-

Senior Member

Chris' Coupe Build #566 - Swarf. Shavings. Filings. Chips. (Panel Fitting)

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

I got THE CALLl!

What's better than building a F5 car? Building a second F5, of course. Wahoo! I can't believe I get to build again! I really enjoyed building the Roadster. It was challenging for me, yet very satisfying. Learning was a huge part of the enjoyment. The F5 Forum here was invaluable.

My eye was on the Coupe as a first build. But after an honest assessment of my skillset (beginner), the MK4 seemed like it would be a better match. And the lower kit price would leave a couple more large Gs in my pocket. So, Roadster became my choice for Build One.

To kickstart the Coupe funding and make this project possible, I said goodbye to my 2019 Camaro SS. Yes, a tear was shed. No Chevy's in Chris' garage? What the heck? What's happening to this crusty old bowtie heart? It was a necessary evil to enable my growing F5 car building addiction.  The silver lining is my "new" garage does not have room for it anyway. More about that later.

The silver lining is my "new" garage does not have room for it anyway. More about that later.

Besides the obvious differences between the Type 65 Coupe and MK4 Roadster, I will be attempting a number of new-to-me items with my Complete kit build:

- Coyote Gen 3 (don't have it yet, so will see what's available later on when I'm ready for it)

- T-56: planning to mate it to the Coyote myself (another first); reverse lockout feature, and backup lights

- Hydraulic throwout bearing: possibly Tilton

- Brakes: Wilwood SuperLite front brakes. 13" Dynapro Wilwood rears. Both are slotted, but not drilled. Gordon Levy Racing.

- Electronic Parking Brake: Wilwood

- IRS with 3.55 ratio

- Power steering: KRC from F5

- Gauges: Speed Hut GPS gauges from F5

- Gas-n side exhaust: Touring model - brushed stainless

- SS fuel and brake lines will attempt my own flares

- HVAC: supplied by F5

- Windshield wipers: specialty Power Windows

- Side windows

- Rear camera: displayed in rear view mirror

- High back seats. TBD: considering Corbeau, but I also like rhk118's selection from Intatrim

- Wheels/tires: staggered 18" SVE wheels from LMR; Front: 275/35. Rear: 315/30. (My Roadster has 17 inch wheels).

- Side mirrors: Brock Racing Equipment

- Digital Guard Dawg ignition with push button start

- Drop trunk storage: will attempt DIY

- Deleted seats, side exhaust, and front brakes

Purpose of the Coupe is mostly a performance cruiser, with some Autocross.

Stewart called me today with an April 15 pickup date. It should traverse the country, arriving at my place about a week later. Interestingly, my completion date was supposed to be 3/31/24. I checked with F5 yesterday, and the chassis and body have not been built. However, I was assured they would be ready in time for Stewart to pick up. So, no nursery picture yet. But, I think the F5 boys will come through with one once it's up in the rack and ready to go.

Oh, boy! This is getting real. Even with one build under my belt, this still feels like a huge, challenging project. I have much to learn. No doubt much of the knowledge I gain will come through this forum. Thanks in advance!

Last edited by 460.465USMC; 04-03-2024 at 09:16 AM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

Senior Member

Wow congratulations! Let the fun begin!

My coupe completion date is 4/27, so right behind you!

-

Senior Member

I’m looking forward to seeing your new kit! I’ll soon be driving over in the Roadster.

-

Senior Member

Originally Posted by

JimStone

Wow congratulations! Let the fun begin!

My coupe completion date is 4/27, so right behind you!

Wahoo! Exciting times, Jim. Congrats! I look forward to reading about your build.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Originally Posted by

Jim Frahm

I’m looking forward to seeing your new kit! I’ll soon be driving over in the Roadster.

Looking forward to seeing your Roadster on the road, Jim! Better yet, looking forward to getting our Roadsters out on the road together.

My plan is to put the Coupe on the lift when it's delivered. Are you doing anything on or around 4/22/24?

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Nursery is Ready!

As I mentioned in my last Roadster post, I moved last Fall. Walking away from a dialed in garage with room to spare to a "new", unfinished garage about half the size was not exactly on my radar. But, my better half is much happier at our new place. Happy wife, happy life. The new garage was an uninsulated metal, post-type building (i.e. "pole barn"). Very common where I live. These are a good option to build a cost effective, sizeable building for vehicles, tractors, etc. Anyway, it's what came with the house. But I wanted it to be more functional with interior walls and a heat source.

So, I spent the last 4+ months framing, insulating, paneling, and painting. It took some time as a one-man crew. I also installed a couple six foot ceiling fans to push the heat off the peak during the winter. In the summer, I'll reverse the blade direction for a cooling breeze. The silver lining is I added a heat pump, which means cooling in the summer! Something my "dialed in" garage did not have.

Finishing a garage full of tools and whatnot is not exactly the smartest move I've ever made. But, I was burned out on moving, and didn't want to do the storage-space-shuffle. It seemed like 25% of every hour was spent moving tools/whatnot out of the way so I had room to work. Move it over there. Move it back. Move it elsewhere. Move it back. Uff Da! (Don't try this at home!).

Here's a view in progress. Hours were clocked on the scaffolding. I opted for OSB instead of sheet rock. The seams are visible after painting, but I prefer a solid surface that better lends itself to hanging tools, etc.

Same view finished. I figure it's about time to hang a little F5 bling, so a steel F5 sign is on the way with my delivery. I'll hang it where the blue arrow is pointing. The 3'x8' mobile workbench in the foreground is something I made a couple Christmas vacations ago. I didn't want to part with it, so it made the move as well.

As I mentioned above, I installed a couple of ceiling fans. Helps move the warm air off the peak during the winter, and reverse to provide cooling air flow in the summer.

Couldn't leave the four-post behind, so hired a flat bed tow truck to move it. The heavy duty casters made this a cinch.

It sure feels good to have a functioning garage again. I plan to put the Coupe on the lift from Day One. (The Civic will shuffle outside whenever I'm actively working on the build).

Now that the functional part of the nursery is mostly dialed in, I'm transitioning to a couple fun, build related tasks. I'm going to try my hand at stainless fuel and brake lines. Without a good source for straight tubing in my area, I will need to straighten the coiled 3/8" and 3/16" SS tubing I bought from Summit. So, I'm building my own tubing straightener based on a design I found on good ol' YouTube. It feels good to get my hands on a build related task. After that I'm going to tackle safety wiring my Wilwoods.

Last edited by 460.465USMC; 04-06-2024 at 12:16 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Nice work! I just renovated my garage too getting ready for kit arrival

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

Rsnake

Garage is looking great

Thanks for stopping by, Greg. It was a lot of work. Glad to be on this side of it.

Keep up the good work on your YouTube channel! I'm enjoying the autocross videos.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Thanks for watching the videos. The Nevada open road challenge is coming up and we shall see how the type 65 does at 165 mph.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

DIY Tubing Straightener. Superlite v. Dynapro

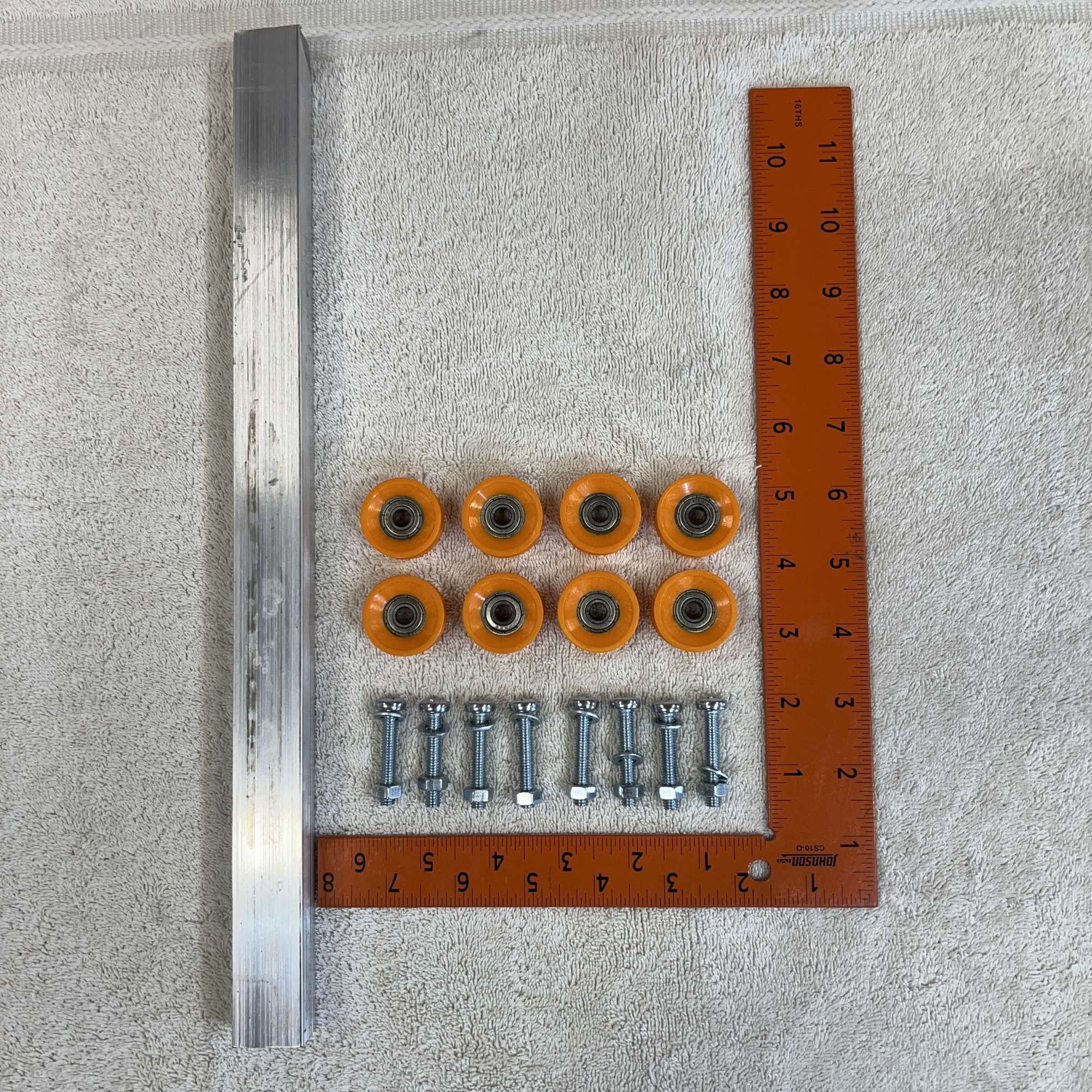

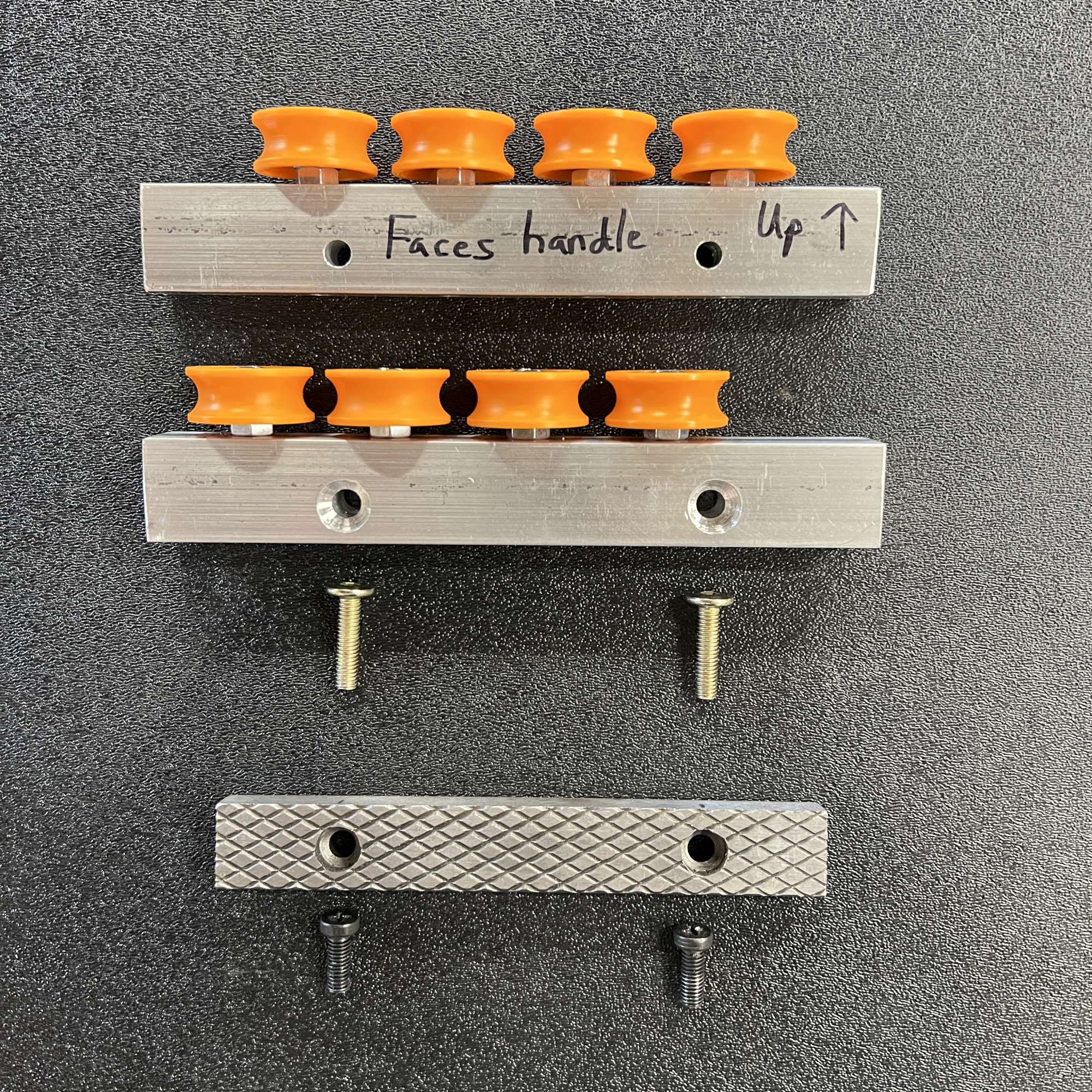

As I mentioned, the stainless tubing I'll be using for fuel and brake lines is coiled. Initially, I hit the easy button and bought a couple handheld tubing straighteners (3/8" and 3/16") from Eastwood. But after seeing a few home-built straighteners, I decided to try my hand at making one. It looked fun to build and saving some coin is not a bad thing. So, I returned the Eastwood units, and settled on a DIY straightener I found on YouTube (there are many!).

I think I spent <$40 for all the parts needed. Buying a short stick of 3/4" aluminum bar stock from a local metal supplier helped keep the cost down.

For me, a drill press is a necessity for this level of precision. Thankful my Dad gave me his a few years ago. It took a minute to tap the 8 (count them) 3/4" deep holes. Here you can see the wheels installed, and the holes to mount to the vise jaws. Original jaw on bottom for reference.

Here it is altogether and ready to go in the vise. These wheels are specifically for 3/8" diameter tubing, but I'm hoping I can also use them to straighten the 3/16" brake lines as well. The clamping force of the vise is obviously adjustable, and it only takes a couple minutes to swap out the vice jaws for the straightening jig. It's too early to straighten my lines, but looking forward to giving this jig a real-world test in a few months. It sure looks promising in the video by the guy who designed it:

.

Wilwood Dynapro v. Superlite Rotors

It's been about 3.5 years since I safety-wired the Wilwoods in my Roadster. A refresher video was in order. One video had a good tip on estimating wire length for each stud pair: measure between studs and multiple by 5 (2.25" X 5=11.25").

Worked perfectly. Thankfully, I remembered to set my torque wrench to 155 inch-pounds. Phew! The process came back to me after the first few were done. I don't know that my quality improved over last time, but I did notice I was faster. Overall, I enjoyed the process, and it feels like I've started the build.

I used the same Harbor Freight safety pliers, and patted myself on the back after finishing the first rotor/hat pair without bloodshed. Three sets of studs later my fingers felt wet. Dang! Safety-wire strikes again. First blood. Those wire ends are sharp.

Here's a picture to show it happened. This is one of the rear rotors.

On my Roadster build I ordered Wilwoods from F5. They sell the Dynapro, drilled and slotted. This time I bought from Levy Racing. I went with Superlite six piston on the front (13"), and Dynapro four piston on the rear (13"). The Superlites are definitely beefier: 1.25" thick v. Dynapro 13/16". No difference in the machined surface area on the rotor, but an increase of brake pad surface area by ~28% (3.9" v. 5.4").

See the difference between the Dynapro (left) and Superlite (right)?

I'm sure the Dynapro would have been just fine for my use at all four corners, but Levy's pricing made it a simple decision. And, it's something different I wanted to try on this build.

Two weeks from today until delivery.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Whoa!! Chris, I just happened by the coupe threads and saw this. HOLY COW man!!! You haven't even painted the roadster yet. I love it and I am more than a little jealous.

Congrats and I will be following along.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Hi Jesse. Great to hear from you! Hope that awesome Roadster of yours is providing plenty of miles and smiles this Spring. I’ve had mine out a few times as weather allows. Loving it!

Yeah, kind of strange for me to start a new build when Build One is still wearing its birthday suit (1,500 miles so far). All I can say is I really enjoy the build process. Getting lost in the garage does me a lot of good mentally and emotionally. I’m thankful to get this opportunity.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Originally Posted by

460.465USMC

Here it is altogether and ready to go in the vise. These wheels are specifically for 3/8" diameter tubing, but I'm hoping I can also use them to straighten the 3/16" brake lines as well. The clamping force of the vise is obviously adjustable, and it only takes a couple minutes to swap out the vice jaws for the straightening jig. It's too early to straighten my lines, but looking forward to giving this jig a real-world test in a few months.

Congratulations on your Coupe build! I made that exact same tubing straightener. I used it for my fuel, clutch and brake lines, and those same pullies worked equally well for all three. It's probably not as likely with the stainless steel lines, but I learned the hard and expensive way that you need to be careful not to over-tighten your vise with the larger diameter lines--I smushed my first set of fuel lines a tiny bit, so that the fittings wouldn't seal.

Have fun with your build--I'm sure I'll be having lots of fun following along!

Jim B

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Thanks, Jim. Getting pretty excited as delivery day inches closer.

Tubing straightener: Great minds think alike.  Great to get some additional real-world feedback. I have high hopes I can get it to work for both sizes. I appreciate your tip on overtightening, and welcome any future tips you send my way. School is always in session for me.

Great to get some additional real-world feedback. I have high hopes I can get it to work for both sizes. I appreciate your tip on overtightening, and welcome any future tips you send my way. School is always in session for me.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Hi Chris,

Really enjoyed following along on your Mk4 build. Will be doing the same with your new build. Wishing you the very best of garage time

Cheers, Nige

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Hello, Nigel. Hope all is well with you down under. I’ve appreciated your tips and suggestions along the way. Always solid. Good to know you’ll pop-in on this build. The more eyes keeping me from boobie-trapping myself the better! Your input is very welcome. Cheers!

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Senior Member

Coupe Left the Nursery

This is probably a picture only the builder/owner will appreciate. The F5 boys were kind enough to send over nursery pics. They also confirmed Stewart picked up my complete kit yesterday, so its cross country trek is underway. I'm pumped!

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 3 Likes

-

Senior Member

I'm excited for you and really looking forward to following your build!

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Delivery Day! Inventory is done.

I ordered my Coupe kit ten months ago, so seeing Eric from Stewart Transport roll up 30 minutes early Monday morning was a bit surreal. I have to say it was as exciting and maybe even more fun than my Roadster delivery 3.5 years ago. It was good to meet Coupe number 566.

Eric was very helpful and friendly. He did a fantastic job throughout the entire unload process. My goal was to lift the Coupe off the cart and onto my four post lift. Since I have bridge jacks (AKA rolling jacks), rolling the cart up onto the lift was not an option. So, it came down to old fashioned muscle and grunt. This is where Eric really shined. We used a couple 2"x6" boards on edge (a la rhk118), one under the front, and one under the rear.

The back half of the Coupe is quite a bit heavier than the front, as others have noted. Heavier than I expected. Between Eric's help and expertise, and the additional muscle of a couple of my sons (i.e. strong, young backs) and brother-in-law, we managed to set it on the bridge jacks. Phew! So good to see it in the garage and on the lift.

I have the nose sitting on end against a wall in the garage, but I'm not sure where I'm going to put the body and nose long-term. My ceiling doesn't lend itself very well to the suspension option. Will noodle on that some more. Ideas are welcome.

After a brief 97 hours of inventory, it's done. Well, everything except the carpet--not going to bother with that. Otherwise, every nut, bolt, butt connector, and 0.25" female spade connector were counted. Maybe it didn't quite take me 97 hours, but it sure seemed like it. I'm more than ready to turn a wrench at this point!

Yee haw! #566 is in the air and ready to land on the cart.

That's Eric on the left. He had the first cart load of boxes off the truck and headed toward the garage in a blink.

Here you can see most of the boxes ready for inventory.

If you could see my smile looking at this view...

The Roadster has a stable mate. They're even color coordinated.

As I inventoried, I set aside the untreated mounts, brackets, etc. for powder coating. Most of the items in this view are part of the door frame and hinge setup.

Box #2 for powder coating.

Some observations:

- I love the body lines even moreso in-person. Though I saw several Coupes at the F5 open house a couple years ago (including Edwarb's excellent build), I was more Roadster focused at that time and didn't linger too long looking over the Coupes.

- Ingress/Egress: yep, it will be a challenge. This is much more obvious in-person than it looks in the pictures.

- GPS vintage gauge set: didn't realize they are different than the Roadster. Tach/Speedo gauges are smaller, but the others are larger. And, no clock. Will be considering adding a clock.

- Over all, the new inventory process went well. Although, it didn't go any faster as I had hoped. But that's likely just an artifact of a small mind's limited processing power.

- Very small POL: just the headliner and heater control valve and controller. Thanks, F5!

- Coupe fastener pack in Box 1: I asked F5 and they sent me an itemized list, as I couldn't find one. I'm more than okay having the fasteners in one box. And, the individually labeled bags are helpful. I found several quantity mismatches between the emailed list and the labels on the bags. I'll ask F5 to supply the difference.

- Will be replacing black oxide fasteners with SS. Only a few were not replaced on my Roadster, and they've rusted.

- Set aside uncoated brackets and mounts in a separate box that I will soon drop off for powder coating--see picture above.

- I tend to reorganize parts (e.g. electrical) that obviously go together into the same box. I find this helps locate them more easily when needed. And, it condenses the number of boxes taking up shelf space.

- I also write the major components on the outside of each box. I find this gives me a quick visual when I need to locate stuff during the build. However, I know I'll still need to consult the inventory pages (now in a three ring binder) now and then.

Let the build commence in earnest. This should keep me busy for a few years, anyway. Wow! What did I get myself into?

Happy building!

Last edited by 460.465USMC; 04-25-2024 at 10:33 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Wow, congratulations! Looks exciting!

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Congratulations Chris! I'm really looking forward to following along! I bet you'll be surprised by how much you learned from your Roadster that will make the Coupe build be even more fun!

Jim B

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Congratulations! Let the Coupe fun begin. Suggestion -- spend a little time with all those parts before sending them off to powder coat. Clean up weld splatter, sharp edges, the laser cut "nibs" that are on many of them, etc. You won't regret it. I'd also be curious if Factory Five fixed the angle on those hood hinges. You may want to hold them back until you trial fit them with the hood.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Not a waxer

All right Chris! I'm going to enjoy watching this come together

Jeff

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Originally Posted by

JimStone

Wow, congratulations! Looks exciting!

Thanks, Jim. It's still a bit surreal, but that's slowly giving way to the fun and learning I'm anticipating with this build.

Originally Posted by

buttsjim

Congratulations Chris! I'm really looking forward to following along! I bet you'll be surprised by how much you learned from your Roadster that will make the Coupe build be even more fun!

Jim B

Appreciate it, Jim. I've been asked a few times, "Why another kit car?" I think you nailed it. I'm really looking forward to applying what I learned on the first build. And, enjoy the new-to-me aspects of this build. Hopefully, I won't repeat too many mistakes.

Originally Posted by

edwardb

Congratulations! Let the Coupe fun begin. Suggestion -- spend a little time with all those parts before sending them off to powder coat. Clean up weld splatter, sharp edges, the laser cut "nibs" that are on many of them, etc. You won't regret it. I'd also be curious if Factory Five fixed the angle on those hood hinges. You may want to hold them back until you trial fit them with the hood.

Fun indeed, Paul! Can't wait to get started. Thanks for the tip on the parts prep. I started removing the nibs on the smaller brackets/mounts the laser leaves behind with a hand file. Will go over the rest of the parts before dropping off for PC.

Originally Posted by

Jeff Kleiner

All right Chris! I'm going to enjoy watching this come together

Jeff

Thanks, Jeff! Always appreciate your seasoned eye keeping a watch on my build. Regarding the Coupe-->Roadster color coordination, don't think I haven't thought many times about you being the one to fix that on the Roadster. Who knows, I may be up for a road trip when I'm ready someday, if you have an opening.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Finish one project and jump onto another. Way to go!

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Congratulations on getting your coupe. Looking forward to following the build.

MK4 Complete Kit. Gen3 Coyote, TKX, IRS. Wilwoods, Forgeline Wheels.

Ordered 11/29/21. Kit received 8/18/22. First start 6/22/23.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

IFS and Steering Rack Progress

I'm still pretty tickled to have received all of the suspension pieces with my delivery. Nice to be able to plug away at the front and rear suspension and keep the march toward roller stage moving forward.

A few issues to resolve:

- PS rack: swapped out the pre-installed bushings with the Breeze aluminum offset centering bushings. Installed the PS rack and centered it within the frame. (I will center the steering wheel and equalize lock-to-lock later).

* The Breeze bushings are nice pieces, but I think they are probably a better fit for the Roadster application. Here's why: it appears the PS rack must be mounted in the top holes (race car height) in order to keep the Breeze adjustment slots accessible. Thankfully, this doesn't actually put the rack at the full upper height, because the offset bushing holes are not centered--see picture below. So, after all is said and done the rack is probably slightly higher than the lower street use holes. After trading emails with Mark at Breeze, I may set ride height about 1/4" lower. If I had to do it over, for the Coupe application I would probably save the money. The silver lining is it was easy to center the rack in the frame. - The 1/2"-20 grade 8 bolts to attach the UCA to the frame stopped a couple threads short of being flush with the nut (I normally like a 2+ threads sticking past the nut). And, they were not mechanical lock nuts as advertised. I emailed F5 last week, but still no word back. So, Ace to the rescue for grade 8, 1/2"-13 x 2" bolts. Already had extra 13 pitch nylon locknuts on-hand.

- Upper ball joint castle nut threads too far down the shaft for reasonable cotter pin engagement. Added spacers to fix--see picture below.

What went well:

- Front UCAs: pushed right into position with a spacer on the rear bushing. Primed the bushings with a bit of grease (4-5 pumps on my grease gun). I like to see it come through the flutes in the bushing before assembly. On a tip I saw in cv2065's build thread, I picked up the Lock N Lube attachment for my grease gun. As he said, no more swinging from the grease gun trying to get it to release. Boy, can I relate to that! Not expensive ($30), and worth every penny IMHO.

- KONI single adjustable shocks: before assembly I made sure they were set for lowest (softest) setting as my starting point. This is the same setting I'm running on my Roadster. This can be checked/adjusted later, but easier now. Link to Koni's website with instructions and video: https://www.koni-na.com/en-US/NorthA...stment-Guides/

- UCA upper ball joints: used my 18" Harbor Freight adjustable wrench to install. (I'll also use it on the IRS UCA nuts later on).

Some resistance on the second one, but overall no serious issues. - Swapped front UCA ball joint dust boots for Energy Suspension (5.13102G) per wisdom of the forum.

- Swapped tie rod ends for Moog and the Moog dust boots for Energy Suspension (9.13101G).

- POR-15. Love this stuff. My favorite coating. Takes some work, but well worth the effort. Coated the tie rod ends, inside face of front hubs, and rear sway bar brackets--see picture below. Also planning to coat the rear hubs, CV axles, and forward facing section of IRS differential.

First up was the PS rack install:

Here's a view of the Breeze offset bushing installed.

Not mentioned in the manual, and probably not necessary, but I like to prime the bushings with some grease before install.

POR-15: no I don't own their stock, but this stuff is awesome! Front hubs, Moog tie rods, and rear sway bar brackets.

I'm not using the tone ring (I think these are for ABS?), so I removed them. Ground a small slot into the ring with my Dremel, then tapped there and they split apart easily.

Added spacers to push the castle nut closer to the end to get cotter pin engagement. Had this same issue with my Roadster. Interestingly, extra spacers from my Wilwood brake kit fit perfectly in both cases.

View of passenger side together and ready for brake install. Planning to trim ~3/16" off the adjustment sleeve and stud of the rear UCA arms, to be sure I can dial in alignment specs later on.

Last edited by 460.465USMC; 05-08-2024 at 06:47 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

I share your love of the POR15. I used red....

Front:

Rear:

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

Senior Member

Wow! I forgot you coated so much of the suspension. Looks fantastic, Scott!

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Nobody sees the rear end unless they lay on the ground but I know how it looks!!

-

Senior Member

Hard to beat a good looking rear end.

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

-

Post Thanks / Like - 0 Thanks, 4 Likes

-

Senior Member

Front Brakes Progress. IRS Prep Started

I've been chipping away at the front brakes, and prepping the IRS bits for installation. I think suspension and brakes are one of the most enjoyable parts of the build for me. It's just plain cool to see all of the underpinnings come together. So much function here.

Front brakes - spindle clearance issue

I recall way back when seeing the interference issue Rsnake encountered while installing his front Wilwood caliper brackets. At the time I even picked up a basic deburring bit set to be prepared--needed one anyway. But it has been long enough I forgot about this issue until I went to install my caliper brackets. It seems the Wilwood Aerolite brackets do not quite fit. The top hole in the bracket doesn't line up with the hole in the spindle. This wasn't an issue with the Dynapro model on my Roadster.

Here's a view of the misalignment caused by the larger Aerolite caliper brackets. Thanks for the heads-up, Rsnake!

The upper ridge seen here on the spindle is where the interference occurs. I decided to grind down the spindle instead of caliper bracket.

Here's what it looks like after I ground down the spindle. Took some elbow grease to get the needed clearance. Then touched up with some black satin enamel. Caliper bracket upper hole lines up perfectly now.

Here are some of the deburring bits I used, along with a flat file.

With that done, it was time to fit the calipers. Mine took one spacer between the spindle and the caliper bracket, and two spacers between the caliper bracket and the caliper to get everything lined up. Passenger side Wilwood brake installed! Don't forget the rotors and calipers are directional (red circles).

IRS prep started: in the meantime, I also started prepping the parts for IRS install.

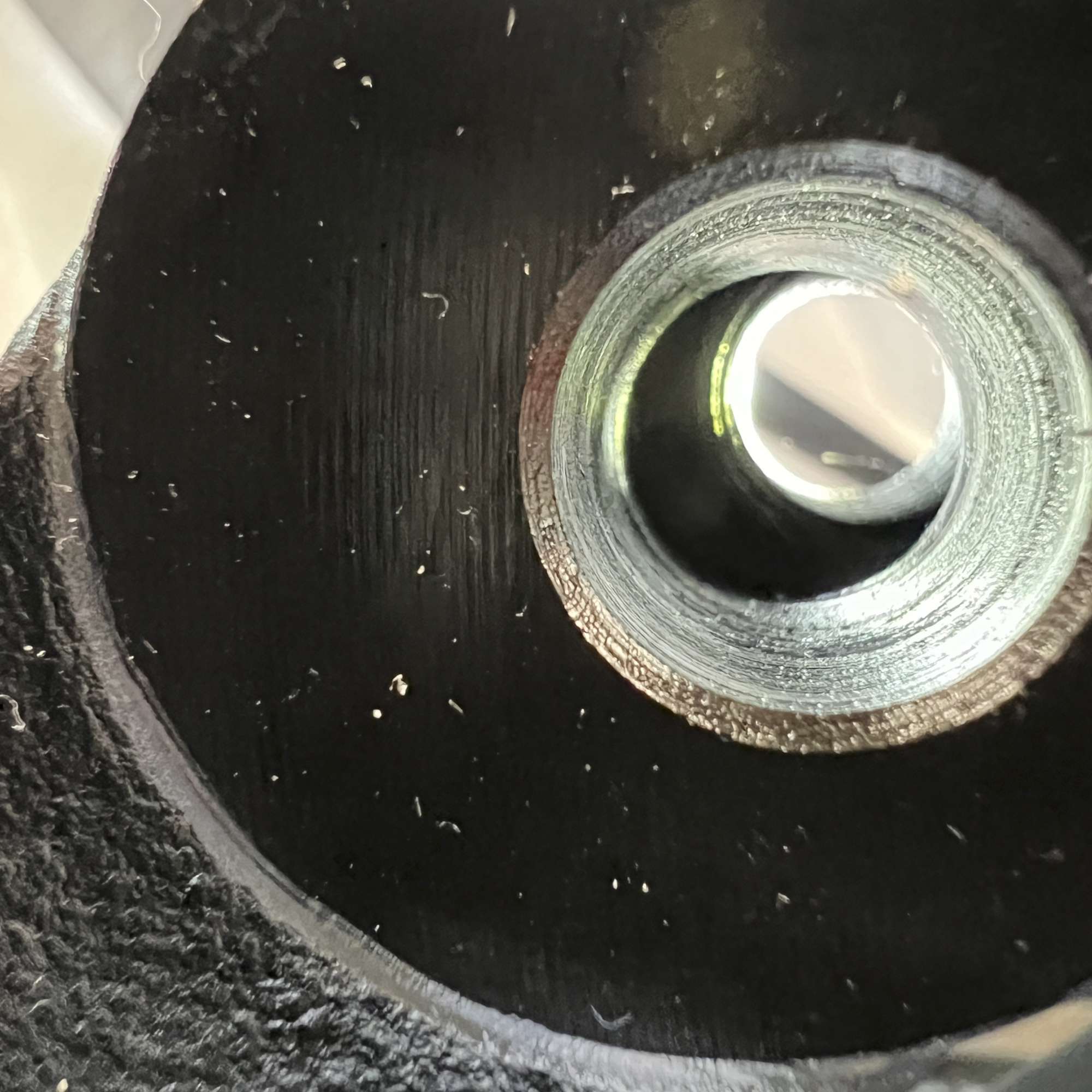

First up was to remove the studs from the rear hubs, and install the supplied 1/2"-20 studs. Unfortunately, I don't have access to a press. Calling around last time I found my local shops didn't want to assume the liability. So, I followed F5 instructions and knocked them out with a hammer. I placed a piece of copper pipe around the circumference of the head of the stud in hopes it will help protect the hub from the hammer blows (2-3 strikes with a mini-sledge). It so happens this is the same piece of pipe I used on my Roadster, so this little piece of copper has held up well after 20 stud removals. I used an impact wrench to pull in the new studs.

Up next was the rear spindle prep. This time around my tool kit now includes a Sawzall. Much better than a hacksaw like last time. I used a 14 tooth blade to trim off the ear as shown in the manual. No problems with it gumming up.

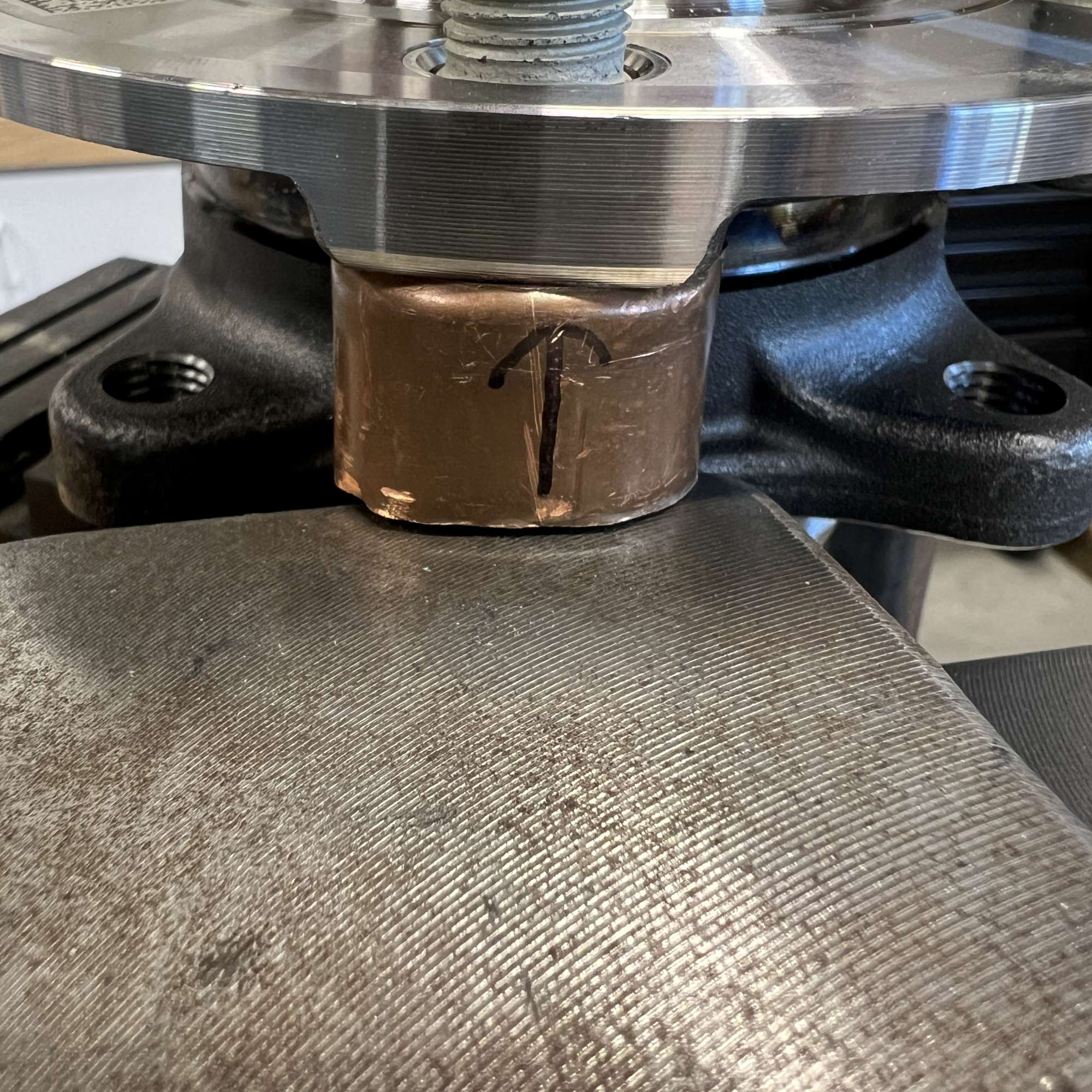

To open up the tapered hole at the top of the spindle, I used a "taper chucking reamer"--pictured below. A new tool to me. It worked well in my 18V drill. It's one thousand times better than using a regular drill bit, which as you all know will just about break your wrists when it grabs. I also put a wire brush bit in my drill to cleanup the spindle. Then applied some clear high temp ceramic to protect it (a la Edwardb).

Still have some more prep to do on the differential (POR-15, etc.). And, I'm going to remove the body before installing it. Hoping to have the rear IRS complete with brakes installed next time.

Build on!

Last edited by 460.465USMC; 05-22-2024 at 04:39 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

My Type 65 Coupe: Ordered May 27, 2021. Arrived November 19, 2021.

I would like to treat my gas pedal as a binary operator. It would be nice to get the cooperation of everyone in front of me.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Originally Posted by

Skuzzy

Nice work.

Thank you, Sir. I'm having a blast.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Originally Posted by

460.465USMC

I ordered my Coupe kit ten months ago, so seeing Eric from Stewart Transport roll up 30 minutes early Monday morning was a bit surreal. I have to say it was as exciting and maybe even more fun than my Roadster delivery 3.5 years ago. It was good to meet Coupe number 566.

Eric was very helpful and friendly. He did a fantastic job throughout the entire unload process. My goal was to lift the Coupe off the cart and onto my four post lift. Since I have bridge jacks (AKA rolling jacks), rolling the cart up onto the lift was not an option. So, it came down to old fashioned muscle and grunt. This is where Eric really shined. We used a couple 2"x6" boards on edge (a la rhk118), one under the front, and one under the rear.

The back half of the Coupe is quite a bit heavier than the front, as others have noted. Heavier than I expected. Between Eric's help and expertise, and the additional muscle of a couple of my sons (i.e. strong, young backs) and brother-in-law, we managed to set it on the bridge jacks. Phew! So good to see it in the garage and on the lift.

I have the nose sitting on end against a wall in the garage, but I'm not sure where I'm going to put the body and nose long-term. My ceiling doesn't lend itself very well to the suspension option. Will noodle on that some more. Ideas are welcome.

After a brief 97 hours of inventory, it's done. Well, everything except the carpet--not going to bother with that. Otherwise, every nut, bolt, butt connector, and 0.25" female spade connector were counted. Maybe it didn't quite take me 97 hours, but it sure seemed like it. I'm more than ready to turn a wrench at this point!

Yee haw! #566 is in the air and ready to land on the cart.

That's Eric on the left. He had the first cart load of boxes off the truck and headed toward the garage in a blink.

Here you can see most of the boxes ready for inventory.

If you could see my smile looking at this view...

The Roadster has a stable mate. They're even color coordinated.

As I inventoried, I set aside the untreated mounts, brackets, etc. for powder coating. Most of the items in this view are part of the door frame and hinge setup.

Box #2 for powder coating.

Some observations

Some observations:

- I love the body lines even moreso in-person. Though I saw several Coupes at the F5 open house a couple years ago (including Edwarb's excellent build), I was more Roadster focused at that time and didn't linger too long looking over the Coupes.

- Ingress/Egress: yep, it will be a challenge. This is much more obvious in-person than it looks in the pictures.

- GPS vintage gauge set: didn't realize they are different than the Roadster. Tach/Speedo gauges are smaller, but the others are larger. And, no clock. Will be considering adding a clock.

- Over all, the new inventory process went well. Although, it didn't go any faster as I had hoped. But that's likely just an artifact of a small mind's limited processing power.

- Very small POL: just the headliner and heater control valve and controller. Thanks, F5!

- Coupe fastener pack in Box 1: I asked F5 and they sent me an itemized list, as I couldn't find one. I'm more than okay having the fasteners in one box. And, the individually labeled bags are helpful. I found several quantity mismatches between the emailed list and the labels on the bags. I'll ask F5 to supply the difference.

- Will be replacing black oxide fasteners with SS. Only a few were not replaced on my Roadster, and they've rusted.

- Set aside uncoated brackets and mounts in a separate box that I will soon drop off for powder coating--see picture above.

- I tend to reorganize parts (e.g. electrical) that obviously go together into the same box. I find this helps locate them more easily when needed. And, it condenses the number of boxes taking up shelf space.

- I also write the major components on the outside of each box. I find this gives me a quick visual when I need to locate stuff during the build. However, I know I'll still need to consult the inventory pages (now in a three ring binder) now and then.

Let the build commence in earnest. This should keep me busy for a few years, anyway. Wow! What did I get myself into?

Happy building!

Congrats on the delivery. I will receive my kit in late August, build on!

MK4 base kit, 2004 Mach 1 donor, 4.6L DOHC, TR-3650 5-speed, narrowed stock axle with 3.55 gears and TruTrac, PS, PB, ABS, 17" Halibrand replica wheels, started 12/2011, registered 9/2014, sold 3/1/2018.

1970 Mustang Fastback Coyote powered Boss 302 tribute. Started 10/14/16.

Gen 3 Coupe Base Kit non-donor build. Ordered 4/5/2024 to be received August 2024.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

IRS Complete.

I've been chipping away at the IRS over the last couple of weeks or so. It was really nice to not have anything on POL or MIK. My only limiting factor was my own garage time. After finishing prep (POR-15 and clearcoat) on the various IRS bits, it was time for assembly.

Issues:

- Tight tolerances: I haven't read any build thread that didn't encounter at least one IRS component (UCA, LCA, and Toe) with mounting tabs too close together. I had it pretty easy on this build, just needed to open up the Toe tabs, and one of the UCA tabs. I prefer to use my large 18" adjustable wrench (Harbor Freight). I found it just as effective as the threaded rod approach. The bonus is it's much faster and easier. I close the jaws of the wrench on each tab mount with a rag between the jaws (one side at a time), and bend the tabs apart a little at a time.

- Differential: these aren't getting any lighter (~95 lbs), and the space to work them up into place is minimal. As reported many times, the tolerances are very tight. Hats off to F5 for the level of precision in their welding. This time around I had my engine hoist. Working solo, I was able to lift it slowly into place. Start the rear bolts first. Once those are started, push the front bolts through one at a time. Did I mention it's tight? A few deep breaths in celebration afterward. Phew!

In addition to POR-15 on the front section of the diff., I cleaned up the rear section. Then coated with clear high temp enamel. A bit of elbow grease, but worth it IMHO.

Nice to have the engine hoist as my second set of "arms". Still not quick or easy for me, but it made all the difference.

Here's a rear view of the left side completed.

View from the front:

As I mentioned previously, I went with the Wilwood electric parking brake. The caliper takes up quite a bit more real estate due to the electric motor. The left and right calipers are swapped to get the necessary clearance. Here's the view from above:

And view from the rear of it all together. Sway bar: a lesson learned from my last build is to loosely thread the fasteners and heim joints so everything is started. Then, they can be torqued down together. Obvious now, but I had to learn the hard way.

Final view from below. If you ask me, the IRS is a thing of beauty. Very cool. As suggested by Edwardb, I assembled the UCA and Toe adjusters for equal thread on both sides.

Next up is the fuel tank, pump, filter, and then on to SS lines. I'm a little apprehensive about the SS fuel lines, but also looking forward to the challenge of making my own flares, etc.

Last edited by 460.465USMC; 06-05-2024 at 12:53 PM.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

If you have your heart set on SS brake lines, I get it. However, may I suggest as others have to consider nickel copper alloy line instead. While the color is a bit unusual, sort of a light copper color, everything else about the product is positive. I have used line from Fedhill USA. They have high quality line that is seamless unlike some cheaper brands. They have the required fittings as well. On my MK4 I built over 10 years ago, I used the nickel copper line from Fedhill. I incorporated ABS into that build. There were 24 connections on my build, no leaks and no failures in the years since the car was built. I used the Eastwood flare tool set as well. Together, easy to make the lines after some test flares are performed. I have now used the Fedhill line on a second build, a 70 Mustang restomod. I made templates from TIG welding rod and formed perfectly shaped lines for the car. Unless you must have SS as in a show vehicle, IMO no reason to not use the nickel copper line as it will make your life easier.

http://www.fedhillusa.com/

MK4 base kit, 2004 Mach 1 donor, 4.6L DOHC, TR-3650 5-speed, narrowed stock axle with 3.55 gears and TruTrac, PS, PB, ABS, 17" Halibrand replica wheels, started 12/2011, registered 9/2014, sold 3/1/2018.

1970 Mustang Fastback Coyote powered Boss 302 tribute. Started 10/14/16.

Gen 3 Coupe Base Kit non-donor build. Ordered 4/5/2024 to be received August 2024.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

Senior Member

Appreciate your thoughts and input, Alan. This build definitely won't be a show car. My build skill level is more along the lines of junior-assistant-builder. It's more about trying something new, and seeing if I can do it. I already have the SS fuel lines, SS brake lines, and the Eastwood flare tool. If I fail with the stainless, then Ni-Cop will be my go-to. I guess I enjoy banging my head against the wall? Who knows, maybe I'll knock some sense in someday.

Chris

Coupe complete kit delivered: 4/22/24.

Build Thread. Coyote. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 0 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote The silver lining is my "new" garage does not have room for it anyway. More about that later.

The silver lining is my "new" garage does not have room for it anyway. More about that later.