-

02-18-2022, 02:56 PM

#321

Senior Member

My complete kit (delivered mid-Oct. 2020) came with two mechanical as well as two no-load LED flashers without ground pigtails (as shown above). I agree it is strange your kit came with the pigtails, and so did Edwardb's on two different kits/orders placed years apart.

I have two no-load LED flashers with ground pigtails on order. All of my testing has been with the kit supplied no-load LED flashers. Since I'm having no other electrical issues (yet!) associated with the very dim LED behavior, I'm hoping the new flashers will solve my issue.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-19-2022, 09:26 PM

#322

Senior Member

Coyote/TKO Drivetrain Prep Started

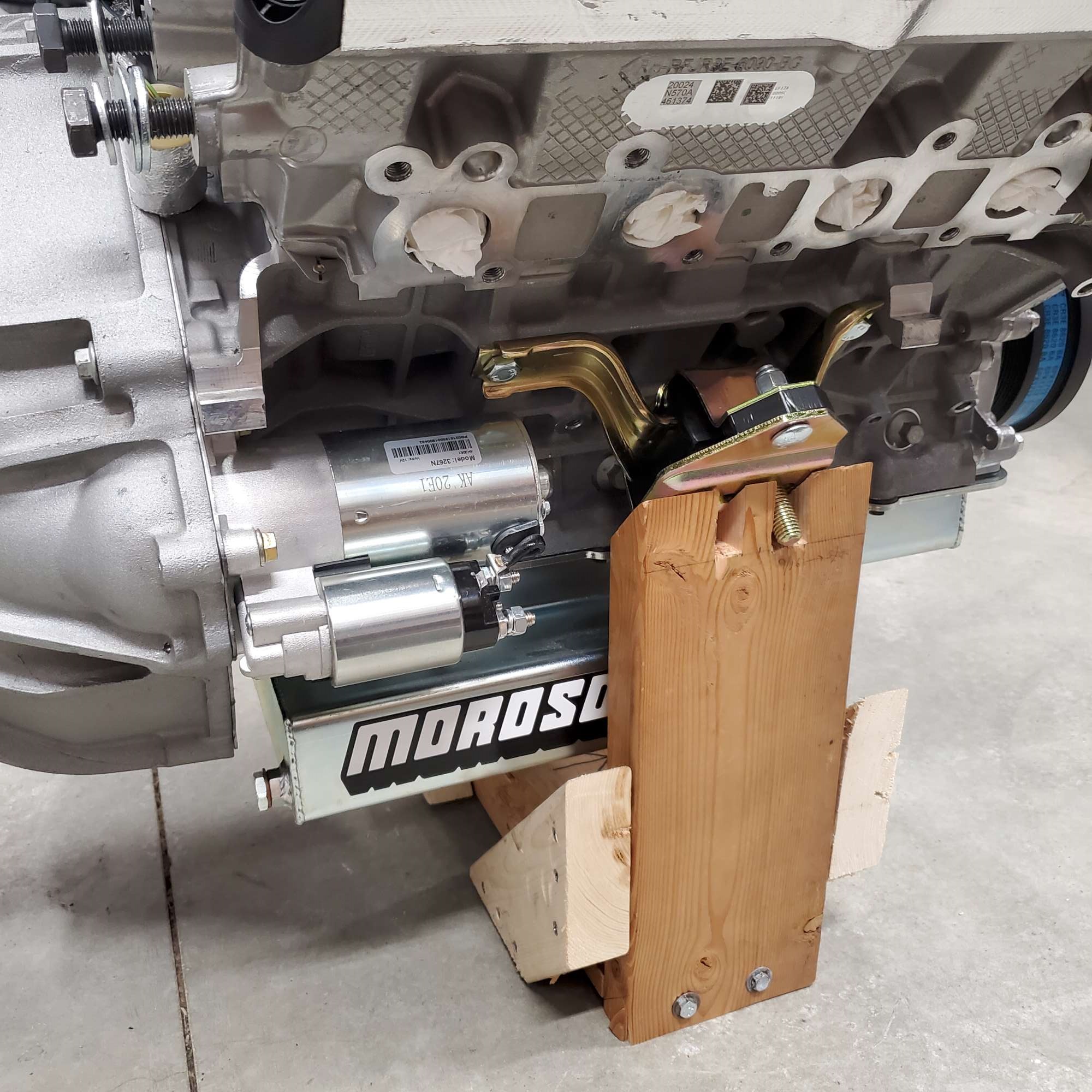

I was able to start prep. on my Coyote/TKO drivetrain today. The stand Forte supplies are heavy duty and nice. However, they block installation of the starter and motor mounts. I noodled on this for a while and reached out to a couple Coyote forum members for their input. Ultimately, I decided to build a simple wood cradle. Of course, I copied the design from the forum (thanks, Edwardb!).

Before I made the cradle I was resting the motor on scrap 2" x 12" wood blocks. The TKO was also supported by blocks in the rear. However, I just wasn't comfortable with all that weight on the Moroso oil pan. No need to introduce unnecessary risk. I think this is much better.

Assembling the motor mounts with the supplied 1/2" spacers was pretty straightforward. I really appreciate F5 powder coating these so I didn't have to. I used an impact driver to pull in the 3/8" x 1.5" carriage bolts, as the square shoulders put up a fight. The build manual does not specify torque for these, so I torqued to 30 ft-lb per the generic torque chart at the back of the manual. It provides recommended torque values for many common size bolts/thread counts. For the 10 MM bolts I torqued to 33 ft-lb--referenced the same chart.

With the Forte stands out of the way there was ample clearance to install the starter. So, checked that task off the list.

Much appreciation to Coyote builders Edwardb and JohnK for letting me bounce off questions on these topics. Very helpful!

Last edited by 460.465USMC; 02-19-2022 at 09:29 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-21-2022, 08:18 PM

#323

Senior Member

Front Running Light LED Conversion...Solved

My no-load LED flashers with ground pigtail arrived. I plugged them in and tested, and no more dim, half-hearted LEDs. Now the left and right front turn signals, and hazard-flasher operation work as expected. This puts me at LEDs on all four corners. Boy, those LEDs are bright, and omni-directional! Really glad this isn't turning into an electrical-feedback-ghost chase.

Thanks again to the forum for the valuable input, and to Papa for recommending these (~$12 each): CEC Industries 12V No-load LED Flashers

Last edited by 460.465USMC; 03-04-2022 at 01:21 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

02-22-2022, 12:14 PM

#324

Senior Member

Originally Posted by

460.465USMC

My no-load LED flashers with ground pigtail arrived. I plugged them in and tested, and no more dim, half-hearted LEDs. Now the left and right front turn signals, and hazard-flasher operation work as expected. This puts me at LEDs on all four corners. Boy, those LEDs are bright, and omni-directional! Really glad this isn't turning into an electrical-feedback-ghost chase.

Thanks again to the forum for the valuable input, and to Papa for recommending these ($12 for a pair):

CEC Industries 12V No-load LED Flashers

Outstanding! Love it when it when you get to the it works stage. Always feels great.

Keep up the good work Chris, you will be go karting before you know it.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-22-2022, 01:56 PM

#325

Senior Member

Thanks, Jesse! Definitely glad this one seems to be put to bed! I have one more LED bridge to cross (headlights), so hope that one goes well. I can’t wait for first start…will be a while at my tuuuurtlee pace.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-27-2022, 10:38 PM

#326

Senior Member

Chris, just catching up on your build. It looks fantastic. Great job on the dash!

MKIV Complete Kit #9822 l BluePrint 347 EFI l TKO600 l Power Steering l Heater/Defrost l

Build Thread

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-28-2022, 02:02 PM

#327

Senior Member

Thanks, JB! It was quite the journey. I learned a lot…still learning a lot!

Not sure what your winters are like, but I hope COBRA XX is seeing some fun driving miles.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-04-2022, 10:11 PM

#328

Senior Member

LED Headlights | Weatherpacks | Tool Chest

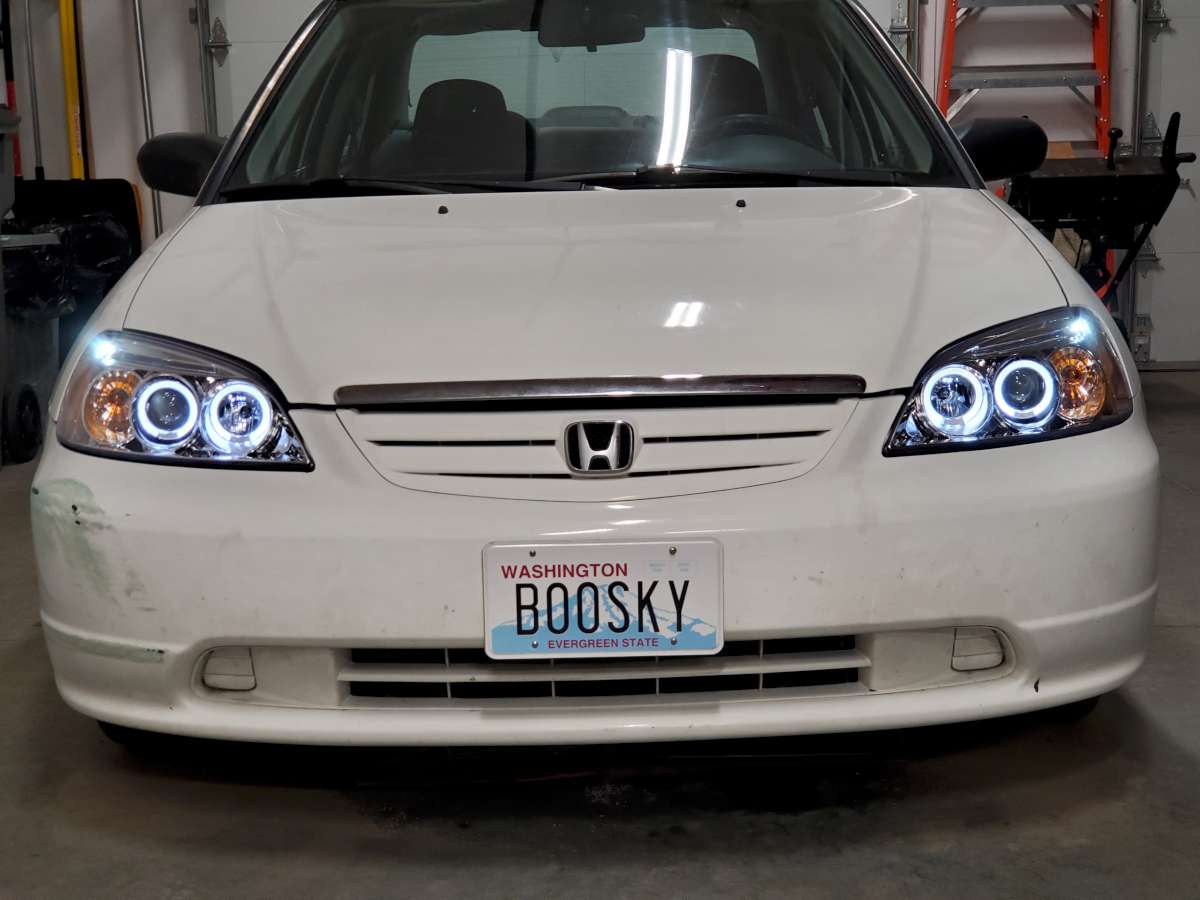

The Lumen LED projector headlights arrived: Lumen 7" LED Projector Headlights. I decided to go with LED projector style lights because of the big improvement they provide for night driving. My house is in a rural area, so good headlights are must. And, they come with halo DRLs. The halos will do amber switchback, but I'm not using that feature. The DRLs will increase my visibility to oncoming traffic. Not a bad thing. I know these are not for everyone, but just what I was looking for.

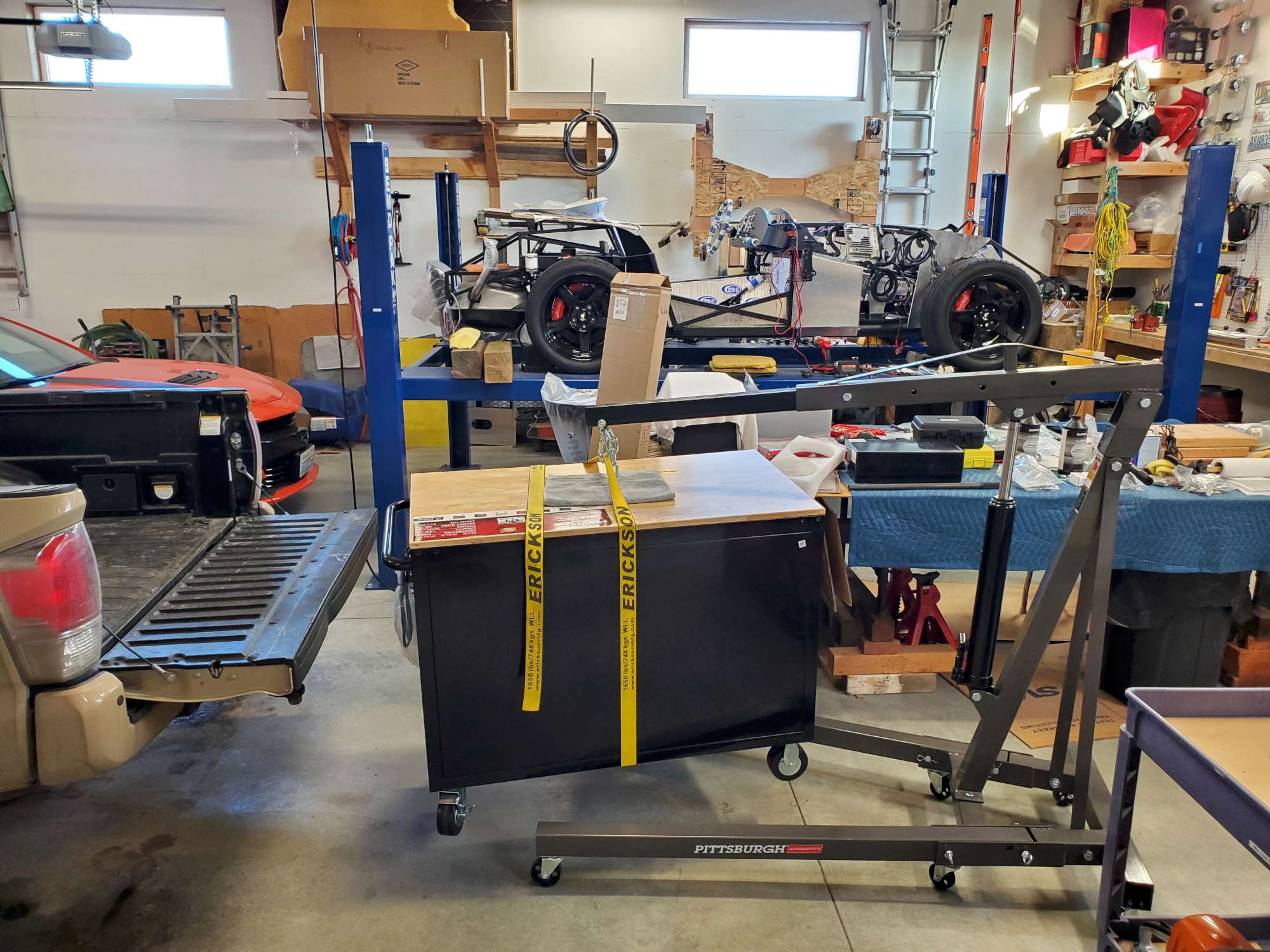

But first, I was able to rebuild my tool budget a bit, so picked up a Husky tool chest. The engine crane was very useful, allowing me to unload it myself.

Very handy rolling chest with wood-top work surface. Drawers handle 100 lbs each, and come with cushioned, grip liners. This means I'm "moving-on-up" from my three-drawer Craftsman, which I've been using since the mid-90s. This is a great upgrade for me!

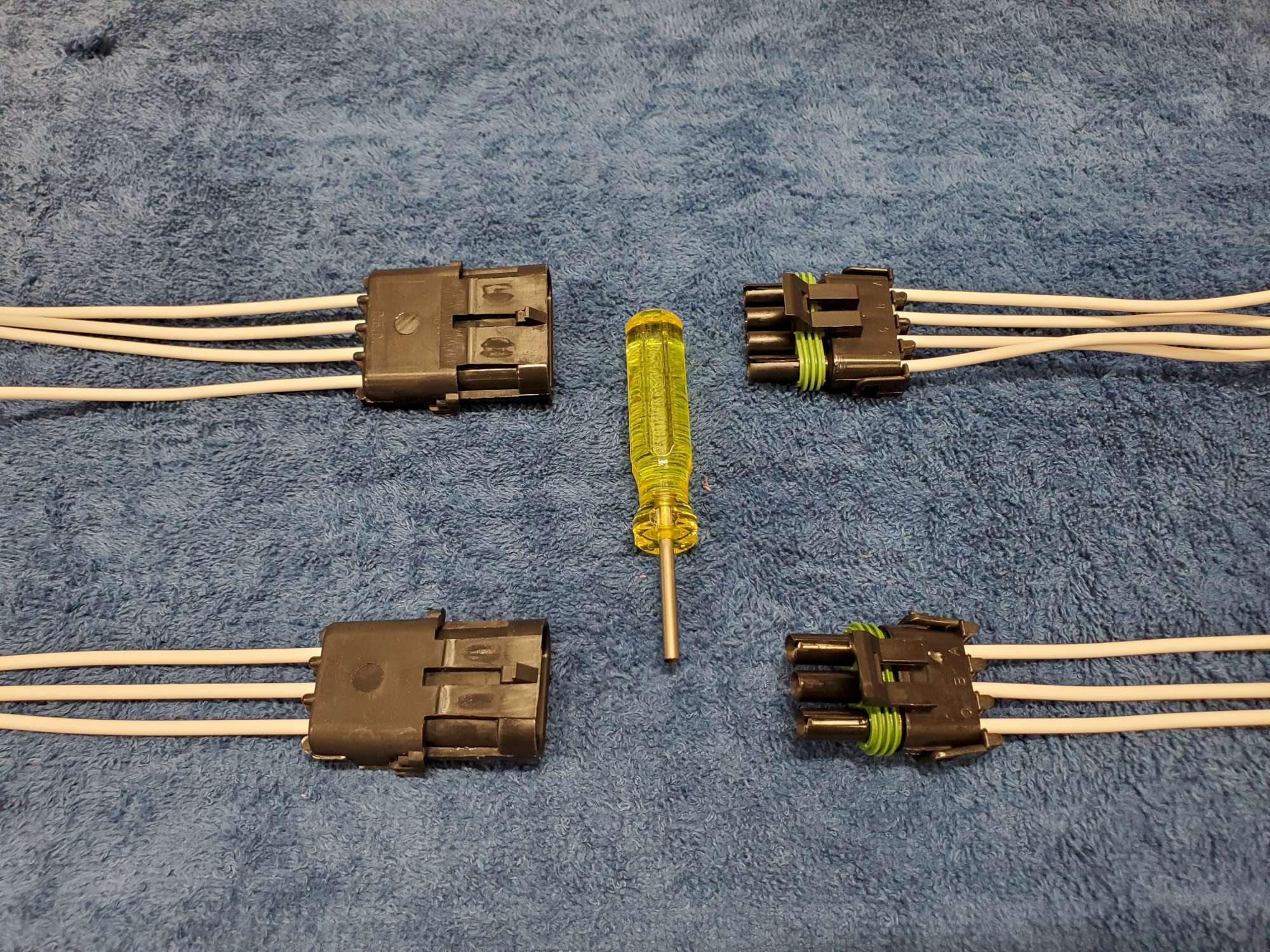

I knew I wanted to use Weatherpack connectors on all four corners; however, just wasn't sure about purchasing a quality crimper at $125+. While researching crimpers, I stumbled upon pre-made Weatherpacks through Del City. I was surprised at how low the prices are per unit. And, they come with a 10 inch pigtail. They use 14 gauge, automotive rated wire. Sold. Of course, this means I introduce additional connection points when I solder in the pigtail ends. But, I'm confident on the durability of soldered connections, and it just cost me a little more time.

The four-way connector is for my headlight connection. Since I'm running LED DRLs, I needed the additional wire. Picked up their $6 pin removal tool while I was at it...just in case.

Headlights soldered into Weatherpacks, and run through bucket. Man, the wires coming out of the headlight are small. Not easy to work with, but I was able to make solid, soldered connections.

Once I was ready to test my wiring I couldn't help myself, and rigged up a way to hold the headlight in place while I tested operation. I'm using one of the two accessory outputs from the Digital Guard Dawg ignition module. This means the DRLs come on automatically when the engine starts, and turn off when ignition turns off. The running light below it still illuminates only with headlight switch. So, for daytime driving headlights will operate in DRL mode. The halo stays on when I turn on the headlights (both for low and high beam). The only bummer is I had to cut off the 3 pin connector, so the five year warranty is probably void.

Out of curiosity I measured the halogen and LEDs to see the difference in Amp draw:

- Halogen low beam: 2.7

- LED low beam: 1.77

- Halogen high beam: 4.2

- LED high beam: 3.66

Last edited by 460.465USMC; 03-05-2022 at 01:27 PM.

Reason: Added Amp draw comparison

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

03-06-2022, 10:52 AM

#329

The build it looking fantastic. The headlights will be nice...

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-06-2022, 01:13 PM

#330

Senior Member

Thanks, Carl! I'm still having a blast on the build.

Looks like I can tidy-up my work surfaces since my electrical will wind down for a bit. The picture above was a little startling. Time to reset as I transition to drivetrain prep.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-07-2022, 02:42 PM

#331

Senior Member

Coyote Cooling Fan Routing - Clearance Question

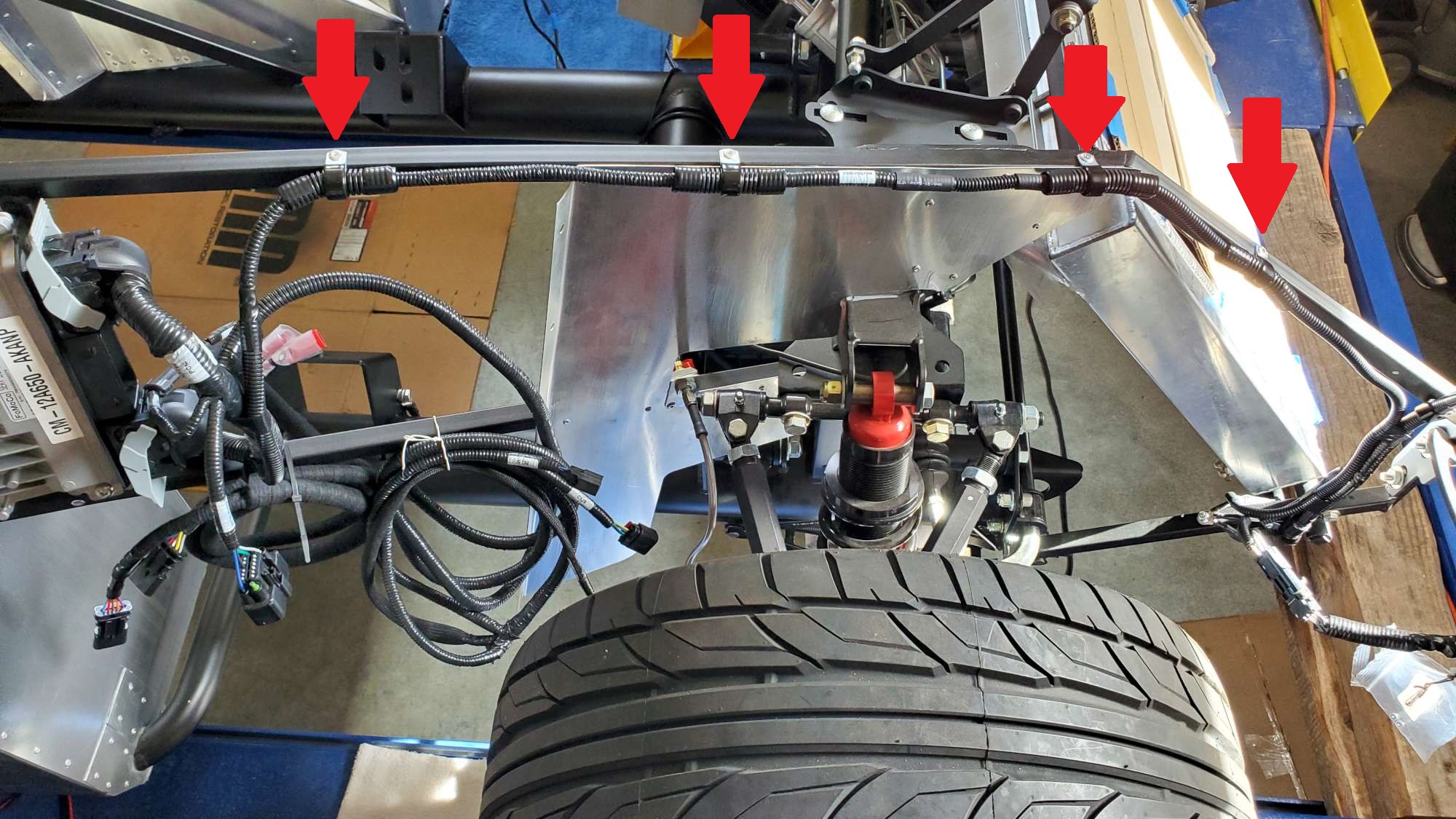

So, I should have asked before, so hoping I'm okay here. I'm using the Coyote PCM to control cooling fan operation. Routed the orange cooling fan wire from the PCM along the PS upper 3/4" tube down to the bottom of the radiator. Then across to the fan wire connector. (Man, was that plastic two-prong connector a bear to slide together!) I hope I never have to pull it apart and re-connect!

My question is whether there are any clearance concerns from the clamps (red arrows) I fastened to the top of the 3/4" tube. Since the F5 supplied Coyote PCM bracket also attaches to this same tube I assumed it would be okay. Am I good here?

Second question: Before I soldered the PCM orange fan wire to the F5 supplied blue fan wire I tested the fan. It works! I can definitely hear it! Granted, it was in my garage with no other competing ambient noise. I had a tip from Fman about his experience with another Cobra owner who runs the Coyote that the noise can be pretty annoying. Anyone with Coyote experience have an opinion on cooling fan noise? I think I read it typically doesn't run much with cruising-type driving around on surface streets, even during warmer summer temps.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-07-2022, 02:56 PM

#332

Chris,

You should be fine with the way you did it. The top of that frame simply gets a piece of foam that will cover those clamps.

Dave

-

03-07-2022, 03:19 PM

#333

Senior Member

That's good news! Thanks, Dave!

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-07-2022, 11:33 PM

#334

Senior Member

Agree shouldn't be an issue. Kind of overkill (my opinion...) with the double convolute. The smaller tube in a cushioned clamp is fine. Will be hidden so maybe no reason to change. But I wouldn't bother with that same treatment elsewhere. Regarding the fan, you can hear it when stopped and at idle. Not so much while driving. The Gen 2 had an issue that Ford programmed it with limits that made it run almost constantly. Which many complained about. I haven't found that to be the case with my Gen 3 in my Coupe. It seems to run only when needed.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

03-08-2022, 12:57 AM

#335

Senior Member

Chris if you think the fan noise will bother you definitely have the option to go with the Flex A Lite 3000 CFM, I can't even hear mine running at idle. I actually have to look at my volt gauge drop a little so I know it has kicked on. Much easier to change it up now than after the car has the body on it. Just something to consider but the FFR fan will also definitely get the job done.

https://www.summitracing.com/parts/flx-105390

Last edited by Fman; 03-08-2022 at 10:08 AM.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

03-08-2022, 01:18 PM

#336

Senior Member

Originally Posted by

edwardb

Agree shouldn't be an issue. Kind of overkill (my opinion...) with the double convolute. The smaller tube in a cushioned clamp is fine. Will be hidden so maybe no reason to change. But I wouldn't bother with that same treatment elsewhere. Regarding the fan, you can hear it when stopped and at idle. Not so much while driving. The Gen 2 had an issue that Ford programmed it with limits that made it run almost constantly. Which many complained about. I haven't found that to be the case with my Gen 3 in my Coupe. It seems to run only when needed.

Hi Paul. I didn’t have the right size cushion clamps on hand to fit the smaller convolute, and I didn’t like the sloppiness. I haven’t done it elsewhere, but I’m sure you’re right on it being overkill…but at least I know it’s not going anywhere!  . Also good to know it will be fine if I run into this again. Appreciate the confirmation re: the clearance issue.

. Also good to know it will be fine if I run into this again. Appreciate the confirmation re: the clearance issue.

Thanks for the reminder on the Coyote Gen 2 v. Gen 3 cooling fan duty cycle. I forgot about that. Good to know you don’t hear it when driving.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-08-2022, 01:22 PM

#337

Senior Member

Originally Posted by

Fman

Chris if you think the fan noise will bother you definitely have the option to go with the Flex A Lite 3000 CFM, I can't even hear mine running at idle. I actually have to look at my volt gauge drop a little so I know it has kicked on. Much easier to change it up now than after the car has the body on it. Just something to consider but the FFR fan will also definitely get the job done.

https://www.summitracing.com/parts/flx-105390

Really appreciate the feedback and link to quieter fan, Travis. I’m going to sleep on this one…tapping the brakes on the upgrade train. Do my kids really need an inheritance?

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

03-13-2022, 11:27 PM

#338

Senior Member

Wiring loose ends | Coyote Install Prep Continues

A few minor updates for last week's activities.

I've probably said this a couple time at least, but glad to be doing something different (anything!) than wiring. However, wanted to wrap up a few wiring loose ends on the list. So, as already mentioned (and shown) I secured the front fan wire from the PCM along the top 3/4" tube down to the fan. Then, similar cushioned clamps and rivets to secure the front wiring harness in the same fashion on the DS.

Then, secured front harness and cooling fan wiring along the bottom of the radiator with cushioned clamps.

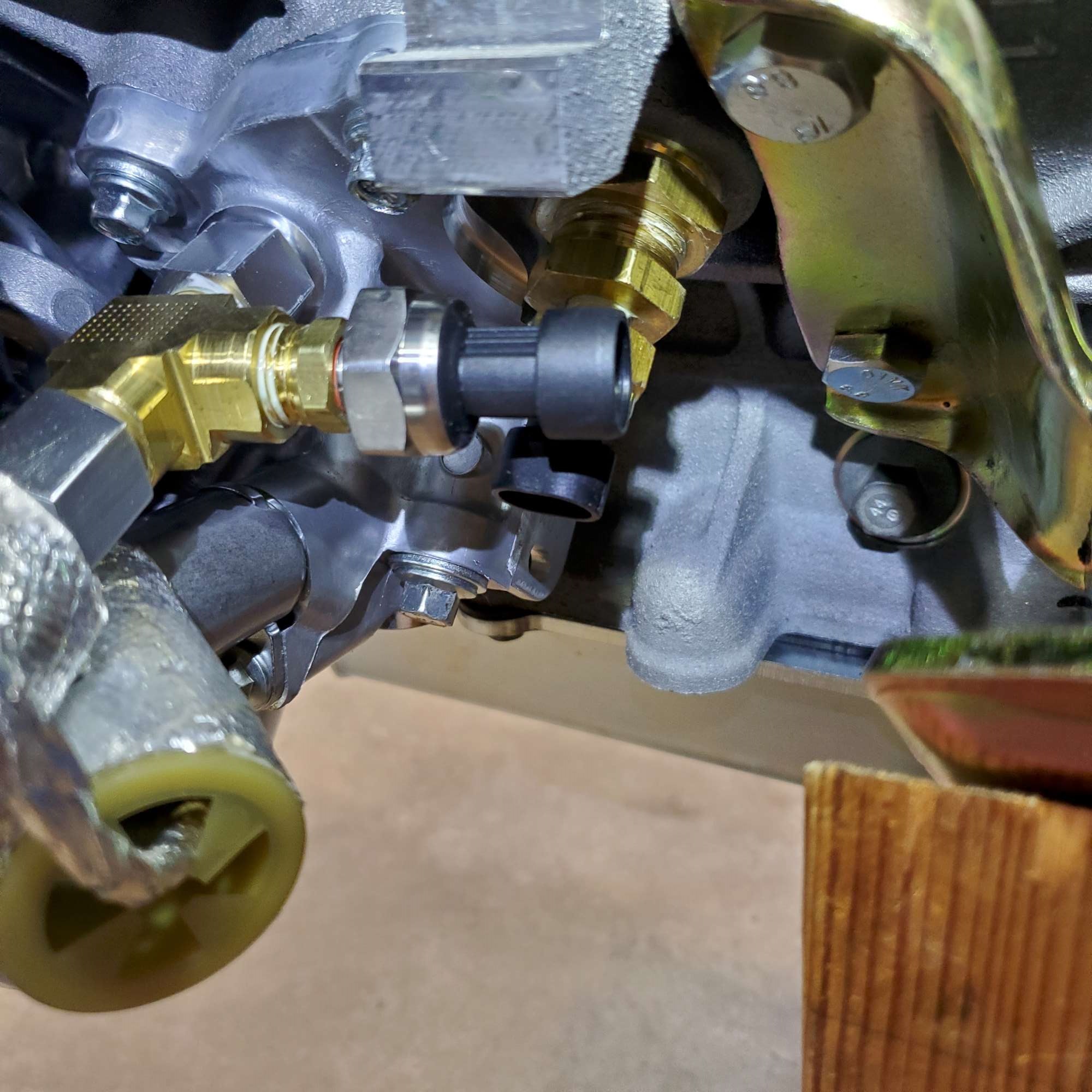

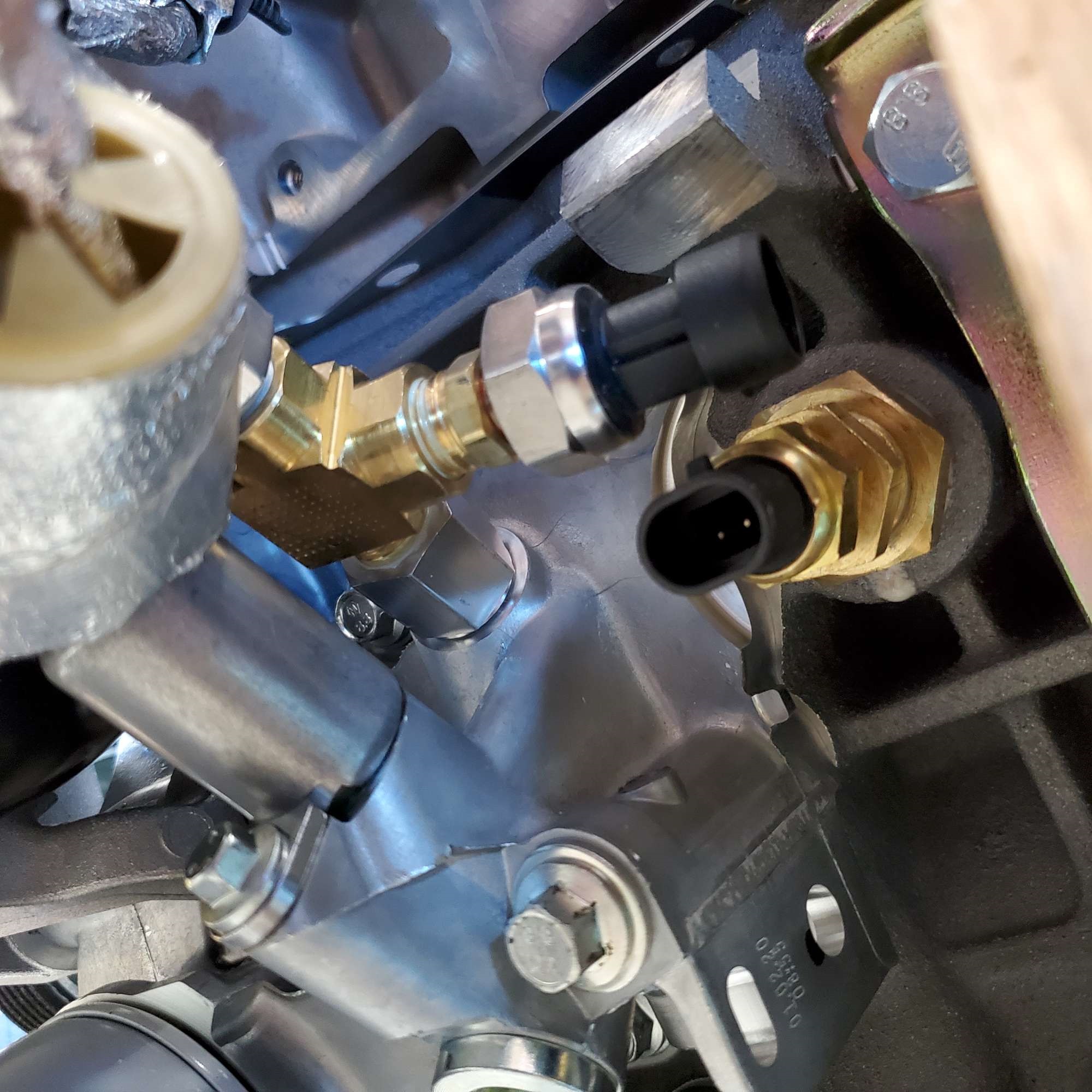

After that it was back to drivetrain prep. for drop-in. Installed the adapter chains for the oil pressure and water temp. sensors. I used Permatex thread sealant instead of the teflon tape called out in the F5 installation manual. I positioned the oil pressure sensor away from the alternator, and 90 deg. away from where the header will be directly above. Hopefully, this won't be a clearance issue during drivetrain installation.

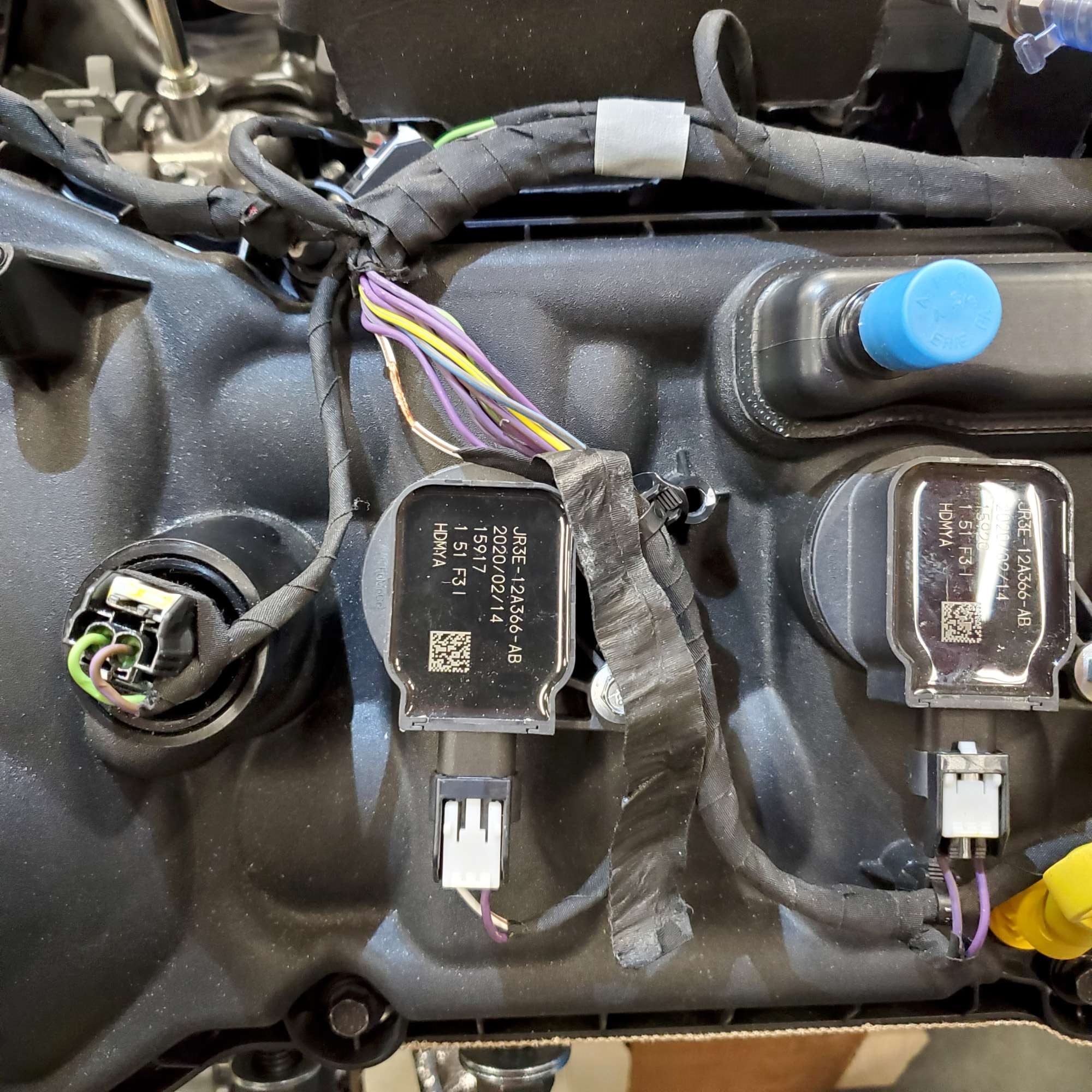

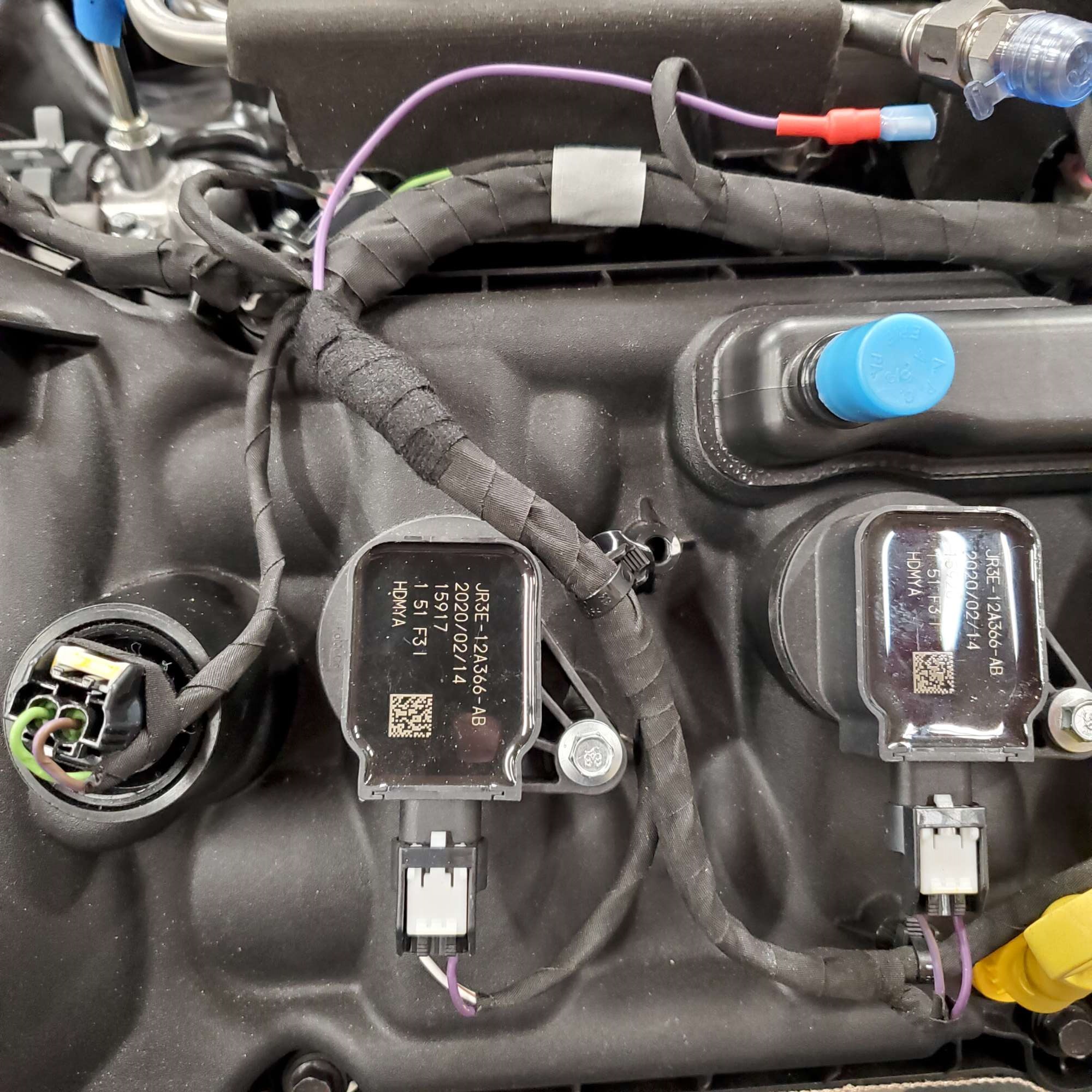

Then, I decided to tap into coil-on-plug #5. Peeled back about 1/2" of wire and soldered on a purple wire to match the one coming through the firewall from the Speedhut tach. I liked how Edwardb did it on his Gen 3, so I followed suit, including the spade connector. I will wrap it with either 1/4" convolute, electrical tape, or cloth wrap after the drivetrain is in. I already have the Speedhut tach. programmed for 1/2 pulse setting for the coil-on-plug option.

Wire bundle opened up for surgery:

All put back together:

I ordered the TKO spacer kit from Forte, and decided to powder coat. While I have the powder coating stuff setup, I also PCd the front and rear jack attachments. I tried a new powder called Burnt Toast. It has some texture, and the sheen matches the chassis pretty closely. Before I put everthing away, I'll PC the headlight mounting and trim rings, and the front turn signal trim rings.

I made most of the plumbing connections on the motor, so not too much more to do there before drop-in. However, I have a pretty good sized list of other items to complete before drop-in, but at least there's a light at the end of the tunnel for drivetrain install! Pretty excited about it.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

03-14-2022, 12:17 AM

#339

Hey Chris. Congratulations on getting through the wiring. That was one of the most time-consuming parts of the build for me, so I know the sense of relief you must be feeling to have that behind you. Can't wait to see that engine go in, and hear the first start!

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-14-2022, 07:36 AM

#340

Chris,

You're making great progress! One tip for you, though. It'll be a lot easier getting the engine in if the radiator is out if the way. It'll also keep you from damaging the radiator.

Dave

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-14-2022, 02:53 PM

#341

Senior Member

Originally Posted by

Papa

Chris,

You're making great progress! One tip for you, though. It'll be a lot easier getting the engine in if the radiator is out if the way. It'll also keep you from damaging the radiator.

Dave

Thanks, Dave. You convinced me. Better to not take any chances, and like you said, the extra room there will likely come in handy when I'm wiggling in the tight 5.0. But dang! This means I have to pull apart and reconnect that impossible fan connector.  Maybe I should just take the opportunity to swap it out for a Weather pack.

Maybe I should just take the opportunity to swap it out for a Weather pack.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-16-2022, 10:01 PM

#342

Senior Member

Was installing some pinch clamps today on a few of the Coyote plumbing questions, and this dangling factory connector caught my attention. It's right above the #5 coil-on-plug, right where I made the tach. wire connection. Somehow didn't notice it then. It looks similar to the connectors on the coils.

Does anyone know if this connector has a home? I'm not seeing anything obvious, and didn't see any instructions.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

04-03-2022, 11:07 PM

#343

Senior Member

More Coyote Install Prep

I took a little detour from the Roadster build to upgrade the headlights on my 2002 Civic. This was my son's car, and I hope to do small upgrades to it over time, as he wanted to do. The older halogens worked, but driving on roads without street lights is a real disadvantage compared to modern projector beam, LEDs, etc. They were a bit more of a challenge to install than I anticipated, as the DS front corner took some damage at some point in its life. So, had to work around mounting points not exactly lining up. In the end I prevailed, and wired in a separate circuit for the DRLs--shown below--which I can control from the inside with a latching SPST illuminated switch. Ben would have liked them. I called him Boosky from the time he was a toddler, until he grew out of it around age ten or so.

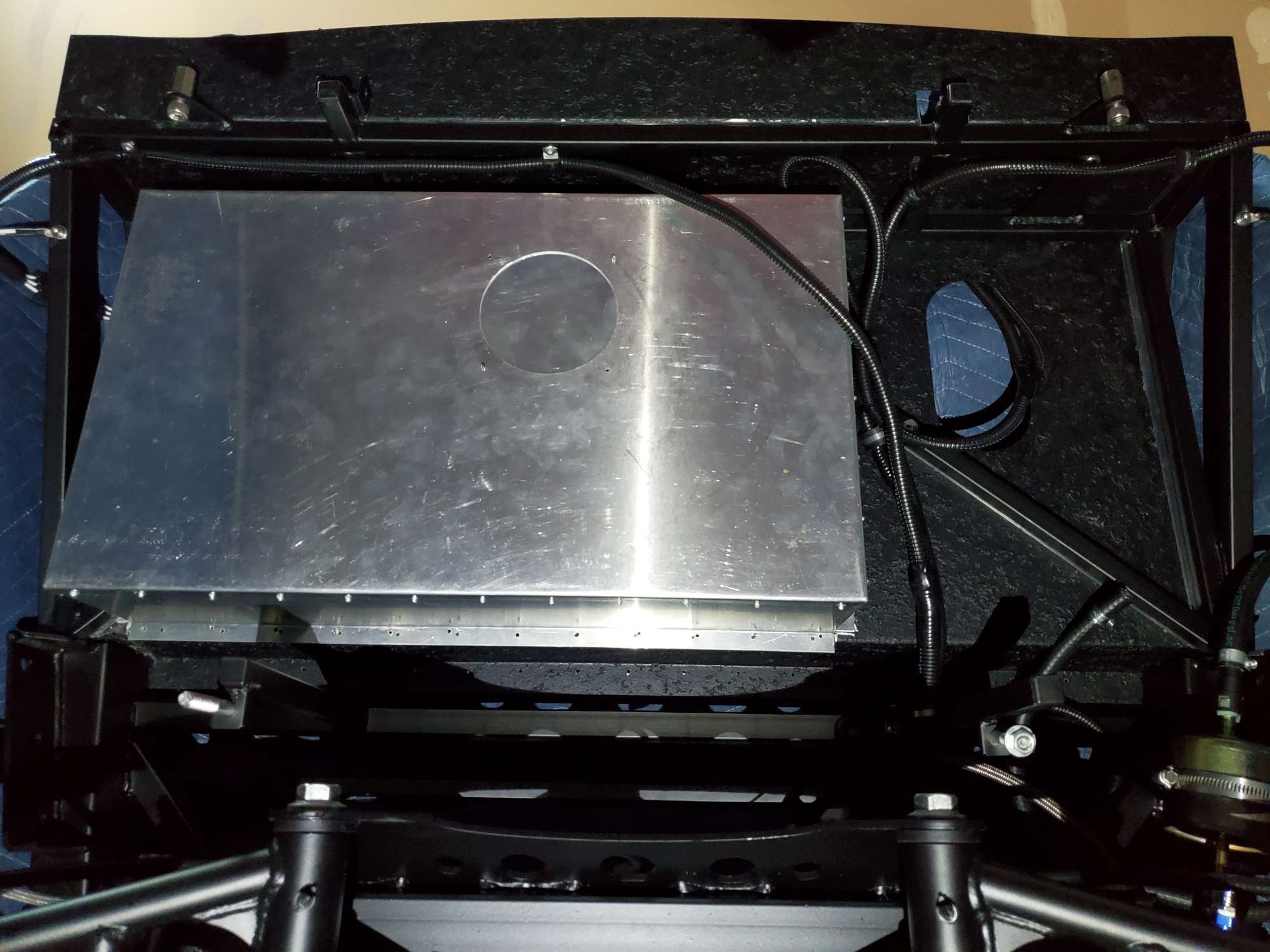

I almost forgot about powder coating the headlight mounting and trim rings. So, took care of that during my last session while I had all the stuff set up. I'm leaving the protective plastic film on as long as I can to protect the lens covers.

I'm whittling down my list of To Dos before installing the drivetrain. One of those items was to finalize the rear harness install. So, dropped the gas tank (again!) and began routing and securing the harnesses with cushion clamps. I left the purple wires in the rear harness in case of future use. While the gas tank was out, I took advantage of the extra working space and filled the IRS. It turns out it had about the right amount of fluid as shipped from F5, so I probably could have just left it. But, I wanted to be certain about the quantity, type, and mix of the friction modifier and gear lube. I found good pricing on these from Amazon:

I also picked up transmission fluid (see above) and some anaerobic gasket maker to re-seal the TKO600 shifter cover after drivetrain install. I bought a 300 CC syringe to navigate the tight quarters to fill the IRS. It worked pretty good to pull the fluids from the container and push them into the differential fill opening. And yes, it put a serious stink on the garage...going on Day 2 so far. I'll fill the transmission before installing it. I'm also testing the fuel lines overnight using the Fragola #900666 (Summit Racing - appreciate Fman's recommend on this kit). I pumped about 85 PSI with a bicycle pump. We'll see what the PSI is tomorrow.

Back to the rear harness install, here's how I routed things:

I referenced Edwardb's rear harness install to ensure no interference with the Russ Thompson drop trunk. I also liked how he added grounds at all four corners, so I did the same. However, I couldn't figure out how he made the nut serts work, so I drilled through both sides of the 3/4" tubes and secured with nylon lock nuts. Added a dab of dielectric grease between the ring terminal and the area where I removed the powder coat. I'll wire up the other halves of the Weatherpacks once I'm closer to getting the body on. My electrical check list is growing ever smaller!

After reading about various coolant leak issues on the forum, I decided to go with Gates Powergrip SB clamps. Getting a tip from JohnK I went with the AllStar Performance brand (appear to be Gates, but rebranded) on Summit Racing. It appears Eddie Motorsports rebrands these as well (also on Summit). I installed my first pair on the 5/8" heater bypass hose on the motor. Just a bit of hot air with the hot air gun and done. I'm already a fan. Easy to install, and they get high reviews for being very effective. Given my propensity for doing things twice, I picked up the Gates removal tool ($30), so when I do have to remove one of these (not if, but when!) thermoplastic clamps, I can do so without damaging the hose. Cheap insurance.

Question: while installing the 10-32 SS socket head screws on my corner grounds, I managed to gall one. Thankfully, I was able to keep twisting the nut until it broke off. I replaced it with the same, but coated the tip with anti-seize the second time around. I'm doing that now (coating stainless on stainless fasteners with anti-seize), but didn't on these because of the nylon lock nuts. Does anyone know if the anti-seize (Permatex) degrades the nylon in the lock nuts? If so, I'll need to remove them and replace with lock washers/regular nuts and a bit of blue Loctite.

Last edited by 460.465USMC; 04-03-2022 at 11:12 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

04-04-2022, 12:15 AM

#344

Hey Chris. That's pretty special that you're continuing on with some of the upgrades on the Civic that your son wanted to do. What a great way to keep him in your thoughts in a positive way.

Great progress on the build! I really like the powder coat on the headlight rings.

I also had issues with SS socket head screws galling, especially when using nyloc nuts. That combo was greater than 50/50 chance of galling if I didn't use anti-seize. No concern with using anti-seize with nylon nuts that I'm aware of.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-04-2022, 11:41 AM

#345

Loving the progress Chris! I'm following close behind! Looking forward to the engine first start video

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-04-2022, 12:40 PM

#346

Senior Member

Originally Posted by

JohnK

I also had issues with SS socket head screws galling, especially when using nyloc nuts. That combo was greater than 50/50 chance of galling if I didn't use anti-seize. No concern with using anti-seize with nylon nuts that I'm aware of.

Hi, John. My galling ratio in that combo is at least 50/50 as well! Appreciate the feedback. I’ll leave them as-is, with anti-seize applied.

Originally Posted by

facultyofmusic

Loving the progress Chris! I'm following close behind! Looking forward to the engine first start video

Hi Dan. I’m looking forward to it as well. That will be a great day for me! I hope it occurs in 2022! No doubt you will pass me given my tuuuuuurtlee pace. That’s a good thing, because then I have another good source for ideas and tips.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

04-04-2022, 10:32 PM

#347

FYI, if you want some locking but think Loctite “blue” might be a bit much, their purple (222) is the way to go.

As with all of their products, keep it away from ABS unless you don’t mind deformed/ugly ABS.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-13-2022, 09:59 AM

#348

Senior Member

How visible are the trunk side panels with body on? Fuel line leaks.

Making progress on my To Do list before drivetrain install, but nothing much to show yet. After finishing up the rear harness install, I started testing the stainless braided fuel lines I made (supplied from Breeze). The return line is leak free, but both ends of the supply line have slow leaks. I'm using the Fragola line test kit. I've gone back and forth with Mark at Breeze, and he thinks the leaks are coming from the tapered metal-to-metal seal between the fitting and the Fragola test plugs. He suggested cinching them just a bit more, but not with the Fragola ends on. See if they leak/seep at final connections, and if so, cinch them just a bit more. He very well may be correct, but I'd much rather prove leak-free connections now, before dropping in the drive train. So, after spending quite a bit of time redoing these connectors from scratch, I decided to step away from this for a bit, and focused on the trunk panels. If anyone has any suggestions, I'm all ears.

All of my trunk panels are now fitted and drilled. I made upper side panels as many have done--more on that in my next update. Unsure how visible the trunk side panels are once the body is on, I decided to coat them black. They turned out pretty bad (okay, it's awful!), but I really don't want to spend more time on them unless they are visible with the body on.

Can someone let me know how visible these are with the body on? (This picture is from the F5 build instruction manual).

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

04-13-2022, 10:21 AM

#349

Not a waxer

See where the panel makes that vertical step down? Once the rear splash panel is installed the portion forward of there is visible behind the rear wheel… but if it’s black it will pretty disappear when the car is on the ground.The portion aft of that is only visible if you’re laying under the car looking up behind the splash panel.

Jeff

Last edited by Jeff Kleiner; 04-13-2022 at 10:23 AM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-13-2022, 10:31 AM

#350

Senior Member

What Jeff said about the side panels. Regarding your fuel lines, I think Mark has a good point. I too have experienced slight leaking (bubbling when underwater) from the Fragola test fittings unless they're cinched down really tight. Try tightening them a bit more. If you're seeing bubbles from the end versus where the connector and the lines come together, pretty good chance they're OK. For the record, multiple builds and I haven't had a single one of these kinds of hose fittings leak once installed.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-13-2022, 11:34 AM

#351

Senior Member

Originally Posted by

Jeff Kleiner

See where the panel makes that vertical step down? Once the rear splash panel is installed the portion forward of there is visible behind the rear wheel… but if it’s black it will pretty disappear when the car is on the ground. The portion aft of that is only visible if you’re laying under the car looking up behind the splash panel.

Jeff

Jeff, you just made my day! I'm going to call it good. My wife thanks you too, as this means I can get these off the kitchen table!

Originally Posted by

edwardb

What Jeff said about the side panels. Regarding your fuel lines, I think Mark has a good point. I too have experienced slight leaking (bubbling when underwater) from the Fragola test fittings unless they're cinched down really tight. Try tightening them a bit more. If you're seeing bubbles from the end versus where the connector and the lines come together, pretty good chance they're OK. For the record, multiple builds and I haven't had a single one of these kinds of hose fittings leak once installed.

Thanks for the feedback, Paul. Yes, they are bubbling a little when under water. I sent pictures and a video to Mark of the bubble leak points, and he thought my connections were good based upon where the bubbles are originating (i.e. the leak is not between the hose and the fitting but between the fittings). The supply line is not losing a huge volume of air: after leaving it overnight it still had PSI. I just wish there were no bubbles like the return line.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

05-05-2022, 02:43 PM

#352

Senior Member

Prep for Drivetrain Install is Winding Down - Part 1

Spring chores were calling my name, so I had to put my toys down, get out of the sandbox, and act like a homeowner for a couple weeks. Now that firewood for next winter is stacked in the woodshed, and Spring weed mitigation is done, I'm back on the build.

On my last update, I mentioned my trouble with minor leaks on both ends of my fuel supply line (return line is leak-free). After consulting Mark at Breeze and the forum here, I'm going to call it good for now. I really don't want to step away from an unresolved issue (especially fuel related!), but not sure what else I can do until I make the final connections and charge the system to the recommended 65 PSI.

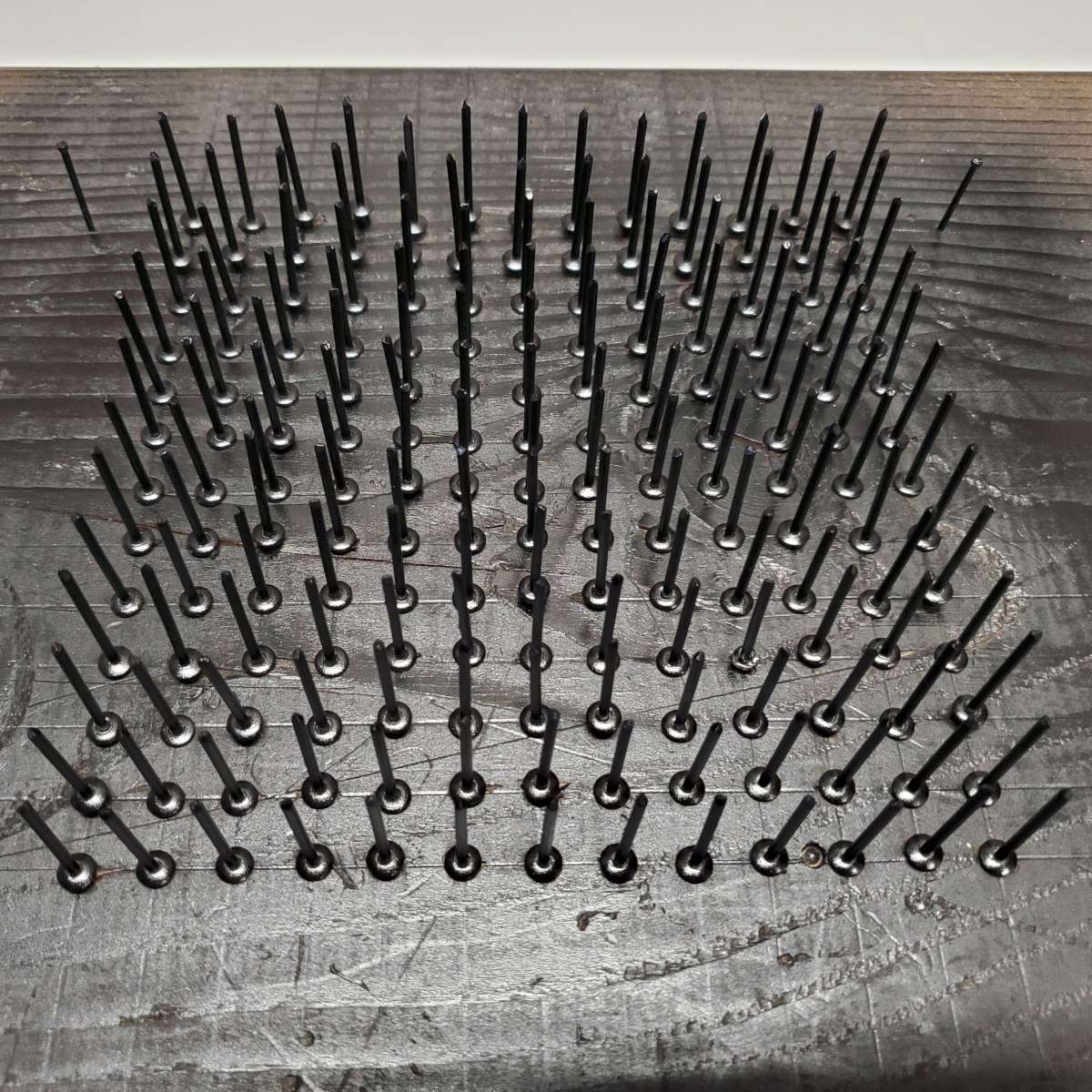

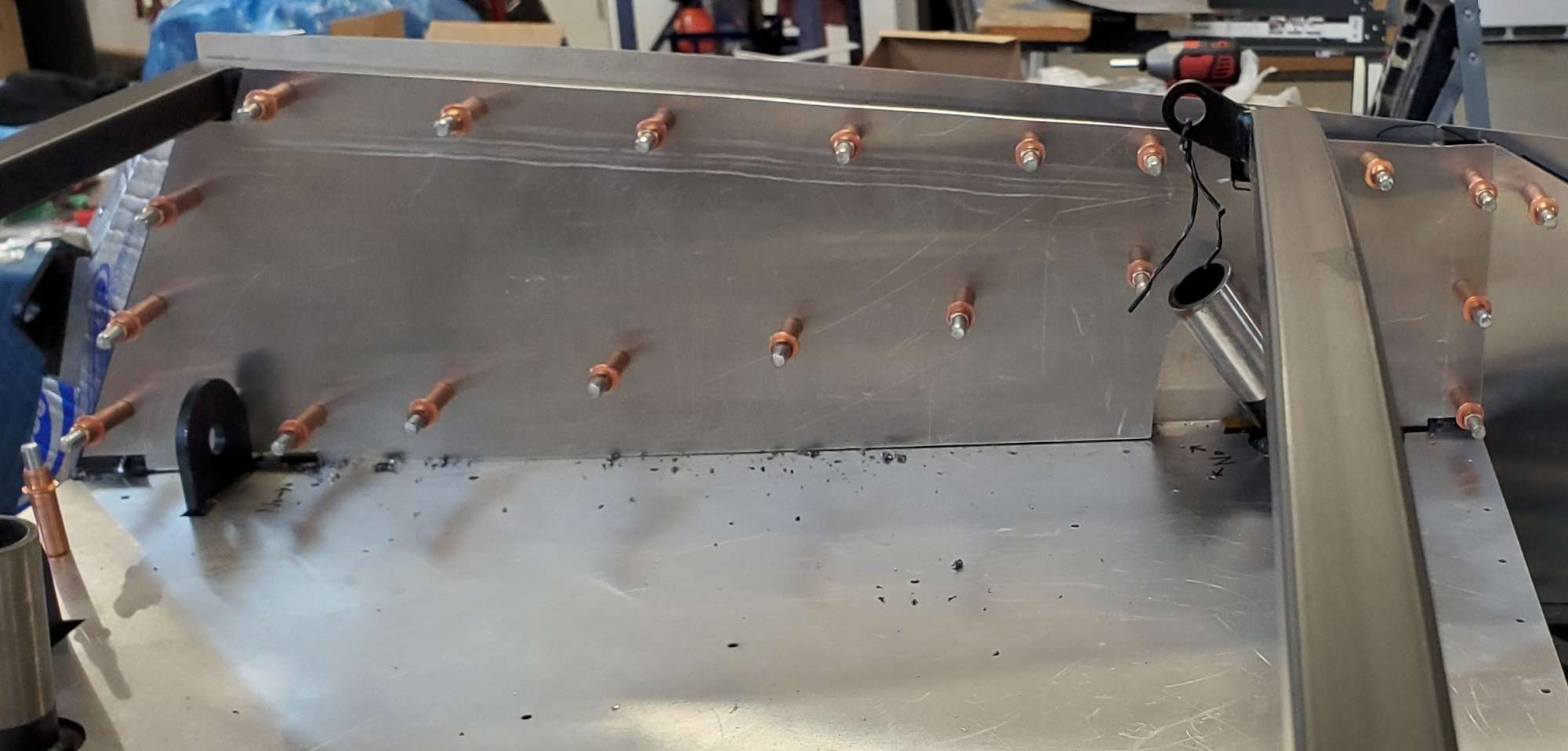

While I was noodling on the fuel leak, I installed the trunk side panels. Since these are not very visible once the body is on--thankfully so given my finger-painting level quality--figured it was a good opportunity to try my hand at painting rivets. My daughter, Grace, ran the drill press while I positioned the "rivet holder" (scrap piece of 2"x12") and together we drilled 120 holes. Just deep enough to accommodate 1/8" short and long rivets. I needed about 65 for the trunk side panels, but made up 100 of the short, and 20 of the long to have extras on hand. This is after applying Eastwood Chassis black from a rattle can.

You can see the silver centers of the rivets once they're installed, but they certainly stand out less than if they were uncoated.

By the way, I've played around a bit with how to keep silicone from hardening after the tube is opened, as I don't typically have enough panel install work at one time to use a whole tube. This plastic cap and plastic wrap combination kept this tube usable for quite some time (at least a couple months). The GE silicone is kind of expensive to be throwing away half-used tubes.

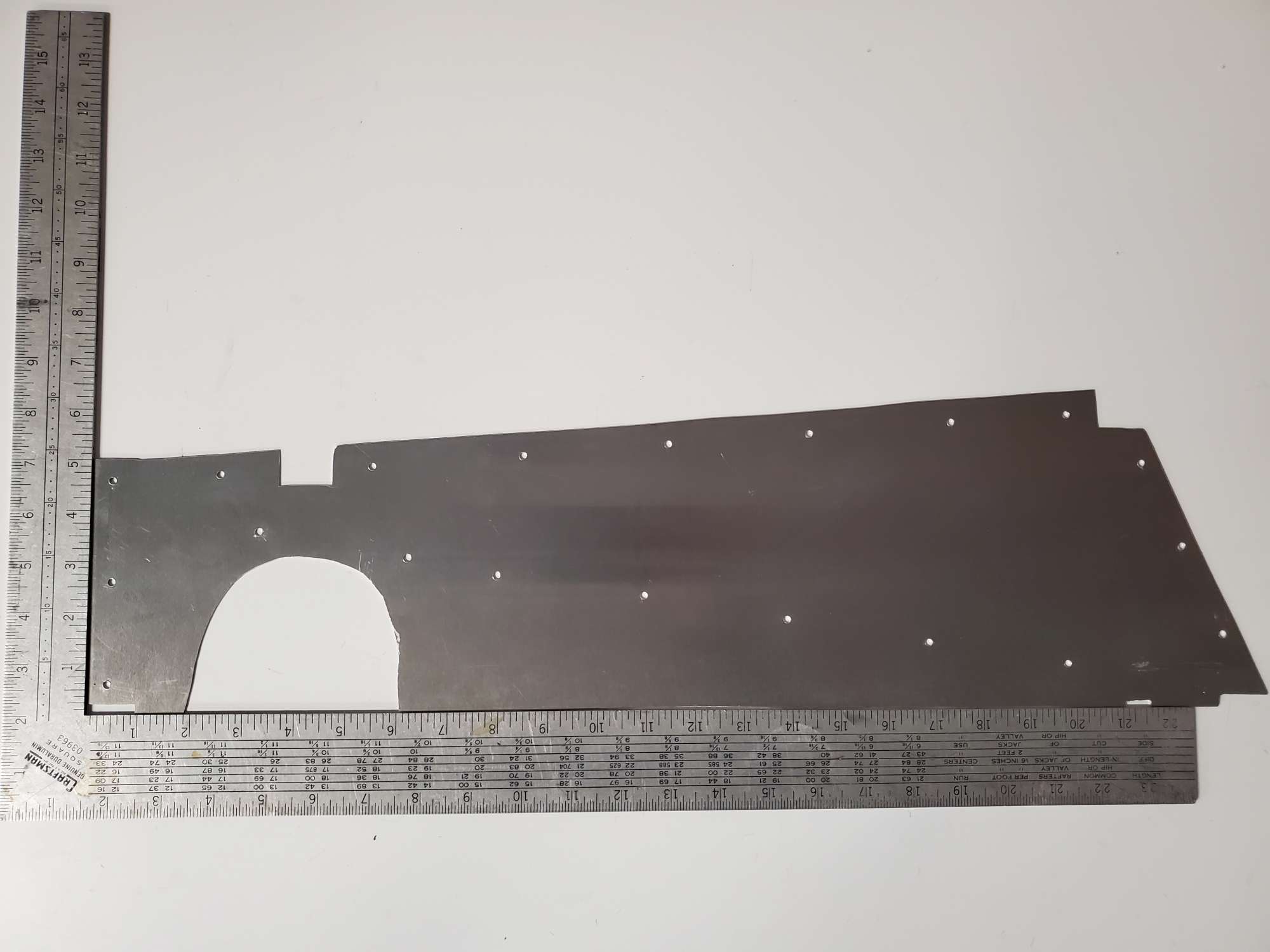

Next up was to make upper side trunk panels. Following in the footsteps of many on the forum, I bought a 0.040 remnant from my local metal supplier, created a template from a cereal box, and then cut out the panel using my jig saw. Like others, I put down painters blue tape (3M) along the lines I cut. It took me a number of hours to cut out and trim both sides (no surprise here) until they fit decently. Working the panel in between the outer roll bar mount, the upper seat belt mount, and the 3/4" tube is the tricky part. I enlarged the semi-circle opening for greater clearance around the roll bar mount until it slid in easier (not easy, but with less binding).

Panel cut out and drilled.

Cleco'd in place. Ready for future installation.

Wanting to close-up all gaps and holes before drivetrain install--difficult to access afterward--I painted and installed the small cover over the hole in the DS of trans tunnel. The black painted rivets came in handy.

Last edited by 460.465USMC; 05-08-2022 at 01:25 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

05-05-2022, 02:44 PM

#353

Senior Member

Prep for Drivetrain Install is Winding Down - Part 2

I followed JohnK's lead in laying a bead of Dynatron seam sealer around the rear shock mounts, and on either side see his post #117. I don't know if it's needed, but I like the idea of a little insurance just in case. Heavy duty tape (Gorilla tape) was used on the other side to keep it from squeezing through. I also used the seam sealer inside the DS FB. Along the inside panel where it meets the 4" chassis tube and the inside panel of the DS FB. And, to seal up some other gaps like around the seatbelt mounts.

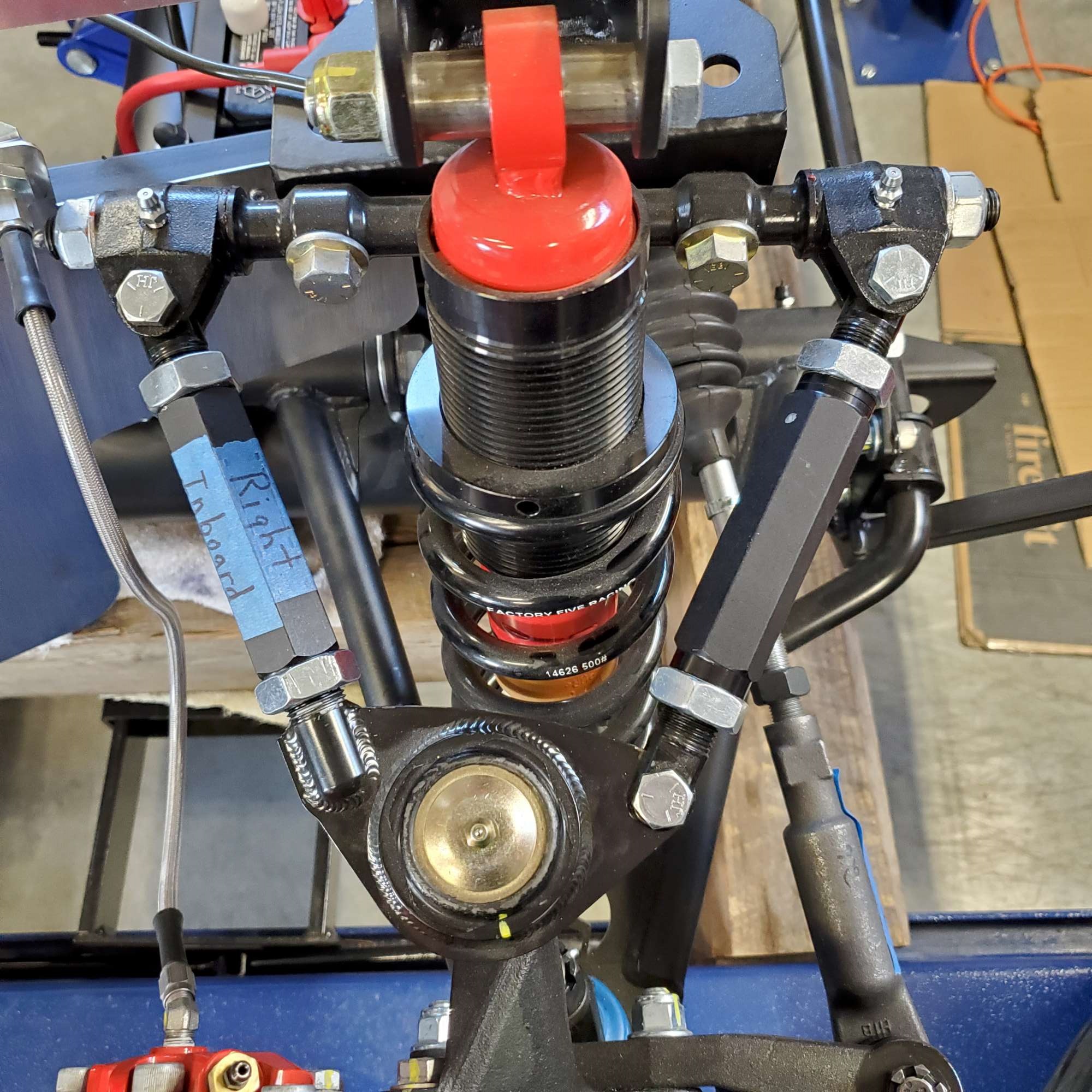

Local builder, Jim, trimmed the rear arms of my front UCAs (thanks again, Jim!). Interestingly, the DS front upper arm is still 1/8" too long. I'm wondering if it will need to be trimmed as well?

On the PS, since the ball joint was torqued down, it didn't want to separate. Not even with some persuasion from a hammer. Needless to say, the welded stud on the PS remains at its original length. So, just the recommended amount was trimmed from the sleeve (~3/16" of each side--basically, the tapered part) and the corresponding amount from the hollow stud.

For reference, here's how the PS looked before trimming (not able to adjust to recommended starting measurements):

After (adjusted to recommended starting measurements)

Does anyone have comments on whether the front arm will need to be trimmed to achieve good power steering alignment?

**Jim came over and figured out my issue. I mixed up the lengths on the DS, i.e. reversed measurements between front and rear arm. So, as JohnK noted below no need to trim forward arm on DS.**

I'm running out of excuses for dropping in the drivetrain...

Last edited by 460.465USMC; 05-08-2022 at 01:31 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

05-05-2022, 05:37 PM

#354

Hey Chris. Looks good! Good luck dropping in the drivetrain. I'm sure it'll be a lot of fun. Can't wait to see photos of it installed.

FWIW - I've never heard of anyone having to trim the front sleeves to get proper alignment.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

05-05-2022, 06:48 PM

#355

Senior Member

Chris, good choice on trimming those front sleeves. Just had a friend in my area go get his car aligned for first time and he did not trim the sleeves and could not reach proper alignment. The shop charged him $500 to take everything apart and trim them down.

Nice job on the build, looking forward to seeing your Coyote land in it's new home!

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

05-05-2022, 08:25 PM

#356

Senior Member

Originally Posted by

JohnK

Hey Chris. Looks good! Good luck dropping in the drivetrain. I'm sure it'll be a lot of fun. Can't wait to see photos of it installed.

FWIW - I've never heard of anyone having to trim the front sleeves to get proper alignment.

Thanks for the input, John. I haven't read of any others cutting the front arms either. I think it best to hold on that until I take a swing at alignment later on.

Thanks for the encouragement. The drivetrain install is a little intimidating for this greenhorn, but I'm looking forward to the challenge.

Originally Posted by

Fman

Chris, good choice on trimming those front sleeves. Just had a friend in my area go get his car aligned for first time and he did not trim the sleeves and could not reach proper alignment. The shop charged him $500 to take everything apart and trim them down.

Nice job on the build, looking forward to seeing your Coyote land in it's new home!

Hi Travis. I waffled on the whole trimming UCA arms, but now that it's done I can't see any down side. Thanks for the kind comments!

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Fman

Fman liked this post

-

05-06-2022, 10:39 AM

#357

Senior Member

Hey Chris,

Did you say you’re going to fill the trans before installing it in the car? I’m not sure if the output shaft area is sealed off from the rest of the trans. If not then all your trans fluid will run out when installing in the car. I’m sure some builders with experience can chime in?

Jim

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

05-06-2022, 12:03 PM

#358

Senior Member

Yes, it's full. I thought I read to fill before hand as it's much easier to access, but maybe I shouldn't have?

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

05-06-2022, 12:14 PM

#359

Jim is right - it will spill out the output shaft opening. You could try taping it up, but I'm not sure how well that will work. I'd probably drain it and then refill after install. I picked up one of these and it made filling up the trans and rear end a lot easier.

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

05-06-2022, 02:38 PM

#360

Senior Member

With all the reading I've done I'm still amazed about how many things I miss. Phew! A messy lesson narrowly avoided! Thanks, Jim and John! Trans fluid coming back out before install!

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote