-

Bryan, the E-brake mod looks great! I've read Lokar no longer makes the clevis set EdwardB used, so what parts did you end up using? I'm about to tackle the E-brake set up and don't like the idea of routing the cable under the 4". I'm actually shocked FFR still does it. If you don't mind, what pulleys/bolt and clevis set up did you use and where did you get them? I gather you probably used the pulleys from McMaster, #3434T24, but the rest is becoming more interesting to find. I'd appreciate any insight you can provide.

-

Bryan,

I am also getting an engine from Mike Forte, albeit a Boss 347 W/Edelbrock Pro Flo 4 EFI and am looking forward to the install. Can you tell me what engine leveler you used?

Thanks

Bill

Roadster MK4 #10653 Date: 4-27-23; First Start: Oct 2023; Go Kart: Nov 2023; Body and Paint: To Kleiner EDD - April 2024; Graduated: TBD

SBF Boss 347, Edelbrock ProFlo 4, Milodon Road Race Oil Pan, Tremec TKX 2.87/0.81 OD, IRS Dakota Digital Dash, FFMetal Firewall Forward, BOIG Lower Cool Pipes, Forte's Mechanical Throttle Linkage and Hydraulic Clutch, Breeze Radiator Fan Shroud- Radiator Support Kit and Battery Forward

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

Senior Member

Originally Posted by

maclonchas

Bryan,

I am also getting an engine from Mike Forte, albeit a Boss 347 W/Edelbrock Pro Flo 4 EFI and am looking forward to the install. Can you tell me what engine leveler you used?

Thanks

Bill

I can tell you I tried one from Northern Tool and it was terrible. This one worked really well, worth the money 100%. With it I was able to remove and reinstall the engine/trans by myself.

-

Senior Member

I lent Junbug mine.

This one

Last edited by danmas; 10-14-2023 at 12:09 PM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

Souleman

Bryan, the E-brake mod looks great! I've read Lokar no longer makes the clevis set EdwardB used, so what parts did you end up using? I'm about to tackle the E-brake set up and don't like the idea of routing the cable under the 4". I'm actually shocked FFR still does it. If you don't mind, what pulleys/bolt and clevis set up did you use and where did you get them? I gather you probably used the pulleys from McMaster, #3434T24, but the rest is becoming more interesting to find. I'd appreciate any insight you can provide.

Thanks. I bought the clevis from Summit. The remainder of the parts I bought from my local Ace hardware... Stainless steel bolt and nuts. For the pulleys, yes, #3434T24 is the two I ordered. The bolt that runs through it I also got in stainless from Ace. I don't recall the sizing but I always try to bring in the parts and fit the nuts/bolts in store before I buy. You'll need to cut the ends of the e-brake cables off and thread them through the lokar clevis but it tightens up really well. No movement at all, so far.

https://www.summitracing.com/parts/LOK-WCA8070

-

Senior Member

Originally Posted by

maclonchas

Bryan,

I am also getting an engine from Mike Forte, albeit a Boss 347 W/Edelbrock Pro Flo 4 EFI and am looking forward to the install. Can you tell me what engine leveler you used?

Thanks

Bill

See Danmas post for the link. He was kind enough to share his lift and leveler with me. Worked great. Key is to ensure your engine is level when you start. It will get a bit crooked when tilting it with the type Danmas shared, but once you get it back to level, it dropped it perfectly into the engine mounts.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Also, Big news! We had our first start today! Video link below. I had a brain fart yesterday when i didn't have power to my ignition. A single question on the forum and a couple of quick answer from some experts here and they straitened me out. I had "dieted" the ignition leg of my harness a bit too much. Once I looked at the wire diagram again I realized I had taken out the IGN->COL cable. Once I dug it out of my box-o-unused/cut cables, everything worked exactly as planned...

https://youtube.com/shorts/E-yKEphqw...6O24YqbQ28fJCC

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

Senior Member

Its been a bit of time since I last updated but since the first start I've slowed down a bit, spent more time with family and went to two weddings, two weekends in a row. Oh, and had a leak in the bathroom that resulted in a full gut and replacement of the shower pan.

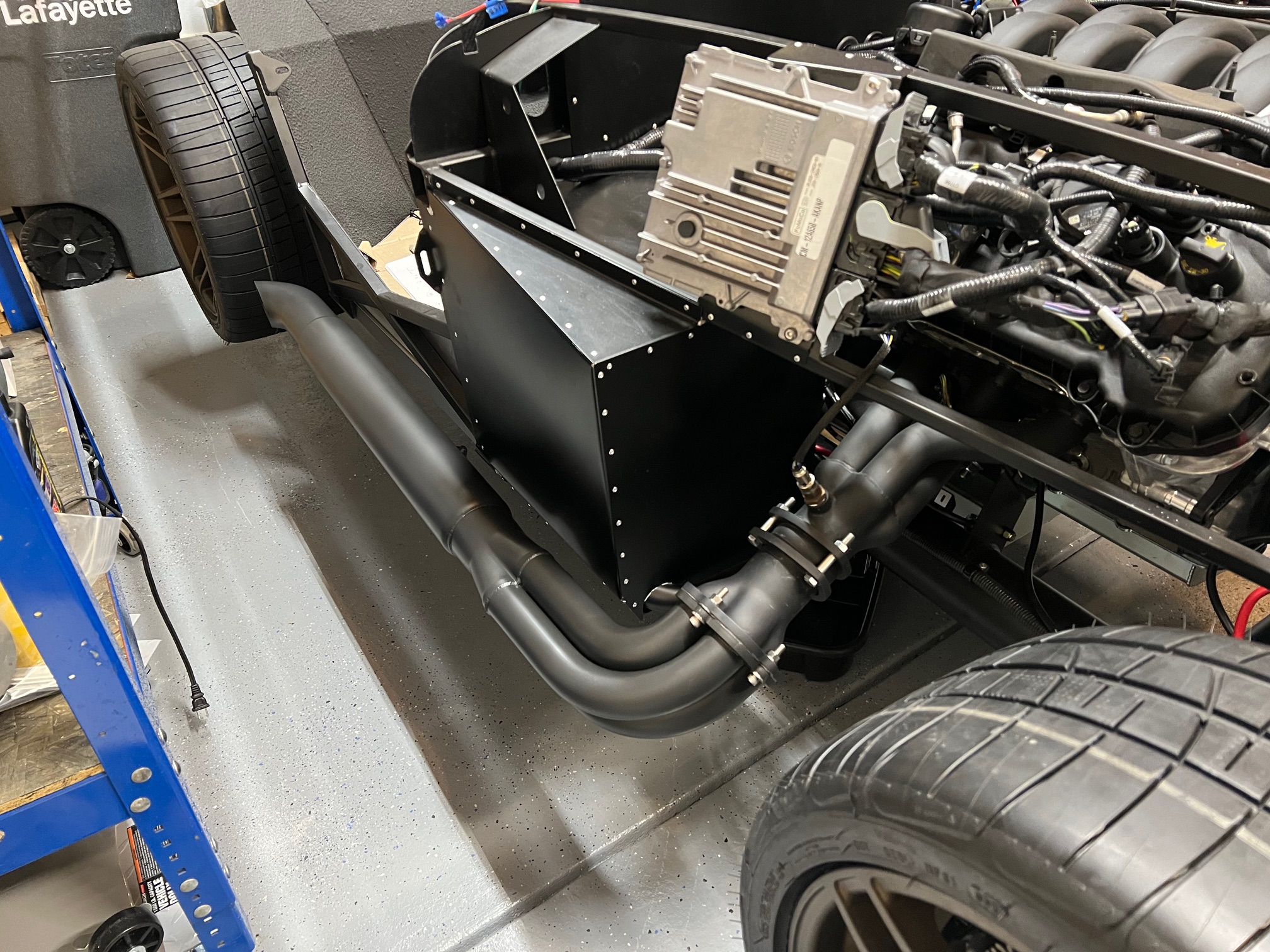

I've completed a handful of small tasks, installed a OEM Ford clutch cable, that is so much smoother than the FFR provided one. Along with the clutch cable I installed a firewall cable adjuster. All of that was pretty straight forward. I also installed my Gasn exhaust pipes and tightened up the ball flanges. They're essentially just hanging off the headers/ball flanges right now but I don't plan to do much go-carting until the spring, and aside from testing my brakes she will stay in the garage all winter (we are already having many nights below freezing).

I'm slowly building my list of sequential tasks to accomplish, and putting thought into how I want to finish my dash wiring, dash mounts, seat sliders, etc.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Senior Member

So its been a few weeks, but we've been slowly making some progress... Bled the brakes two weeks ago and after a few boneheaded mistakes got everything snugged up and no leaks. We used a combination of using the Motive pressure bleeder then followed the wilwood bleeding video instructions. The brakes feel solid all around and I plan to bleed them once more before first go cart. We didn't fill the Motive pressure tank with fluid, we just filled the reservoirs (front brakes/rear brakes) and pressurized each system until very few to no bubbles were coming out the bleed lines. I would stop periodically to ensure that the reservoir didn't run out of fluid.

One tip, go around to all of your brake line joints and unions and verify each is tight. I thought I did this at least two times, but I happened to miss one line that was just finger tight (flexible line from hard line to caliper)... which caused me to believe it was leaking. So I drained the entire front system, then when I went to take the flexible line off, I realized it was barely finger tight! So I suggest checking all the joints/unions more than once! Anyway, I tightened it up, filled the reservoir and pressure bled that system again. No issues once it was tightened up!

-

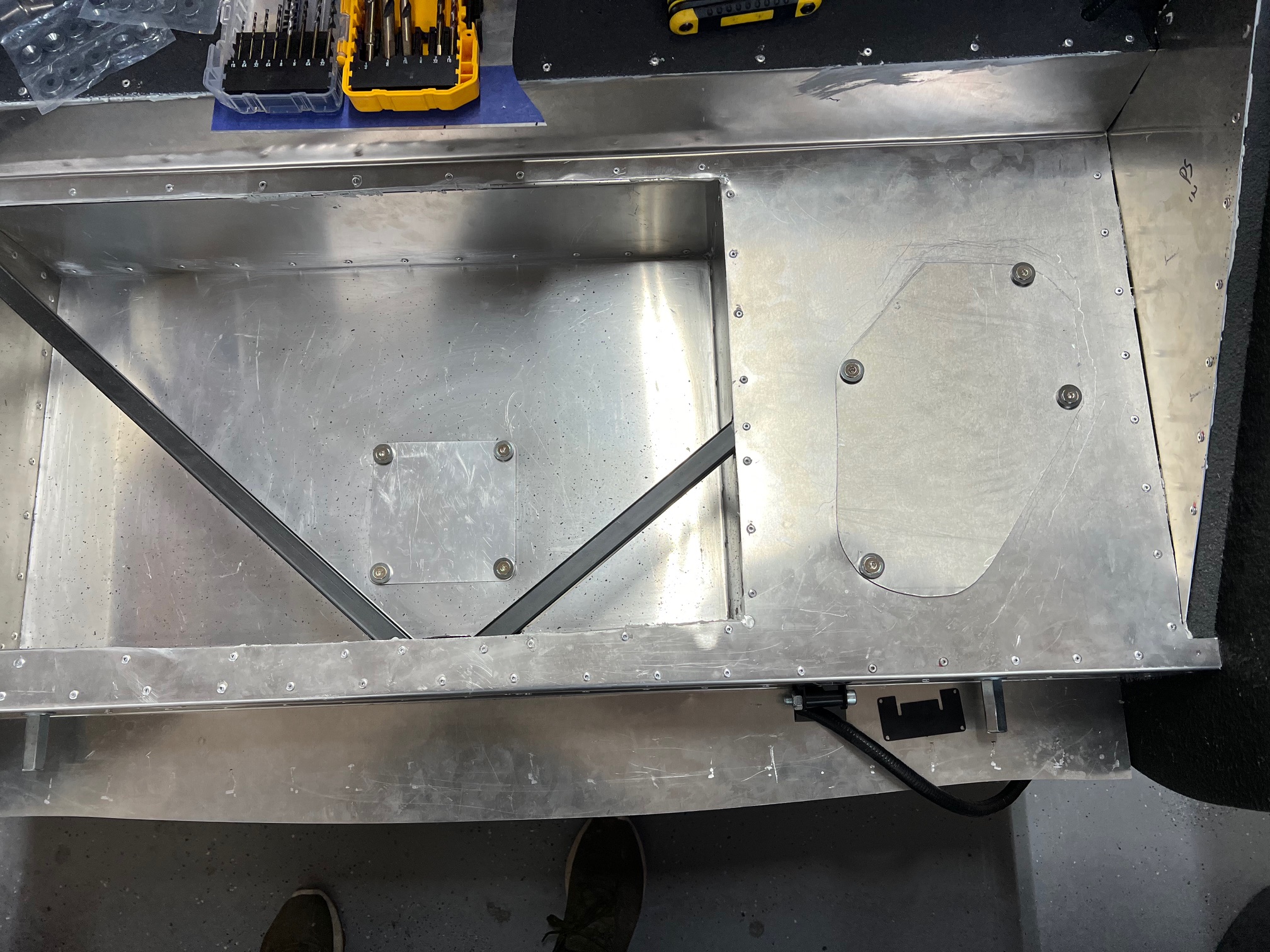

Senior Member

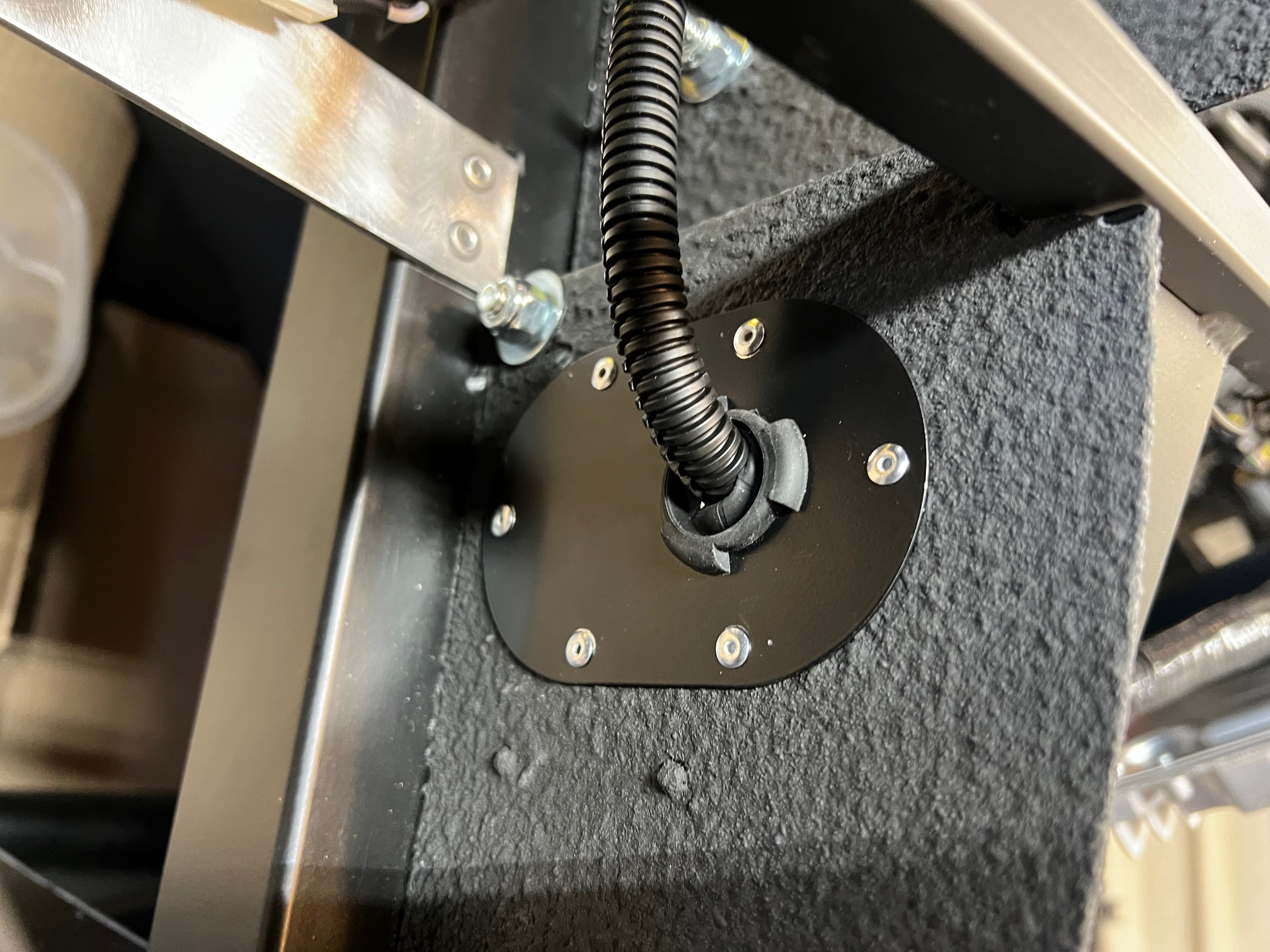

I also tested out a new rivnut tool i bought on my fuel system covers in the trunk area. Per some great guidance from someone on the site, they recommended I expand the hole covering the fuel pump connection. Just in case I ever need to get in there, having a bigger hole will make it much easier. I just used part of the piece I cut out of the trunk floor to add the drop trunk to make the new cover. Additionally I decided to make use of some of the spare/extra decorative screws I bought to hold my dash to the frame. I'm not sure if I plan to keep them or not, but I'll see how it looks once the carpet is installed. I also plan to spray the lower trunk area with additional sound insulation, once the weather warms up in the spring... it's been pretty cold the last few weeks in CO!

Last edited by Junbug; 01-21-2024 at 10:19 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

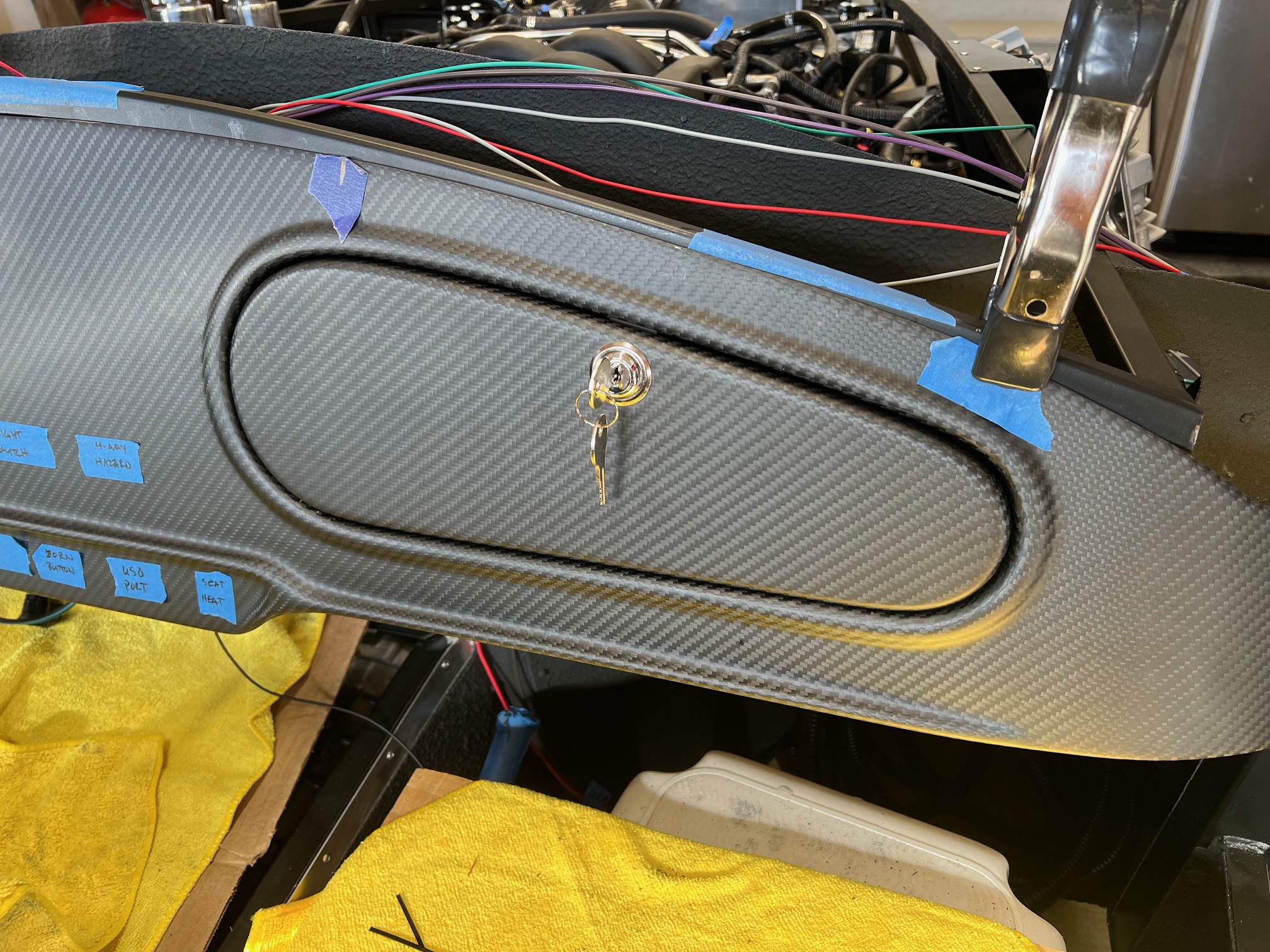

More incremental progress this weekend. Finally finished putting the glovebox together. I thought it was very tedious and a bit frustrating but in the end it seems fine. I’ll be pulling the locking tab and catch out again to powder coat them but other than that it seems done. I also plan to look into a different locking mechanism on then glovebox door. Opening it can be a bit finicky as your only leverage to pull the door open is using the key. Something with a finger hold or bull tab would be much more convenient.

-

Senior Member

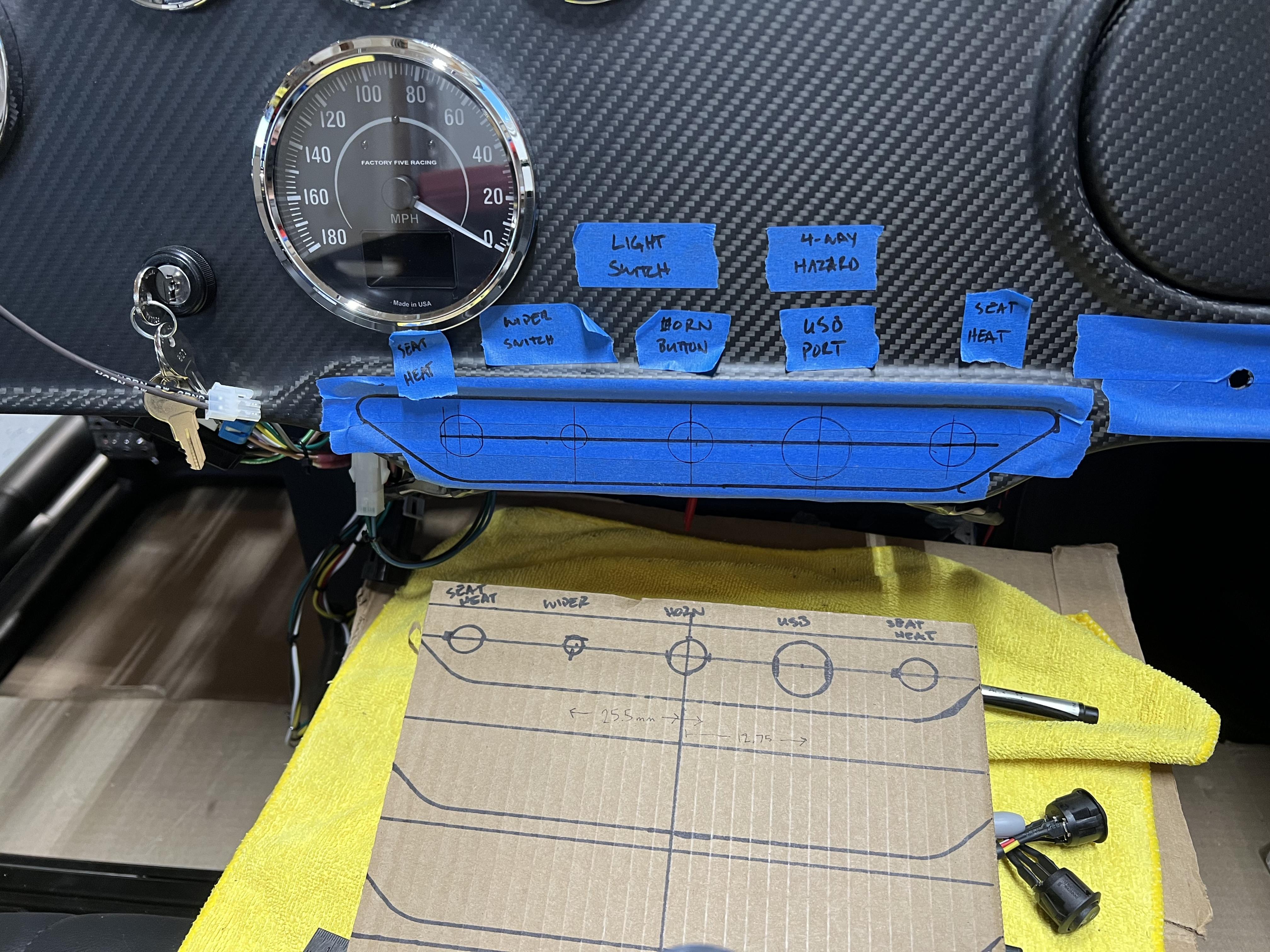

Also plan to finalize my dash switch locations. Laid things out as you can see in the pics below. Plan to drill and mount things this week. Still working on final locations for my headlight switch as the four-way hazard switch. Somewhere above the lower dash area is the plan.

-

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Here are the brackets I made to go under the top dash rail and the rivnuts, screws and washers that will hold the dash in place. I also have a grab handle under the glovebox with 1/4 inch steel support bars and three different under dash supports (DS, PS, middle) that will help keep the dash in place. I still haven't determined how I plan to secure these tabs to the top rail, but likely either rivets or rivnuts...

-

Senior Member

-

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

-

03-05-2024, 09:48 PM

#100

Senior Member

The next project was final placement of the wiper motor and wiper motor wiring.

Here's the final location for my wiper motor. There is just enough room for the wiring to clear the top of the motor and stay below the 3/4" bar. Likewise, on the bottom there is enough room for my coyote harness to fit under the motor, and stay snug up against the firewall.

I used the factory cutout on the PS side of the firewall for the location of the wiper wiring to penetrate. Pretty straight forward.

-

03-05-2024, 09:50 PM

#101

Senior Member

-

03-07-2024, 10:50 PM

#102

Senior Member

I like what you're doing, Bryan. Really looks like a quality build. A number of custom touches.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

03-31-2024, 04:31 PM

#103

Senior Member

We put the wheels on her, gave her a rough alignment (with strings and following Jeff Kleiner's recommendations on the upper control arms) fired her up and took her out for the first go-cart ride. Both my son and wife came along (at different times)... She ran great, and only one minor issue, considering all that could have gone wrong!

https://youtu.be/QqAKTAfHerI

https://youtube.com/shorts/uv2vQP024...M5pIQSPQHK2-nG

Lots of big smiles!

Last edited by Junbug; 03-31-2024 at 04:34 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-31-2024, 04:39 PM

#104

Senior Member

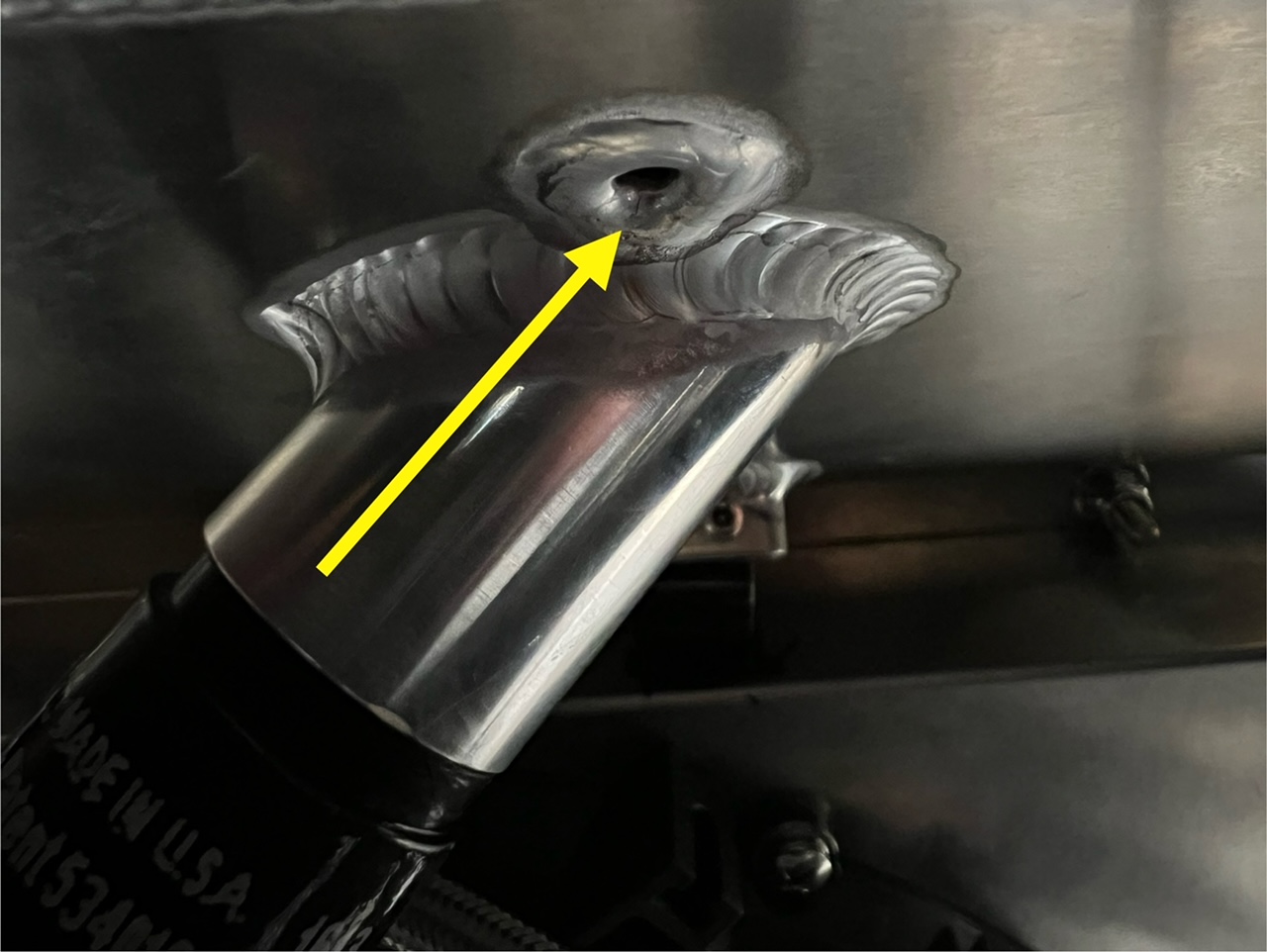

So, post first drive we went around and checked all joints, unions and connections for leaks, looseness and drips. Nothing to speak of except the coolant expansion tank. I found that there appears to be a small crack or bad weld on the bottom of the tank, where the overpressure release eyelet from the fill cap goes through the tank and comes out the bottom. I verified it wasn't coolant leaking through that eyelet, but rather forming a drip and coming through a small crack/gap in the weld. See point of arrow in pic below. I've reached out to the manufacturer to see what they plan to do. Worst case I'll need to take it to a local aluminum/fab shop and see if they can fix it. I'm not an expert at welding or aluminum welding so I'll go with asking the pro's for advice on this.

One more disappointing part will be taking off the gates power grip clamps and having to buy new ones...

-

04-05-2024, 09:18 AM

#105

Senior Member

Originally Posted by

Junbug

We put the wheels on her, gave her a rough alignment (with strings and following Jeff Kleiner's recommendations on the upper control arms) fired her up and took her out for the first go-cart ride. Both my son and wife came along (at different times)... She ran great, and only one minor issue, considering all that could have gone wrong!

Lots of big smiles!

Congrats, Bryan! Huge milestone with great success.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

04-06-2024, 08:17 PM

#106

Senior Member

So the company I ordered the expansion tank ended up shipping a new one. Couldn't get a hold of them via phone, or an email response for a few days, but miraculously got a shipping confirmation on Wednesday... The replacement expansion tank should arrive on Monday. So I spend the day draining what fluid I could from the leaking tank, removing the power grip clamps and taking the tank off. Went relatively smoothly, though it was painful cutting the clamps off as they're single use. Ordering more replacements tonight.

Additionally I took the time to cut/fit my radiator protector/cover. Tip of the hat to JohnK, as he did the same solution and it seems easy, straight forward and simple. Plus I think it looks great. I may also change out the upper breeze hinge bolts as they contrast with the other stainless bolts, but that's something that can come later.

-

06-03-2024, 09:10 PM

#107

Senior Member

-

06-09-2024, 09:28 PM

#108

Senior Member

So we test fit the body today for the first time. Nerve racking, but in the end, it fit quite nice. I'll be linking a separate post asking questions about where/what I need to trim and adjust. Overall it went quite well... For prep, I removed the roll bars, removed the steering wheel, put the tires on (though this isn't necessary). Other preparation was to add 3/4" blocks at the intersection of the horizontal square bars along the engine compartment, and the cross bar that holds the upper radiator. Those help keep the body at the right height, making it easier to put your quick jack bolts through the body holes. Also, I didn't have any foam, or bulb seal anywhere... I don't want to tear that up on the first fitment.

The back end is pushed all the way forward, and just slightly touches the back end of the vertical trunk supports, and rests on the peak of the breeze cubby wall (I may trim that by 1/4" or so). The rear quickjack bolts line up almost perfectly with the Kleiner Trunk mod so I think the back end seems good.

This is the DS outrigger which I know will need to move about 1/2" toward the passenger side. I believe this will help the engine compartment hole line up more evenly between the two hood hinge support brackets.

This is the PS outrigger which I'll likely move about 1/4" to the passenger side, for the same reason above. Likewise I'll make sure the space between the two outriggers stays the same, per the advice on the forum

The engine compartment hole seems OK. I believe the key fitment here is even spacing between each of the hood hinge mounting brackets. You want the same overhang (1/4"-1/2") on each side.

I know I'll need to do some trimming on the dash rolled edge, especially on the DS. I will first take the body off and adjust the outriggers, then re-fit the body to see what shifts around before measuring and taking any material off the dash rolled edge. The PS seems to have a bit of a gap, but overall fitting quite well.

-

06-09-2024, 10:05 PM

#109

Not a waxer

You really need to have the bulb seal on. Don't try to center the hood opening on the tubes around the engine bay---the hood opening is in the center of the body. You center the nose by measuring from the shock tower to the outer edge of the wheel opening.

Jeff

-

06-10-2024, 03:04 PM

#110

Senior Member

-

06-30-2024, 12:37 AM

#111

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-30-2024, 08:53 AM

#112

Senior Member

-

06-30-2024, 09:09 PM

#113

Senior Member

-

06-30-2024, 10:09 PM

#114

Senior Member

I also added the weather-strip and fit the trunk... not final but good enough to move forward with other tasks. I also don't want to do too much as Kleiner will be doing the body. I just want to be able to drive this summer!

-

07-20-2024, 12:35 PM

#115

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

08-12-2024, 09:24 PM

#116

Originally Posted by

Junbug

Also, Big news! We had our first start today! Video link below. I had a brain fart yesterday when i didn't have power to my ignition. A single question on the forum and a couple of quick answer from some experts here and they straitened me out. I had "dieted" the ignition leg of my harness a bit too much. Once I looked at the wire diagram again I realized I had taken out the IGN->COL cable. Once I dug it out of my box-o-unused/cut cables, everything worked exactly as planned...

https://youtube.com/shorts/E-yKEphqw...6O24YqbQ28fJCC

I think i've done the same thing and 1 year later. I have no power at the ignition (Batt. terminal). So how did you fix it? Run a wire from the 12v buss bar to the ignition Batt terminal?

-

08-18-2024, 02:56 PM

#117

Senior Member

Originally Posted by

Dave108

I think i've done the same thing and 1 year later. I have no power at the ignition (Batt. terminal). So how did you fix it? Run a wire from the 12v buss bar to the ignition Batt terminal?

Dave,

Sorry for the delayed response. I had "dieted" out the actual power cable to the ignition/key. I hadn't cut it off yet, but it was just flopping around behind the dash. Once I connected it up, verified with the wiring diagram, she started right up, well after turning over a few times she did!

-Bryan

-

08-18-2024, 02:58 PM

#118

Senior Member

I made some incremental progress over the last few weeks. Added the front quick jacks after the grommets arrived. I had to shape the body holes a bit which took some time, but I think they look great. I'll likely cut the tips off the bolts so the end cap acorn nuts cover the shiny bolt head. I'll PC those and the washers when the weather cools off a bit. i can't PC the nylon lock nuts but I have some matching spray paint that should keep them muted..

-

08-18-2024, 04:03 PM

#119

Not a waxer

Pro tip: if you change the quick jack tubes to 3/4" O.D. they'll fit the grommets.

Jeff

-

08-18-2024, 06:20 PM

#120

Senior Member

Originally Posted by

Jeff Kleiner

Pro tip: if you change the quick jack tubes to 3/4" O.D. they'll fit the grommets.

Jeff

Good to know

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote