-

Originally Posted by

BRRT

Hey Terry, your accessory drive setup looks great!

When you had your engine in, did you check your driveshaft? FFR provided driveshaft #16038 with my order. Due to it being so short, I only had about 1 3/8" of engagement with the transmission output shaft. Most of the yoke was hanging out.

I contacted FFR and sent some pics. They have driveshaft #60175 on the way to me. My engine is still in for test fitting, so I will see how it lines up once it arrives.

Thanks Jeff, I'll definitely measure before I drop it back in. Appreciate the heads up.

-

Originally Posted by

Its Bruce

Looks good. How do intend to plumb between the lower radiator and thermostat housing?

It shouldn't be too difficult since the radiator inlet and outlet are both on the passenger side, but those are famous last words.

-

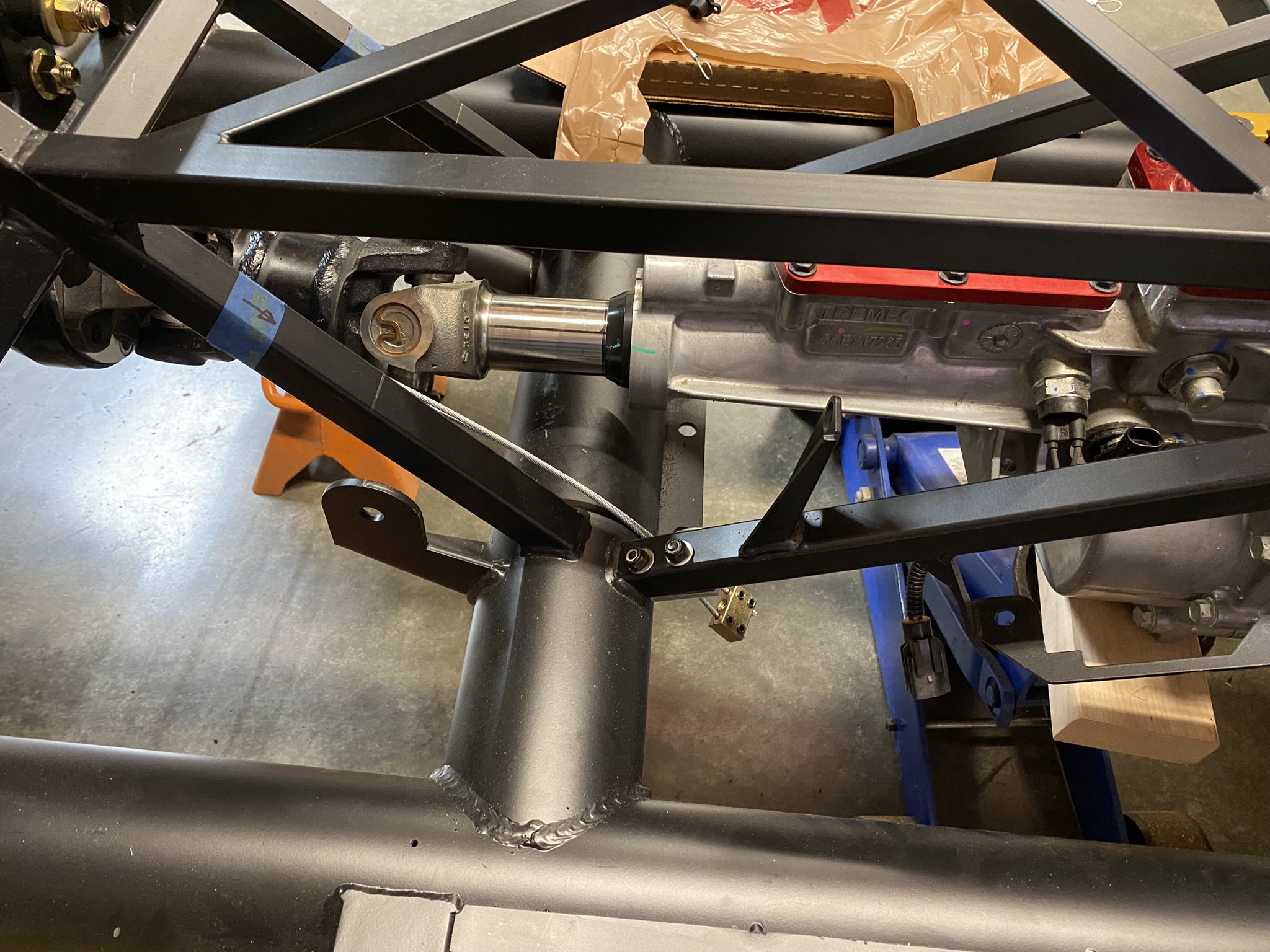

Bellhousing Alignment

Not much new to report, other than I removed the drivetrain assembly and installed the clutch and Tilton 6000 hydraulic throwout bearing. Prior to that I checked the alignment of the bellhousing and was pleased to find that I don't need any adjustments (i.e. offset dowels).

In case it helps anyone else, I used an alignment method prescribed by Silver Sport Transmissions. It's very simple and straightforward. They describe it in this video:

Using this method, I ended up with a final number of 0.0025, which is within the 0.005 tolerance required by Tremec. I believe the smallest available offset dowel 0.007, which wouldn't help here.

-

Post Thanks / Like - 1 Thanks, 1 Likes

BRRT

BRRT liked this post

-

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

-

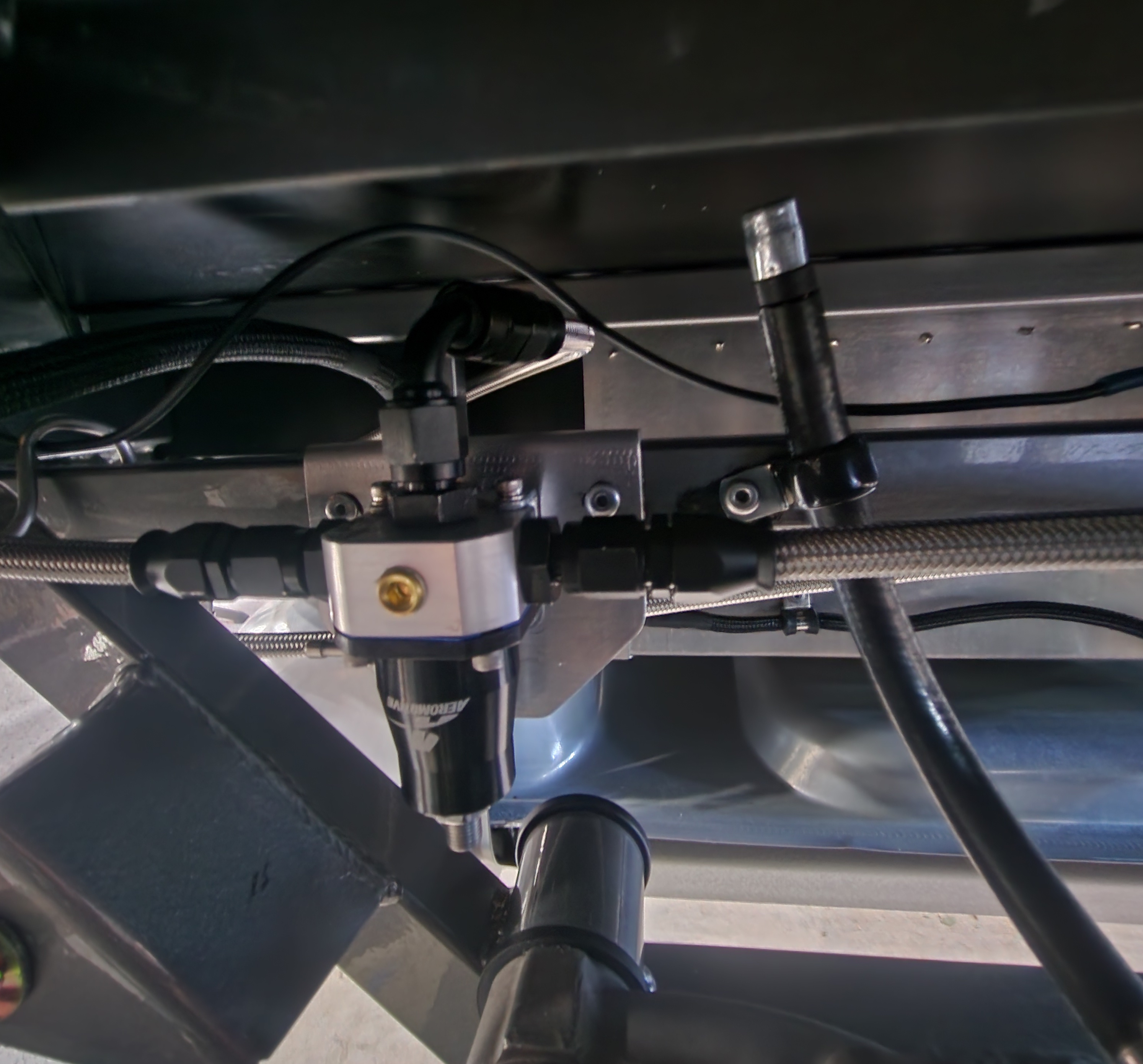

The fuel lines are all in place and pressure tested with my compressor and soapy water. Good old-school leak test. Of course I'll double check when the system is pressurized with fuel. The regulator sits just inside the passenger side rear wheel well and is very accessible.

Last edited by OB6; 04-21-2024 at 06:28 PM.

-

One thing I'll need to figure out is the connection to the lower port on the radiator. The tow loop is right there and doesn't provide much room, so I think I'll need to trim or remove it completely (maybe replace with a threaded tow hook like you'd see on many modern vehicles). Other than that, the routing is pretty straightforward.

Last edited by OB6; 04-21-2024 at 06:28 PM.

-

Wow, going on a couple months since my last update. Glad blogging isn't my day job.

The engine bay is filling up, with a lot of time spent on thinking through things like hose routing, tank placement intake design, etc. And then sourcing the parts. It's all a lot of fun, but definitely time consuming.

20240609_170954.jpg

In the most recent previous post, I mentioned how the lower radiator might be a challenge because well, this is an LS and I also have a custom radiator. I had to make a hose out of three molded hoses. Good thing the local NAPA guys are really patient didn't mind me sitting there with the catalog and asking them to retrieve certain hoses. In the end, I bought about twelve hoses and kept five to complete the upper and lower hoses. I made sure to keep the part numbers for future reference. I had to insert a 1.25" to 1.5" transition in the upper hose.

20240609_172503.jpg

20240609_172517.jpg

I went with Canton expansion and overflow tanks. I found out Canton operates an eBay store where they sell their blemished items for about 50% off in many cases.

Expansion/surge tank:

20240609_171004.jpg

Overflow tank (the bracket's will be removed and coated):

20240609_171012.jpg

The system is designed around this diagram (thanks to fellow builder Bruce for pointing me to it). I had seen it on the internet before, but not the variation without the heater.

LS cooling system - no heater_resize.jpeg

Last edited by OB6; 06-09-2024 at 05:54 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

The intake took some consideration. I thought about keeping the filter in the engine bay like most people do, but GM is pretty specific about spacing requirements for the MAF sensor. Granted, plenty of people have deviated from those requirements with fine results. But I'd like to keep this in-spec as much as possible, and I'd also like to see if I can get cooler air into the engine ("cooler" is an amusing word when you live in Texas). It turns out that it's been done before with a MKIV... see this post in It's Bruce's build.

I essentially copied Bruce's setup (what's the imitation/flattery saying?) after a bunch of PM's exchanged...

20240609_155202.jpg

20240609_141309.jpg

This is just temporary hardware... no need for 1.5" bolts.

20240609_141251.jpg

The filter will end up looking like this:

IMG-20230704-WA0005.jpg

Last edited by OB6; 06-10-2024 at 09:26 PM.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

As other LS builders have noted, the factory dipstick is not an easy fit mostly because of the engine mounts. After jacking around with it for a while, I finally decided to install a Lokar unit, which worked perfectly.

A small bend to the Lokar bracket, along with a spacer and cap screw, and it's all good:

20240609_180936.jpg

Fairly clean routing to the dipstick port:

20240609_180948.jpg

-

Senior Member

Originally Posted by

OB6

As other LS builders have noted, the factory dipstick is not an easy fit mostly because of the engine mounts. After jacking around with it for a while, I finally decided to install a Lokar unit, which worked perfectly.

A small bend to the Lokar bracket, along with a spacer and cap screw, and it's all good:

20240609_180936.jpg

Fairly clean routing to the dipstick port:

20240609_180948.jpg

That starter/motor mount/motor mount adapter/header/spark plug area sure gets crowded when it comes time to install a dipstick tube. I did something real similar after trying to bend and modify 2 GM dipstick tubes.

Yours looks real clean!

----------------------------------------------

Jeff

Roadster delivered 8/27/23

Chevrolet Performance LS3

Build Thread

-

Originally Posted by

BRRT

That starter/motor mount/motor mount adapter/header/spark plug area sure gets crowded when it comes time to install a dipstick tube. I did something real similar after trying to bend and modify 2 GM dipstick tubes.

Yours looks real clean!

Thanks Jeff - yes it's a tight area. I ruined one GM dipstick before deciding I needed to go a different route. I couldn't get a smooth enough bend that fit without the dipstick getting stuck.

-

Senior Member

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

A quick panel for the relays and such...

20240614_112349.jpg

-

I got the air filter installed. This should work well. The rest of the intake is at the coater getting treated with cermet along with the headers.

20240621_171418.jpg

20240621_171434.jpg

-

Time for another series of procrastinated build posts. Overall, I'm getting prepared for first start. Things that need to be done before that include the following:

- Fill tank and test fuel system pressure

- Prime and fill engine with oil; will be using Driven BR30

- Install new master cylinders and bleed the hydraulics... more on that below.

- Temporarily install oil pressure and water temp gauges

- Maybe pressurize the cooling system prior to first start, or just let 'er rip and see what happens. System is filled with DexCool.

- Adjust/set the Tilton hydraulic throwout bearing. I guess this isn't really necessary for first start, but it would be nice to have it done

- Install side pipes

The engine bay is 99% done.

20240706_131111~2.jpg

I decided to have the headers ceramic metallic coated... essentially the same as JetHot.

20240703_121140.jpg

Also had the intake pipes coated the same way. The heat reduction won't provide a material benefit in this application (compared to the headers), but they look nice and match.

20240712_172720.jpg

Power steering lines are installed. I kept it simple and just routed them over the X member. Lee Power Steering was a great source for everything.

20240712_172448.jpg

I finished the gas pedal using an extra pedal pad that I ordered from Mike Forte a while back. I think it came out pretty well. The nice thing is how adjustable it is. I can move it up, down, and side to side if needed. We'll see how the current position works out and go from there.

20240711_180535.jpg

20240711_180545.jpg

20240712_171334.jpg

-

Leaking Wilwood MC

I mentioned above how I needed to install new master cylinders. I've always had this feeling that it will be "when" and not "if" one of the Wilwood MC's fails... based on nothing more than what I've read here and other forums (not necessary FFR related). I even contemplated proactively replacing all of them before I get the aluminum buttoned up, but I didn't make it a priority. Until this morning.

I started to bench bleed the clutch MC and wouldn't you know... it started leaking. I didn't get upset or annoyed... I just grabbed my wrenches, removed all three MC's and headed down to Summit Racing for new Tiltons. Sometimes it's better to just find a different solution and move on. I'm not taking it up with FFR or Wilwood... it's just not worth my time, and I have zero interest in installing a new Wilwood or rebuilding it.

20240714_154607.jpg

-

Almost ready for first start. Just tested the fuel system -- no leaks, fires, or explosions, and 58 lbs at the rail.

Just need to install the side pipes.

20240720_103026.jpg

-

First start!

Big day today with the first start of the LS3. No leaks or funny noises. All systems were operating perfectly according to the OBD2 scanner. Fans came on as they were supposed to. It really helped to have a couple friends there to check things along the way.

https://www.youtube.com/shorts/1GEP8Us2VCA

https://www.youtube.com/shorts/5xKEotfrAAs

Those are just temporary wheels and tires. I'll put rubber on the Halibrands sometime in the next few months. These work fine for now, and no worries about dinging them up.

Last edited by OB6; 08-04-2024 at 06:12 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

08-04-2024, 04:07 PM

#100

Nice Job Terry! Congratulations on this milestone

Craig C

-

Post Thanks / Like - 1 Thanks, 0 Likes

OB6

OB6 thanked for this post

-

08-04-2024, 05:54 PM

#101

Senior Member

Great job! I've been watching your LS build and taking some pointers, although mine is for a coupe.

-

Post Thanks / Like - 1 Thanks, 0 Likes

OB6

OB6 thanked for this post

-

08-04-2024, 07:57 PM

#102

Senior Member

Congrats! That sounds just like it should!!!!!

I'm currently fitting doors, hood, and trunk. Once that's complete I'll be ready to get it licensed.

-

08-05-2024, 08:00 AM

#103

Not a waxer

Congrats Terry! I've been quietly following along because I may be venturing down a similar path soon. Thanks for the documentation!

Jeff

-

08-05-2024, 10:16 AM

#104

Originally Posted by

cc2Arider

Nice Job Terry! Congratulations on this milestone

Craig C

Originally Posted by

JimStone

Great job! I've been watching your LS build and taking some pointers, although mine is for a coupe.

Thanks guys!

Originally Posted by

Jim Frahm

Congrats! That sounds just like it should!!!!!

I'm currently fitting doors, hood, and trunk. Once that's complete I'll be ready to get it licensed.

Cool, thanks Jim. BTW, your clutch pedal stop is gold. Good luck with the body fitment... I'm not looking forward to that.

Originally Posted by

Jeff Kleiner

Congrats Terry! I've been quietly following along because I may be venturing down a similar path soon. Thanks for the documentation!

Jeff

Glad it helps Jeff. I should probably call you soon to get in your queue.

-

08-06-2024, 09:36 PM

#105

Senior Member

Sounds great  . I enjoy the oh so common "whoa, it actually started. Oh yah, I should be checking the oil pressure..."

. I enjoy the oh so common "whoa, it actually started. Oh yah, I should be checking the oil pressure..."

MK4, 427LS3, IRS, T56 Magnum, Wilwoods

-

Post Thanks / Like - 0 Thanks, 1 Likes

OB6

OB6 liked this post

-

08-06-2024, 09:59 PM

#106

Originally Posted by

Its Bruce

Sounds great

. I enjoy the oh so common "whoa, it actually started. Oh yah, I should be checking the oil pressure..."

Yeah I was expecting it to crank a little longer than it did, so it took me by surprise when it came to life. It almost looked like the ignition switch shocked me. Lol

-

08-25-2024, 04:44 PM

#107

Dash

The dash is almost done. The four mounting brackets behind the dash are installed and the screws are countersunk to keep them from showing under the leather and the closed cell backing (probably 1/16 or 1/8, no more). Thanks to others before me for the idea (and especially) to John Ibele for his assistance via PM.

This process wasn't without drama. I originally attached a 0.40 backing layer to help with rigidity. Unfortunately I used 3M Super 77 which I've had great results with in the past. Unfortunately I think this Texas heat isn't conducive to proper curing, and furthermore I read that it only has heat resistance up to 150 degrees -- which could spell trouble when the dash inevitably sits in, again, the Texas heat and sun. I should have done more research before using 77. Luckily I was able to remove the backing layer without any damage to the dash. I chose to move forward without it, and only use small pieces of backing in certain places as needed (for example, between the dash and mounting brackets). I'll use panel adhesive for that.

I used a variation of the comp layout, sitting in position to make sure I could see everything well. Because of this, I decided not to place any gauges to the left of the steering wheel hub. Additionally I decided to place the clock above the grab handle... a decision that I knew would be a "love it" or "hate it" thing. I like it a lot -- IMO it gives some balance and something extra to the dash. I'm sure many will disagree.

The only other items I'll add to the face of the dash are the e-brake button (probably to the left of the steering hub), a couple billet push-button switches for high-beams and interior lights, and the check-engine light. I want to keep it as clean as possible. The hazard switch is built into i.e.427's turn signal switch. The switches for headlights, ignition, and wipers will all go under the dash in the panels I built.

-

08-26-2024, 07:06 AM

#108

Looks good Terry! I like that you are making your own special customizations

What's the part number for your grab handle?

Craig C

-

08-26-2024, 07:55 AM

#109

Senior Member

Originally Posted by

OB6

The dash is almost done. The four mounting brackets behind the dash are installed and the screws are countersunk to keep them from showing under the leather and the closed cell backing (probably 1/16 or 1/8, no more). Thanks to others before me for the idea (and especially) to

John Ibele for his assistance via PM.

This process wasn't without drama. I originally attached a 0.40 backing layer to help with rigidity. Unfortunately I used 3M Super 77 which I've had great results with in the past. Unfortunately I think this Texas heat isn't conducive to proper curing, and furthermore I read that it only has heat resistance up to 150 degrees -- which could spell trouble when the dash inevitably sits in, again, the Texas heat and sun. I should have done more research before using 77. Luckily I was able to remove the backing layer without any damage to the dash. I chose to move forward without it, and only use small pieces of backing in certain places as needed (for example, between the dash and mounting brackets). I'll use panel adhesive for that.

I used a variation of the comp layout, sitting in position to make sure I could see everything well. Because of this, I decided not to place any gauges to the left of the steering wheel hub. Additionally I decided to place the clock above the grab handle... a decision that I knew would be a "love it" or "hate it" thing. I like it a lot -- IMO it gives some balance and something extra to the dash. I'm sure many will disagree.

The only other items I'll add to the face of the dash are the e-brake button (probably to the left of the steering hub), a couple billet push-button switches for high-beams and interior lights, and the check-engine light. I want to keep it as clean as possible. The hazard switch is built into i.e.427's turn signal switch. The switches for headlights, ignition, and wipers will all go under the dash in the panels I built.

I like it.

I too wanted something on the PS dash to break up the blank space, especially since I wasn't having a glove box there.

I think Shelby himself put the speedo on the PS dash to piss off race officials who required a speedo in a race car.30B1875D-81E2-42B0-B2A7-12C3394E6915.jpg

-

08-26-2024, 08:51 AM

#110

Originally Posted by

cc2Arider

Looks good Terry! I like that you are making your own special customizations

What's the part number for your grab handle?

Craig C

Thanks Craig. It's a 12" stainless handrail from West Marine, model # 12868733.

-

08-26-2024, 08:52 AM

#111

Originally Posted by

egchewy79

I like it.

I too wanted something on the PS dash to break up the blank space, especially since I wasn't having a glove box there.

I think Shelby himself put the speedo on the PS dash to piss off race officials who required a speedo in a race car.

30B1875D-81E2-42B0-B2A7-12C3394E6915.jpg

Thanks - I really like your dash... the layout and the color. Yes, that would seem to fit Shelby's personality.

-

09-08-2024, 07:39 PM

#112

First Go-Kart

Today was a fun day. I got the first go-kart ride in, and everything went well.

https://www.youtube.com/shorts/DqVVPk_36so

https://www.youtube.com/shorts/7T60COm1-YQ

A few observations:

- The clutch and hydraulics are silky smooth, with no chatter, funny noises or other weird things. Phew.

- I'm very glad I went with power steering.

- Pedal placement seems to be really good. I wasn't hunting for any pedal or snagging my sneakers on anything. Maybe I'll need to make adjustments after the carpet is in, but for now it's all good.

- I need to tighten up the exhaust, as I was getting some popping on decel. Easy fix, and no surprise because I know I didn't fully tighten the collector.

- One tiny coolant leak at the expansion tank. I'll give it another heat cycle or two because the Gates Powergrip clamp might tighten further. If not, it's a minor fix.

- I've haven't done an alignment yet, and I could tell.

- The tires are marginal at best, but I only expected to use them as rollers. I bought the wheels from a guy in town, and the tires came off our daughter's Mazda when I replaced her tires. They're fine for now, but I'll look forward to getting tires for the 18" Halibrands.

- It's been a while since I've been in a car with this kind of power-to-weight ratio. Good lord.

Last edited by OB6; 09-08-2024 at 07:41 PM.

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

09-10-2024, 03:14 PM

#113

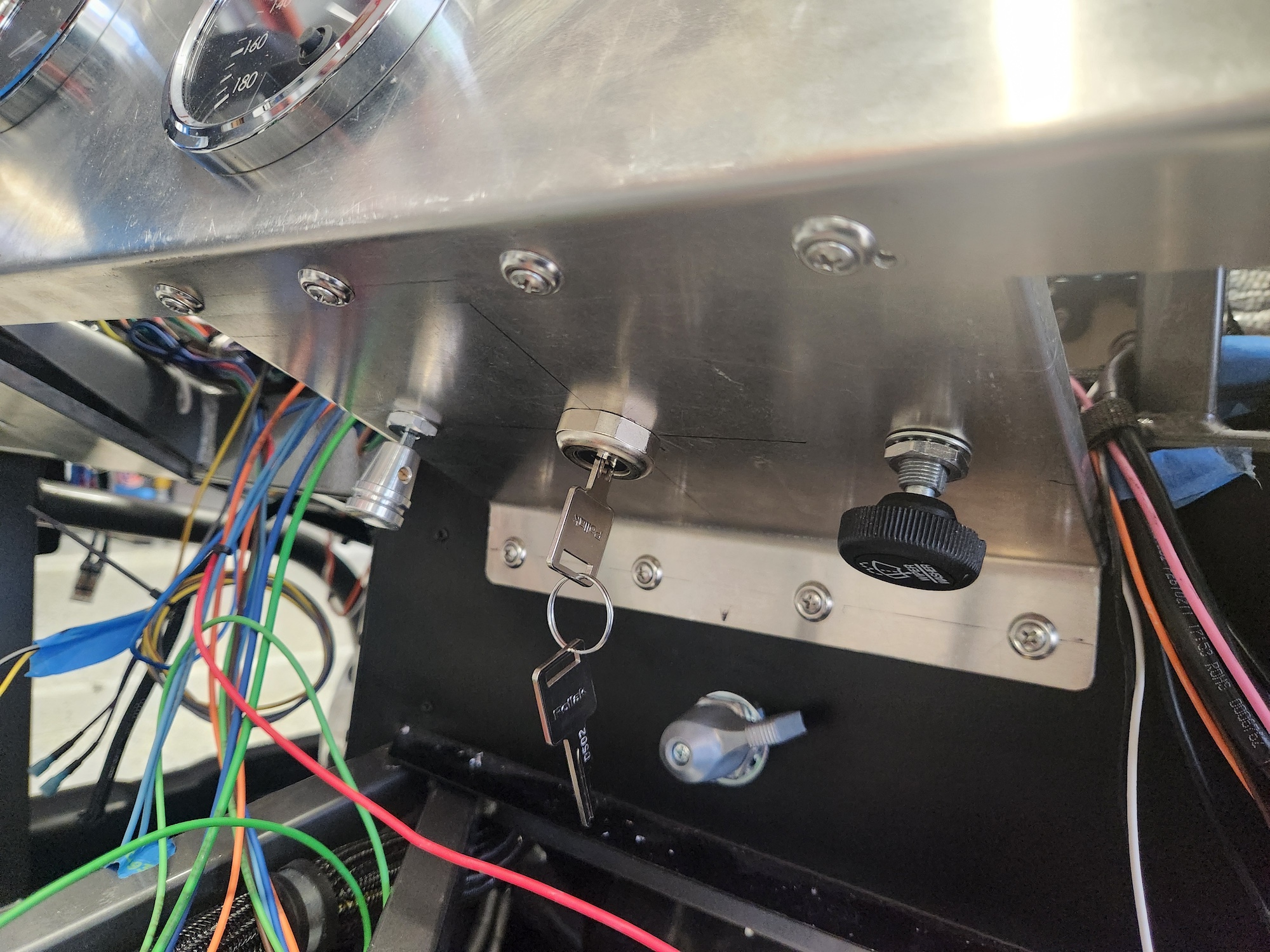

Just a few dash updates I forgot to post.

I was able to get the bracket for the handrail completed, although it needs to be painted or powder-coated. I made it with 1/8" x 1" flat steel, 1" angle, and some 5/16 and 1/4-20 fasteners I had. I'll use proper locking hardware at final install. That said, it's rock solid as it sits, and should make the handrail very useful.

I decided to place the ignition, wiper, and headlight switches under the dash on the center panel. This should help keep the dash layout cleaner.

-

09-11-2024, 02:17 PM

#114

If you want to powder coat that, and any other small parts, youíre welcome to come over one of these coming weekends. Between sanding, degreasing, spraying, and baking, it would only take about 45 minutes. Iíve gotten pretty decent at powder coating things over the last several months.

-

09-11-2024, 02:31 PM

#115

Senior Member

Congrats on the go carting! I just got there a couple weeks ago...sure is gratifying to hear and feel it do it's thing for the first time, isn't it? Hard to believe the mechanical part is pretty much over...it's all about the body from here on out. (Hopefully.)

-

10-17-2024, 07:44 PM

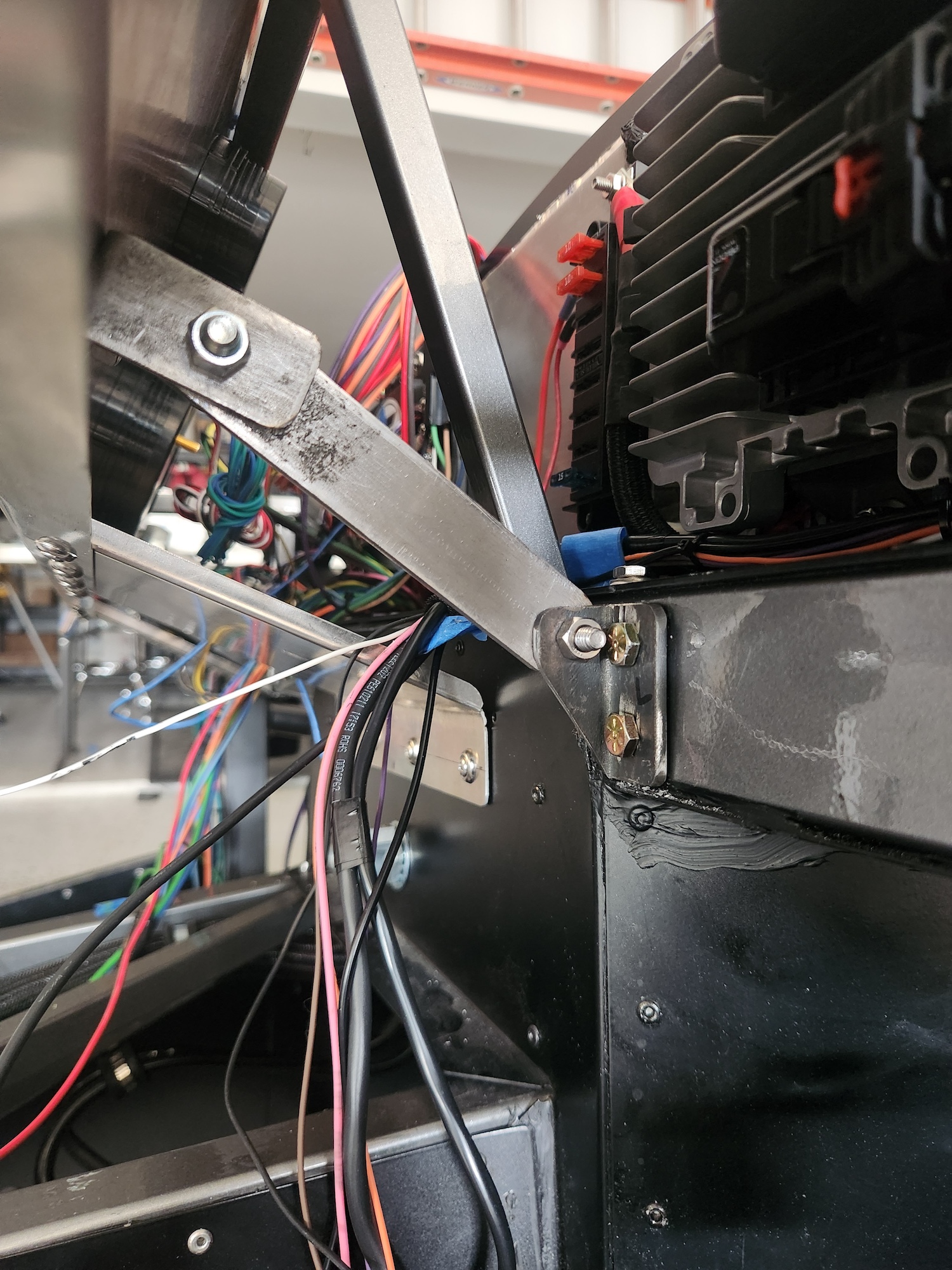

#116

Slow progress, but wiring is an enjoyable part of the build for me and I've spent time thinking through things as I go along. I completed the dash wiring and made sure it's easy to service/modify and disconnect from the main harness when needed. I ended up with four weatherpack connectors. I could have used fewer larger connectors, but decided to use what I had on-hand.

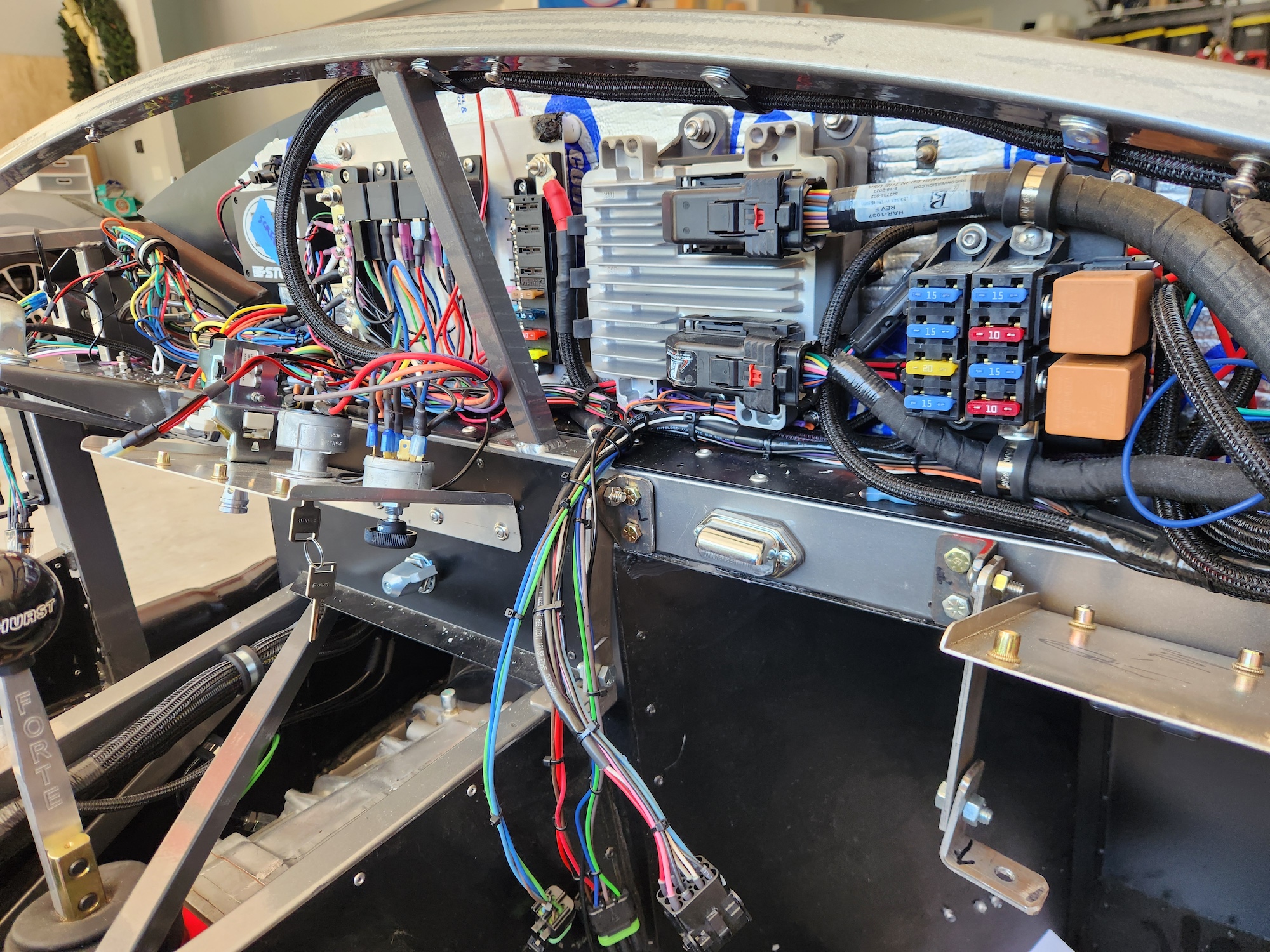

The clock is powered by a 12v constant feed.

You may notice a small device in the picture above -- it's a low voltage sensor for the battery light on the dash. This one is from American Autowire and very simple to install. Options are limited when using a one-wire alternator, and this one seemed like the most practical. It's designed to trigger the light when voltage drops below 11 volts. Ron Francis makes a similar unit.

I spent some time cleaning up the space between the firewall and dash. Despite how it may look, it's actually quite organized and all of the wires are very accessible if needed (hopefully never). There's a lot going on in there with the harness, ECU, ECU fuse panel, auxillary fuse panel, grounding buss bar, relays, e-Stopp, etc.

I installed the dash and plugged in the four connectors, and everything worked right out of the gate. I started up the engine to confirm the guages work, and they do. Fuel gauge is calibrated and the all-important clock keeps time (connected to a constant 12v instead of dash power). Overall, a big milestone in my small world.

A couple needed changes:

- The LED switches are way too bright, so I'll add a resistor to each in order to dim them a bit. Luckily they only illuminate when the switch is pressed. I also need to order a different switch for the high beams because the one I have illuminates white instead of blue. I must have clicked the wrong option when I ordered. Easy enough to swap out.

- I've realized the relays could be difficult to replace without removing the dash. Relay sockets would be better than direct spade connectors to the relays. I should have done that from the start. Not sure what I was thinking there.

-

10-18-2024, 02:38 AM

#117

Senior Member

Looks great. Nice job on the wiring. Oh, and now the hands illuminate on the clock unlike the earlier offerings...

Cheers,

Nige

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

-

10-18-2024, 06:18 AM

#118

Great job Terry and good persistence getting all those solutions buttoned up for a successful first start.

Roadster MK4 #10653 Date: 4-27-23; First Start: Oct 2023; Go Kart: Nov 2023; Body and Paint: To Kleiner EDD - April 2024; Graduated: TBD

SBF Boss 347, Edelbrock ProFlo 4, Milodon Road Race Oil Pan, Tremec TKX 2.87/0.81 OD, IRS Dakota Digital Dash, FFMetal Firewall Forward, BOIG Lower Cool Pipes, Forte's Mechanical Throttle Linkage and Hydraulic Clutch, Breeze Radiator Fan Shroud- Radiator Support Kit and Battery Forward

-

10-18-2024, 06:35 AM

#119

Senior Member

Originally Posted by

Nigel Allen

Looks great. Nice job on the wiring. Oh, and now the hands illuminate on the clock unlike the earlier offerings...

Cheers,

Nige

I might have missed it, but is the illuminated clock hands a new offering from speedhut?

-

10-18-2024, 07:00 AM

#120

Senior Member

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

. I enjoy the oh so common "whoa, it actually started. Oh yah, I should be checking the oil pressure..."

. I enjoy the oh so common "whoa, it actually started. Oh yah, I should be checking the oil pressure..."