-

02-10-2024, 08:26 AM

#201

Senior Member

Picture of the T-56 Shifter. Maybe the crossbar will interfere, maybe it won't:

-

02-10-2024, 12:13 PM

#202

Senior Member

Nice progress! Responses to two of your activities:

That amount of slip joint showing for your build is fine. With IRS the diff doesn't move. So you don't need as much exposed joint and possible movement as with a solid axle setup. The only downside is with it that close, it may be difficult to remove the driveshaft. Mine will tip in and out without undoing anything but it has a little bit more slip joint showing. I'd leave it like it is though.

For the radiator, I've found the FF setup with the rubber hose bumper on the bottom mounts and the crossover piece on the top it's fine. There isn't a lot of vibration plus it's captured inside the tanks versus hanging on a flange like on the Roadster. As for the shield on the bottom, I agree the bottom of the radiator is exposed. The shield you're talking about in the video at least for me is a little over the top. I've seen 4-wheelers with less. Although I know he does a lot of autocross and cones can do some damage. (Just don't hit 'em.  ) For mine, I made a screen out of SS mesh and an aluminum frame. Should handle road debris, rocks, whatever. All I figure I need.

) For mine, I made a screen out of SS mesh and an aluminum frame. Should handle road debris, rocks, whatever. All I figure I need.

Last edited by edwardb; 02-10-2024 at 12:16 PM.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

02-11-2024, 03:41 PM

#203

Senior Member

Originally Posted by

edwardb

Nice progress! Responses to two of your activities:

That amount of slip joint showing for your build is fine. With IRS the diff doesn't move. So you don't need as much exposed joint and possible movement as with a solid axle setup. The only downside is with it that close, it

may be difficult to remove the driveshaft. Mine will tip in and out without undoing anything but it has a little bit more slip joint showing. I'd leave it like it is though.

For the radiator, I've found the FF setup with the rubber hose bumper on the bottom mounts and the crossover piece on the top it's fine. There isn't a lot of vibration plus it's captured inside the tanks versus hanging on a flange like on the Roadster. As for the shield on the bottom, I agree the bottom of the radiator is exposed. The shield you're talking about in the video at least for me is a little over the top. I've seen 4-wheelers with less. Although I know he does a lot of autocross and cones can do some damage. (Just don't hit 'em.

) For mine, I made a screen out of SS mesh and an aluminum frame. Should handle road debris, rocks, whatever. All I figure I need.

Thanks Paul. The engine and transmission fit gets a little more complicated now (just bolding for people perusing this) - was playing around with the angle of the transmission and it is now sitting flush with the driveshaft universal joint. Going to try and oblong the engine mounting holes on both sides (on the mounts obviously) and possibly on the frame to see if I can find 1/2" of forward motion on the entire engine/transmission. Will see how it goes. Now the Stifflers driveshaft hoop appears too long, and is more over the U-joint at the differential and not over the driveshaft proper where it should be. Also decided to just cut out the crossmember and reinforce so the shifter plate can be easily accessed if I ever have to replace that inner seal again down the road).

I really like the screen protector you made for the lower part of the radiator. I'm going to do something (screen like you, or maybe the hex-aluminum sheets a lot of the roadster guys use). I went to the FFR open house last summer and one of the coupes had a car in front of him kick up a rock on the highway and it punctured his radiator. He made it to the show but was leaking. Unfortunately the radiators were backordered at the time and FFR didn't have any on hand. I think he had a tow home. There are worse things like cracking your oil pan or cooler, but the radiator's exposure is real.

Last edited by rhk118; 02-11-2024 at 03:52 PM.

-

03-02-2024, 05:58 AM

#204

Senior Member

OK, I am all caught up... Wheres the updates?!

Higgy

MK4 #11012 picked up 04/16/24

351W, 3 link, single roll bar

MK4 #10616 picked up 4/10/23

302w, 4 link, 17's, dual roll bar SOLD

MK4 #9759 picked up on 4/3/19

351C, 3 link, 17's, dual roll bars SOLD

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-02-2024, 07:18 AM

#205

Senior Member

Originally Posted by

Higgybulin

OK, I am all caught up... Wheres the updates?!

Higgy

Haha! Thanks Higgy. Work has been a bit crazy leading up to a vacation, then vacation, then catchup week after vacation (multiple long weekends seem better than full vacations to me, the before week and after week are exhausting). Will be getting back to it shortly. Still at deciding if I need a custom driveshaft after all and working on a new transmission mount bracket. Once that bracket is made engine will be getting painted and I'll start wiring.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-04-2024, 03:07 PM

#206

Senior Member

Seats

OK, here's something that arrived today. Finally got my seats in. These are Stoneleigh seats custom built by Intratrim Automotive Interiors in Britain. It took about 3 months from order to arrival and I am very happy with them to say the least. I found them through a couple roadster builds I follow on Instagram, and when pricing them out they come in about the same price as all other name brand sports seats--so one thing lead to another and....well, here they are (and wife saw them, sat in one and gave her wholehearted approval). You can customize everything on these (which I did but stuck to black as thats my interior color with some white stitching to break things up a little), they are heated (I am in New England after all), and they can embroider logos.

I am very happy with my fit in the kit Cobra seats in terms of the bottom and these have a very similar fit on bottom (whew). What I found (for me anyway) is that in the kit seats the transmission tunnel and the wall up to the sill naturally bolster me side to side, so these have back and shoulder bolstering but not so much on the bottom. These are a fiberglass shell that measures 16.5 inches at the bottom width, and the seat to back angle is the same as the kit seats. So these will easily fit between the tabs, and should sit far back, which I found was my strong preference when comparing the Corbeau Evolution X to the Vinyl Roadster Seats. My car is still at my friends shop working on a custom transmission bracket so will hopefully get over there and try them in soon.

Last edited by rhk118; 03-04-2024 at 03:14 PM.

-

Post Thanks / Like - 1 Thanks, 4 Likes

-

03-04-2024, 08:43 PM

#207

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-05-2024, 04:45 PM

#208

Wow! Those look nice.

I opted for the crack-back bucket seats, which I think are very comfortable, and I like them, as they remind me of my first car which was a '68 Firebird with the factory ram air, 400 c.i. V8 and the Muncie 4-speed fitted with a Hurst Super-Comp T-Handled shifter. THAT car had too much engine; like the Sunbeam Alpine/Tiger - more power than brakes :-)

FWIW, a key consideration for builders of "The Coupe" is head protection. With the roll cage, a minor incident with another vehicle on public roads translates to head injury. I have a Steve McQueen Bell helmet which I'll don when I am deliberately driving fast (is there any other way???), but I am second guessing whether I should have at least considered protection against "the crack back" and / or side impact protection :-)

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-06-2024, 10:30 AM

#209

Senior Member

Originally Posted by

LateApex

Wow! Those look nice.

I opted for the crack-back bucket seats, which I think are very comfortable, and I like them, as they remind me of my first car which was a '68 Firebird with the factory ram air, 400 c.i. V8 and the Muncie 4-speed fitted with a Hurst Super-Comp T-Handled shifter. THAT car had too much engine; like the Sunbeam Alpine/Tiger - more power than brakes :-)

FWIW, a key consideration for builders of "The Coupe" is head protection. With the roll cage, a minor incident with another vehicle on public roads translates to head injury. I have a Steve McQueen Bell helmet which I'll don when I am deliberately driving fast (is there any other way???), but I am second guessing whether I should have at least considered protection against "the crack back" and / or side impact protection :-)

Bob, I imagine it's easy enough to get some kind of head pad mounted on the roll cage behind your head for this, that was my other consideration. Also on the Kirkey website they sell adhesive closed cell foam padding for roll cages that I will mount to the roll cage next to the side of my head as I can see that being a problematic point of side impact, I have a big melon, not from smarts, probably too much air up there!

-

03-07-2024, 04:25 PM

#210

I am using Longacre roll bar padding. Bought a couple extra sticks of the size for the roll bar tubing (to add to the couple of sticks that came with the build). The sticky tape needs zip tie reinforcement. The roll cage is still a "blunt impact" for any significant impact tho ... Side impact is probably the greatest risk, as most folks are using a high back chair methinks ...

If I am going to drive aggressively, I put on the Bell helmet and pretend I am Steve McQueen :-)

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-08-2024, 07:43 AM

#211

Senior Member

Originally Posted by

LateApex

I am using Longacre roll bar padding. Bought a couple extra sticks of the size for the roll bar tubing (to add to the couple of sticks that came with the build). The sticky tape needs zip tie reinforcement. The roll cage is still a "blunt impact" for any significant impact tho ... Side impact is probably the greatest risk, as most folks are using a high back chair methinks ...

If I am going to drive aggressively, I put on the Bell helmet and pretend I am Steve McQueen :-)

Honestly I've had the same thought RE the helmet. Its going to be so loud in there that likely will help my ears haha!

-

03-08-2024, 12:20 PM

#212

I found that the open face helmet doesn't do much to knock down the dB's. This is mostly due to fit I think. A closed face helmet with the "neck gaitor" would do better.

Once you start down the helmet path, you'll likely get distracted by communication systems, particularly if you ride with a partner a fair amount.

I continue to do tweaks to cabin noise dampening. I have recently installed SecondSkin adhesive-backed noise dampening panels on the interior of my roof (where the headliner would be if I had chosen to install that). It really damps the drum head that is the roof panel, it has a nice appearance and "hand", and is very easy to install. It is quite thin / light, which translates to "it will likely not peel off the interior of the roof over time due to gravity and the characteristics of butyl." I hope ... :-)

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-13-2024, 03:37 PM

#213

Senior Member

Originally Posted by

LateApex

I found that the open face helmet doesn't do much to knock down the dB's. This is mostly due to fit I think. A closed face helmet with the "neck gaitor" would do better.

Once you start down the helmet path, you'll likely get distracted by communication systems, particularly if you ride with a partner a fair amount.

I continue to do tweaks to cabin noise dampening. I have recently installed SecondSkin adhesive-backed noise dampening panels on the interior of my roof (where the headliner would be if I had chosen to install that). It really damps the drum head that is the roof panel, it has a nice appearance and "hand", and is very easy to install. It is quite thin / light, which translates to "it will likely not peel off the interior of the roof over time due to gravity and the characteristics of butyl." I hope ... :-)

Thought about this a lot Bob. Wondering if there is room to bow those rollcage bars out to the side a bit or up towards the roof a bit to make some room for the noggin'....posted a different thread about this on the main coupe page to see if I can get some pictures of how much space there might be, don't have my body.

-

03-13-2024, 03:56 PM

#214

Senior Member

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

03-13-2024, 04:09 PM

#215

Senior Member

-

03-13-2024, 09:15 PM

#216

Hi Hank,

I'm not an expert, but I think you want a max operating angle no greater than 3 degrees and no less than 1/2 degree. This applies in any plane.

Brent

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-14-2024, 10:28 AM

#217

Originally Posted by

burchfieldb

Hi Hank,

I'm not an expert, but I think you want a max operating angle no greater than 3 degrees and no less than 1/2 degree. This applies in any plane.

Brent

For that short of a driveshaft, a maximum of 2 degress is a better number to shoot for.

My Type 65 Coupe: Ordered May 27, 2021. Arrived November 19, 2021.

I would like to treat my gas pedal as a binary operator. It would be nice to get the cooperation of everyone in front of me.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-20-2024, 05:17 PM

#218

This second photo caught my eye. It's probably the camera perspective, but the steering hub does not appear to align with your crotch - ha!

If it is any consolation, the steering shaft (and steering wheel) in my build points left. It is like Daytona (Oops, here comes another left turn :-). I am canted to my left in my build. This aligns with the foot-box, which also positions the body left and is mouse-nuts in the grand scheme of things. Haha!

FWIW ... Make sure your body is aligned with the steering shaft as you set your seats, not some arbitrary spacing from aluminum sidewall or some such.

It is great to watch this build !!

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-21-2024, 08:30 AM

#219

Senior Member

Originally Posted by

LateApex

This second photo caught my eye. It's probably the camera perspective, but the steering hub does not appear to align with your crotch - ha!

If it is any consolation, the steering shaft (and steering wheel) in my build points left. It is like Daytona (Oops, here comes another left turn :-). I am canted to my left in my build. This aligns with the foot-box, which also positions the body left and is mouse-nuts in the grand scheme of things. Haha!

FWIW ... Make sure your body is aligned with the steering shaft as you set your seats, not some arbitrary spacing from aluminum sidewall or some such.

It is great to watch this build !!

Thanks Bob, Yes I'm aware that the seats in this tend to not point "forward". These photos just have the seats sitting in there flat. There is so much room on either side (compared to the Corbeau's) that I will have quite a bit more wiggle room to offset them or angle them in one direction or another. I also am going to put them on sliders so they will go up a little from floor height but will be positioned so they can slide all the way back. That should then fit most drivers. For me I want my seating position "dead nuts" on or as close to that as it can be otherwise that would be a reason not to take long journeys (nuts and bolts I'm screwed  ). If I'm thinking about seating position while driving then it's wrong, if that makes sense. I am going to adjust those side upper rollbars as well...so seating position first, then see if there's enough room to adjust those around my noggin. If not I have no issues wearing a helmet.

). If I'm thinking about seating position while driving then it's wrong, if that makes sense. I am going to adjust those side upper rollbars as well...so seating position first, then see if there's enough room to adjust those around my noggin. If not I have no issues wearing a helmet.

I'm also on a non-ozempic diet haha...if I lose a few #'s I'll fit in the car better. Gained a bit of weight not being able to do my usual weight lifting/activity with the herniated disc last year. That is still bothersome (and now a "feature" of my body) but better enough that I've been able to start exercising again.

Last edited by rhk118; 03-21-2024 at 08:35 AM.

-

03-21-2024, 11:32 AM

#220

Senior Member

I need more motor pics!!!

MK4 #11012 picked up 04/16/24

351W, 3 link, single roll bar

MK4 #10616 picked up 4/10/23

302w, 4 link, 17's, dual roll bar SOLD

MK4 #9759 picked up on 4/3/19

351C, 3 link, 17's, dual roll bars SOLD

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-22-2024, 09:50 PM

#221

I'm looking forward to seeing how you "bow" those side bars on the roll cage. In my car, which is dang close to the era of your kit, there is not much more than a finger width between the roll bar and the fiberglass laterally, and less in the region of the rear quarter windows. There is more room to move or bow the bars up; maybe as much as 2" near the front and maybe 1.5" at the rear hoop (due to the slope of the roof). My sense is you will need some careful measurements with the body dry-fitted. It is an interesting idea: better clearance for the noggin and a bit better visibility out the top of the window. Those upper roll bars are clearly visible through the door cutout from outside the car and not tucked as well as the A-pillar roll cage uprights, for example.

I have decided to lose the rear quarter scoops, a.k.a.: the Big Ears. They serve no function except creating drag, turbulence and noise, and pressurizing the cabin. When I say "lose", I mean filling the cutout for the scoop mounting flange and smoothing the body lines. They used to have a function in the originals (rear brake cooling), but most of us are not designing that ducting for any of our rotors. If I were, I'd use a different approach anyway.

Glad to hear you are getting past some of the problems with your herniated disc!!

-

04-20-2024, 06:20 AM

#222

Senior Member

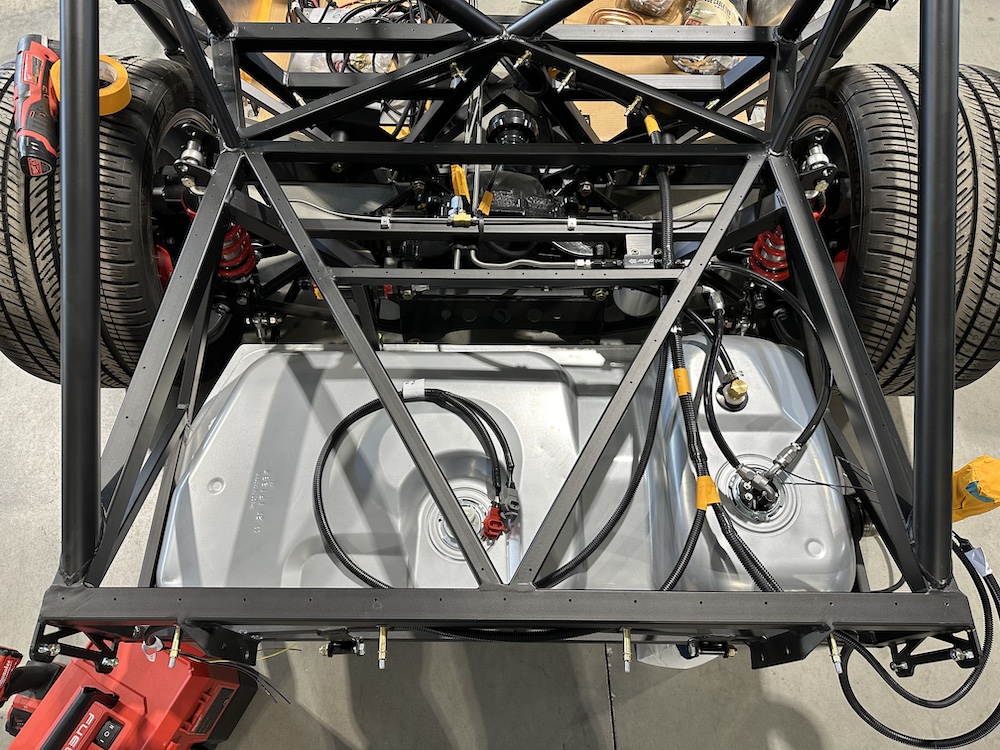

Not much of an update as have had a lot going on the past couple months. Picking up where I left off, had to cut out the crossbar in the transmission tunnel, shortened it and placed it transversely leaving enough room that I can remove the T-56 shifter plate if ever needed in the future. With the 302 block and T-56 the shifter was too far back, even with pulling everything forward 3/4" by adjusting the engine mounts. Also removed the bracket for the parking brake as I am using an electric parking brake in my build. I then ran the rear wiring harness along the right side of the tunnel there as well and up the crossbeam at the front of the tunnel:

Started wiring. For now I have just laid out where I want the rear wiring harness to run, as well as the electronic parking brake cables and mounted P-clamps. Need to perform harness surgery and will fuse the 2 harnesses together. There is A LOT of extra wire in the parking brake harness to remove, and will also need to tap in power for the T-56 reverse lockout/backup light controller I will be using - so will run backup light wires, EPB wires, and speed sensing wires into 1 harness and fuse the 2 together. Need to shorten some things and change slightly where they exit the harness. The orange tapes are marking where I need to tie things in or pull things out of the harness. I've never done harness surgery before but figure this an easy enough harness to start with, maybe will give me confidence with the main wiring harness.

Ran it along the right side of the transmission tunnel to the back, and you can see the smaller electronic parking brake wires splitting to the left and right calipers lying on the differential as well:

Here is one of the EBP connections, sorry out of focus but you can see where the electronic parking brake module plugs in by the zip tie:

One scary part of the build was a bit of a surprise. Prepping the engine block for paint, removed the valve covers and found what we've figured out to be ceramic tumbling beads sitting on top of the engine in the corners. Inspecting the valve covers there is a little metal shelf inside and there were several more wedged in there which is where they came from/managed to hitchhike into my engine build.

The valve covers I'm using are vintage replica Shelby valve covers from Shelby American. They are stamped steel and powder coated silver, these beads must be from the tumbling process after powder coat I assume and holy crap this is scary. Not something I would ever have thought of to check for, and glad I looked under that shelf inside because ticking time bomb. My engine was dyno'ed with these valve covers on. So because of this I had to remove the oil pain and inspect and fortunately no signs of any of these or any fragments of these in the oil pan. They are slightly larger than BBs (10/32 bolt there for comparison). Have a bit of a knot in my stomach over this, was going for a vintage look of a period-correct Shelby SBF but one without the vintage look of smoke coming out the back. One of the risks of building your own engine I guess  ...once again proving that the path of least resistance with these in time, materials, angst, and money is to just put in a Coyote like FF clearly designed them for.

...once again proving that the path of least resistance with these in time, materials, angst, and money is to just put in a Coyote like FF clearly designed them for.

Last edited by rhk118; 04-20-2024 at 06:41 AM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

04-20-2024, 01:40 PM

#223

Senior Member

Phew! Great catch, Hank! "...was going for a vintage look of a period-correct Shelby SBF but one without the vintage look of smoke coming out the back". Very funny, and couldn't agree more.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

04-24-2024, 05:41 AM

#224

Senior Member

I'm not suggesting they smoke, but don't want to be the guy with that re-creation or feature! If I wanted to I'd just tape a smoke bomb to the back and drive around that way like we did on our bikes back in the day!  So glad the block wasn't painted before putting the engine together otherwise would have never seen those. Sometimes its better to be lucky than good as they say...

So glad the block wasn't painted before putting the engine together otherwise would have never seen those. Sometimes its better to be lucky than good as they say...

-

04-28-2024, 02:59 PM

#225

Senior Member

Rear Wiring Harness

Just about completed the rear wiring harness. I say just about as haven't finalized where the exit point of the transmission wiring harness will be from the main portion of the harness in the transmission tunnel. I ended up cutting the entire rear wiring harness apart as I am running a rear backup camera, rear electric Wilwood parking brake system, one on each caliper, and the Bowler T-56 harness which provides reverse solenoid lockout, power to the reverse lights (and will use this for the backup camera), and VSS speed sensing for the Speedhut gauge. I had sent my kit GPS Speedhut gauge back to Speedhut and they converted it to a VSS-sensing speedometer for a shipping charge of $15. Very lovely and easy to work with folks.

So rather than running all of that separately out back, I tied it all into the harness so I'm running "1" harness out back. I also ran the reverse camera wire through this harness but didn't "tie it in" to the harness so I can slide it front to rear to get the reach I need between the mirror and the camera once I finalize their positions.

Photos on the forum aren't working at the moment so hopefully this works:

Front of the harness is on the left, and the taillights are on the right. The bundle of wires on the left are the transmission harness speed sending and power wires. Another bundle are the 4 wires going to the left and right emergency parking brake actuators (that harness came with about 6' extra wire and definitely had to be cut down anyway), and the other bundle of wires is the reverse backup cam wire. In the harness I ran a backup light + wire from the transmission harness out to the driver side rear of the car with the brake light. Will ground and jump to the other light and backup camera in the back of the car.

Next wire with the 3 connectors is the transmission computer, reverse sensor, and backup lockout solenoid harnesses. The next 2 are the left and right parking brake actuators. Note if you're going to use these the left side gets mounted on the right caliper and vice-versa, otherwise the wires will get caught in the shock. Next 2 wires are fuel pump power using the harness wires, and the fuel sender using the harness wires, both of those were quite long and shortened maybe 20" each. Finally the last 2 are the left and right brake lights, backup camera wire up top, and the green wire at the bottom is the backup light power from the transmission. I re-wrapped everything using fabric loom rather than the plastic tubing as it seems a bit easier to work with, especially when deciding where to pull certain branches out.

Last edited by rhk118; 04-29-2024 at 06:03 PM.

-

06-09-2024, 08:07 AM

#226

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-09-2024, 08:29 AM

#227

Like that look. Nicely done.

My Type 65 Coupe: Ordered May 27, 2021. Arrived November 19, 2021.

I would like to treat my gas pedal as a binary operator. It would be nice to get the cooperation of everyone in front of me.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-09-2024, 11:04 AM

#228

Senior Member

MK4 #11012 picked up 04/16/24

351W, 3 link, single roll bar

MK4 #10616 picked up 4/10/23

302w, 4 link, 17's, dual roll bar SOLD

MK4 #9759 picked up on 4/3/19

351C, 3 link, 17's, dual roll bars SOLD

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-09-2024, 08:50 PM

#229

Man, that looks really sharp!

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-09-2024, 09:29 PM

#230

Senior Member

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-25-2024, 05:48 PM

#231

Hey Hank,

Congratulations on all your progress. I’ve read and re-read the last two pages of your thread and I have concerns and questions about the T56, which as you know I am installing like you. I received mine from Mike Forte in April 2023. I have not messed with the covers the way you have.

However, before I get into my stuff, I want to say I am super impressed by the quality of your work! Your research and your execution are exemplary.

You say “Hopefully your vent is a good one and works properly, test it” - how do you test it?

You say “If the shifter is in the rear position you are likely safe from leaks” – mine is in the rear position, which is how it came and I don’t intend changing it. So hopefully I will be good

I will make my transmission tunnel panels removable; this shouldn’t be hard with the simplistic vinyl covering approach I am taking.

Very much like the way your seats are between the mounts and it gives you more leg room. I currently have the FFR low backs but may consider something like what you have if the leg room is a real issue.

Not sure where you are with the wiring but I did end up running separate power and ground to my alternate fuse box. Seemed like a good idea at the time! I am still working on the wiring because I switched to using the Speedhut sender wires rather than the ones in the harness. I did this because the Speedhut tech suggested it because of the shared ground in the harness. I also was late adding my 4 in 1 transmission control unit and have wires from that going all over the place. I made both of these changes before I moved house and didn’t take the time to route the wires somewhat cleanly. Now it bugs me, so I am reworking it.

For your transmission mount you reference adding a couple of tabs – do you have any additional pictures that show how these support the mount?

Thanks for taking the time to post all that you have.

John.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

06-25-2024, 06:49 PM

#232

What are the other projects you have in the background here Hank? You are having too much fun methinks

:-)

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

07-03-2024, 02:46 PM

#233

Senior Member

Hey John - sorry for the delayed reply. I think some of the T-56s early on came with bad vents, and that comment was based on forums from 2007-2008ish. If the vent was bad then you were more likely to get rear end leaks on the T-56 because pressure would build up inside. I suspect that isn't an issue now. The leaks around the shifter boot - there was a lot of this on T-56 related forums. If the shifter is fully forward then there is less "spash" of transmission fluid onto the bottom of the shifter boot, more "splash" of fluid in the mid position with more reported leaks. By cutting out the crossbar in mine was able to get the shifter fully forward in mine. The thought here is if it starts to leak you can replace the plate and shifter boot. I don't see this mentioned as a problem here on the forum, so I struck it up to be something to be aware of - that the T56 could eventually leak around the shifter plate/boot and might need servicing. So that crossbar in mine that I replaced doesn't cover or interfere with the ****fer plate and it can be changed out in the future easily if needed. Hopefully overthought problem and never needed!

I'll get better photos of the plate. Basically with the t-56 the mounts will be further back than the limits of the bracket with a 302.

Last edited by rhk118; 07-03-2024 at 03:20 PM.

-

07-03-2024, 02:51 PM

#234

Senior Member

Hey Bob! Lots of stuff going on. Work is absolutely nuts and been eating up some of my free weekends for the past 4-5 months. Also had my eldest Daughter graduate from High School which involved a surprising number of events at school, meetings, parties, family visiting, coordination of older family members traveling some distance...etc. all while my other kids were full on spring sports every day. I did manage to make it to a 7 hour track day a couple of weeks ago (7 20-minute) sessions, so that was fun...can't wait to get the Daytona there!

My takeaway from that is I will likely need some kind of intercom system in the Daytona for passenger-driver that isn't one of those wired microphones that you stuff into your helmet then wire yourself to the other person's helmet....that wire kept getting stuck in the shifter going across my console and pulling on the microphone/earpiece with shifts into fast corners....and that was in a normal relatively quiet car...maybe there is a wireless system or I can put jacks into the transmission tunnel or somewhere the driver/passenger can plug into and not have a wire running across the transmission tunnel and near the shifter.

Finally...I am considering adding the Turkey Pan to the Weber setup. Turns out there is a shop within an hour of my house that makes them for Jim Inglese (Jim gave me their name, great guy him!)....The thought being it will hide a bunch of the wires going over the engine and I'd like to not have interference with any wires and the throttle mechanism either, but then might need to cut an intake hole in the hood. Cool.

I think I've gotten very good at outfitting the thing without actually accomplishing any building!

Last edited by rhk118; 07-03-2024 at 03:28 PM.

-

07-08-2024, 09:53 AM

#235

Originally Posted by

rhk118

Hey John - sorry for the delayed reply. I think some of the T-56s early on came with bad vents, and that comment was based on forums from 2007-2008ish. If the vent was bad then you were more likely to get rear end leaks on the T-56 because pressure would build up inside. I suspect that isn't an issue now. The leaks around the shifter boot - there was a lot of this on T-56 related forums. If the shifter is fully forward then there is less "spash" of transmission fluid onto the bottom of the shifter boot, more "splash" of fluid in the mid position with more reported leaks. By cutting out the crossbar in mine was able to get the shifter fully forward in mine. The thought here is if it starts to leak you can replace the plate and shifter boot. I don't see this mentioned as a problem here on the forum, so I struck it up to be something to be aware of - that the T56 could eventually leak around the shifter plate/boot and might need servicing. So that crossbar in mine that I replaced doesn't cover or interfere with the ****fer plate and it can be changed out in the future easily if needed. Hopefully overthought problem and never needed!

I'll get better photos of the plate. Basically with the t-56 the mounts will be further back than the limits of the bracket with a 302.

Hi Hank, as always thanks for sharing all the info and for doing the research! Currently I plan to keep my shifter in the rear most location. I tested fitted the gear stick that comes with the kit - leans forward significantly and I think it will put the shifter in a good location, so that is my current plan.

Your seats look great. I noticed they fit between the seatbelt connections- i am wondering how much further back the seats go because of this. I have to low backs that came with the kit and they are to wide to go between the seat belt connections. I am wondering if I should try other options, or hack into my seats to get them as far back as possible.

Thanks

John

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

07-08-2024, 01:39 PM

#236

Originally Posted by

rhk118

Hey Bob! Lots of stuff going on. Work is absolutely nuts and been eating up some of my free weekends for the past 4-5 months. Also had my eldest Daughter graduate from High School which involved a surprising number of events at school, meetings, parties, family visiting, coordination of older family members traveling some distance...etc. all while my other kids were full on spring sports every day. I did manage to make it to a 7 hour track day a couple of weeks ago (7 20-minute) sessions, so that was fun...can't wait to get the Daytona there!

My takeaway from that is I will likely need some kind of intercom system in the Daytona for passenger-driver that isn't one of those wired microphones that you stuff into your helmet then wire yourself to the other person's helmet....that wire kept getting stuck in the shifter going across my console and pulling on the microphone/earpiece with shifts into fast corners....and that was in a normal relatively quiet car...maybe there is a wireless system or I can put jacks into the transmission tunnel or somewhere the driver/passenger can plug into and not have a wire running across the transmission tunnel and near the shifter.

Finally...I am considering adding the Turkey Pan to the Weber setup. Turns out there is a shop within an hour of my house that makes them for Jim Inglese (Jim gave me their name, great guy him!)....The thought being it will hide a bunch of the wires going over the engine and I'd like to not have interference with any wires and the throttle mechanism either, but then might need to cut an intake hole in the hood. Cool.

I think I've gotten very good at outfitting the thing without actually accomplishing any building!

Hi Hank!

I am keen to hear what you come up with for an intercom. There are of course avionics systems, complete with jacks you mention that might be fitted to helmets. These tend to be quite expensive. Without a helmet, most states disallow headsets in cars. The assumption is you are listening to loud music :-) There may be helmet oriented systems developed specifically for race cars, but those often don't provide for a passenger, or have a "keying" capability

I was interested in the turkey pan at one point, but the clearance at the rear of the intake manifold is kinda non-existent. I carved the lip of cowl just to provide clearance for some low-profile stack filters on the rear-most stacks. You may be able to modify the turkey pan to handle the rear-set position of the SBF in the coupe frame, but you will face removing throttle bodies, ..., etc. to handle any maintenance of items under the turkey pan.

With high-overlap cams, the turkey pan initially served to help contain fuel mist from being expelled into the engine bay by the stacks during the exhaust cycle. I suppose the pan also helps to direct cooler air to the stacks (if you are using some cowl induction (hole in the bonnet.). With the cam I believe you are running, the first of these benefits is negligible.

Looks cool tho!! :-)

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

07-08-2024, 06:05 PM

#237

Look up the intercom setups the Baja runners use.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

07-25-2024, 01:31 PM

#238

Rob, do you have a link you can share?

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

07-28-2024, 08:01 PM

#239

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

08-02-2024, 10:49 AM

#240

Senior Member

Thanks fellas….been a busy summer for me….thought I’d get more of the build done but been having great weather and A LOT of visitors this summer. Been more family-focused this summer, figure once everyone is back in school this fall I’ll tear back into the coupe.

Rob - appreciate that link…time to start researching these.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

) For mine, I made a screen out of SS mesh and an aluminum frame. Should handle road debris, rocks, whatever. All I figure I need.

) For mine, I made a screen out of SS mesh and an aluminum frame. Should handle road debris, rocks, whatever. All I figure I need.

). If I'm thinking about seating position while driving then it's wrong, if that makes sense. I am going to adjust those side upper rollbars as well...so seating position first, then see if there's enough room to adjust those around my noggin. If not I have no issues wearing a helmet.

). If I'm thinking about seating position while driving then it's wrong, if that makes sense. I am going to adjust those side upper rollbars as well...so seating position first, then see if there's enough room to adjust those around my noggin. If not I have no issues wearing a helmet. ...once again proving that the path of least resistance with these in time, materials, angst, and money is to just put in a Coyote like FF clearly designed them for.

...once again proving that the path of least resistance with these in time, materials, angst, and money is to just put in a Coyote like FF clearly designed them for.