-

Originally Posted by

460.465USMC

Thanks for the background and chiming in, John. I recall what Edwardb did to get a workable oil pickup on his Gen 3. It didn't look easy to me. Glad I have PLENTY of stuff to do on the build before I'm in a pinch for a shallow oil pan/oil pickup. I'm hoping Moroso has it figured out by the time I'm ready.

Agreed, Georgie puts out high quality/custom work. I remember what he did on your build. It was great.

Good to know - I haven't even ordered the kit yet so no where near needing to deal with this, I'm just trying to get all my ducks in a row before I drop any cash on this project. I've also heard from my Canadian rep that FFR is working on the driver's side header for it since the bolt pattern is different (same as the 5.2 from what I've read) and that's coming soon. I think the twin intake should fit and have seen some good videos about how it makes the car more drivable at low rev's and also increases the power (like we need more right?). I just feel that overall it has more potential but like others have said the 4x is plenty.

-

For those that are interested this is a good video that compares the single Gen 3 to the Gen 4 dual intakes - https://youtu.be/lMyA_6rJJAg?si=f_vKnTc-IZYTYnHt

-

Senior Member

Testing the DIY Tubing Straightener

I previously mentioned making a DIY tubing straightener I copied from a design I found on YouTube. Yesterday, it was finally time to test it on the 3/8" SS tubing I'll be using for my supply and return fuel lines. It worked well.

If you have absolutely nothing better to do, here's a one-minute video of me straightening my first 6' section of tubing. The genius of this design is that it's vice mounted. This makes it easy to finely adjust the two sets of pulleys to press against the tube with just the right amount of clamping force. Not too much. Not too little.

Next comes the challenging part (for me): forming the tubes to run through the left side of the transmission tunnel as others have done. I really struggled to bend the brake tubing on my Roadster build. Multidimensional thinking is not my forte. I suspect this time will be no different. I will have to estimate the location of the jog for T-56 shifter clearance, as I don't yet have my transmission. Thankfully, there are pictures from others who've already done this.

Last edited by 460.465USMC; 10-06-2024 at 05:35 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Apparently I have nothing better to do so I watched the video  . It looked like it worked pretty well but difficult to tell from the angle of the camera. Do you feel like it straightened the line well or were there still humps and jogs in it afterwards?

. It looked like it worked pretty well but difficult to tell from the angle of the camera. Do you feel like it straightened the line well or were there still humps and jogs in it afterwards?

Coupe complete kit ordered: 9/26/24. Gen 4 Coyote. T-56. IRS w/3.73. Wilwoods. PS. HVAC. Side windows.

-

Senior Member

Very little if any in the way of humps or jogs. The 6'3" piece I straightened has a gentle bow. I'm a newbie in all this, so I may prove myself wrong here, but I don't expect the slight bow to come into play as I bend the tube. I'll see if I can grab a picture and post here.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Here's a picture of the 3/8" SS tubing next to a piece of rigid conduit after I ran it through my DIY straightener. I don't know if it's typical to have a gentle curve in coiled SS tubing after it's been through a straightener. Or, if my straightening process needs improvement?

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Hey Chris. Nice work with the DIY straightener. That’s pretty cool. When I was straightening coils of SS tubing I ended up with a similar bow in the tubing. In my experience, ff you run it through again, pulling down slightly on the end as it’s coming out of the straightener in the opposite direction of the bow, it should straighten it out. A tiny bit of bow isn’t a big deal. The tubing has enough spring in it that as you set it in its final position on the chassis and clamp it you can pull it straight.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Gen4X ECU Shipped!

I thought there could be some interest in an update on my Coyote Gen 4X ECU (M-6017-M50HM). I received notice today that it finally shipped (Summit Racing). I emailed Dan G. at F5, as I'm curious if they've also received theirs, or will receive it soon. Looking forward to their Coyote fitment update for the Gen 4X.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Fuel Tank Progress. Fuel Line Fail.

Fuel Line Fail

Bad news first--not bad, really. Just disappointing. My attempt at 3/8" SS tubing is a Fail. Why? I believe the root cause is my handy dandy DIY straightener (and I was so proud of it!). However, after several attempts, I found the straightener is pressing the tube into an oval shape. I believe this is caused by a slight misalignment between the pulleys as they face each other. One side of pulleys sits >1/16 inch above the other row. Just bad quality control in the straightener manufacturing process (by yours truly). I think the straightener would work fine otherwise, but do keep in mind the amount of pressure from the vise.

I could either re-make/fix my straightener (time), and buy more SS tubing ($$). Or, go with the SS braided option (like I did on my Roadster build). I chose to go braided. Plus, I was able to return the pricey Tube Swage Let-Lok connectors (for the hardline) to cover the braided hose. Big thanks to Mark at Breeze for helping out! A great forum vendor, he is (in my best Yota impersonation)! Ultimately, I decided not to make 3/8" SS tubing a career project. There are so many other challenges I'm looking forward to in this build. Moving on.

Fuel Tank Progress

The fuel tank install was pretty straight forward overall. The new parts for me are the Pro-M hangar, Walbro pump, and Trick Flow filter. New to me, but far from new on this forum.

Straightening the raised lip on the front of the tank (per instructions) so the 3/4" square tube will snug up flush. I tried these clamps (HF specials), and they worked pretty good.

I found this Walbro power connector that snaps into the fuel pump for a solid connection. Less than $10.

Here is a view of the hangar and pump together, ready to be installed (part numbers for everything below). The Molex crimp and seal butt connectors are not cheap, but I trust Edwardb's recommend for this application. The fuel filter sock is not attached in this picture, but it was before going into the tank. I was glad to see Walbro supplied pinch style clamps, as I had a worm-drive clamp fail early on my Roadster. The pinch tool is something I have on hand for lawn sprinkler repair.

The bracket that secures the filler tube caught me off guard. Something I've read about in the past, but had since forgotten. Others have improved upon this setup (e.g. JimStone, Edwardb), but I'm calling F5's design functional and good enough. Admittedly, dropping the tank full of gas in the future would be a pain in the hind quarters, because it's not easy to get an Allen wrench in there to loosen the bracket (filler tube and bracket must be removed for tank install and removal).

Placement of the Trick Flow fuel filter similar to others.

Here's what the Trick Flow looks like with the cannister cover removed. Talk about easy maintenance for fuel filter replacement!

IRS vent (<$10), and fits perfectly in the F5 supplied IRS breather hose. (Thanks, Fman!).

Part numbers and a few musings

- Tank straps - rear bolts: used SS 5/16" again. The hoops in the straps are too small for the provided 3/8" bolts. I'm sure I could bang them in--removing plenty of paint in the process. Plus, difficult to remove when/if I need to remove the straps (had to a few times during my Roadster build-up).

- Tank straps - front bolts: bought 3/8"-18 x 2.5" socket heads. I know there are workarounds, but I'm not going to mess around again trying to get the straps closed over the bolt with the too short (2.25)" kit-supplied bolts. Especially, since I seem to pull the tank off/on more times than I care to admit during the build up. Probably not an issue for other builders.

- Tank filler gasket: Ford F4ZZ-9072-DA. This is a highly recommended/documented upgrade. There have been a number of leakage reports on the forum. Easy and cheap insurance to do now.

- Fuel level sender: measured 15 ohms (empty) and 160 ohms (full) as expected. Similar to my Roadster.

- Walbro fuel pump (Now TI Automotive (P/N: GSS340BX): 255 lph

- Pro-M Racing hangar (1986 – 1997 Mustangs) with 3/8" inlet/outlet and 6AN female connections

- Walbro wiring harness (VPN-94-615). Shown above. Clicks into the pump connector

- Molex 19164-0077, Perma-Seal™ Heat Shrink & Crimp Step-Down Butt Connector (Del City). Cut the wires to length so they're not resting or making contact with the hangar.

- Light coating of motor oil on the round gaskets (not the square edged ones), and tightened retaining rings with channel locks. "Use the O-ring [gaskets] included with the kit not the square profiled O-ring sent with the sender"

- Got the fuel pump and bracket assembly installed without having to notch the tank opening. Great tip from Rsnake showing this was possible! Check out his build video #14, around the 11 minute mark.

- Bought a Dorman vent for the IRS breather hose end (see picture above). I don't like the idea of leaving it open.

P.S. My Gen 4X ECU just arrived. A quick glance and so far it looks identical to the Gen 3 (same/similar DBW accelerator pedal, O2 sensors, etc.).

Last edited by 460.465USMC; 10-17-2024 at 09:22 AM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Great write up!

Now I understand your choice to abandon the SS fuel hard lines. Honestly, it's probably for the best. So much easier to deal with flex lines I'm learning.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

For what it's worth, I used a combination of flex line and NiCop on my last build. There are many pros and cons to all sides of the story but installing PTFE/steel braid with AN fittings to run the length of the frame rails made a ton of sense to me. I know OEM is in lawsuit avoidance mode with hard lines but in these applications I truly feel either direction is more than adequate. If I recall correctly, I used all Fragola hose and a combination of Fragola and Summit fittings.

Coupe complete kit ordered: 9/26/24. Gen 4 Coyote. T-56. IRS w/3.73. Wilwoods. PS. HVAC. Side windows.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Swarf. Shavings. Filings. Chips. (Panel Fitting)

As I was waiting for SS braided fuel line from Breeze, I turned to panel fitting. Yes, swarf is a new term to me. According to the ever trusty inter-webs, it's a term synonymous for the shavings, filings, chips, etc. that pile up from from drilling, grinding, machining, etc. That's pretty much what I've been doing over the last couple of weeks. Creating an abundance of swarf.

- Wilwood pedal assembly: install was pretty straight forward per F5 instructions. I had to file down the brake and clutch switch mounting tabs, so they would lay flat. Top triangle bracket didn't quite square up to the diagonal cross member--see picture below. So, I added some spacers (washers) to shim the gap--see picture.

- Top of footbox panels. It only took me 11 rivnuts for the left footbox cover panel. That is, before I asked myself why not simply tap the chassis for these 10-32 SS button heads? D'Oh! Forehead slap! That panel can feel like one-of-a-kind, because the rest of the panels are fastened without rivnuts. One more thing (translate as palm smacking forehead again!): I managed to locate one of the holes directly (and I mean directly) above one of the 1/4"-20 bolts used to secure the triangle pedal box bracket to the diagonal cross member--picture below. I can now say from experience SS bolts don't like to be tapped. The fix? Low profile 10-32 weld nut--see picture below. That first panel almost became a career project. Sheesh!

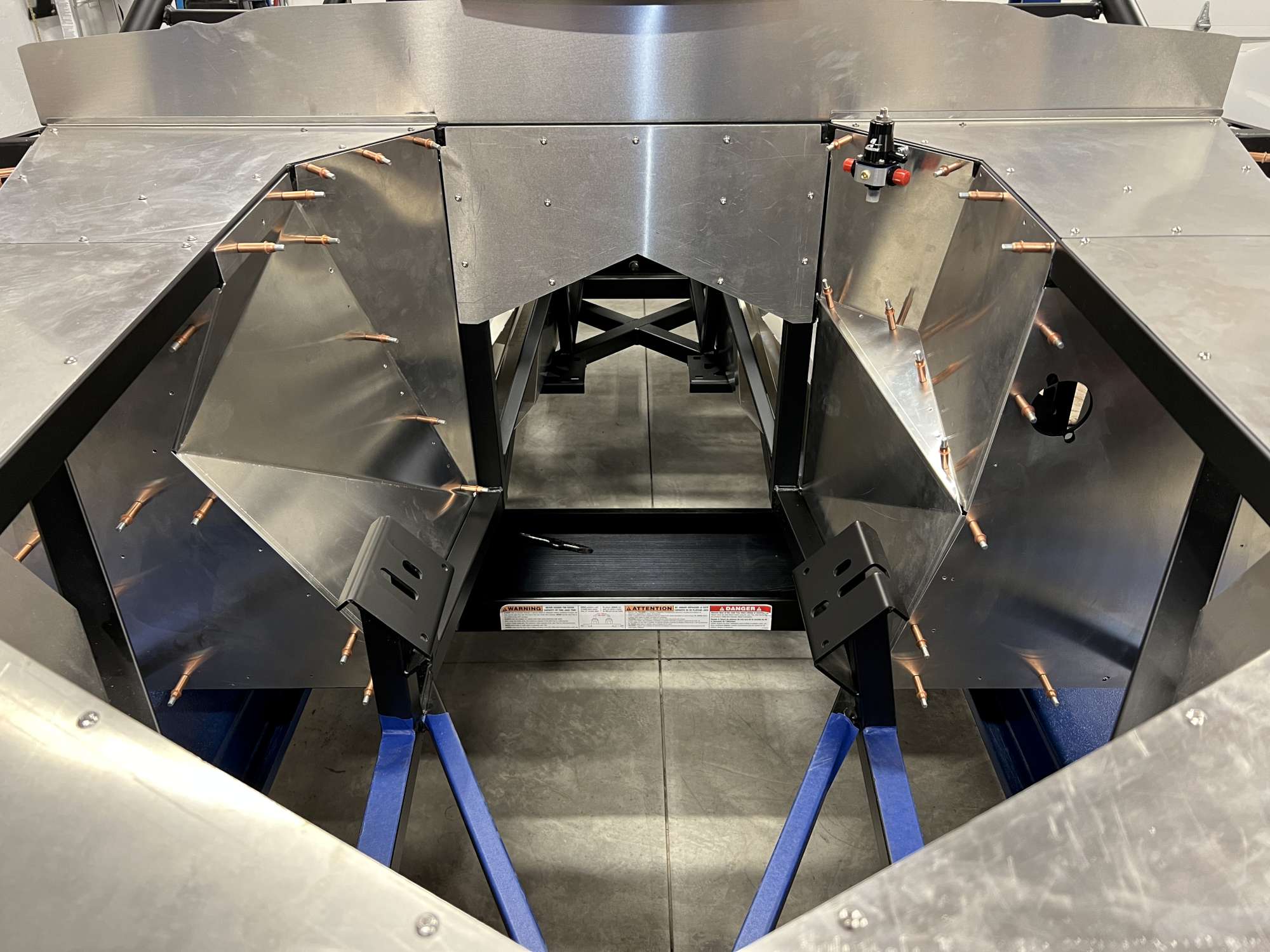

- Engine bay panels: next up was making up four engine bay panels that sit forward of the footboxes (as others have done). I think it makes for a clean looking engine bay. Easy to pull off if access is needed by removing a few 10-32 screws. I also made a panel for the area above the transmission tunnel. A clean look IMHO.

- Aeromotive fuel pressure regulator (40-75 PSI; 13129) and gauge (0-100 psi; 15633 - not yet installed). I mounted it in a location I've seen others use. Easy access for the fuel line connections. The socket head screws supplied for the mount use a 9/64" hex bit (i.e. allen wrench), not a common size.

- At this point both footboxes are fitted for all their panels, as well as the above mentioned additional panels I made.

Left side footbox. Here you can see shims for the pedal assembly bracket, as well as the low profile weld nut to fix my mislocated hole. Attached the weld nut with JB Weld (what else?) after removing the powder coat for a good bond.

Here's a view looking down on the additional panels I made. These will be powder coated to match the chassis black, once I have my first batch ready. I dig the SS button head contrast against the black.

Aeromotive pressure regulator is mounted with two 10-32 screws. That particular chassis member isn't very thick for tapping. So, I ran the holes through both sides, and secured with nuts. The panel above the transmission tunnel is also visible.

The footboxes sure have a lot of gaps--here's just one example on the right side FB. No doubt a more professional install could minimize them, but they're still there. Wondering what others have done to close these gaps?

Moving on to the cockpit panels.

Last edited by 460.465USMC; 11-14-2024 at 06:40 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

I will likely use silicone on the hidden areas. I plan on 3D printing and painting a part to cover the hood latch bolt mount.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Didn’t use the filler tube retainer on mine, that sh”t goes in like 6in, never coming out. I see people attempting hard lines on every build, why why why, completely unnecessary. Not ragging on you just hoping someone else reads this in the future too. AN flex is superior in every way. Stainless or nylon doesn’t matter.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

burchfieldb

I will likely use silicone on the hidden areas. I plan on 3D printing and painting a part to cover the hood latch bolt mount.

Appreciate your input, Burchfieldb. I just don't remember this many gaps on my Roadster build, and I still have a loooong ways to go. 3D printing sounds like a sweet solution; however, I don't have the equipment or know-how. Someday...maybe.

Originally Posted by

Kbl7td

Didn’t use the filler tube retainer on mine, that sh”t goes in like 6in, never coming out. I see people attempting hard lines on every build, why why why, completely unnecessary. Not ragging on you just hoping someone else reads this in the future too. AN flex is superior in every way. Stainless or nylon doesn’t matter.

Hello Kbl7td. No offense taken. I've checked in on your build and I'm a bit envious at your creativity and skill. Some really cool stuff going on there.

Stainless lines? Just a new challenge I wanted to try on this build, but it ain't going to happen. I used braided flex lines on my Roadster build. I agree: they are a solid setup, indeed. Appreciate you dropping by.

Last edited by 460.465USMC; 11-15-2024 at 01:57 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Chris - pretty good progress so far. I really like the engine compartment panels, I will probably go the same direction - did you use 6061 or 5052? Still haven't decided on a color for my panels but I guess I have a few months to figure that out. I really like the button heads that have the built in washer. The last car I built I used a significant number of button heads but hadn't seen those like a lot of F5 builders use. I spent a lot of time centering SS washers so they weren't off by 1/32nd  .

.

Can't really help on the built in "venting" in the foot boxes but I am sure other builders will ring in on that subject. I would suspect it's important to to seal up every gap, regardless.

Coupe complete kit ordered: 9/26/24. Gen 4 Coyote. T-56. IRS w/3.73. Wilwoods. PS. HVAC. Side windows.

-

Senior Member

Originally Posted by

PNWTim

Chris - pretty good progress so far. I really like the engine compartment panels, I will probably go the same direction - did you use 6061 or 5052? Still haven't decided on a color for my panels but I guess I have a few months to figure that out. I really like the button heads that have the built in washer. The last car I built I used a significant number of button heads but hadn't seen those like a lot of F5 builders use. I spent a lot of time centering SS washers so they weren't off by 1/32nd

.

Can't really help on the built in "venting" in the foot boxes but I am sure other builders will ring in on that subject. I would suspect it's important to to seal up every gap, regardless.

I used 6061 because those are flat, no bends. And, I like the extra rigidity for those. However, I'm going to try to build a recessed trunk box next, so picked up some 5052 remnants from my local metal supplier, as I'll need to bend 90 degree corners.

On the Roadster, it was critical to seal any and all gaps in the footboxes to keep the engine heat out. I assume it's similar for the Coupe, but wow! A lot more gaps to deal with in the FBs.

Last edited by 460.465USMC; 11-15-2024 at 01:58 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Filling any holes or gaps is a must, especially when you add the panels your adding. The engine bay heat is real. there are a number of ways to close off the holes/gaps. I used clear silicone, aluminum tape and a two part marine putty.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

I really like the direction this build has taken. Namrups speaks the truth. I've been in his car, its warm

and loud

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

11-19-2024, 10:20 AM

#100

Senior Member

Originally Posted by

Namrups

Filling any holes or gaps is a must, especially when you add the panels your adding. The engine bay heat is real. there are a number of ways to close off the holes/gaps. I used clear silicone, aluminum tape and a two part marine putty.

Thanks, Scott. Kind of what I figured. And, it makes sense that the heat transfer from the engine bay would be similar to the Cobra. I'll be installing Thermo-Tec on my FB panels (and others), so that should double as insulation from the heat, and help close some of the gaps. For the exposed gaps, I'll have to address those one by one to see how I can close them. But not in a way that shouts DIY.

Originally Posted by

Blitzboy54

I really like the direction this build has taken. Namrups speaks the truth. I've been in his car, its warm

and loud

Thanks, Jesse. I think both of us are having a blast on our second builds. I will be going with the Gas-N pipes, so I hope those tame the exhaust noise a tich.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

12-12-2024, 03:16 PM

#101

Senior Member

HOLY COW!! Not sure how I missed this; feel like I'm showing up to a party at 10 when the invite said 7. Congrats on the build, Chris, it looks like as much fun as the first. And you're doing a top notch job as usual. Strangely, our roadsters are still exactly the same color of gel coat red, so I'll skip the part where I give you a hard time about starting a second build before finishing your first. I'll continue to enjoy your updates, glad to see you dove in again!

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

12-12-2024, 04:00 PM

#102

Senior Member

Hi John! Yeah, you can call a spade a spade. Needless to say, the build process is so rewarding for me. I fully accept I'm not following the proven path paved by so many great F5 builders before me.

Yes, I'm having a blast (again!). Given my limited garage space at our "new" place, and funding needed for a second build, I had to make a choice. However, it was smiles for me the whole time driving my Roadster in gel coat. Yep, I miss it!

I hope you stop by from time to time. Your observations and tips are high value to me. I look forward to seeing your beauty in its new "clothing".

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

12-12-2024, 09:13 PM

#103

Senior Member

Originally Posted by

460.465USMC

I'm still pretty tickled to have received all of the suspension pieces with my delivery. Nice to be able to plug away at the front and rear suspension and keep the march toward roller stage moving forward.

A few issues to resolve:

- PS rack: swapped out the pre-installed bushings with the Breeze aluminum offset centering bushings. Installed the PS rack and centered it within the frame. (I will center the steering wheel and equalize lock-to-lock later).

* The Breeze bushings are nice pieces, but I think they are probably a better fit for the Roadster application. Here's why: it appears the PS rack must be mounted in the top holes (race car height) in order to keep the Breeze adjustment slots accessible. Thankfully, this doesn't actually put the rack at the full upper height, because the offset bushing holes are not centered--see picture below. So, after all is said and done the rack is probably slightly higher than the lower street use holes. After trading emails with Mark at Breeze, I may set ride height about 1/4" lower. If I had to do it over, for the Coupe application I would probably save the money. The silver lining is it was easy to center the rack in the frame. - The 1/2"-20 grade 8 bolts to attach the UCA to the frame stopped a couple threads short of being flush with the nut (I normally like a 2+ threads sticking past the nut). And, they were not mechanical lock nuts as advertised. I emailed F5 last week, but still no word back. So, Ace to the rescue for grade 8, 1/2"-13 x 2" bolts. Already had extra 13 pitch nylon locknuts on-hand.

- Upper ball joint castle nut threads too far down the shaft for reasonable cotter pin engagement. Added spacers to fix--see picture below.

What went well:

- Front UCAs: pushed right into position with a spacer on the rear bushing. Primed the bushings with a bit of grease (4-5 pumps on my grease gun). I like to see it come through the flutes in the bushing before assembly. On a tip I saw in cv2065's build thread, I picked up the Lock N Lube attachment for my grease gun. As he said, no more swinging from the grease gun trying to get it to release. Boy, can I relate to that! Not expensive ($30), and worth every penny IMHO.

- KONI single adjustable shocks: before assembly I made sure they were set for lowest (softest) setting as my starting point. This is the same setting I'm running on my Roadster. This can be checked/adjusted later, but easier now. Link to Koni's website with instructions and video: https://www.koni-na.com/en-US/NorthA...stment-Guides/

- UCA upper ball joints: used my 18" Harbor Freight adjustable wrench to install. (I'll also use it on the IRS UCA nuts later on).

Some resistance on the second one, but overall no serious issues. - Swapped front UCA ball joint dust boots for Energy Suspension (5.13102G) per wisdom of the forum.

- Swapped tie rod ends for Moog and the Moog dust boots for Energy Suspension (9.13101G).

- POR-15. Love this stuff. My favorite coating. Takes some work, but well worth the effort. Coated the tie rod ends, inside face of front hubs, and rear sway bar brackets--see picture below. Also planning to coat the rear hubs, CV axles, and forward facing section of IRS differential.

First up was the PS rack install:

Here's a view of the Breeze offset bushing installed.

Not mentioned in the manual, and probably not necessary, but I like to prime the bushings with some grease before install.

POR-15: no I don't own their stock, but this stuff is awesome! Front hubs, Moog tie rods, and rear sway bar brackets.

I'm not using the tone ring (I think these are for ABS?), so I removed them. Ground a small slot into the ring with my Dremel, then tapped there and they split apart easily.

Added spacers to push the castle nut closer to the end to get cotter pin engagement. Had this same issue with my Roadster. Interestingly, extra spacers from my Wilwood brake kit fit perfectly in both cases.

View of passenger side together and ready for brake install. Planning to trim ~3/16" off the adjustment sleeve and stud of the rear UCA arms, to be sure I can dial in alignment specs later on.

Chris - great work. I have not ordered the Breeze spacers as yet so do you think I should pass? Sounds like with the new engineering in the frame mounts they're not necessary?

Coupe complete kit ordered: 9/26/24. Gen 4 Coyote. T-56. IRS w/3.73. Wilwoods. PS. HVAC. Side windows.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

12-13-2024, 10:13 AM

#104

Senior Member

Hi Tim. I think the two sets of mounts (upper for race height) have been available for quite some time, so no engineering change there that I'm aware of. The only engineering change I'm aware of relative to the steering rack mount is the new hold-down bracket F5 shipped out to builders who bought them within a certain time range as I noted above.

The Breeze offset spacers were on my list of new things to try. But as I mentioned above, I really don't see the advantage in the Coupe application. The one exception is centering the rack is a breeze (sorry--that pun slipped right out).

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

12-13-2024, 10:24 AM

#105

Senior Member

Originally Posted by

460.465USMC

Hi Tim. I think the two sets of mounts (upper for race height) have been available for quite some time, so no engineering change there that I'm aware of. The only engineering change I'm aware of relative to the steering rack mount is the new hold-down bracket F5 shipped out to builders who bought them within a certain time range as I noted above.

The Breeze offset spacers were on my list of new things to try. But as I mentioned above, I really don't see the advantage in the Coupe application. The one exception is centering the rack is a

breeze (sorry--that pun slipped right out).

Thanks for steering me in the right direction... . I was thinking more like details on the rack had changed but I think I'll see how it works without and if needed I can always order. I think he ships pretty quickly.

. I was thinking more like details on the rack had changed but I think I'll see how it works without and if needed I can always order. I think he ships pretty quickly.

Last edited by PNWTim; 12-13-2024 at 10:27 AM.

Coupe complete kit ordered: 9/26/24. Gen 4 Coyote. T-56. IRS w/3.73. Wilwoods. PS. HVAC. Side windows.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

. It looked like it worked pretty well but difficult to tell from the angle of the camera. Do you feel like it straightened the line well or were there still humps and jogs in it afterwards?

. It looked like it worked pretty well but difficult to tell from the angle of the camera. Do you feel like it straightened the line well or were there still humps and jogs in it afterwards?

. I was thinking more like details on the rack had changed but I think I'll see how it works without and if needed I can always order. I think he ships pretty quickly.

. I was thinking more like details on the rack had changed but I think I'll see how it works without and if needed I can always order. I think he ships pretty quickly.