Weíve been back from our Oregon family visit for a little over a week now, and back on the build. While we were gone, several packages of parts arrived. Really happy to receive the spindles, which are now installed. Also received the driveshaft, even though I wonít need it for a long time. Also received a box of a number of smaller items. So the good news, Iím down to 8 backorder/missing parts. The bad news is that this includes the rear UCAís, LCAís, CV axles, and Wilwood brakes. So Iím not able to make any progress with the rear suspension, or install the brakes. Kits after mine are being delivered with some of these parts. GrrrÖ Back on the phone Monday.

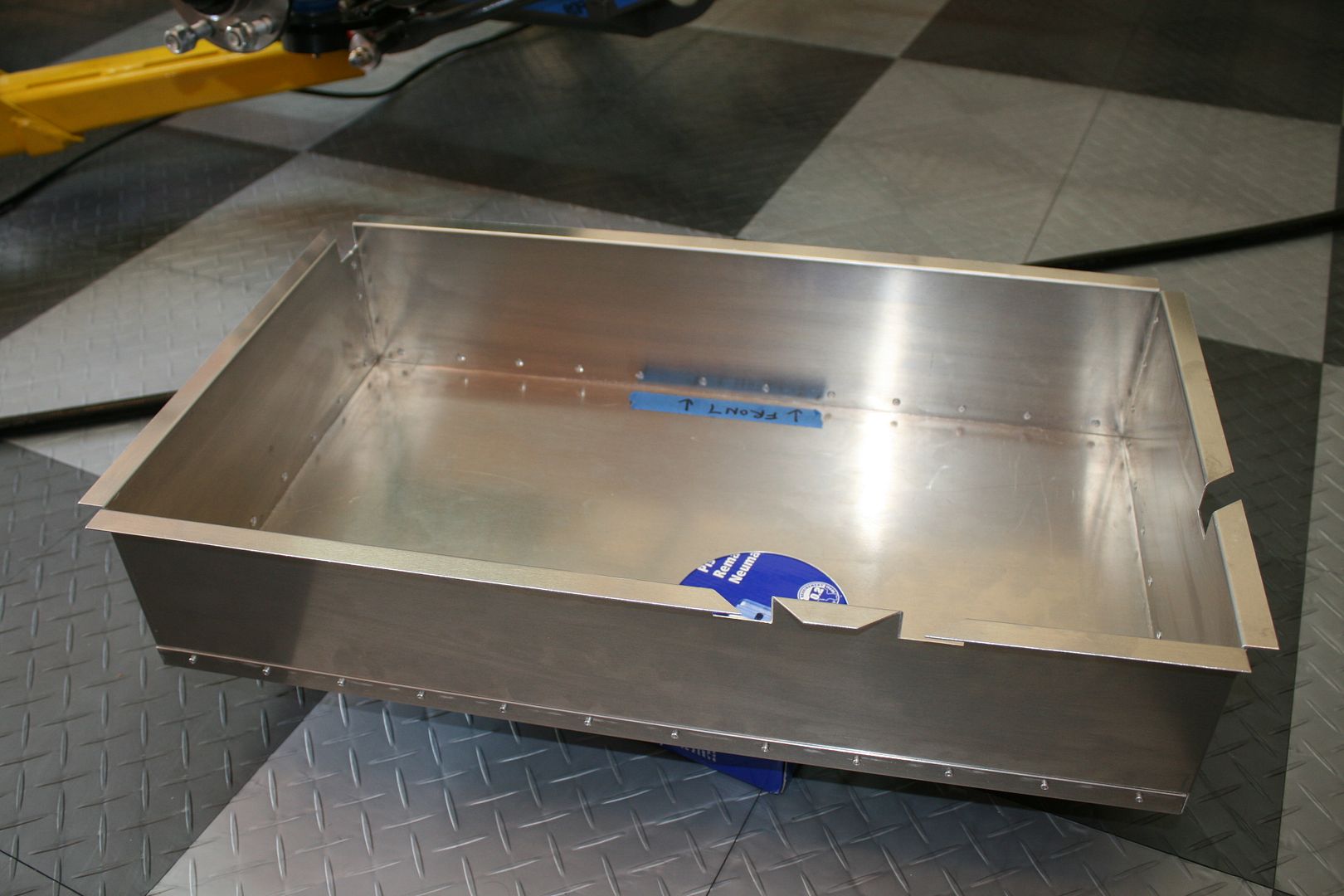

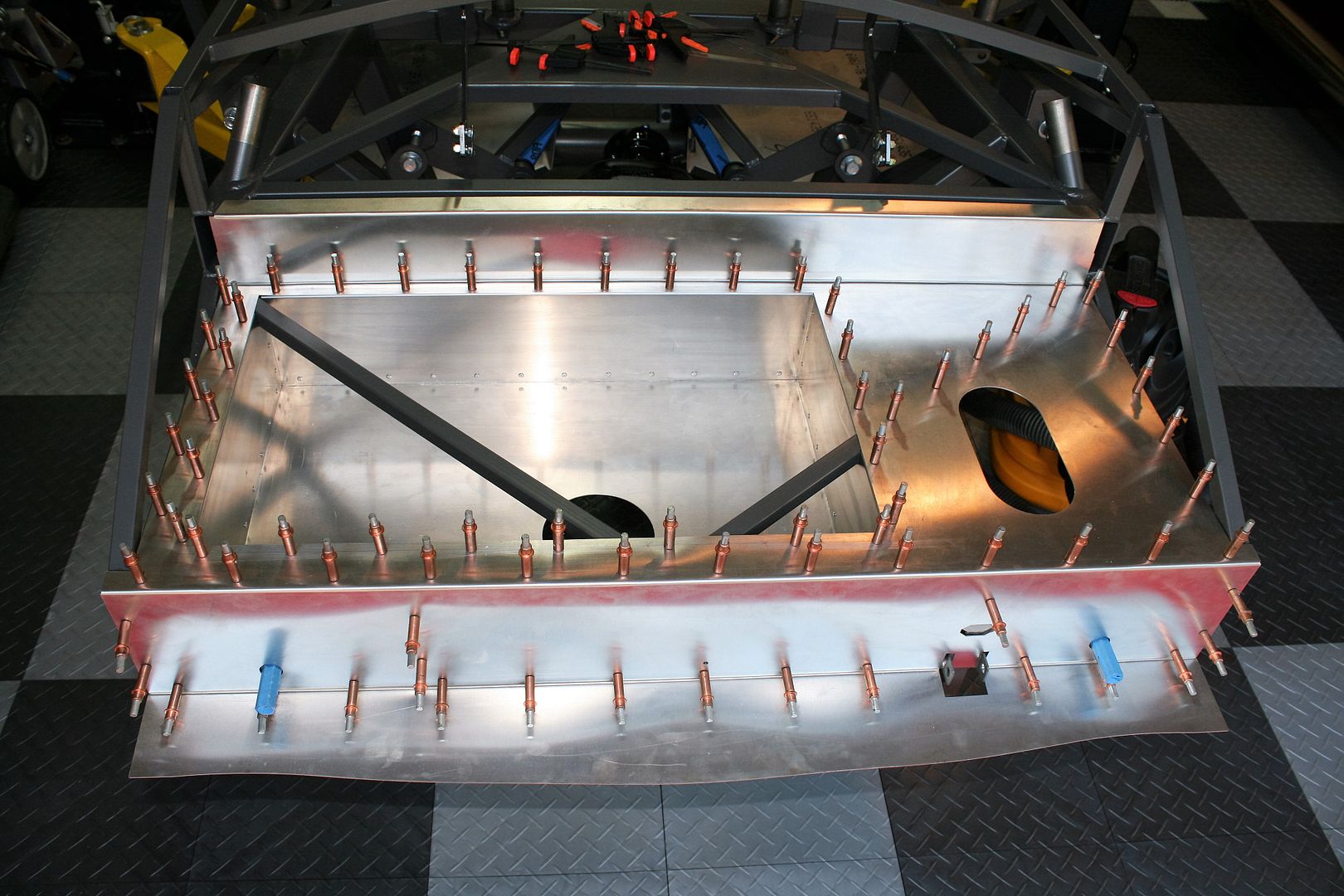

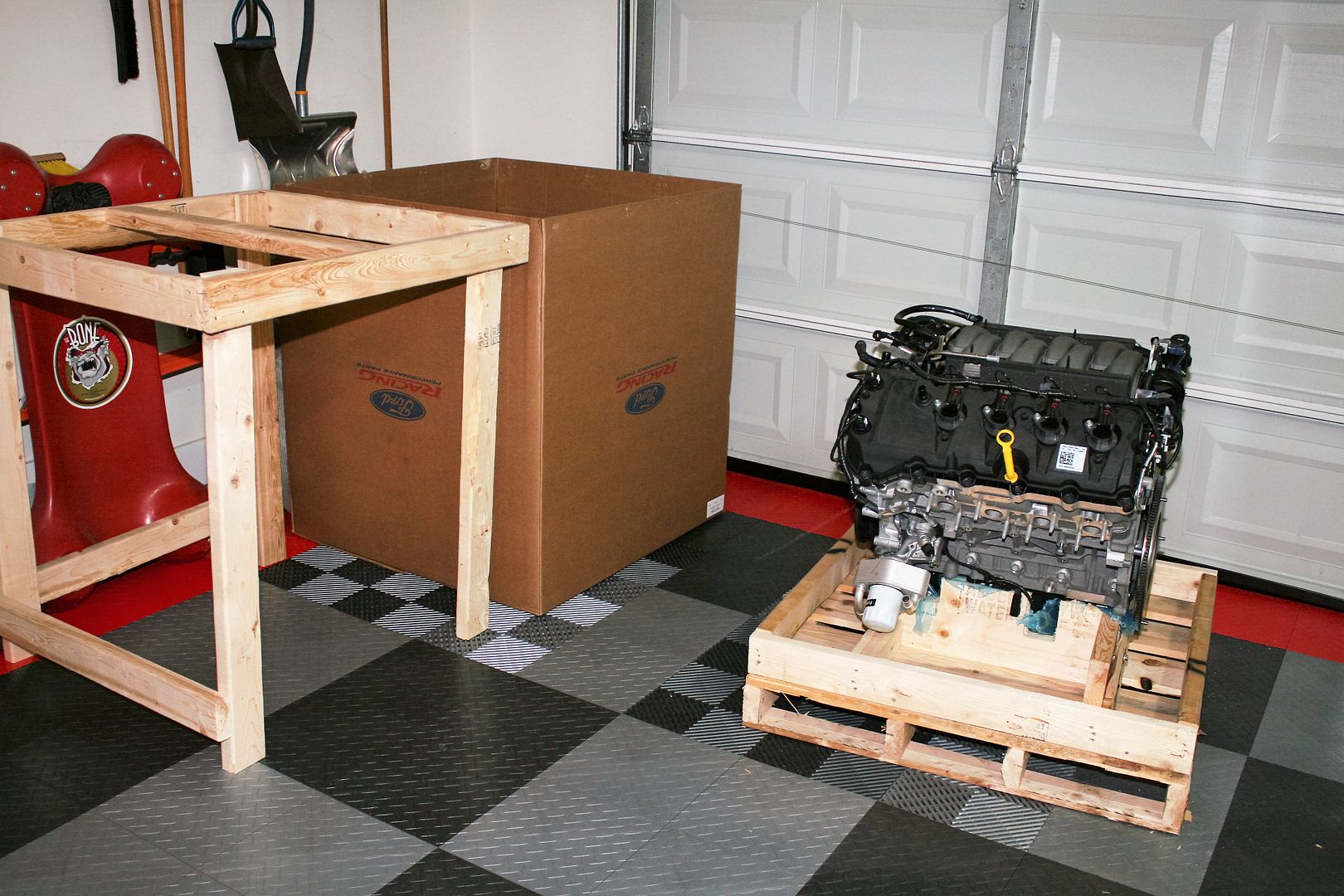

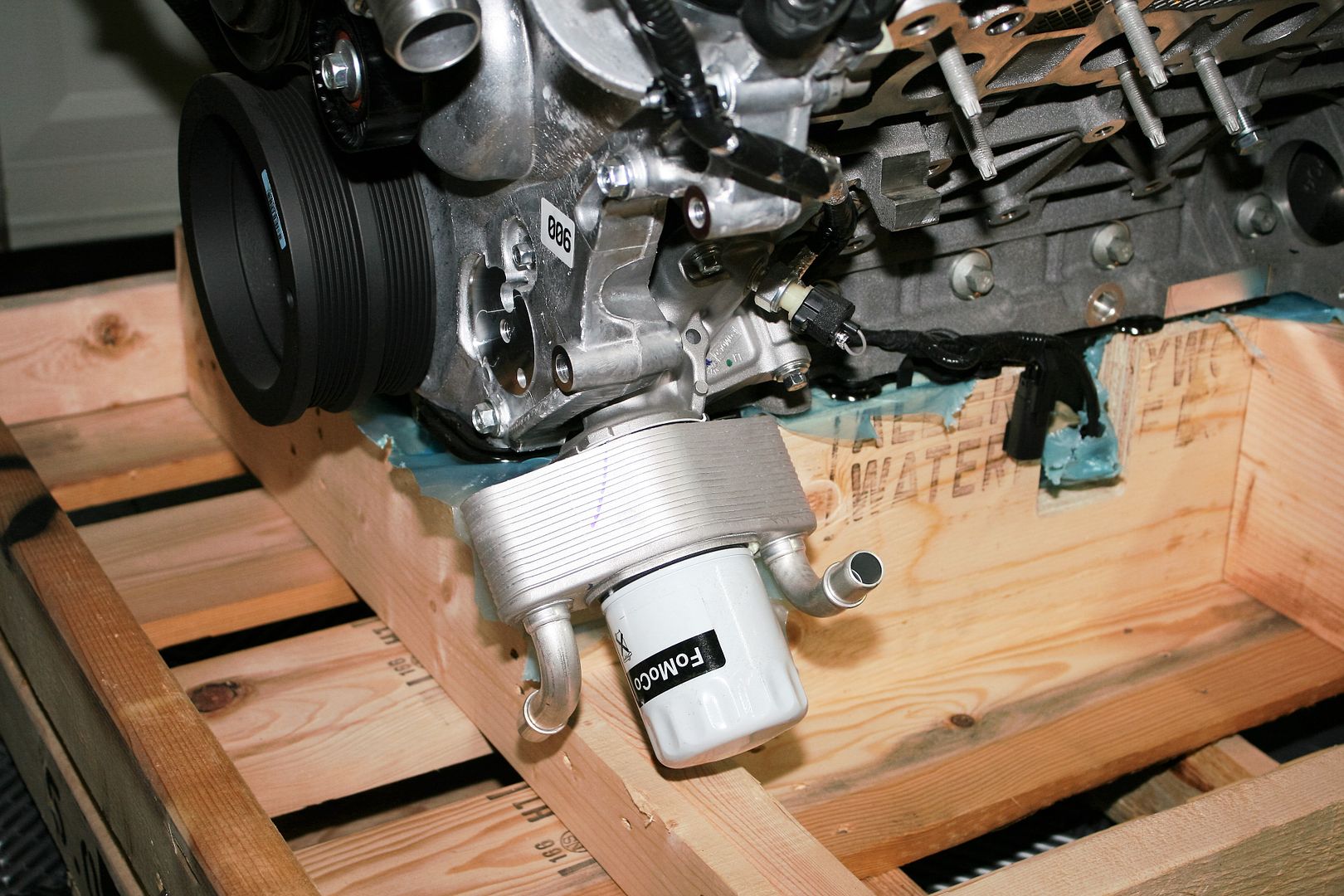

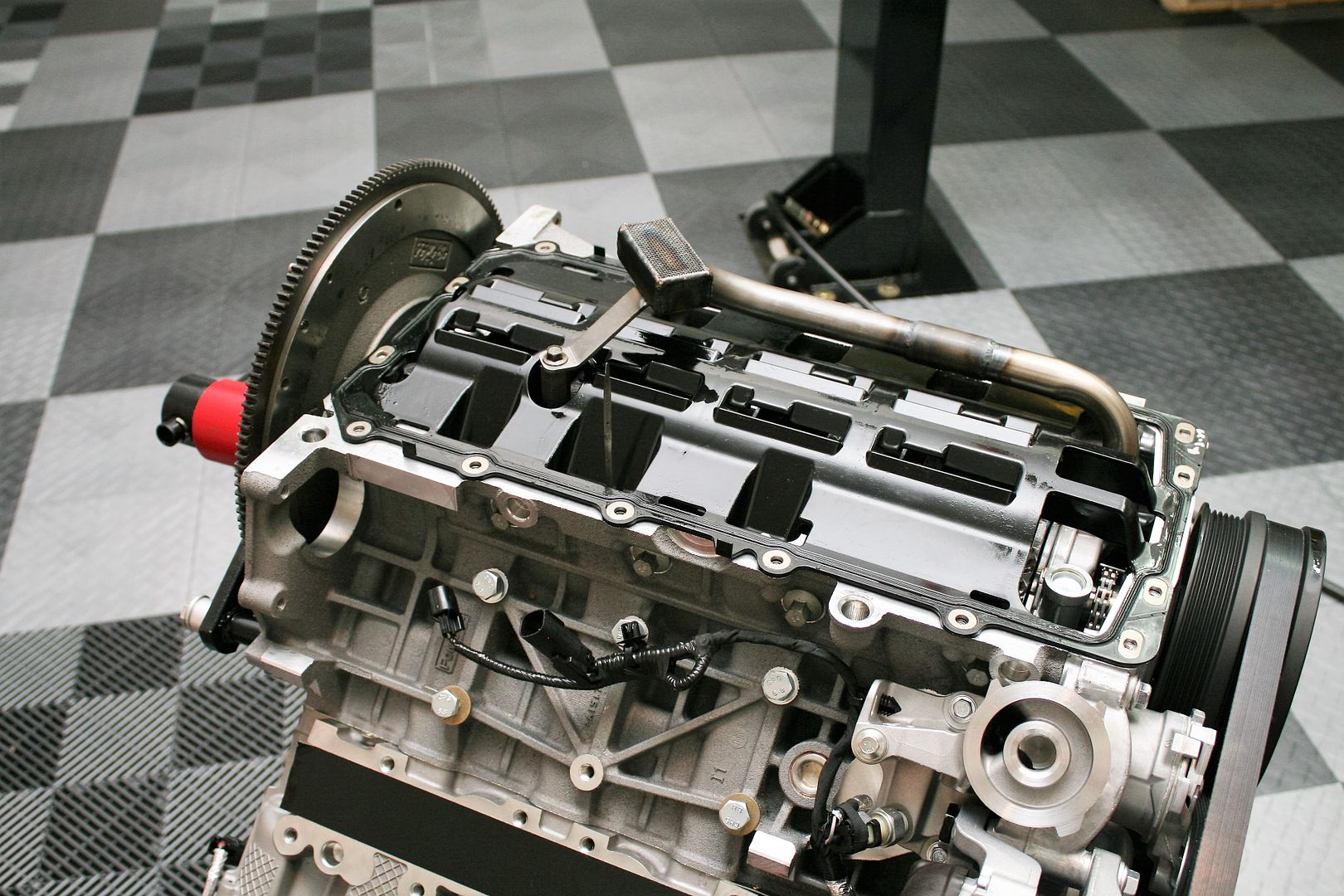

Used some of the time off to finalize some of the build plans, and order some more stuff. In other words, spend moneyÖ Decided to go ahead with GAS-N SS sidepipes. Even though the kit came with FF SS sidepipes, Iíve used the GAS-Nís on my previous builds, and love the looks, sound and overall quality. Got hold of Georgie and theyíre already here. Works of art. Also going with the custom SS stainless headers. Called GP Headers (not Stainless Headers any more) and should have the Coyote double collector pipes in a few weeks. No hurry. Ordered and received an in-tank fuel pump from Breeze. Ordered and received a turn signal assembly from Russ Thompson along with my machined steering wheel hub. Found Russ also offers a trunk expansion box. I was going to make my own, but decided to get the one from Russ. Like all his stuff, itís first class. Thanks to another forum member who contacted me, I also received a box of King DS Coyote mod panels and firewall that he decided not to use. Huge thanks. These forums are an amazing resource. I was considering making them myself. Now that I see them, would have been challenging.

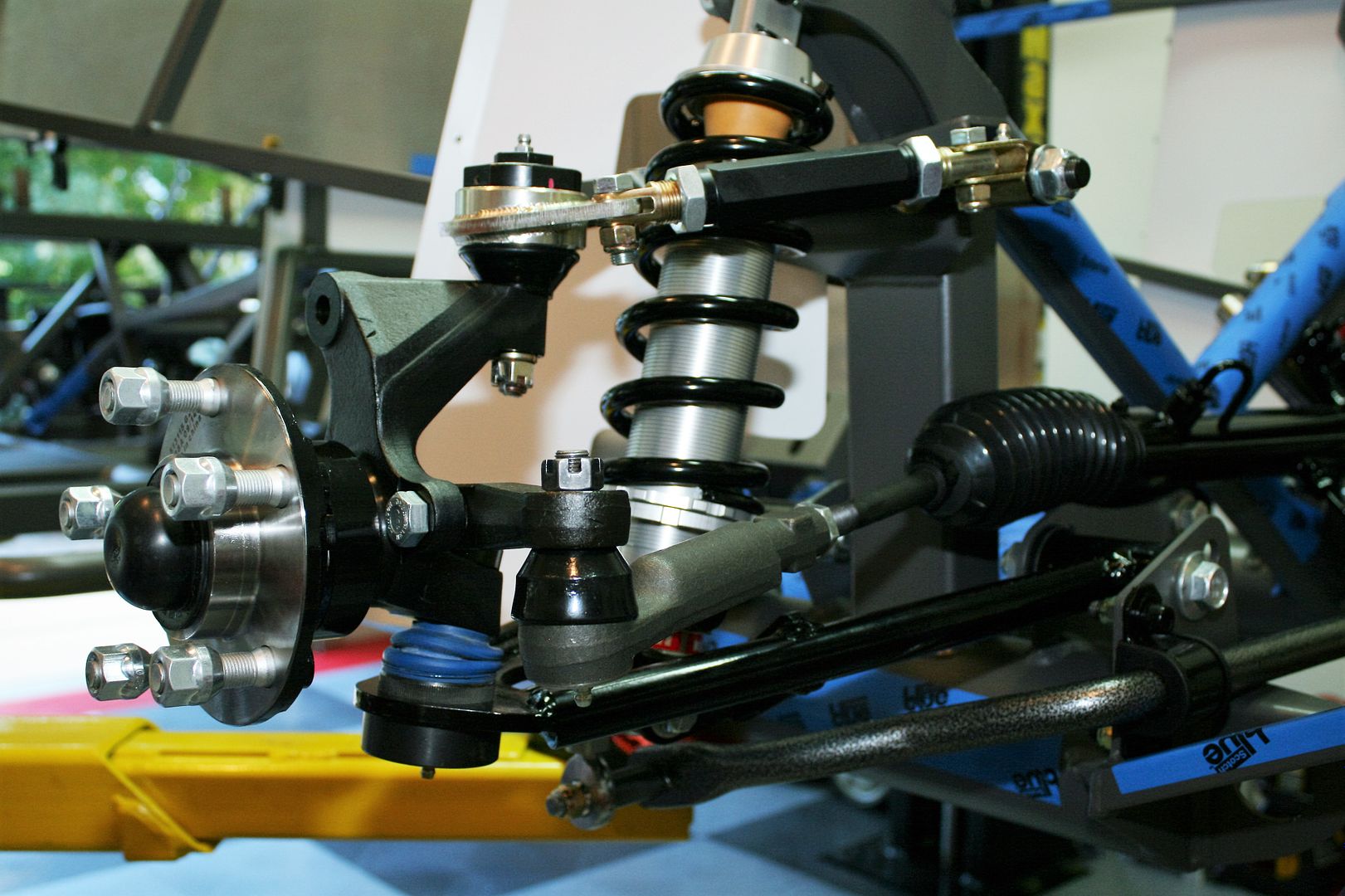

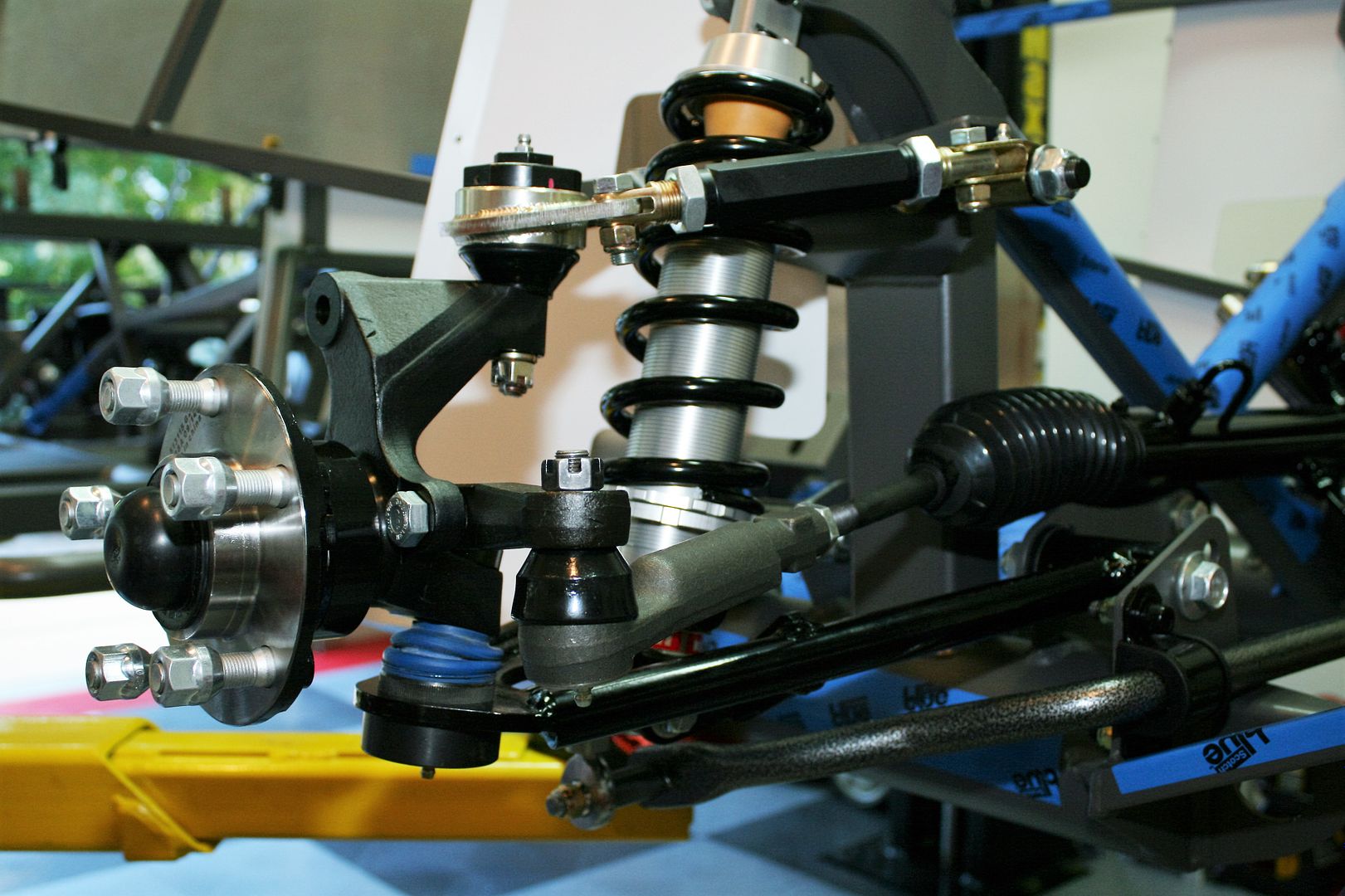

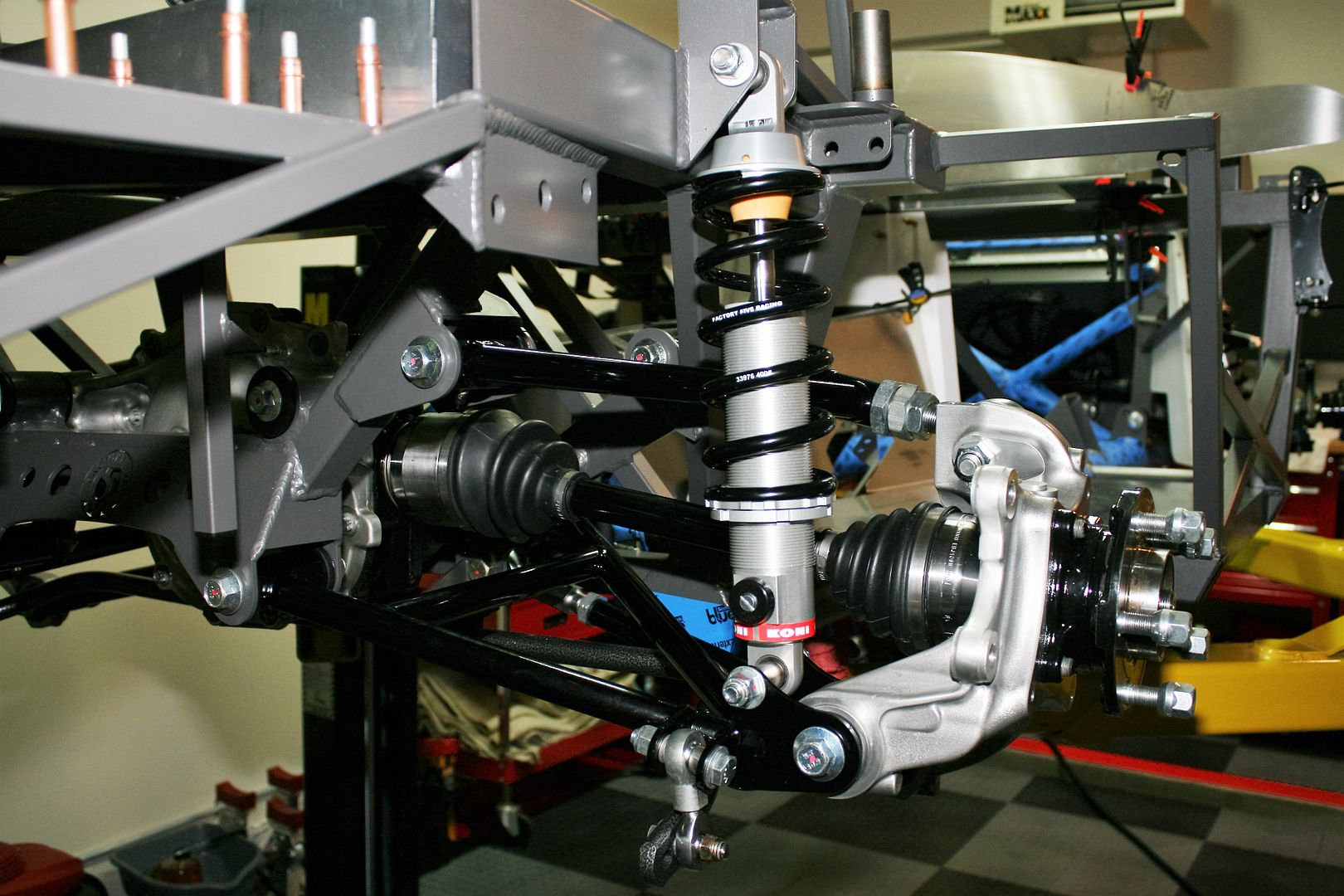

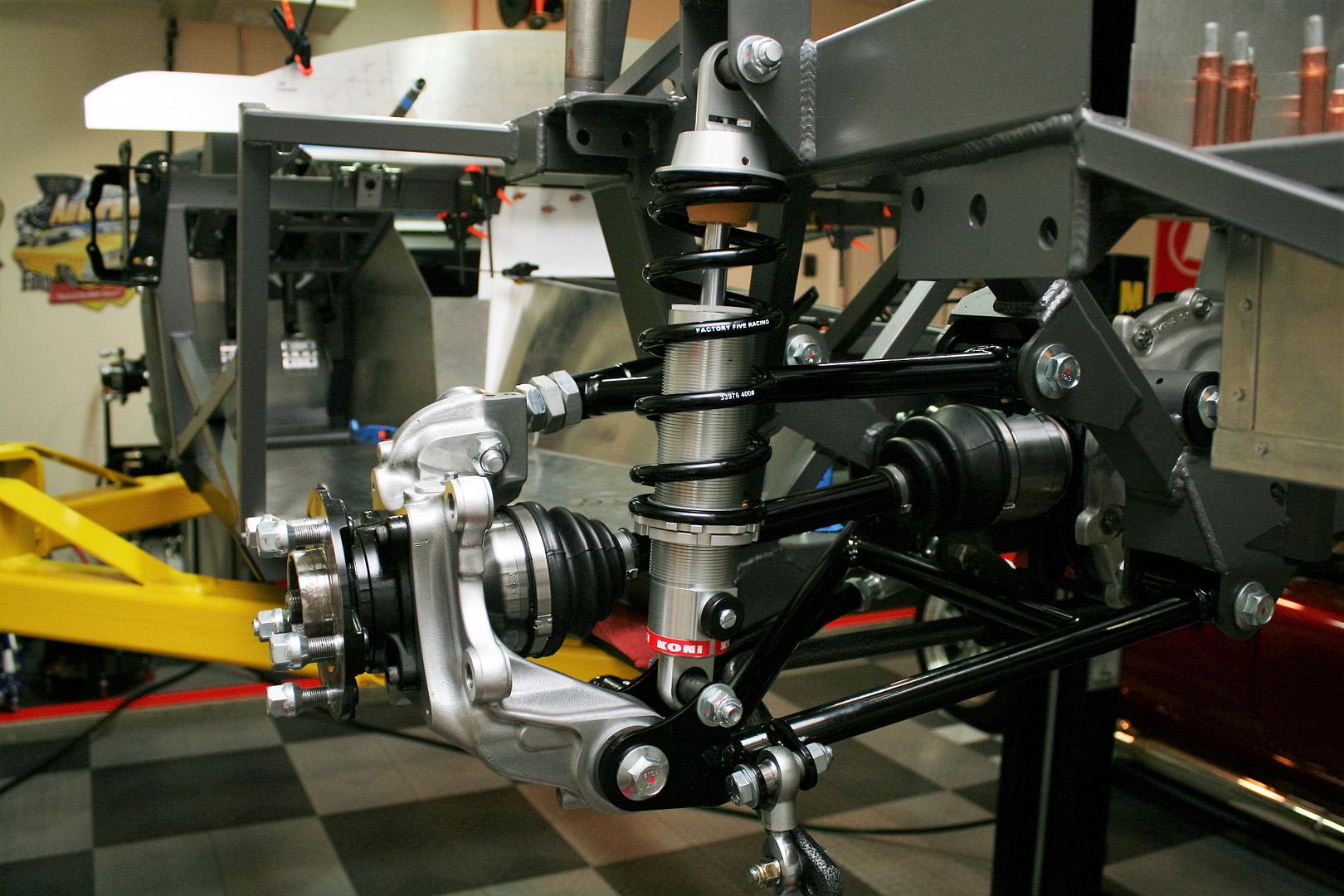

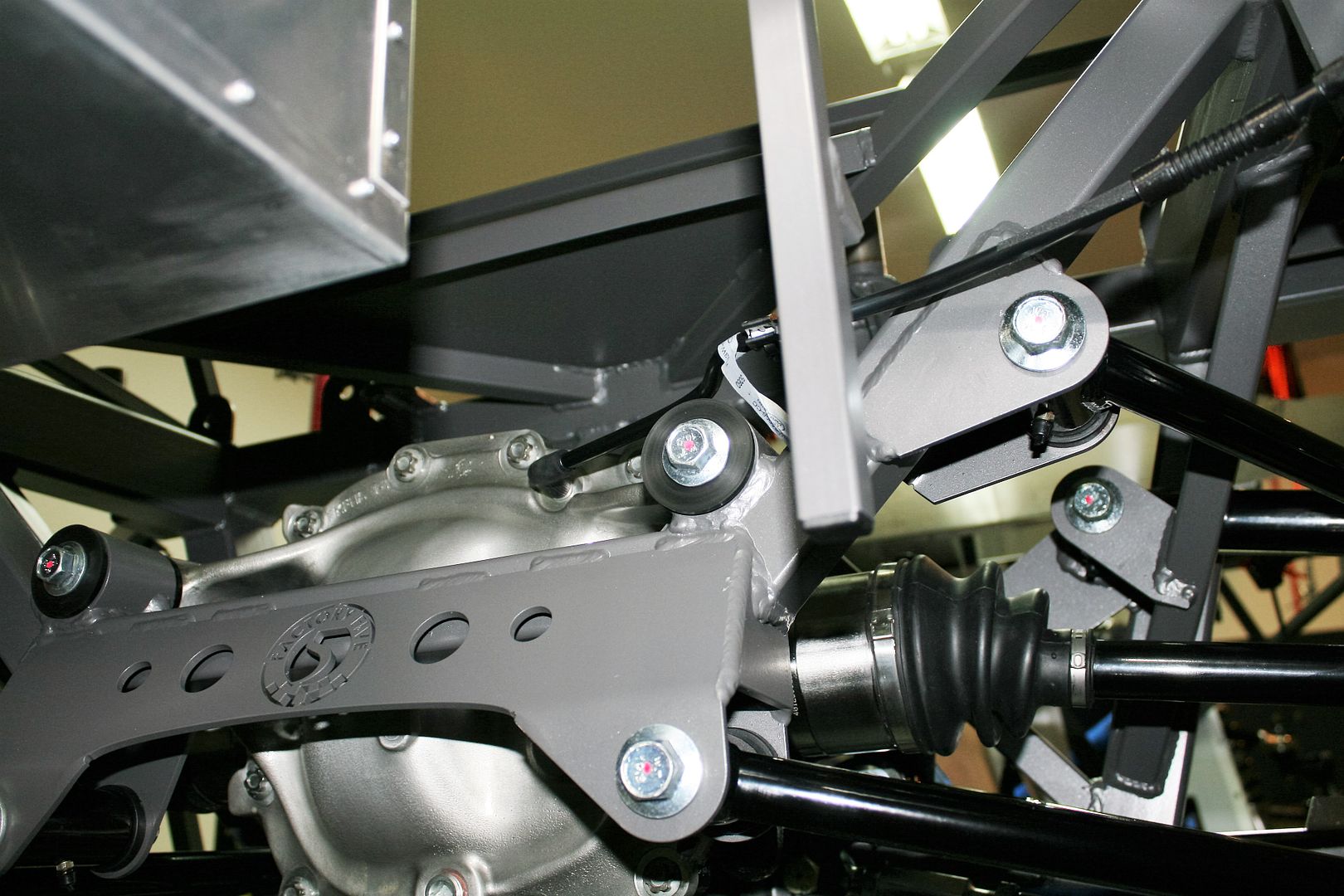

So for some build updates, first thing was to get the newly received spindles installed. Everything went fine. The ball joint tapers pulled in and tightened without drama. I used the FF spacer for the lower ball joint, and needed a hardened washer for the Howe upper ball joints. The hubs slipped on with no sanding or large hammers. Nice smooth fit. Torqued the spindles nuts to 250 ft-lbs, which Iíve now decided is my personal limit. Ouch. As you can see from the pics, I pried off the tone rings. I have no plans for ABS, plus I think theyíre kind of ugly. Then I put some POR15 on the back side of the hubs. Canít help myself.

I did a SWAG on the UCA for camber and caster, and then used a magnetic laser level to get the toe in the ballpark. I mainly wanted to do a sanity check on the length of the inner tie rods. I have about 1 inch of threads left on both sides of the threaded section on the tie rod ends. So there will be no cutting required. This the second time Iíve used this combination of Breeze PS rack and Moog tie rod ends. Perfect. Yes I know the cotter key isnít installed in the castle nut yet. Later.

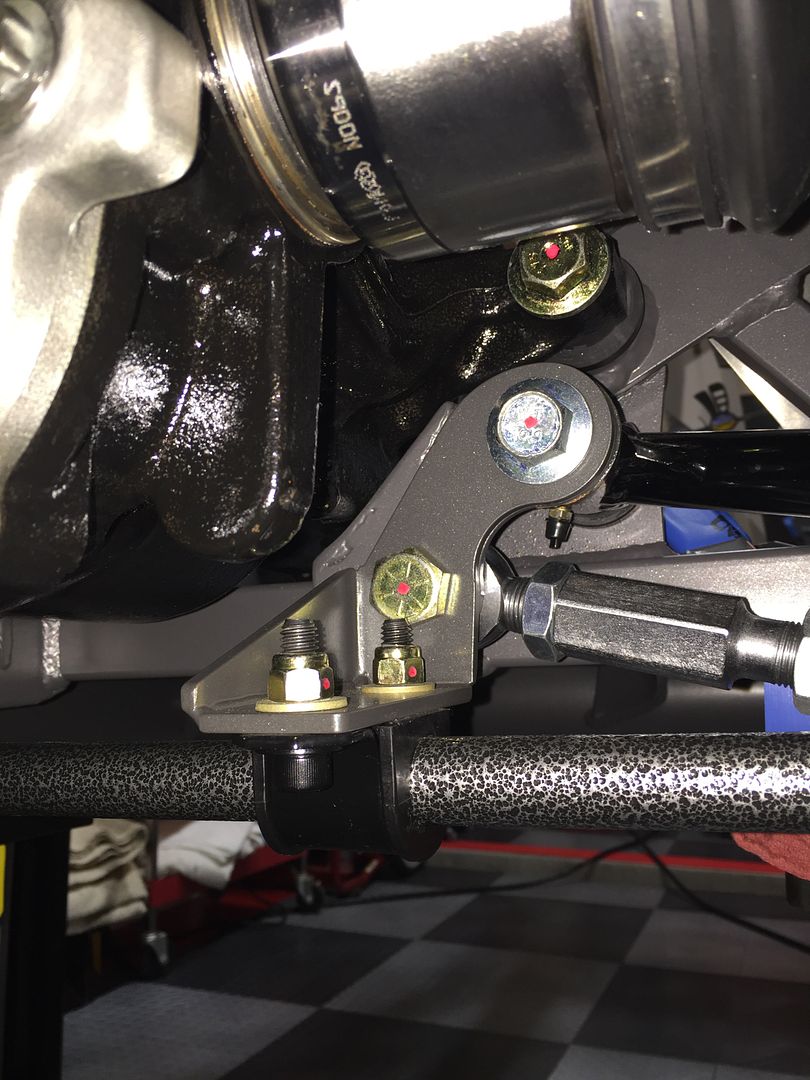

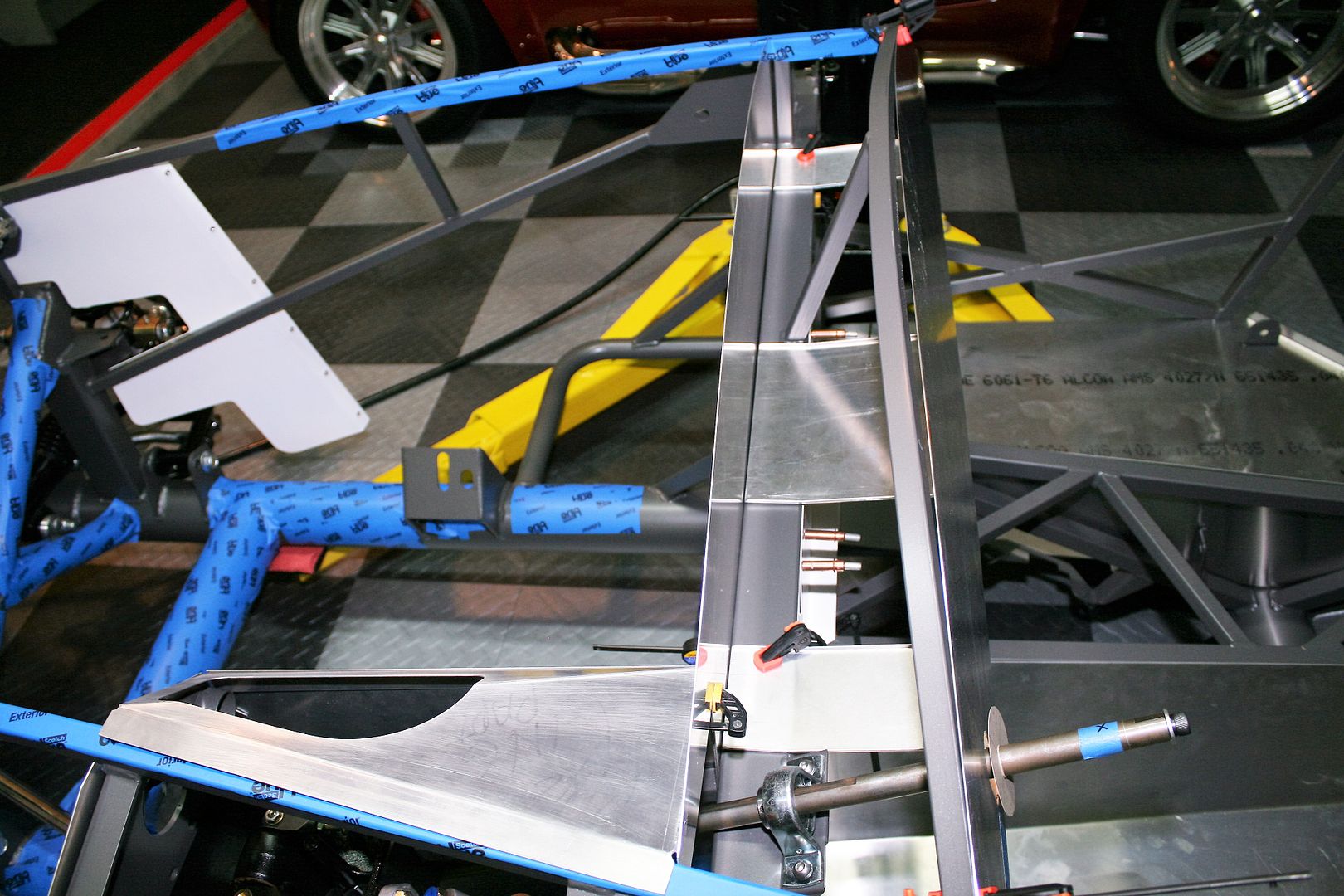

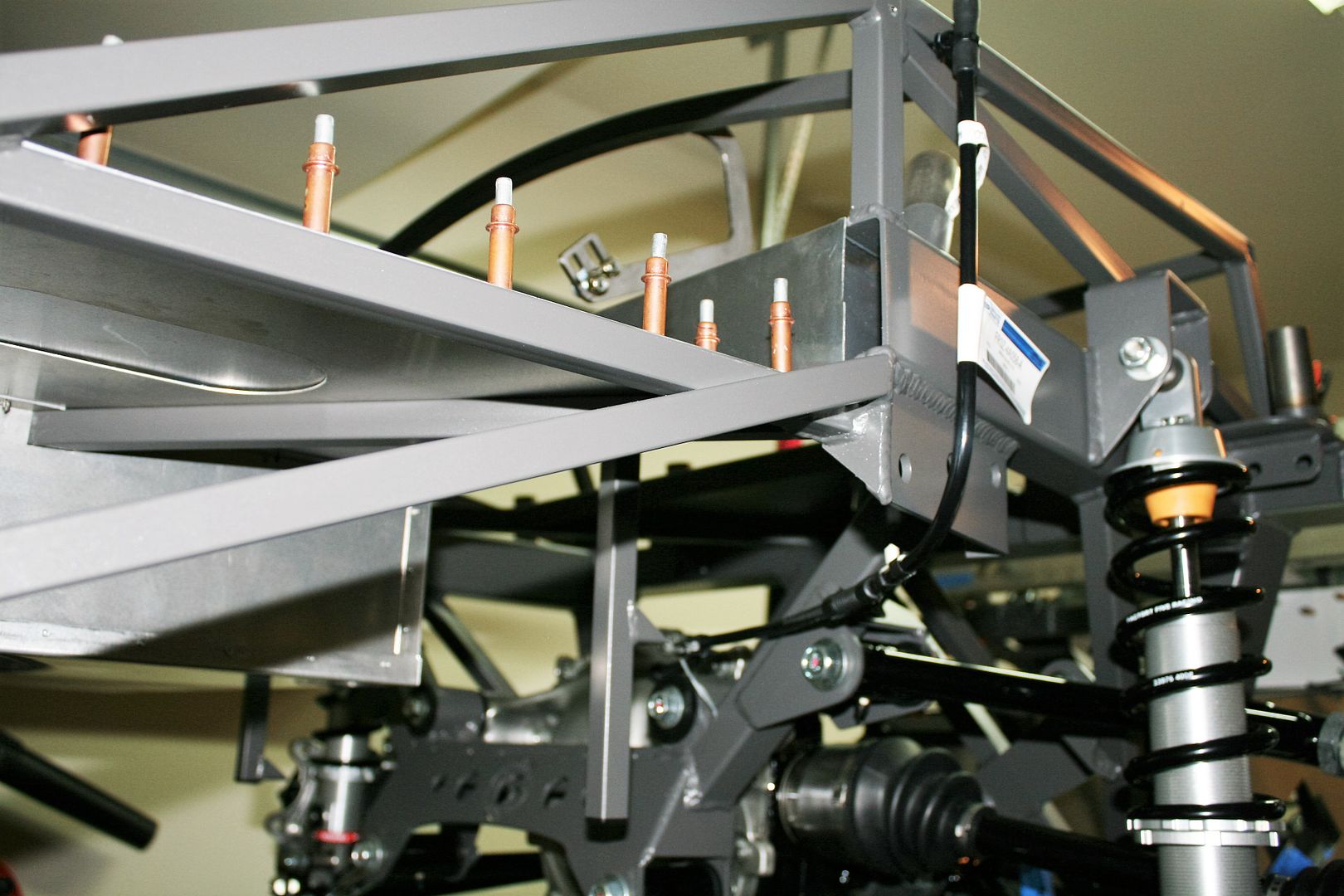

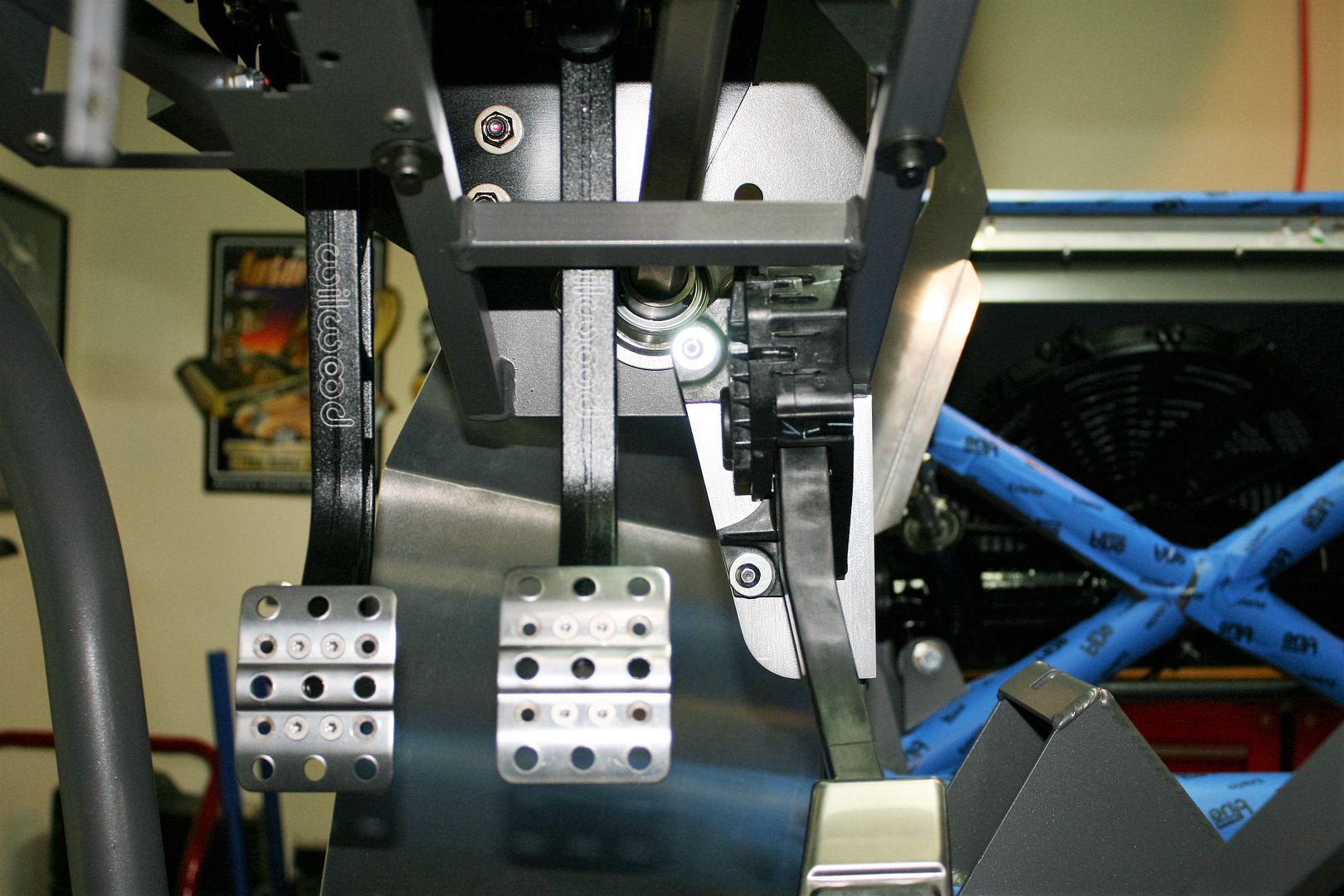

The final item to wrap up the front suspension was the sway bar. I posted pictures of the front frame mounts before. Once the sway bar is bolted on up front, itís attached to the underside of the LCAís using a longer bolt on the lower shock mount, two rod ends, a bolt and spacer. The instructions show cutting all but 1/2 inch of threads from the male and female rod ends. Those things are HARD! But itís done and turned out well. The instructions didnít say so, but I put red Loctite on the rod ends before putting them together. I donít have instructions yet for the rear sway bar, but the parts provided are all almost exactly the same, so Iím expecting a similar setup.

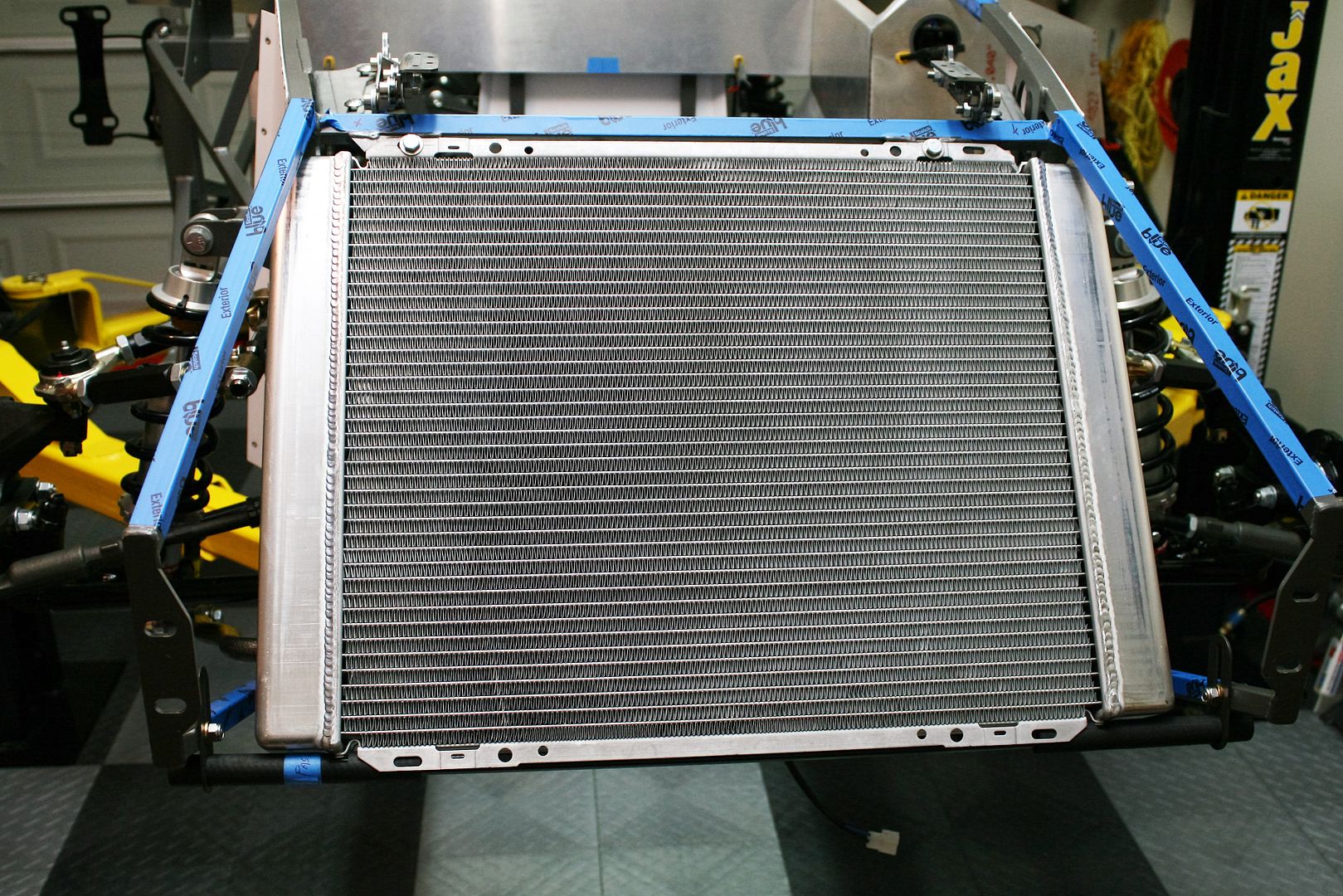

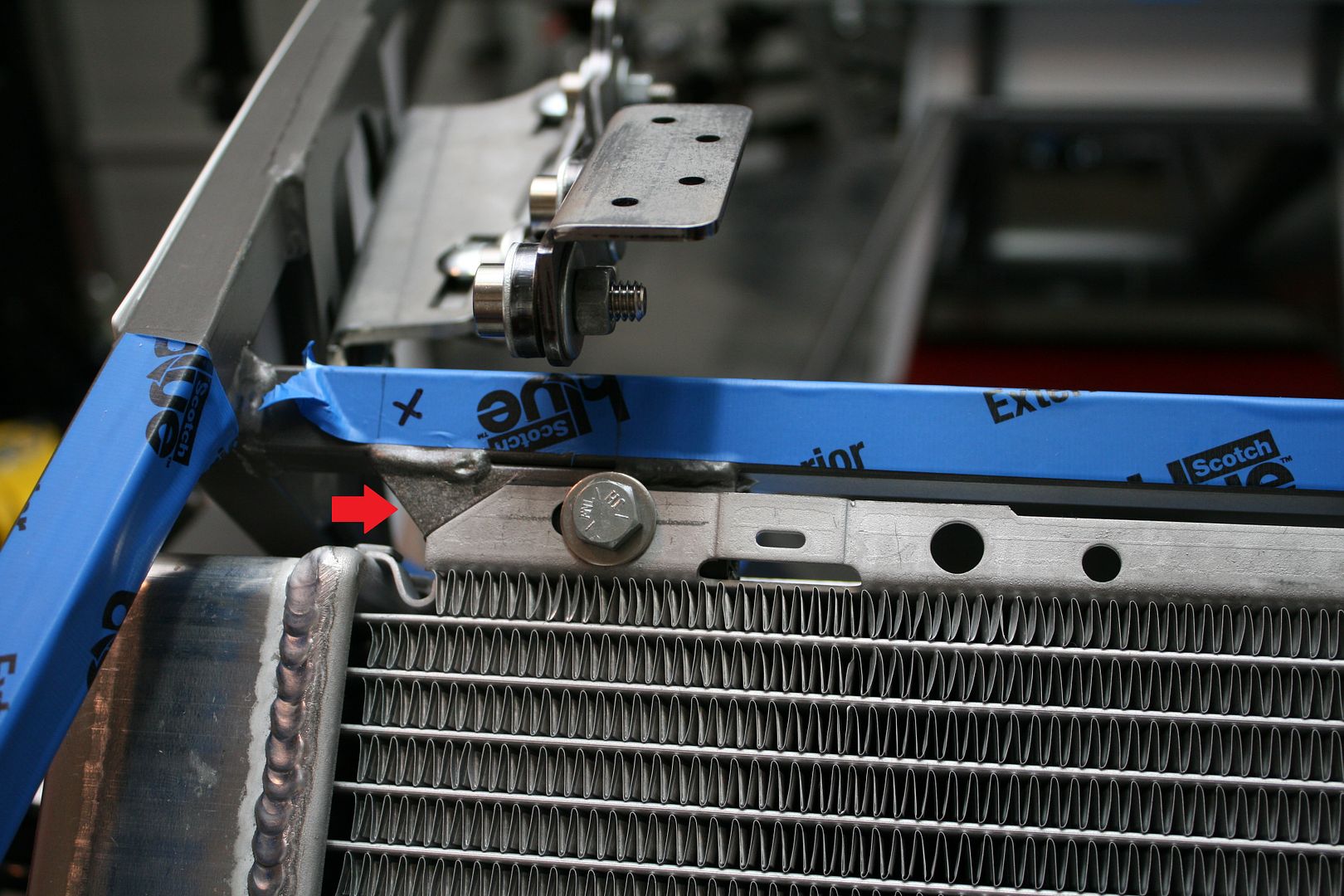

I decided to cut the hole in the Breeze shroud and get that part ready for powder coat. The hole follows the inner outline of the FF supplied cooling fan. I put 10-32 nutserts in the mounting hole locations, which makes it real easy to install the fan and remove if necessary for service.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

I'm enjoying #7750 so much it's hard to image selling it, but that's the plan. Sadly, it's now hunkered down until spring. Several have expressed interest. If all goes according to plan, probably about a year from now.

I'm enjoying #7750 so much it's hard to image selling it, but that's the plan. Sadly, it's now hunkered down until spring. Several have expressed interest. If all goes according to plan, probably about a year from now.