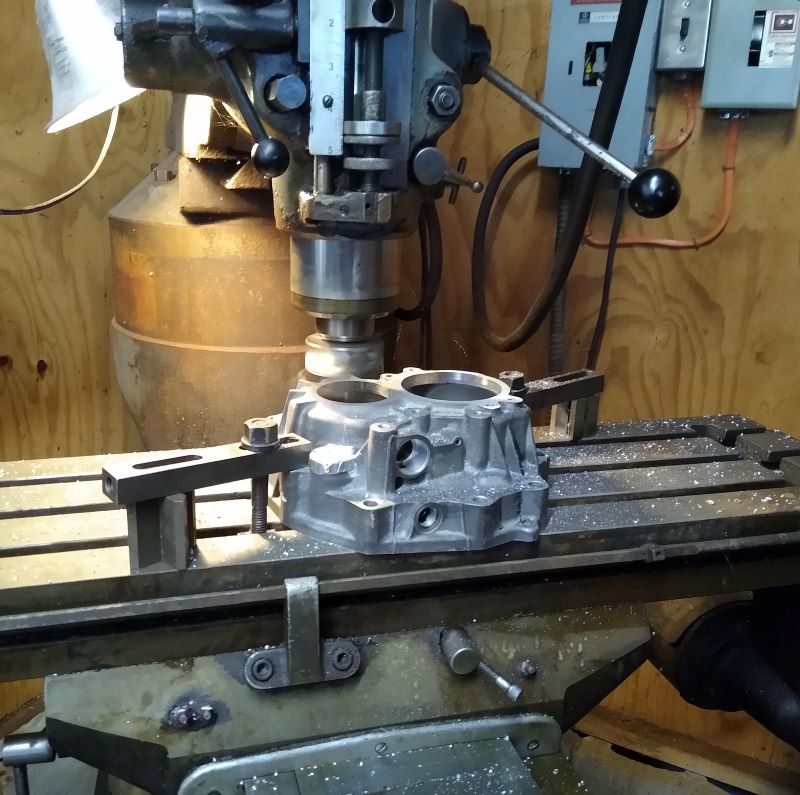

Shortening the 6MT case Part 2

I got over to my brother in-law's garage to mill the tail section to its final dimensions. Now I need to cut some plugs and weld them to the case to close up the holes.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote