-

Senior Member

John's EZ36R H6 818R Build

John's EZ36R H6 818R Build

It's about time I started my build thread. I've been following the 818 since its beginning, waiting patiently to pull the trigger and start my next project. From the first time I saw Wayne's thread on putting in an H6, I was sold. Love the idea of a naturally aspirated torquey motor, and then there is the exhaust note. I do a number of open track events each year and my current track / street car takes a lot of abuse for it. The 818 checked all the right boxes for me as a track car.

- Light weight

- Easy to work on

- Inexpensive parts

- Able to be built in my garage

Having 165k on the donor, I found many of the donor parts to be unusable so I have been replacing and rebuilding as I go. You find all kinds of cool stuff, like busted teeth in the transmission  .

.

trans.jpg

As the donor was from the north east, lots of rusty parts too.

Here is a quick timeline to bring you up to speed.

Last edited by Hobby Racer; 01-19-2017 at 09:52 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Test Fitting EZ36R

Luckily I can install / remove the motor trans combo in a few minutes which makes it easy to do trial and error stuff.

I will be using STI Group N motor and transmission mounts. The motor mounts will require custom plates to join the block to the rubber mounts.

Last edited by Hobby Racer; 01-30-2017 at 09:40 AM.

-

Senior Member

Frame Mods for EZ36R

Like others on the forum that are installing an EZ36R or an EZ30R, modifications are needed. Some have moved the engine trans combo back ~ 1 in. but I decided to notch out the frame where the cam phasers hit the frame. This will allow me to use an STI 6 speed in the future if I need too.

Right side cam phasers hit the frame

Frame notched out to allow motor / trans combo to fit using the stock position.

IMG_20170118_134856.jpg

Boxing in the notches.

IMG_20170119_122802.jpg

Everything welded up.

IMG_20170120_130441.jpg

Now for some paint to finish it up.

Last edited by Hobby Racer; 03-04-2017 at 07:04 PM.

-

Senior Member

Cadillac ATS-V Brembo Conversion

Originally I was going to use the WRX 4 pot front and 2 pot rear brakes until I came across this article on nasioc outlining an inexpensive big brake upgrade for Subaru's

Sold these to fund my big brake upgrade

1.jpg

After doing much research I decided to use the Cadillac calipers and STI rotors for both the front and rear of the 818R! I used the kit mentioned in the nasioc thread to mount the front calipers and fabricated mounting brackets for the rear.

Best part is that now I have the same calipers, brake pads, and rotors for the front and rear. I only need one of each as spares!

front1.jpgfront2.jpgrear1.jpgrear2.jpg

Last edited by Hobby Racer; 01-24-2017 at 10:02 AM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Your right! It is about time for this build thread.  . Are you eliminating the front pitch stop mount by using the motor and trans mounts your using?

. Are you eliminating the front pitch stop mount by using the motor and trans mounts your using?

Be advised that I'll be following your thread with the intention of using many of your ideas.

-

Cadillac...what?!?!?!?!?!?!??!

-

Senior Member

Originally Posted by

flynntuna

Are you eliminating the front pitch stop mount by using the motor and trans mounts your using?

Correct, but I have the option of installing the extra front mount should the engine pitch front to rear too much.

-

You have good skills. Now if you can figure out how to dry sump the EZ36 I will be eternally indebted to you.

"Good Judgement comes from Experience. Experience comes from Bad Judgement"

Owner: Colonel Red Racing

eBAy Store:

http://stores.ebay.com/colonelredracing

818R ICSCC SPM

Palatov DP4 - ICSCC Sports Racer

-

fasterer and furiouser

awesome rear brakes! any more pictures of your brackets? I am doing the same but with wilwood calipers/rotors

A well stocked beverage fridge is the key to any successful project.

-

Senior Member

Originally Posted by

Sgt.Gator

You have good skills. Now if you can figure out how to dry sump the EZ36 I will be eternally indebted to you.

Funny you should say that, I am starting off with an Accusump and will closely monitor the pressures during testing. If I see that it is not sufficient I plan to fabricate a dry sump pan and build a scavenge only system, similar to what you guys have done for the EJ's. I'll definitely post info if that comes about!

-

Senior Member

Custom rear brake caliper brackets

Originally Posted by

longislandwrx

awesome rear brakes! any more pictures of your brackets? I am doing the same but with wilwood calipers/rotors

I posted this in different thread, but here they are again to keep this all in one thread. They were very easy to fabricate, 3/16 in. plate for the bracket with the holes and 1/4 in. plate for the caliper mounting ears.

IMG_20161230_160324.jpgIMG_20161230_160356.jpgIMG_20161230_160312.jpgIMG_20161230_160402.jpg

-

Moonlight Performance

Looks awesome and I'm sure it will work well. I'm using the Subaru 4/2 pots with factory master cylinder and pedals and am not happy at all with the brake performance. Have been spending a lot of time trying to tune and adjust the brakes to get them to my liking and am still not there yet. Hope this setup works well for you.

-

Senior Member

Originally Posted by

Hindsight

I'm using the Subaru 4/2 pots with factory master cylinder and pedals and am not happy at all with the brake performance.

I did a lot of analysis on the 4/2 pots and the ATS-V swap prior to pulling the trigger. The 4/2 pots are all wrong for the balance of the 818 compared to the WRX. I found a great online brake bias calculator and ran the stock 4/2 pots and the ATS-V brembo brakes.

Turns out, with my Wilwood pedal setup, the 4/2 pots are way to front biased and the ATS-V brembos are almost perfect. If you are interested I can post the results.

-

Moonlight Performance

Sure, I would be interested in seeing it. The only issue is that the wilwood pedal setup is expensive and would require a lot of re-work for me at this point. I also don't think it would work with my ABS setup (or really any ABS setup). I'd really like to keep the ABS.

I just checked out the calculator and noticed that there is nothing in there factoring the leverage on the pedal (IE where the foot pad is vs where the pushrod is). I would think that would change your numbers substantially, though probably inconsequential for calculating front to rear bias.

Last edited by Hindsight; 01-20-2017 at 10:34 AM.

-

Senior Member

Originally Posted by

Hindsight

I just checked out the calculator and noticed that there is nothing in there factoring the leverage on the pedal (IE where the foot pad is vs where the pushrod is).

I used the more advanced Dual Master Cylinder Calaulator that is referenced from the original link I posted. This one takes the pivot point, and many other factors, into consideration.

Here is the 4/2 pot analysis:

818R with stock 06 wrx brakes.pg1.png818R with stock 06 wrx brakes.pg2.png

And here is the ATS-V brembo setup.

818R_ATS_Calipers_split_MC_bore.pg1.png818R_ATS_Calipers_split_MC_bore.pg2.png

I really wish the forum would let you upload PDF's larger than 200kb! Important results are in the lower right corner of the second page for both setups.

Last edited by Hobby Racer; 01-20-2017 at 06:44 PM.

-

Senior Member

Stock Fuel Pump Assembly w/Hydramat

To avoid fuel starve I am going to try the Holley Hydramat. This one connects directly to the Walbro 255 replacement pump I purchased so no adapters needed. I quickly learned that the FFR tank is to short to fit the stock fuel pump hanger, much less one with a Hydramat attached. Time for the modifications!

I cut off the bottom section of the pump hanger and welded on a spring loaded radiator clamp to hold the fuel pump in a position perpendicular to the tank bottom. This made it so the Hyrdramat sits perfectly flat against the tank floor.

IMG_20170122_141151.jpgIMG_20170122_145059.jpg

I then used small magnets and some safety wire to craft hold downs for the ends of the Hydramat to keep it as close the the bottom of the tank as possible. With the fuel pump hanger assembly completed I was just able to get it into the tank without bending anything.

Trick Hydramat hold downs

IMG_20170122_150643.jpg

Completed fuel hanger assembly

IMG_20170122_145927.jpg

Picture in tank

in-tank.jpg

Last edited by Hobby Racer; 01-24-2017 at 06:26 PM.

-

Administrator

Man all that stuff looks great!!!!!!!!!!!

-

Tazio Nuvolari wannabe

I like it too! I think this is a better solution than a surge tank with all the additional plumbing, pump and wiring. It's also rare that anyone will need more than a stock or common upgrade, in-tank pump can do.

-

Senior Member

Originally Posted by

Wayne Presley

Man all that stuff looks great!!!!!!!!!!!

Thanks Wayne, that means a lot. I always follow your posts with great admiration.

Originally Posted by

Scargo

I like it too! I think this is a better solution than a surge tank with all the additional plumbing, pump and wiring. It's also rare that anyone will need more than a stock or common upgrade, in-tank pump can do.

I also like the simplicity and compact packaging of using this system instead of an external swirl pot. I hope the Hydramat performs as well as expected.

-

Moonlight Performance

I like the hydramat hold-down idea so much I may copy it.... though I might use bar magnets directly on top of the hydramat in an effort to pin it to the tank instead of using safety wire. I dunno if strong magnets will be strong enough but I guess I will soon see. Also, big thanks for posting the picture of it in the tank!!! In my head, I remember the small in-tank baffle being much closer to the pickup, and I also forgot that the attachment point of the hydramat is not centered - I was concerned the hydramat wouldn't fit due to the baffle being in the way and that I'd have to pound the baffle flat but then worried about it's edge cutting into the hydramat over time. Guess I don't have to worry about that!

I will be interested in seeing if this solves starvation issues on the track. If it doesn't, you can always add a surge tank later (like I am doing). The Radium surge tank offers a version with a built-in fuel pressure regulator which substantially cuts down on the plumbing and keeps things really clean. It's very expensive though.

-

Senior Member

I like the hold down trick too, though I'm going to spring for the aluminum Boyd tank, so the magnets won't work. Holly has an epoxy based hold down, but I not sure if I trust it or more accurately my skill in installing it. Lol I wonder if Biyd would weld in aluminum studs or bolts to the bottom to secure the mat.

-

Administrator

Just bond some steel plates in the bottom of the tank for the magnet stick to. Then you can remove it if you needed to.

-

Senior Member

Originally Posted by

Wayne Presley

Just bond some steel plates in the bottom of the tank for the magnet stick to. Then you can remove it if you needed to.

Wow, that's brilliant. Thank you.

-

Senior Member

Fabricated Motor Mounts!

Well I have been working to fabricate some motor mounts for the EZ36R and I have to say, it was not as bad as I thought it was going to be.

I started with a new set of STI Group N mounts and removed the top plates (they will not be used).

IMG_20170128_172942.jpgIMG_20170128_173002.jpg

Next I grabbed some 1 1/2" angle iron and some plate steel, both 3/16" thick. Measuring and getting the angles correct was the hardest part. The FFR mounting tabs are angled inward ~21 degrees and pitched forward ~10 degrees. This required a compound bend in the flat plate to attach to the third mounting point on the EZ36R block.

IMG_20170126_163537.jpg

Finally I bolted everything up and tack welded the angle and plate steel pieces together while they were on the car to ensure a perfect fit up. Then removed the mounts for final welding. I also added a gusset down the center for added strength.

IMG_20170128_173017.jpgIMG_20170128_173027.jpgIMG_20170128_173042.jpgIMG_20170128_173100.jpg

I designed them so that nothing hangs below the underbelly of the car as I will be installing a full under-tray for better aero.

I'll post pics of them installed after I paint them.

Last edited by Hobby Racer; 01-28-2017 at 07:45 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Originally Posted by

Hobby Racer

To avoid fuel starve I am going to try the Holley Hydramat.

This one connects directly to the Walbro 255 replacement pump I purchased so no adapters needed. I quickly learned that the FFR tank is to short to fit the stock fuel pump hanger, much less one with a Hydramat attached. Time for the modifications!

I cut off the bottom section of the pump hanger and welded on a spring loaded radiator clamp to hold the fuel pump in a position perpendicular to the tank bottom. This made it so the Hyrdramat sits perfectly flat against the tank floor.

IMG_20170122_141151.jpgIMG_20170122_145059.jpg

I then used small magnets and some safety wire to craft hold downs for the ends of the Hydramat to keep it as close the the bottom of the tank as possible. With the fuel pump hanger assembly completed I was just able to get it into the tank without bending anything.

Trick Hydramat hold downs

IMG_20170122_150643.jpg

Completed fuel hanger assembly

IMG_20170122_145927.jpg

Picture in tank

in-tank.jpg

Awesome! I am going to do this same install. Nice photographs.

-

Senior Member

Seats mounted

Finally got both seats mounted in the car. Now I can finalize the steering column position and adjust the pedals. I put the driver seat on universal sliding rails I got off eBay. They give me 3 1/2" of travel, from the front lower cross bar to the rear firewall. Not a ton of adjustment, but every little bit helps. I mounted both seat as low in the chassis as I could.

The passenger seat is non adjustable as it touches the front lower cross bar and is only 1/2" off the rear firewall.

-

Senior Member

Quick Update

I've been working on the shifter and cable system. I am using the optional aluminum FFR shifter but running the cables straight back. This required fabricating two bell cranks to reverse the cable push/pull direction so the transmission shift pattern is preserved.

Its coming out really nice. I'll post pics this weekend.

-

Tazio Nuvolari wannabe

Nice. Looking forward to seeing them. I hope you have taken advantage of all the people here on the forum who have done their own and documented it! Lots of good ideas...

-

Senior Member

Originally Posted by

Scargo

Nice. Looking forward to seeing them. I hope you have taken advantage of all the people here on the forum who have done their own and documented it! Lots of good ideas...

Definitely... this forum is full of great ideas and helpful people, one of my favorite places on the web!

-

I just noticed you're in Syracuse. Myself and Mechie both lived there for a bit. While he's farther away now, I'm just East of Rochester. I'll have to see this thing as progress moves along.

-

Senior Member

Originally Posted by

305mouse

I just noticed you're in Syracuse. Myself and Mechie both lived there for a bit. While he's farther away now, I'm just East of Rochester. I'll have to see this thing as progress moves along.

Wow, small world. Definitely have to get together when the weather gets better.

-

Senior Member

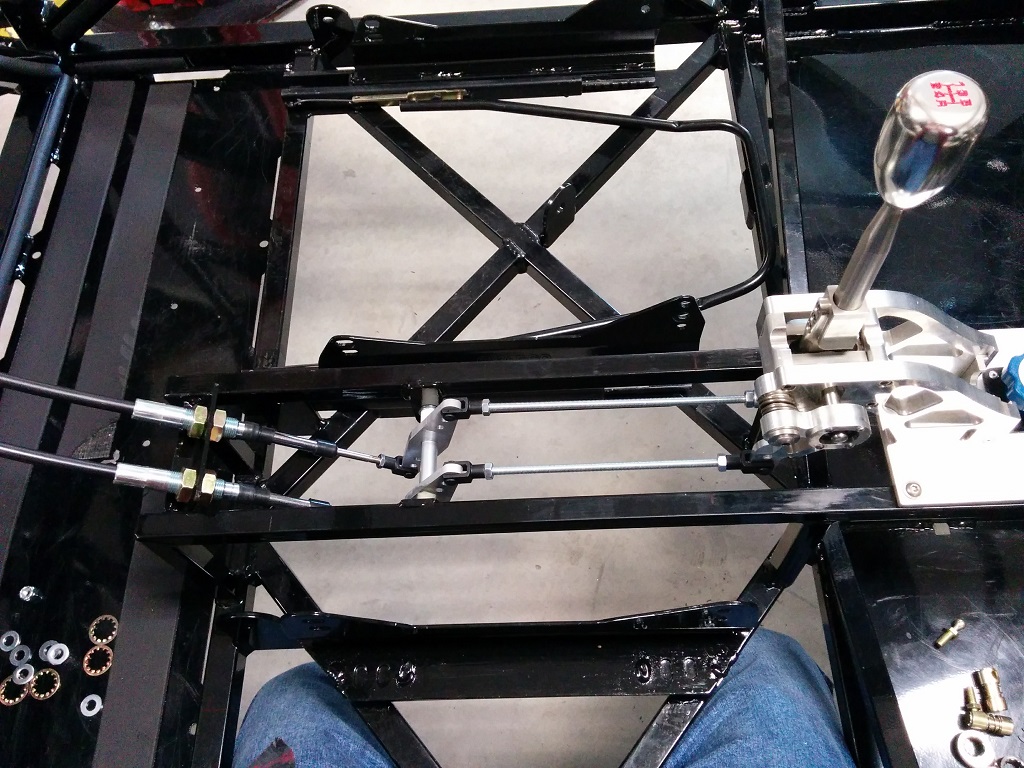

Optional FFR aluminium shifter with cables straight back

I purchased the optional K-tuned FFR aluminum shifter from another forum member and really love the looks and operation, it really is art. However, the forward facing cable layout FFR uses leaves much to be desired. After reading many MR2 shifter conversion threads, I decided to do my own rear facing cable conversion using my FFR aluminum shifter. Initially I was going to turn the shifter backwards and go from there, but I decided to leave it facing forward. Either way would require dual bell cranks to change the direction of throw for the forward and side motion so the transmission shift pattern would be normal.

I then cut the front of the shifter off to make room for my Wilwood brake adjuster; made a new base plate and started fitting the bell cranks. Each bell crank has three adjustment locations for the cable and shifter connection allowing a large amount of adjustment for shift throw. The final cable routing allows for an almost straight shot back to the transmission. I am also using Mechie's rear bell crank to eliminate the large loop for the twisting motion of the shift shaft. My new cables will only need to be 70" total length!

The bell cranks are made from 1/4" aluminum plate with 5/16" Oilite bronze bushings pressed into the pivot for smooth operation.

IMG_20170304_115132.jpg IMG_20170304_095353.jpg IMG_20170304_165858.jpg

Last edited by Hobby Racer; 03-04-2017 at 07:10 PM.

-

Senior Member

Very ingenious Hobby racer. I love it.

Gets my vote for best 818 IIIE award. (IIIE= ingenious innovative Idea and execution)

Bob

Last edited by Bob_n_Cincy; 03-05-2017 at 01:21 AM.

-

That's fantastic! Which linkage did you end up going with - the ball joint or clevis?

-

Senior Member

Originally Posted by

Zach34

That's fantastic! Which linkage did you end up going with - the ball joint or clevis?

I haven't decided yet. I'm leaning toward the ball joints because they allow for easy, no tool adjustments. But until I test run it through the gears I am leaving my options open.

-

Tazio Nuvolari wannabe

That's very slick. Can you speak to your decision to reverse the direction at the shifter vs doing it at the tranny, where you would have only one reversal bellcrank required.

I vote for the clevises. Where did you get the clevises... McMaster-Carr?

-

Moonlight Performance

SLICK! Very nicely made parts!

Where are you going to put the e-brake? Going with electronic?

-

Senior Member

Originally Posted by

Scargo

That's very slick. Can you speak to your decision to reverse the direction at the shifter vs doing it at the tranny, where you would have only one reversal bellcrank required.

I vote for the clevises.

I had already purchased Zero Decibel's rear bell crank shifter kit and did not want to waste it! Plus it would still have required two bell cranks in the rear as I would have needed to eliminate the large loop that FFR uses for the twisting motion of the shift shaft. My cables are now very short and almost completely straight making for a very precise shift feel.

Originally Posted by

Scargo

Where did you get the clevises... McMaster-Carr?

Yes, McMaster-Carr, I love that place!!!

Originally Posted by

Hindsight

SLICK! Very nicely made parts!

Where are you going to put the e-brake? Going with electronic?

No e-brake as this is track only car and I am using front brake rotors on the rear (no parking brake inner drum).

-

Senior Member

Dan

818S #17 Picked up 8/1/13 First start 11/1/13 Go Kart 3/28/14

-

Tazio Nuvolari wannabe

Originally Posted by

Hobby Racer

I had already purchased Zero Decibel's rear bell crank shifter kit and did not want to waste it! Plus it would still have required two bell cranks in the rear as I would have needed to eliminate the large loop that FFR uses for the twisting motion of the shift shaft. My cables are now very short and almost completely straight making for a very precise shift feel...

No e-brake as this is track only car and I am using

front brake rotors on the rear (no parking brake inner drum).

I could have said, "Because Race Car!" for you...

I understand now since you had that nifty stuff from Zero Decibel. Still, it could be done with one bellcrank mounted on the bracket in the back for the shaft "in and out". I have the S2K shifter I will mod for mine.

.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

. Are you eliminating the front pitch stop mount by using the motor and trans mounts your using?

. Are you eliminating the front pitch stop mount by using the motor and trans mounts your using?