-

01-17-2023, 01:51 PM

#561

Senior Member

Hi JB. That put a big smile on my face. I can just see your "sanitation container" in my mind's eye; nicest one on your street, mind you. I've got to see a picture of it. Too cool.

Yeah, this whole car build thing has bit me pretty hard. It's way too fun. Even though I'm a ways off from catching up with you, I'm already thinking, "What's next"? The bigger question is what kind of strategy do I need to cook up to convince my wife that I'll someday need another car project. I need to noodle on that one--good thing she doesn't read my build thread.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-18-2023, 07:34 PM

#562

Senior Member

: Yeah, this whole car build thing has bit me pretty hard. It's way too fun. Even though I'm a ways off from catching up with you, I'm already thinking, "What's next"? The bigger question is what kind of strategy do I need to cook up to convince my wife that I'll someday need another car project. I need to noodle on that one--good thing she doesn't read my build thread.

I'm not even a third of the way through with mine, and I'm already wanting to build another one--partly to do everything RIGHT the next time. It's fun, but also quite challenging for me, and beats sitting around on the sofa.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-28-2023, 10:13 PM

#563

Senior Member

Body Fitment Begins

I had a choice to make: (1) wait until Spring to work on body fitment in the driveway, or (2) build dust containment. Since spreading fiberglass dust throughout my garage is not something I care to do, it's Option 2 for me.

I thought about this quite a bit, and decided the easiest and cheapest option for me was to hang sheets of plastic from the ceiling. I picked up a roll of 10'x100' plastic sheeting (6 mil). I tacked it to the ceiling by wrapping one end around 1"x3" scrap lumber, and fastening the lumber to the trusses. To encourage the sheeting to hang vertical (i.e. added weight), I also attached scrap lumber to the bottom of the sheet.

When rolling the chassis into the dust containment area for body fitting, I roll up the plastic from the bottom. I attached 1/8" nylon rope through eye hooks in the ceiling which hang down. This allows me to suspend and hold the plastic curtain pieces in place when rolling the chassis into/out of the dust containment area. It's roughly 10' wide by 20' long. Not the most spacious area, but it works.

Of course, my DIY dust room cost more and took way more time than I expected. What else is new? Seeing it for the first time, my wife said it looked like I was building a murder room. Uff da! Not the vision I'm going for.

I also had to relocate where I was suspending the body from the ceiling. Here it is above the chassis ready for first fitment. The body has not been on the chassis since my kit arrived in Oct. 2020. As a solo builder, the ratcheting pulleys and PVC pipes were key for easing the body on.

Wow. As many builders have commented after seeing their first body-on fitment, it's quite a sight. I've been staring at the chassis for 27 months. As JohnK said, it turns out I'm building a car afterall.

I feel like a proud papa holding his baby for the first time: this is the best looking Roadster I've ever seen. Nevermind no windshield and the gel coat.  At first glance, it appears I'll need to trim the rear trunk lip, as the body needs to move forward to achieve the 1/4" gap forward of door striker. There's plenty of gap between the front cowl lip and dash. I'll thread in the threaded rod into the rear QJ couplers once I get these first few rough fitment steps/trimming out of the way.

At first glance, it appears I'll need to trim the rear trunk lip, as the body needs to move forward to achieve the 1/4" gap forward of door striker. There's plenty of gap between the front cowl lip and dash. I'll thread in the threaded rod into the rear QJ couplers once I get these first few rough fitment steps/trimming out of the way.

I may need to trim the top of the Breeze cubby wall as well. I think I'll proceed in baby steps when it comes to trimming--one area at a time.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 4 Likes

-

01-28-2023, 11:37 PM

#564

Senior Member

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-29-2023, 07:02 AM

#565

Senior Member

You ain't kidding, that looks amazing.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-29-2023, 11:44 AM

#566

Senior Member

The first time you get the body on is quite a day. Black and red is so sharp. I had second thoughts on the color initially as a result. Speaking of witch have you narrowed down your color choice (ducks behind a desk).

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-29-2023, 11:54 AM

#567

That's awesome Chris! That feeling of seeing the body on the chassis for the first time is priceless.

MkIV Roadster build: Gen 2 Coyote, IRS, TKO600. Ordered 10/24/18. Delivered 1/29/19. Engine installed 8/8/21. First start 9/12/21. First go-kart 9/17/21. Off to paint 4/11/22. Back from paint 12/30/22.

Build thread here.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-29-2023, 12:42 PM

#568

Senior Member

Originally Posted by

Jim Frahm

Looking good my friend.

Thanks, Jim. You're making good progress. Won't be long and you'll be here yourself. Let me know when you're ready, and I'll come over and help you put the body on.

Originally Posted by

mmklaxer

You ain't kidding, that looks amazing.

Much appreciated, sir. Though it pretty much looks like every other MK4 at the point, given the hours of blood, sweat, and tears--yes, all three!--she's a beauty in the eyes of this beholder.

Originally Posted by

Blitzboy54

The first time you get the body on is quite a day. Black and red is so sharp. I had second thoughts on the color initially as a result. Speaking of witch have you narrowed down your color choice (ducks behind a desk).

First body fitting is pretty cool. I couldn't agree more, Jesse. I also like black and red together. Though painting won't be until at least 2024, right now I'm ruminating on orange w/black stripes, white w/black stripes, or a smoky/milky gray (stripe color TBD). The problem with orange is the red Wilwood calipers won't mesh. Also, the dark green you chose is in my top five.

Originally Posted by

JohnK

That's awesome Chris! That feeling of seeing the body on the chassis for the first time is priceless.

Spot on, John. Looking forward to seeing yours finished and on the road in the near future.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 1 Thanks, 0 Likes

JohnK

JohnK thanked for this post

-

02-03-2023, 10:55 PM

#569

Senior Member

Love it! Can't wait to see it with paint.

MKIV Complete Kit #9822 l BluePrint 347 EFI l TKO600 l Power Steering l Heater/Defrost l

Build Thread

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-04-2023, 07:58 AM

#570

Senior Member

Good luck with this stage of your build. Your 14 steps for body fitment, along with these later posts are going to be a big help for me later on. You're getting close, and I'm looking forward to your completed roadster.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-04-2023, 11:26 AM

#571

Senior Member

Originally Posted by

buttsjim

Good luck with this stage of your build. Your 14 steps for body fitment, along with these later posts are going to be a big help for me later on. You're getting close, and I'm looking forward to your completed roadster.

Thanks, Jim. It really helped to write down the major steps I found through researching the forum. Makes it a little less intimidating for me. I'm going to edit that post with additional learnings as I go through the process. I'm so indebted to this forum, I want to give back in any way I can.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-11-2023, 04:43 PM

#572

Senior Member

Body Fitting Progress and a Question: Part 1 of 2

Well, I've had the body on four different times so far. It must be quite a sight to see me put it on, but somehow I manage to get it into place each time. Maybe I'll be a little more graceful and efficient after another half dozen.

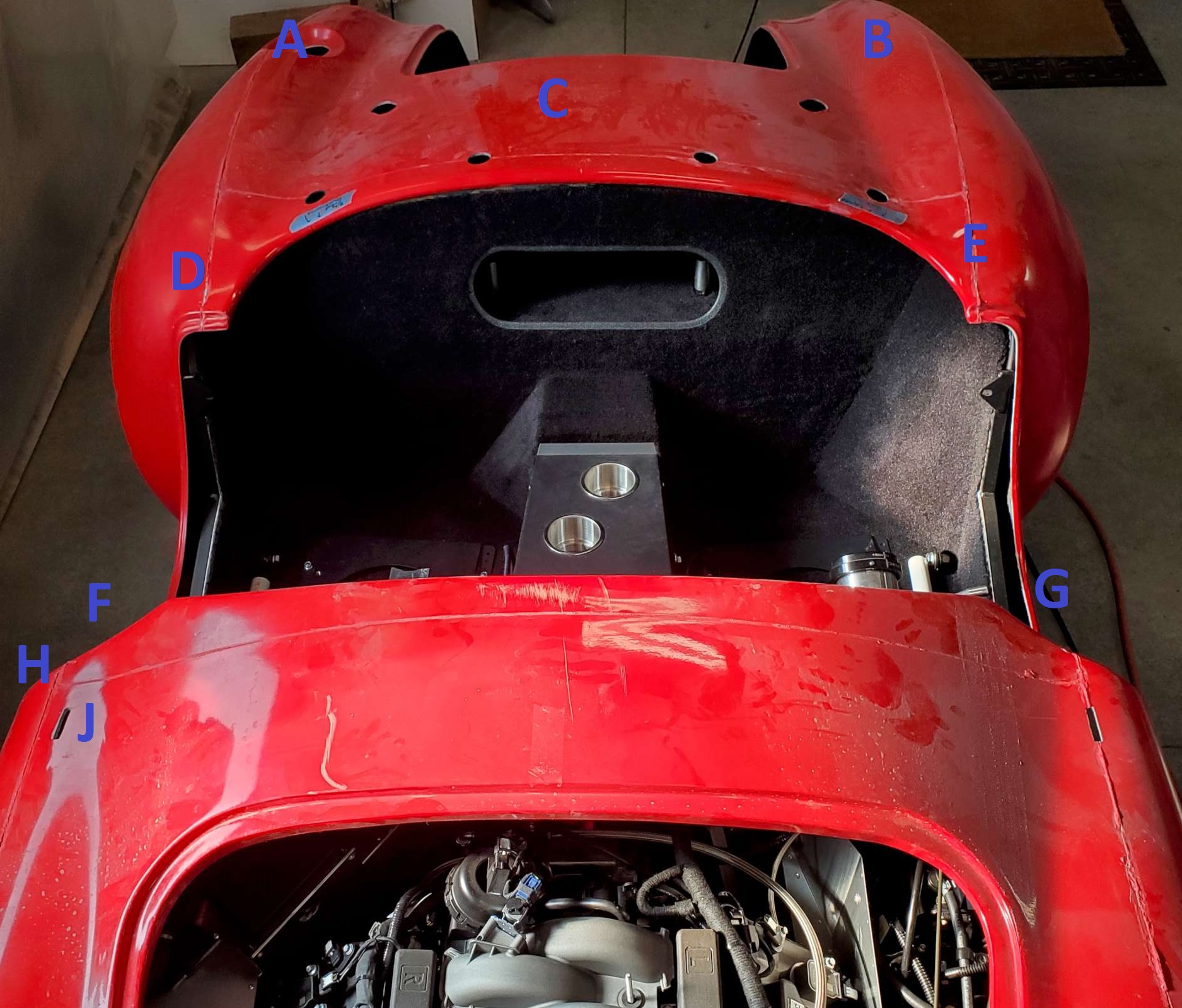

After celebrating the body on for the first time, it was time to get to work on several areas: where the bulb seal was fully compressed, body contact on the outer dash wings, big gap above the dash etc. Here are the specific areas I needed to address:

- (A) & (B) Trimmed along top and rear edges of trunk side panels. Bulb seal was compressed. This was needed to allow body to move forward.

- (C) Trimmed top of Breeze cubby wall using my angle grinder. This was needed to allow the body to drop down closer to the rear cockpit wall. Scraping the Thermotec and carpet away from both sides was especially fun. It was so enjoyable, I trimmed it twice.

Turns out the second trim was unnecessary afterall. Doh!

Turns out the second trim was unnecessary afterall. Doh! - (D) & (E) Trimmed outer sides of cockpit wall. Bulb seal was fully compressed, and preventing body from dropping down into place.

- (F) & (G) Trimmed outer wings of dash. Full contact with the body, and keeping it from dropping down into proper gap above the dash. I made my own dash out of 0.080 aluminum, and perhaps didn't bend it enough, or at the correct angle. This area also received two rounds of trimming.

- (H) Trimmed firewall extension. Bulb seal fully compressed, preventing body from dropping down to proper gap above the dash on the right side.

- (J) Trimmed 1/4" of inner vertical edge of the U-channel in the firewall extension. This would have interfered with the PS windshield post--see picture below.

- I also trimmed the rear cowl. Front cowl was trimmed just before I applied the underbody coating.

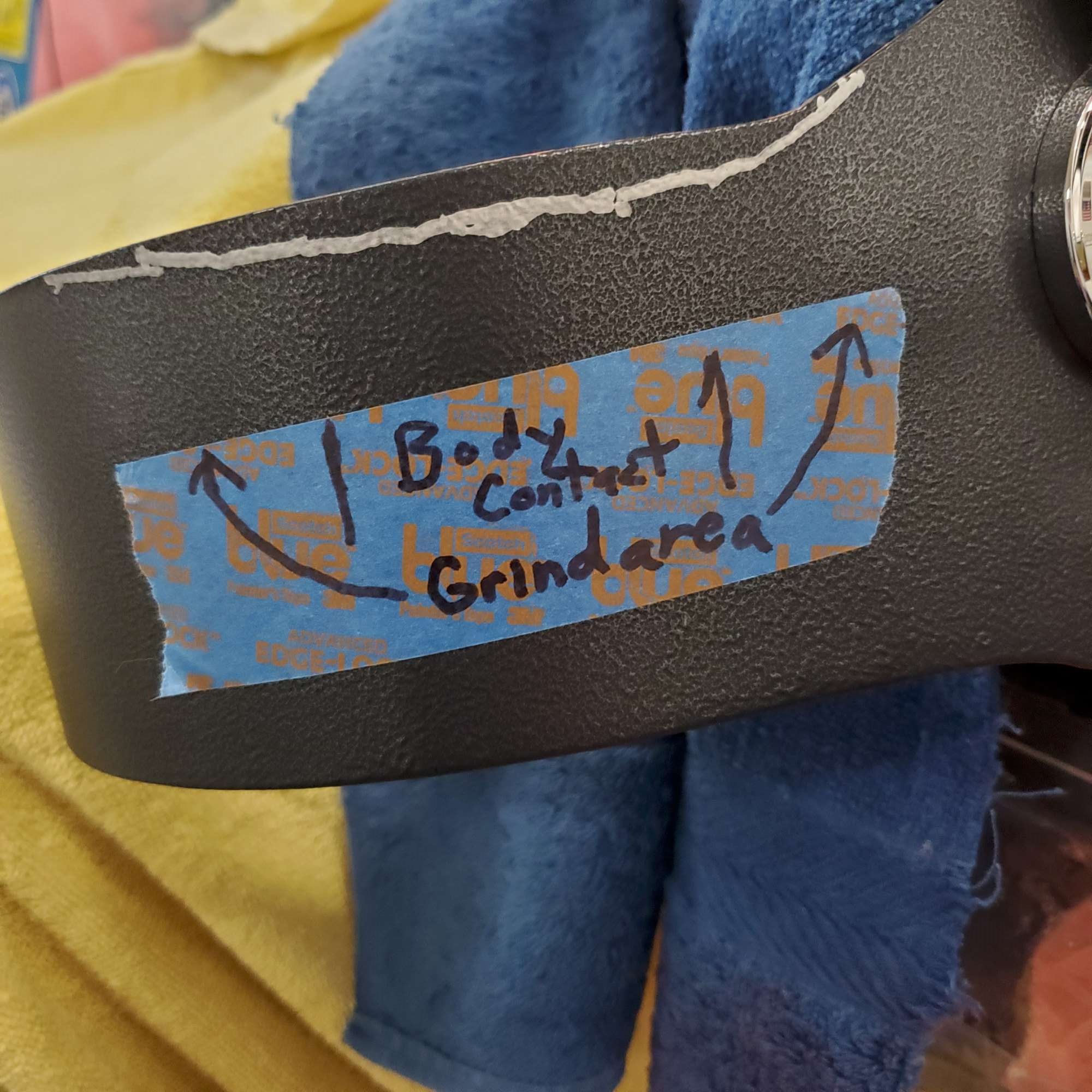

(F) & (G) Here's what the DS of the dash outer wing looked like before trimming. I had to make a couple passes, ultimately trimming an additional 1/2" below the line shown here. The PS needed the same trimming, as the contour of the body swings down pretty far in this area.

(H) Here's what the firewall extension looked like after first round of trimming. Had to trim once more so the body would nestle down on the PS to match the gap above the dash on the DS.

(J) Here you can see the vertical edge protruding into the body slot opening where the windshield post will slide through.

Time for a couple tool additions: pneumatic angle grinder and air saw. Both advertised CFM requirements at 90 PSI that are well within my 13 gallon compressor's CFM capacity. However, my compressor runs continuously when using them, especially the grinder. So, to reduce the duty cycle I stopped every so often to allow it to catch up. The air saw is DIY grade from Eastwood. Also picked up some drum sanders for my electric drill.

A couple of questions: the first is do I have the door flange far enough forward of the door striker? The distance between the top of the striker and the forward edge of the door flange is short of 1/4". Is it enough?

Last edited by 460.465USMC; 02-13-2023 at 11:48 AM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-11-2023, 04:44 PM

#573

Senior Member

Body Fitting Progress and a Question: Part 2 of 2

The second issue is I have ~1/4" gap between the rear wall and the body--see picture below. Unless I somehow installed the cockpit wall too low (is that even possible?), I can't figure out what might be causing this gap.

- The side rocker panels are tucked in below the chassis.

- The top of the Breeze cubby wall is not making contact with the body.

- The bulb seal along the trunk sides is not compressed.

- There is wiggle room between the outer sides of the cockpit wall and the body.

What else could be causing this gap? Will it settle over time?

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-12-2023, 11:35 PM

#574

Senior Member

Hey Chris, great progress, and even better for all the rest of us, great documentation. This will be super helpful! I wish I could help you with the gap at the rear of the cockpit. Hopefully others will chime in. Keep on chugging ... having your wonderful documentation completed just ahead of my next steps is really handy!

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-13-2023, 11:59 AM

#575

Senior Member

Thanks, John. Documenting helps me keep my head straight on where I've been and informs me on next steps. Glad if you find it useful too. Each build is unique, so others may not need to trim much, or in the same areas (or at all?).

Still scratching my head on the gap above the cockpit wall. When I remove the body next I'm going to remove the bulb seal from the cockpit wall sides to see if that makes a difference. If it does, then I'll need to trim that area....again. If no difference, than back to head scratching.

To address the door striker clearance, I may trim 1/4" or so from the rear trunk lip when the body is off next. Though the bulb seal isn't compressed there, the body is making solid contact with it.

In my case, this body fitting business is a LOT of trial and error.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-14-2023, 01:14 PM

#576

Not a waxer

Hey Chris,

Good talking with you over the weekend! I pulled a body this morning but before doing so I ran tape right up to the underside of the rear rollover to show the overlap on the rear bulkhead then took this photo after lifting the body:

I shot this from the other direction:

I have another car with the body off and it measures exactly the same. Hopefully these will give you some reference to help sort out where your issue lies.

Cheers

Jeff

Rear wall1.jpg

Rear wall2.jpg

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-14-2023, 02:13 PM

#577

Senior Member

Hi Jeff. Thanks again for chatting with me. It was a very helpful conversation.

Wow, that's a lot of overlap in the first photo. In comparison, my body must be sitting above the cockpit wall quite a bit. Holy smokes! I will be pulling the body off soon, so can then measure the distance shown in the second picture.

Much appreciated, sir!

Last edited by 460.465USMC; 05-28-2023 at 07:07 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-20-2023, 11:28 PM

#578

Senior Member

Body is Centered....and a Windshield

I fiddle-farted around a bit more with the unwanted 1/4" gap above the cockpit wall, as well as the clearance between the door flange and door striker. Here's where I landed:

- The next time I was putting the body on I noticed when the lower rocker panel is pulled away from the chassis the body sits right down and over the cockpit wall. Since the rockers will be adjusted during door fitment, I'm going to leave it for now. If the 1/4" gap does not disappear, I will look into extending the carpet above the cockpit wall to fill the gap (good suggestion from Jeff).

- Trimmed rear trunk lip 1/4" to allow more play in forward body movement. This gave me confidence I can achieve the 1/4" gap between the door flange and door striker.

- Next, I moved on to locating the nose. To get it centered I measured from the chassis (upper shock mount attached to chassis) to the edge of the wheel well lip. Then adjusted the body left and right until these measurements were equal. Per a good tip from Mr. Kleiner, I picked up SS tubing from Onlinemetals.com (0.75" OD x 0.065" Wall x 0.62" ID Stainless Round Tube, 304 Seamless - Part #: 12927) and rubber grommets from ********** (they shipped out same day). The grommets can also be purchased from Metro (EX17-B from Metro Molded Parts). I cut the tubing to 5.5" lengths (4 each) with my angle grinder, and then deburred.

- After centering the nose on the chassis, I was relieved to find the quick jack holes in the chassis lined up with the holes in the body. No need to break out the big hammer. However, the body holes needed to be opened up a bit for the grommets to fit.

- I glued a 1/2" thick piece of rubber on each 3/4" tube next to the hood hinge bracket. With the body sitting on these and anchored by the SS tubes/grommets in the QJ holes, it is very solid.

With that done for now, I moved on to the windshield install. Here are a few highlights/observations from my experience:

- I can confirm the brass threads in the windshield frame are soft. I thought I was being very careful, but still managed to cross thread a few of the holes. Doh! Thankfully, I had a M5-0.8 tap on-hand from my NRG removable steering wheel adapter project, which made quick work of cleaning up the threads. Also, the channel closes in pretty tight where the screws thread in, so in at least one spot I "tapped" the channel. One word of caution: to reduce the chance of buggering up the threads, minimize the number of times these side posts are removed/installed.

- I bought the body cutout option with my kit, which meant the slots for the windshield posts were cut for me. The slots were cut parallel with the body (front to back), but my windshield posts angle outward. The result is the openings are now pretty wide, but I think my Replicaparts trim plates will still cover them. Before I started adjusting these slots, I traced around the trim plates so I could keep an eye on the footprint of what they will cover.

- Both side posts needed a little trimming: removed about 1" from the left and 3/4" from the right. When drilling the holes and trimming the length I anchored them in my bench vise. Even though I started with a 1/16" pilot hole and gradually opened it with larger bits, the larger ones really wanted to grab the post and twist it. Probably not a good practice to torque the posts while they're attached to the windshield. I tapped the side posts for the 1/2"-13 supplied bolts, a tip I picked up on the forum. One more thing on the side posts, I wanted the holes to be centered on the post. Since the they didn't perfectly line up with the holes on the chassis, I slotted the chassis holes to match with my air saw.

- The Styrofoam in the windshield box provides a nice "cradle" to lay the windshield until it's ready to install.

- Working solo, I needed a way to prop the windshield in position (27" from top screw to top inside of door flange). I notched a piece of scrap 1"x3" to hold it in place while I marked the holes, and again to hold it in position as I tightened down the 1/2"-13 bolts.

- I used one of the washers that came with the windshield hardware as a shim on the Right side lower post. The rest of the posts were flush with the chassis.

Here's a picture of the channel I mentioned above that was so narrow I tapped it to aid the screw in finding the hole and engaging the brass threads.

I used the air saw to slot a couple of the holes. This not only provided a little extra wiggle room, but also allowed me to center the holes in the posts. I'll touch these up with paint next time I remove the body.

My high-tech windshield placement instrument.

And, we have a windshield.

I think I'm ready to move on to door fitment. As always, I'm grateful to the forum for all of the great tips and guidance.

Last edited by 460.465USMC; 06-26-2023 at 04:18 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-21-2023, 12:33 AM

#579

Looks like its 3.5” in Jeffs photo. Mine is 3.5” also. Thanks for documenting the process. I am about to fit the body too.

Ordered 9/24/2020, Delivered 1/18/2021 MK4 Roadster, 3 Link, 15" Halibrands, Blueprint Carb 347/TKX Installed 3/13/2022, first start 10/2022, go cart 11/2022, CA SB100 Reg Complete 12/2023

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-21-2023, 06:39 AM

#580

Senior Member

I feel like I almost broke both wrists trying to drill the 1/2" hole into my posts. The drill bit wants to grab and violently twist the drill.

I found there was enough play in the chassis holes that I didn't need to open up the upper hole for the post. My mark was off midline as well, but you can just drill on the marked midline and be fine. make sure you shim any gaps between the post and chassis to prevent possible cracking down the road.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-21-2023, 07:22 AM

#581

Not a waxer

Originally Posted by

egchewy79

I feel like I almost broke both wrists trying to drill the 1/2" hole into my posts. The drill bit wants to grab and violently twist the drill…

TIP: Use a step bit—-they go through brass like butter and won’t torque you. Go up to 5/16 on the step then finish with a 27/64 and tap for 1/2-13 as Chris mentioned. Makes windshield installation and removal soooooo much easier when you don’t have to fumble around with a nut!

Jeff

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-21-2023, 09:33 AM

#582

Senior Member

Is fiddle farted a technical term? Rooted in metric or imperial?

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-21-2023, 09:55 AM

#583

Senior Member

Originally Posted by

egchewy79

I feel like I almost broke both wrists trying to drill the 1/2" hole into my posts. The drill bit wants to grab and violently twist the drill.

Everyone should have a set of Rotobroach cutters like these or these I've had a set of the Bluepoint ones for decades and they still amaze me how well they cut and how handy they are.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-21-2023, 10:24 AM

#584

Senior Member

Originally Posted by

Jeff Kleiner

TIP: Use a step bit—-they go through brass like butter and won’t torque you. Go up to 5/16 on the step then finish with a 27/64 and tap for 1/2-13 as Chris mentioned. Makes windshield installation and removal soooooo much easier when you don’t have to fumble around with a nut!

Jeff

useful info to have 18mo ago. that drill nearly took me for a ride!!

-

02-21-2023, 10:52 AM

#585

Senior Member

Originally Posted by

Daddy O

Looks like its 3.5” in Jeffs photo. Mine is 3.5” also. Thanks for documenting the process. I am about to fit the body too.

Good to know, Daddy O. You're right. After taking another look I agree it's 3.5". I'm hoping the gap is reduced once I fit the doors.

Originally Posted by

egchewy79

I feel like I almost broke both wrists trying to drill the 1/2" hole into my posts. The drill bit wants to grab and violently twist the drill.

I found there was enough play in the chassis holes that I didn't need to open up the upper hole for the post. My mark was off midline as well, but you can just drill on the marked midline and be fine. make sure you shim any gaps between the post and chassis to prevent possible cracking down the road.

You ain't kidding, Chewy. I'm glad I was only using my Milwaukie 18V drill. An electric half inch drill wouldn't have been so kind to my wrists.

I forgot to mention I shimmed the Right side lower post. The rest sit flush against the chassis. I'll add that note in now. Thanks for mentioning it.

Originally Posted by

Jeff Kleiner

TIP: Use a step bit—-they go through brass like butter and won’t torque you. Go up to 5/16 on the step then finish with a 27/64 and tap for 1/2-13 as Chris mentioned. Makes windshield installation and removal soooooo much easier when you don’t have to fumble around with a nut!

Jeff

Believe it or not I thought about a step bit, but my short attention span must have kicked in. I couldn't agree more on how much the 1/2"-13 helped the install. I didn't even have to remove my fuse panel.

Question: when going with the tapping method, is it recommended to add a dab of Loctite blue to in place of the nylon lock nut?

Originally Posted by

Blitzboy54

Is fiddle farted a technical term? Rooted in metric or imperial?

Clearly rooted in Imperial, no?

Originally Posted by

Mike.Bray

Everyone should have a set of Rotobroach cutters like

these or

these I've had a set of the Bluepoint ones for decades and they still amaze me how well they cut and how handy they are.

And yet another tool I've never heard of. Thanks for posting, Mike.

Last edited by 460.465USMC; 05-28-2023 at 07:15 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-22-2023, 10:02 AM

#586

Senior Member

Originally Posted by

460.465USMC

Question: when going with the tapping method, is it recommended to add a dab of Loctite blue to in place of the nylon lock nut?

Or, you could just put the nyloc nut on the back after you've run the fastener through the tapped hole. Should be easier to reach once you don't need to access both sides at once. Great progress, by the way!

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-26-2023, 06:44 PM

#587

Senior Member

Door Latch Mod ("Old" Style)

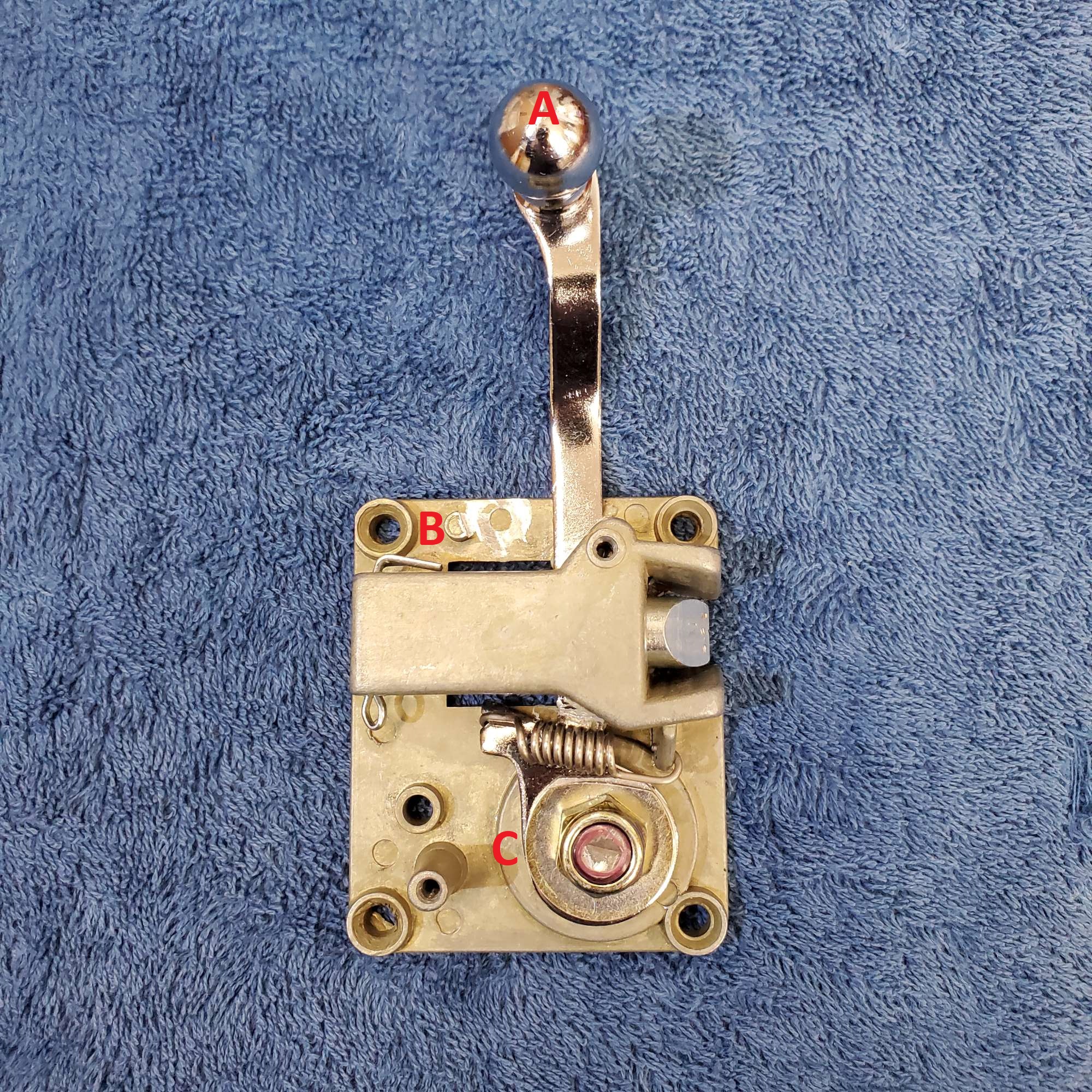

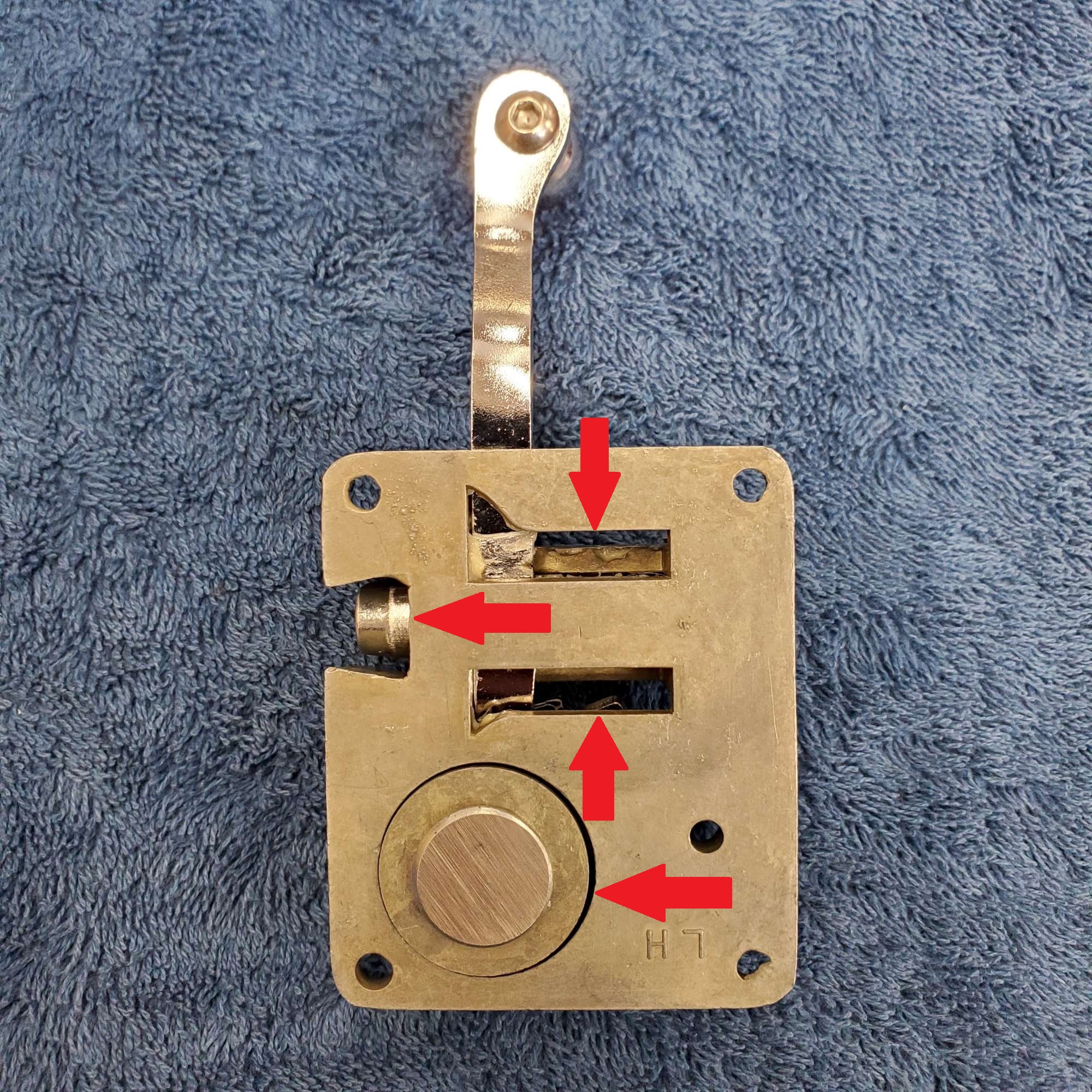

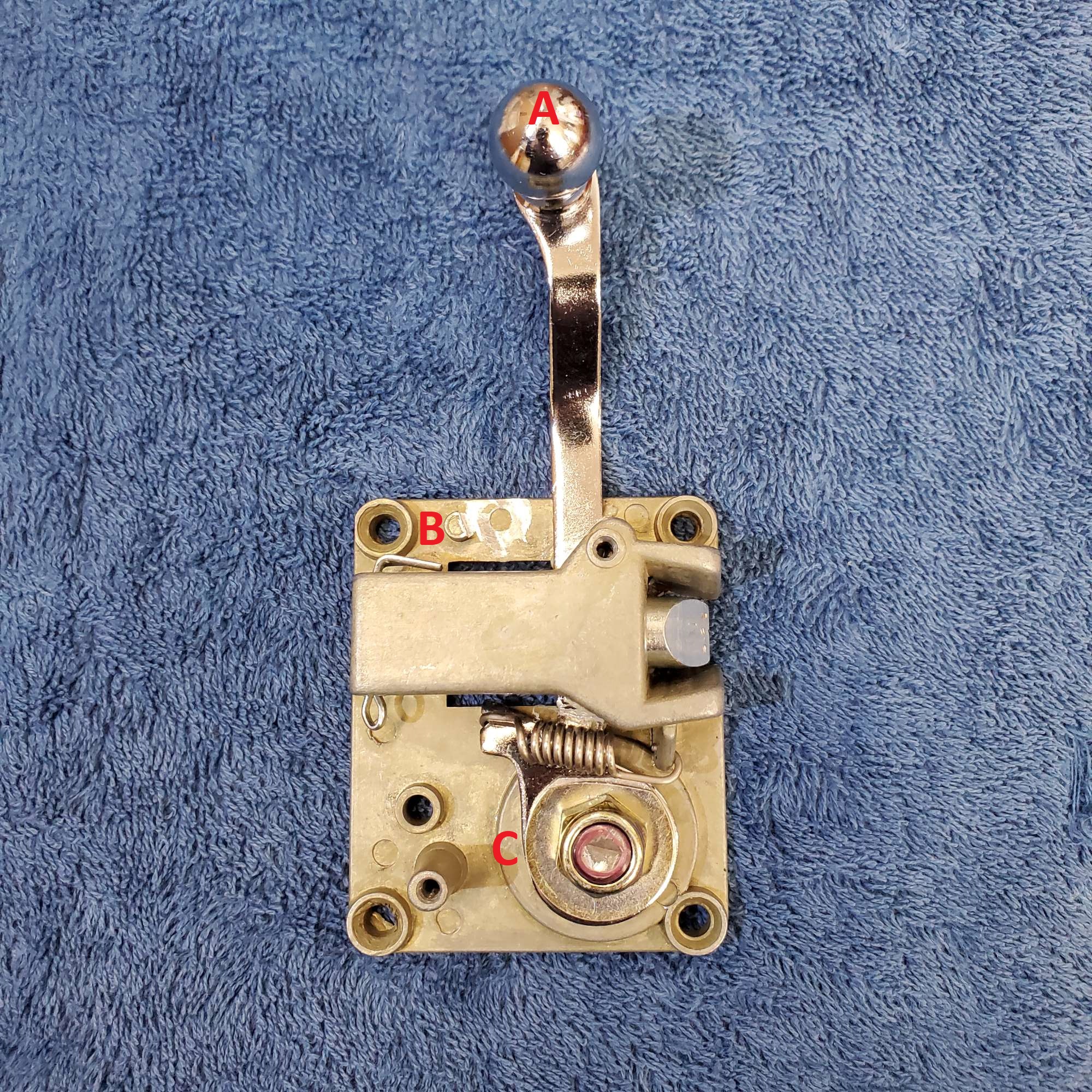

At this point I guess I should refer to the style of latches that came with my kit as the old style. There are numerous recommends and posts on the forum to complete a number of mods/improvements for durability and functionality. I'm not exactly blazing a trail here with new info., but it feels good to have them done now that I've started door fitment.

Here's how my door latch mods turned out:

- (A) First up was drill and tap the knob for 10-32 button head SS screw. There are reports of it working loose over time. I anchored my latch assembly in my drill press vise. It drilled and tapped pretty easily. I cut down the 10-32 screws to about 1/4" in length, not including the head.

- (B) Like other builders, my latch pins did not fully retract--see second picture below. They protruded at least 1/16". This protrusion reportedly tends to catch, not allowing the door to open. Using a stone on a Dremel and a small flat file I removed 25%-30% of the latch arm stop. Now the pin sits sub flush when fully retracted.

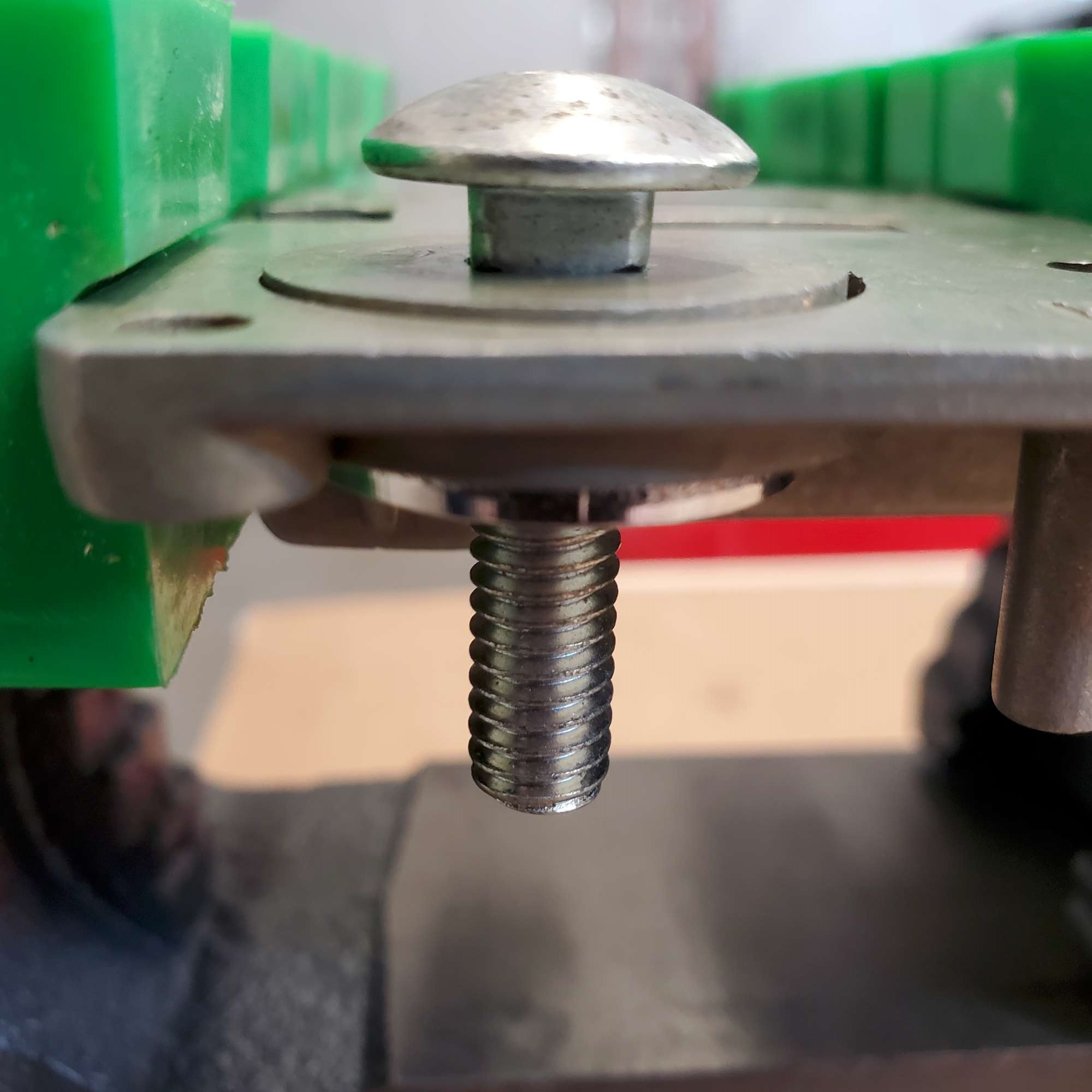

- Next, I opened the square hole for the 5/16" carriage bolt. Just a few light strokes with a small flat file and it popped right in, sitting flush.

- Then I flattened the dome of the carriage bolt down to about 0.080" (2 mm) with a belt sander. This is to allow clearance to the door. The carriage bolts I had on hand were too long. So, I measured the height of the standoffs for the latch cover, and cut the bolts to length.

- (C) I secured the latch lever where it attaches to the pivot with a couple washers. The ID of the first washer should be 1/2" to slip down over the round center of the pivot. The OD of this washer should be minimal to avoid contact with the spring. You can see how I removed some material from the washers to provide clearance away from spring. I added a very thin spacer (washer) with smaller ID left over from my Wilwood brakes to provide clamping force between the nut and lever arm.

- Chamfered the hole about 1/16" in the wedge shaped striker that the latch pin engages--see last picture. Did this after the fact per Kleiner's recommend below. Thanks, Jeff.

- Finally, I applied white lithium grease to the moving parts (red arrows below). Through a stroke of genius, I determined no need for me to disassemble: in theory the pin spring and keeper could fly out when removing the cotter pin. They could bounce off the wall, and drop into a garbage can full of saw dust and metal shavings. In theory.

- For the pivot mechanism, I applied silicone spray to both the front and the rear sides. Worked the latch arm a number of times. Rinse and repeat.

Latch pins didn't fully retract. Here's what they looked like before I ground down the latch arm stops.

As received, a 5/16" carriage bolt will not slide into the square hole of the pivot center. Just a few quick strokes with a small flat file to remedy.

Here the now flat head of the carriage bolt is seen. The red arrows are where I applied white lithium grease. I used silicone spray to penetrate the pivot joint. Also, the head of the 10-32 SS button head screw that secures the latch knob is visible.

Here's the 1/16" chamfer I added to the striker where the pin engages.

Last edited by 460.465USMC; 03-02-2023 at 01:30 PM.

Reason: Added comment and picture of chamfer in striker.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

02-26-2023, 06:54 PM

#588

Great work on the door latches Chris! I'm struggling with the newer Mk4 door latches as we speak and boy do I wish I got the old-style door latches. Much smaller and unlatches in a way that actually makes sense!

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-26-2023, 07:17 PM

#589

Not a waxer

One last thing Chris—-see that coil spring above “C”? Get rid of it.

OK, one more one last thing—-the hole in the wedge shaped striker that the latch pin engages…take a countersink bit and put a nice 1/16” chamfer on it.

Carry on!

Jeff

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

02-27-2023, 10:38 AM

#590

Senior Member

Originally Posted by

Jeff Kleiner

One last thing Chris—-see that coil spring above “C”? Get rid of it.

OK, one more one last thing—-the hole in the wedge shaped striker that the latch pin engages…take a countersink bit and put a nice 1/16” chamfer on it.

Carry on!

Jeff

Hi Jeff. Thanks for putting eyes on this. What does that spring do (or not do well) that it should be removed? Does it cause the latch arm to bind or something?

Also, thanks for the tip on the chamfer in the striker. Easy enough to do now.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

03-13-2023, 03:37 PM

#591

Senior Member

A Door Opens. A Door closes.

With the door latch improvements done, I moved on to setting the DS door in place. I pushed the rocker panel up against the 2" square tube, and in all the way. Then held it there using a scissor jack while I fiddle-farted (that one was just for you, Blitzboy!  ) with centering the door. With the slotted hinges/mounts it can be moved forward/aft, left/right, and up/down. Uff-da!

) with centering the door. With the slotted hinges/mounts it can be moved forward/aft, left/right, and up/down. Uff-da!

My door needed to be sanded down to fit in the opening (I think this is normal). Laying down a 1/4" thin line on the door to match the curve of the body opening gave me a guide for sanding. I opted for a sanding block and elbow grease to remove the material. As a first timer, no need for me to up the risk of removing too much glass with the die grinder. It comes off pretty fast with 60 grit or 36 grit.

After many iterations of centering the door in all six directions I came up with this position.

The door alignment certainly isn't perfect. For one, the top forward corner of the door protrudes out from the body a bit. I think this may be typical as well. I'm assuming the body Pro will need to build up the body in this area.

Once I had the door centered, I tightened the two socket head hinge bolts, and the nuts on the four door studs. Per Mr. Kleiner's advice, I added a thick (slightly less than 1/8") washer between the lower forward door stud and the hinge. I set aside the supplied nylon lock nuts for now. I'm using standard nuts until I put the doors in for the final time. The DS rocker panel is now secured in place with a couple #10 self-tapping screws through the factory holes. I will slot these holes left/right next time I have the body off, so they can be dialed in exactly after paint. Replacing the #10 self-tappers will be 1/4-20 SS button heads into rivnuts in the 2" square tube.

Next, it was time to install the latch. The manual speaks of a spacer for the latch, but doesn't show it. It's been so long since inventory I completely forgot what they were, and the fact I had them. They are laser cut, and 3/16" thick. If needed, they're used during this step, that is, aligning the latch to the door strike.

Door latch spacer:

I used it on the driver's side. Remains to be seen if the PS will need it. I picked up a couple 5/16" ID x 3/4" steel spacers at Ace for the striker bolts. I think it looks better and is more solid than stacked washers to set the striker distance away from the strike mount (as shown in the manual). Just had to shave it about 1/4" to fit. It's visible in the picture below.

To fasten the latch assembly to the door, I tapped for 10-32 screws. Upon a closer look, I see the steel backing behind the fiberglass is plenty thick to tap for 10-32 (thank for the suggestion, Edwardb). The manual doesn't specify the hardware here. I used socket head screws, because the hole closest to the lever (upper left in picture below) doesn't have clearance for a button head.

Door latch installed with socket head 10-32 screws.

And with the shiny cover on the latch. I don't know why the manual says to toss the acorn nuts to secure the striker. They fit perfectly for me, and give it a nicer finish.

I know a functioning door latch is only a big deal to me. But pix or it didn't happen, no? There were a lot of steps to get to a functioning door. Here's an exciting 13 sec video of the DS door latch operation  : https://youtube.com/shorts/NxzpQEgaJo8

: https://youtube.com/shorts/NxzpQEgaJo8

Last edited by 460.465USMC; 03-14-2023 at 10:19 AM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-13-2023, 03:53 PM

#592

Senior Member

Nice work and nice pace you're keeping, Chris! I can't decide whether I'm keeping pace because I have more time on my hands, or because you're writing up fantastic advice just before I need it. Unless you think I'm kidding I'll share just one photo:

Untitled by John Ibele, on Flickr

Yeah, your windshield post, converted to Word and font size increased for clarity, required reading for any of my helpers touching the car last weekend. I could feel either creepy or just a bit like a leech, but ... I'm basically without shame. You wrote it, I'm using it

When you have the other door dialed in, is it going to be "When one door closes, another one opens"?

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

03-13-2023, 04:22 PM

#593

Senior Member

If I can give back even 1/50th of the help and guidance I've received from the forum, it will be very rewarding.

Once my PS door goes in it might be, "When one door closes, the other one falls off". But hopefully not.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-13-2023, 04:55 PM

#594

Senior Member

Hey quick Q if you don't mind. Mr. Kleiner would like it if I left gapping the panels to him, but I can already tell I'm going to have an interference fit at the top inside edge of the door, where it meets the body in front and back. How much material did you remove here? It's just out of view in your last two photos. Thanks!

MK4 #7838: IRS 3.55 TrueTrac T5z Dart 347

The drawing is from ~7th grade, mid-1970s

Meandering, leisurely build thread is

here

-

03-13-2023, 05:10 PM

#595

Senior Member

Nice work securing your balls, nothing worse than loosing a ball... happened to me before I installed the McMaster threaded ball. Your solution is also a great way to secure your balls.

Nice work on the entire door mech! you are moving right along! Hopefully you can get some good drive time in this spring!

-

Post Thanks / Like - 1 Thanks, 2 Likes

-

03-13-2023, 05:18 PM

#596

Senior Member

I would like to leave it to the Pro as well, but my decision to drive in gel coat for at least a season precludes that option. Basically, I just removed enough material around the perimeter to provide clearance for the full swing of the door. If you look at the thin line in the first photo those are the areas I sanded. I don’t think I removed more than 1/8” in any particular area. Definitely not more than 3/16”. Keep an eye on your sanding angle.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

03-25-2023, 02:22 PM

#597

Senior Member

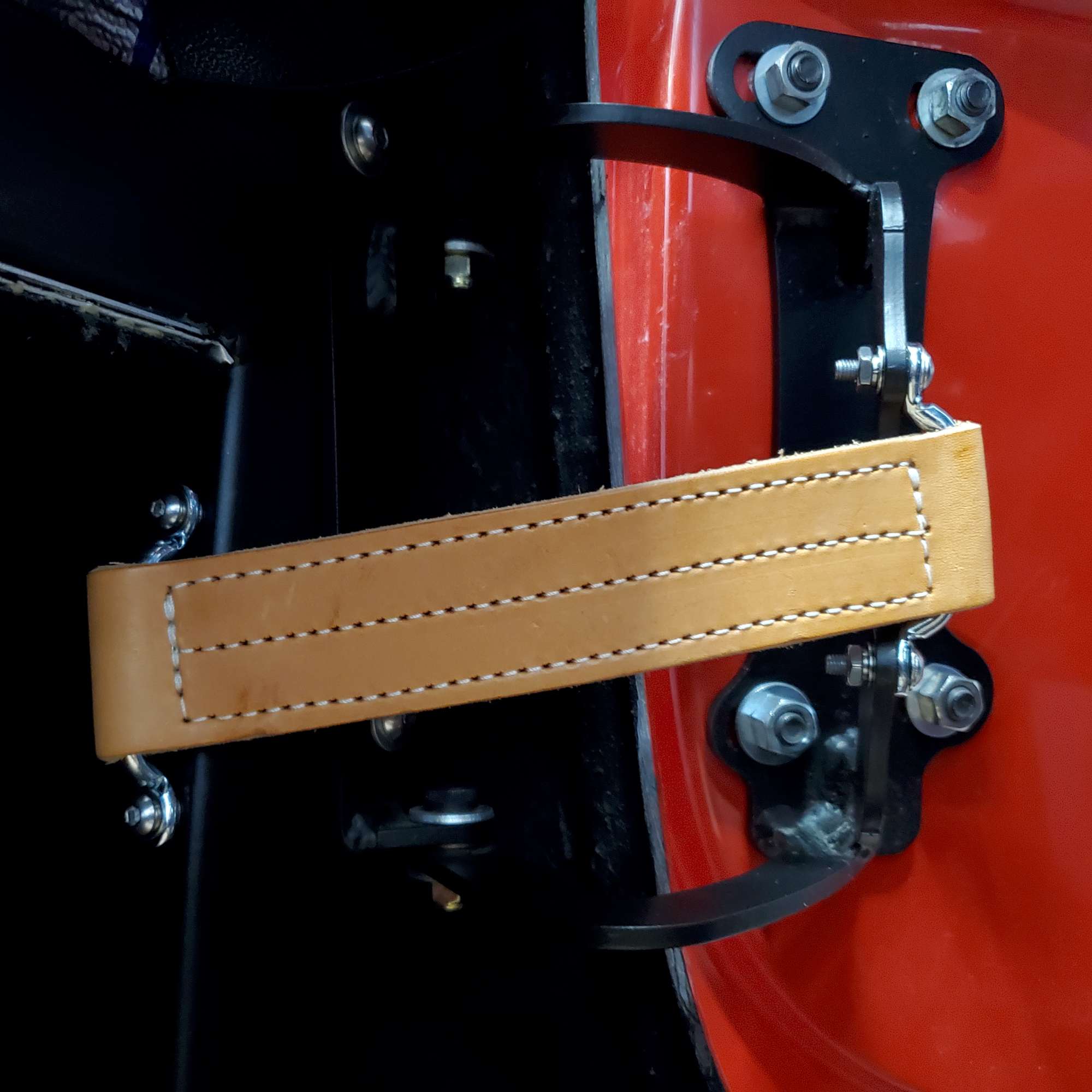

PS Door. Check Straps. Louvers.

I've been chipping away since my last update. A little bit of progress on most days. With the DS door complete, I tackled the PS door. As has been mentioned by Mr. Kleiner, each door has its unique adjustments and tendencies. It required some sanding, but it seemed to center a little easier. Perhaps because it was my second door?

Sorry, but no video for the PS door.  Here's a picture of the latch secured with the door in place. The doors have a satisfying thunk when they close. Not quite like the steel doors from the 60s, but it's a good sound to me no less. Especially, considering how light they are compared to the older steel doors.

Here's a picture of the latch secured with the door in place. The doors have a satisfying thunk when they close. Not quite like the steel doors from the 60s, but it's a good sound to me no less. Especially, considering how light they are compared to the older steel doors.

Check straps: I like to finish up an area when I can, so moved on to the check straps. I used 10-32 SS button head screws instead of rivets. For the 2" square tube side, I installed 10-32 rivnuts. Gives it a more professional, finished appearance, IMHO. The exposed standard nuts on the door side of the hinge will be replaced with 10-32 SS acorn nuts later on. As will the nuts on the 3/8" door studs. Here's a view of the PS check strap. I'll try my hand at vinegaroon to make them black.

Side louvers: I went with the assembled side louvers from F5. I liked the approach Edwardb used (no surprise there) in his 20th anniversary build to install them so they are removable. Not sure if I'll ever need to, but the louver opening would make a handy access hole if needed in the future. I bought the adhesive mount studs - 97590A567 from McMaster, and attached them via the supplied angle brackets. The brackets are attached to the louver via 6-32 SS button heads and nylon lock nuts. I made sure the studs were flush with the outside face of the louvers. It's important to locate the bracket to louver holes while the studs and louvers sit on a flat surface. Otherwise, there will be a gap between the inside of the body and the louver when installed. The louvers are now at the powder coating shop, along with the front nose grilles, splash panels, quick jacks and tubes, and side exhaust heat shields. All will be black.

Driver side louver on the bottom (finished side up) and PS on the top (finished side down). Note the 6-32 screws are pretty well hidden on the finished side.

Next, I started hood fitment. My first step was to install the hinge brackets to the hood. I hemmed and hawed about using rivets to attach these, and ultimately decided the leftover 3/16" stainless steel rivets from my Breeze battery install would suffice. It's all I can do to install these with my hand rivet tool. I actually don't mind installing rivets by hand v. power tool. The one exception are these 3/16" stainless rivets. Oof!

It surprised me a bit to find not all the holes in the hood align to the holes in the hood bracket. I had to drill out several holes on the hood side to get alignment. I found the two best holes on each bracket so they are set to roughly the same inward pointing angle. Then I installed rivets in these holes. Then I drilled through the bracket into the hood to get the hood side hole aligned. These brackets feel very solid with the four SS rivets.

Here's an example of a hood hole that didn't align with the bracket.

Hood fitment continues. I've made two passes with the orbital sander (I'm liking my DIY dust containment "room"), and the hood now centers in the body opening. I hope to have the spacer/bumpers in, handles installed, and prop rods installed for my next update.

Happy building!

Last edited by 460.465USMC; 03-29-2023 at 11:15 PM.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

03-27-2023, 10:35 AM

#598

Senior Member

I had the same issue with the hood bracket. The difference was it was post paint so I was STRESSED drilling it out but not punching through. best to get this all sorted now.

-

03-27-2023, 09:14 PM

#599

Your 10-32 bolts for the check straps look a bit long for acorn nuts.

You may need to source shorter bolts or make these shorter.

-

03-28-2023, 10:14 AM

#600

Senior Member

Hi Rob. Appreciate the calibrated eye. You may be right. I haven't measured them yet. If I had a nickel for every bolt I've shortened on this build.... I keep the Dremel and angle grinder within arm's reach.

I keep the Dremel and angle grinder within arm's reach.

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

At first glance, it appears I'll need to trim the rear trunk lip, as the body needs to move forward to achieve the 1/4" gap forward of door striker. There's plenty of gap between the front cowl lip and dash. I'll thread in the threaded rod into the rear QJ couplers once I get these first few rough fitment steps/trimming out of the way.

At first glance, it appears I'll need to trim the rear trunk lip, as the body needs to move forward to achieve the 1/4" gap forward of door striker. There's plenty of gap between the front cowl lip and dash. I'll thread in the threaded rod into the rear QJ couplers once I get these first few rough fitment steps/trimming out of the way.