Visit our community sponsor

Thanks:

6

Likes:

24

-

Installing Inner Rockers

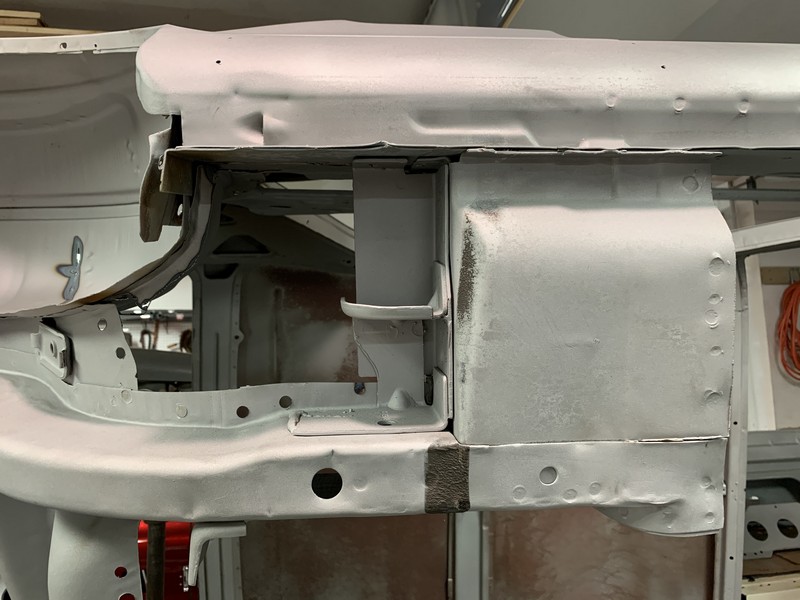

In order to turn the coupe into a convertible, I have to install all the reinforcements into the coupe frame to turn it into a convertible frame. This begins (I hope!!) with the installation of the inner rockers. These major girders run all the way from the front of the frame to the back of the back of the cabin area in the original convertibles. After they are installed, the rear torque boxes are attached to the inside rockers. However, in a coupe that already has rear torque boxes installed, it is a bit more complicated. I considered just removing the existing torque boxes and installing new ones after the rockers were in place. However, the coupe frame is already factory welded in exactly where it should be. I really didn't want to mess with it. Because I will be using the MTF front frame that actually attaches to these rear torque box locations, I really did not want to take a chance on getting them in even a slightly different place. So I decided to leave the rear torque boxes where they are and make the inner rocker fit around them. This required cutting and fitting the inner rockers around the rear torque boxes. This was not easy feat!! I started with the easy part: the small section aft of the torque box.

I cut off the rear section of the inner rocker after measuring three times and sleeping on it overnight! (I didn't want to screw this up!!) The basic cut was just a 90 degree cut off, but that's where the simplicity ended. I had to grind the top and bottoms to slightly different lengths, and then had to cut a slot for one piece of the rear torque box.

It took quite a bit of fitting and grinding to get it to fit just right, but I got it.

After drilling eight holes for spot welds, I welded this piece into place. The photo doesn't show it, but I went back and welded the inner rocker rear piece to the torque box whereever I could reach. The inner rocker is a fully attached member of the torque box.

Lesson next: this one is about "weld through" primer. I had picked up a couple of cans from Napa to touch up those areas that I had to cut and grind. The inner rocker itself is already coated with "weld thru" primer material. So apparently weld thru primer has zinc or copper to conduct the weld arc. Long story short, you can weld thru this stuff, but it makes and awful sound and splatters all over the place. I don't know if napa's paint is low quality for this purpose, but I gave up on it and ended up wire brushing off all the "weld thru" primer on and around all the welds after the first dozen or so. What a mess!!

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Visit our community sponsor

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote