-

06-13-2023, 12:40 AM

#121

Originally Posted by

lance corsi

Mark, I have a tri-lobed cv joint if you want it. Pay shipping from Cincinnati?

I'll take it, send me a PM?

-

06-18-2023, 08:44 PM

#122

-

06-28-2023, 10:50 AM

#123

Originally Posted by

Mark Eaton

We had upgraded to the fancy FFR shifter with our original order. I really like the way it looks.

Thanks for this Mark. Timely. I was looking at doing the same thing for the same reasons. At least this is a good heads up that some variation in length is to be expected. Not like we're building custom cars here or anything... =)

Personally, I think the FFR shifter looks even better in the reversed orientation. Nice work.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

10-06-2023, 10:21 PM

#124

Exhaust

My Brother in-law came into town a few weeks ago and we worked on the Exhaust. We welded in this Magnaflow muffler I got from Summit.

Sounds great!

https://www.youtube.com/watch?v=o2ThRtHXZcQ

Nick and I wrapped it with titanium wrap last weekend.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Fman

Fman liked this post

-

10-09-2023, 10:13 PM

#125

-

01-09-2024, 07:45 PM

#126

Leaking Cooling Lines

Over the break Nick and I got in some good wrenching time. We noticed a leak in these lines. cold weather. I figured it was rigged enough and time for more permanent solution

Here are the Gates PowerGrip hose clamps

-

01-09-2024, 08:51 PM

#127

Senior Member

Nice work. Great to see build is still going and getting in time with your son.

-

01-10-2024, 09:00 PM

#128

Nick's a senior

Thanks Mike, Yeah we're still at it. Nick is a senior and more engaged in the build than ever. I am determined to finish this thing before he graduates. Including paint. My MK4 still isn't painted.

Nick wanted to use this photo for his senior photo. I told him he needs to put on a tie. At least he managed to cut his hair, sort of, lol...

Last edited by Mark Eaton; 01-10-2024 at 10:02 PM.

-

01-14-2024, 11:48 PM

#129

-

02-19-2024, 01:35 PM

#130

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-19-2024, 01:41 PM

#131

For time sake I don't want to go crazy with the doors. Just need them functional with functioning windows. However, I am thinking of plugging in to the actuators

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-26-2024, 11:29 AM

#132

Have you considered camloc fittings as a "tab under the panels" solution?

I'm a huge fan of them. They are not cheap, but they are small and man do they hold strong (the 2600 & 2700 series are fine for most applications, but if you need a really strong hold the 4002 series are very robust). If you aren't familiar with them, it can take a bit of time to get a sense of how they work. You also need either (a) a wide range of stud sizes, or (b) pretty precise measurement of your combined panel thickness.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-03-2024, 12:34 AM

#133

Originally Posted by

Santiago

Have you considered camloc fittings as a "tab under the panels" solution?

I have not but you have my interest. Is there a thread that used them I can look at?

-

03-03-2024, 12:46 AM

#134

Door frame and skin fittings

It seems to me the critical part of the door has to do with the frame alignment being as accurate as possible. The door skin appears to be a wobbly amorphous exostructure which needs to be one paint stick away from the body. I figured I would try to set up the door frame to be 2 paint sticks from the body and as even as possible.

I had to raise the top a little and pull it forward slightly on the driver side.

Not sure yet how it will affect the interaction with the fenders

-

03-03-2024, 02:10 AM

#135

Senior Member

Originally Posted by

Mark Eaton

MG]

Not sure yet how it will affect the interaction with the fenders

It is important that you install fenders and hood before the doors.

I use a straight edge about half way up my door to verify flushness with side sail and fender.

Notice that the exposed door sill get wider toward the front of the door.

Click on images below to enlarge.

door_alignment.jpg door_alignment2.jpg

Last edited by Bob_n_Cincy; 03-03-2024 at 02:23 AM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-03-2024, 11:20 AM

#136

Originally Posted by

Bob_n_Cincy

It is important that you install fenders and hood before the doors.

I use a straight edge about half way up my door to verify flushness with side sail and fender.

thanks for the tip, I had to take the fenders off to get the height and length of the top correct. I'm trying hard not to cut anything away and make it all fit by "massaging" it together.

-

03-03-2024, 11:23 AM

#137

Senior Member

Fun to watch you and your sons project, what a great experience for him. Looking forward to seeing it all painted up! Will this be his daily driver? What color are you going with?

-

03-03-2024, 02:32 PM

#138

McCam, I spent at least 40 hrs on each door getting the windows operating to my satisfaction. They’re a real fiasco. Body fitment was no picnic either. I think most probably give up on having properly operating windows. It’s near impossible to get the car water tight. Good luck with yours.

Kit #361, arrived 10/2015, still in progress

818C highly modified, corvette suspension

Estimated completion summer 2023!

1989 turbo Supra 5 sp

2017 Tundra

-

03-03-2024, 04:49 PM

#139

Originally Posted by

Fman

Fun to watch you and your sons project, what a great experience for him. Looking forward to seeing it all painted up! Will this be his daily driver? What color are you going with?

Thanks Fman, I appreciate your comments! Definitely not his daily driver, I just don't think it will be waterproof or very reliable. This project has been about the journey and not the end result. We have had countless hours together over the last few years working away on it. If it was to blow up tomorrow it was easily worth the 18 odd thousand I have spent on it because it has been such a positive experience in both of our lives.

Nick has decided to go to college in New Mexico next fall, my alma mater. When he comes to visit us for breaks he can toodle around town in it, or autocross. He and I also have this goal of some day taking it to the Oregon Raceway and racing like a real race car!

Right now we are planning on Anthracite Gray Metallic with a flat matte satin finish.

Last edited by Mark Eaton; 03-03-2024 at 05:13 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Fman

Fman liked this post

-

03-27-2024, 08:28 AM

#140

-

03-27-2024, 08:33 AM

#141

wheels and tires

I have the FFR upgrade wheels and am wondering if anybody used something different for tire size than the FFR recommended, 215/40/17 Front and

255/35/18 Rear . I have a feeling that front tire is going to rub. The OEM wheels and tires were rubbing while we were go-karting...

-

03-27-2024, 09:12 AM

#142

Senior Member

Mark,

We are using these wheels and the recommended tires, and they do not rub. They have the proper offset versus the OEM wheels, so as long as you have tucked away the coolant hoses, and followed the "rough alignment specs" for the UCA's it should be fine. Now...we are having rubbing problems with the left rear tire after final assembly...and paint. Still working on that one.

818 "S"pyder delivered 11/27/20, using 2007 Impreza 2.5l NA donor. Work mostly being done by my son Liam...body work and paint being done by dad (that's me)

MK3.1 #6583RD, built from 2008-2019, sold 11/2011

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-28-2024, 08:55 AM

#143

Senior Member

Originally Posted by

Mark Eaton

I have the FFR upgrade wheels and am wondering if anybody used something different for tire size than the FFR recommended, 215/40/17 Front and

255/35/18 Rear . I have a feeling that front tire is going to rub. The OEM wheels and tires were rubbing while we were go-karting...

The fronts are particularly difficult as you need a relatively short tire < 24" tall. The rears are much more forgiving. I have used 215/40/17's and 225/40/17 Hoosier's on the front with no rubbing. On the rear I have used all the way up to 275/35/18's, although those are very tight!

No matter what tires you run you will need to use steering restrictors to limit the total lock to lock travel as the tire will rub on the inside splash shield at the limits of travel if not.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-28-2024, 10:20 AM

#144

Thanks for the advice guys, I'll start looking for tires and steering rack restriction device.

-

03-28-2024, 12:11 PM

#145

Senior Member

These are track car observations that probably don't apply to a street driven car. Not sure where an autocross car fits in.

I have 215 in front with no rubbing issues other than lock to lock. I don't have rack spacers. I just know how far I can turn the wheel. The only time I get understeer is in the rain, so I see no reason to go wider because I try to avoid the rain in my open top car.

I have 255 in rear. With the FFR wheels, I needed 10mm of spacers to keep them from rubbing the lower control arms. I have Powerflex Black bushings. Rubbing was worst with the OEM bushings. I can't see going any wider without changing out the control arms. While I don't think wider front tries would improve the car's balance, I do thing wider rears would. Maybe someday I'll change out the control arms. Mostly because then I could try out some slicks that don't come in 255 sizes.

A note on using wheel spacers - make sure you can get at least 9.5 turns on the lug nuts.

A note on FFR wheels - they are a visual upgrade over OEM Subaru wheels, but not as strong. I have demoted my FFR wheels to street use only because while they still balance, they are easily bent pounding track curbs. A car destined for more than an occasional "gentle" track day needs wheels better suited for the track.

Last edited by Dave 53; 03-28-2024 at 12:18 PM.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

03-29-2024, 08:17 AM

#146

Power Window Modifications

I've decided to take my best shot at power window modifications and replicate what FFRWRX did. Here's my initial mock up.

I'm making these out of 1-2/2" x 3/4" metal stick, I think its .08" thickness.

I have a ways to go...

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-29-2024, 08:56 AM

#147

Thinker of thoughts

It is a lot of work making the window frames, but to me at least, worth it. It makes for very nicely working windows that will seal and are fully supported anywhere along the travel. It will also make you realize just how bad the window design is. You can't have a window that goes up and down in tracks that has a different curve on the front and back. So even the added tracks are a bit of a compromise design.

Rick

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-29-2024, 12:58 PM

#148

Senior Member

Originally Posted by

Mark Eaton

I've decided to take my best shot at power window modifications and replicate what FFRWRX did. Here's my initial mock up.

I'm making these out of 1-2/2" x 3/4" metal stick, I think its .08" thickness.

I have a ways to go...

Maybe look into a "tube roller". I used one to make this bike and it seems like it would work for your window frame project.

20170811_143232.jpg

Last edited by Dave 53; 03-29-2024 at 01:00 PM.

-

03-29-2024, 01:49 PM

#149

I’m gonna pop some popcorn! Keep us posted. I wouldn’t count on the roof curvature alone as a template. But a fully guided window mechanism is the only way to seal the side windows. I wish you luck.

Kit #361, arrived 10/2015, still in progress

818C highly modified, corvette suspension

Estimated completion summer 2023!

1989 turbo Supra 5 sp

2017 Tundra

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-29-2024, 05:21 PM

#150

Since I gave up on my 3D printed targa top and bought the FFR top, I have the same plan for windows. Thankfully I get to watch you do it first

-

03-30-2024, 09:57 AM

#151

Originally Posted by

Dave 53

Maybe look into a "tube roller". I used one to make this bike and it seems like it would work for your window frame project.

20170811_143232.jpg

Wow!!

-

03-30-2024, 07:20 PM

#152

Thinker of thoughts

Originally Posted by

Dave 53

Maybe look into a "tube roller". I used one to make this bike and it seems like it would work for your window frame project.

The issue with trying to roll/bend channel is that if you bend it one way the side walls want to go out (excess material). So you hammer that back in and it bends another way. I thought of making some sort of rolling bender specifically for channel. It would have to be capable of rolling in various directions for the window frame. I thought it would be a huge effort for something that may or may not have worked.

Rick

-

03-30-2024, 09:20 PM

#153

My current plan was just pie wedge cutting them. Is that what you guys did?

-

03-30-2024, 09:40 PM

#154

Would it be useful to try using styrene U-channel and heat form it around the window edges? Once cooled, it should at least fit the window curvature in 2 dimensions. For example:

1/4 in. D x 3/8 in. W x 48 in. L Black Styrene Plastic U-Channel from Home Depot

If I had a coupe rather than a roadster, I’d try it before suggesting it.

-

03-31-2024, 09:02 AM

#155

Thinker of thoughts

Originally Posted by

Ajzride

My current plan was just pie wedge cutting them. Is that what you guys did?

That's what I did. Ended up with something like 60 welds on each one. The window frame isn't flat, so you have to do it in 3 dimensions.

-

04-02-2024, 10:29 PM

#156

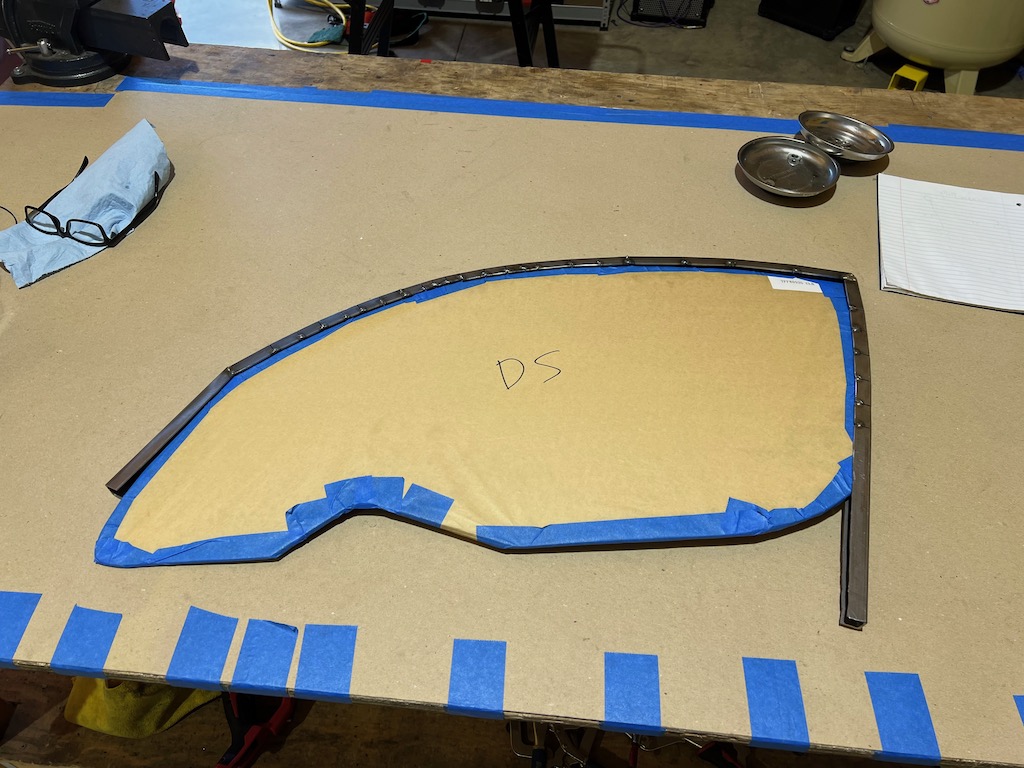

Window Mods

Here's where I am after the weekend. This is challenging...

There is a significant difference in the curvature between the DS and PS glass. PS glass is more curved .

-

04-03-2024, 08:56 AM

#157

Originally Posted by

Mark Eaton

There is a significant difference in the curvature between the DS and PS glass. PS glass is more

IMG_1463.jpeg

-

04-12-2024, 09:47 PM

#158

-

04-16-2024, 06:55 AM

#159

Senior Member

Is it possible to have a shop adjust the window using heat or something to flatten it out more? I am not sure if glass can warp. Now you have me nervous and wanting to measure mine. Maybe you could make a Lexan version? Lighter and easier to work with. If you have a window track, then the Lexan window should just ride and curve to that. Good luck to you. I am curious as to how you are going to solve this one.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote