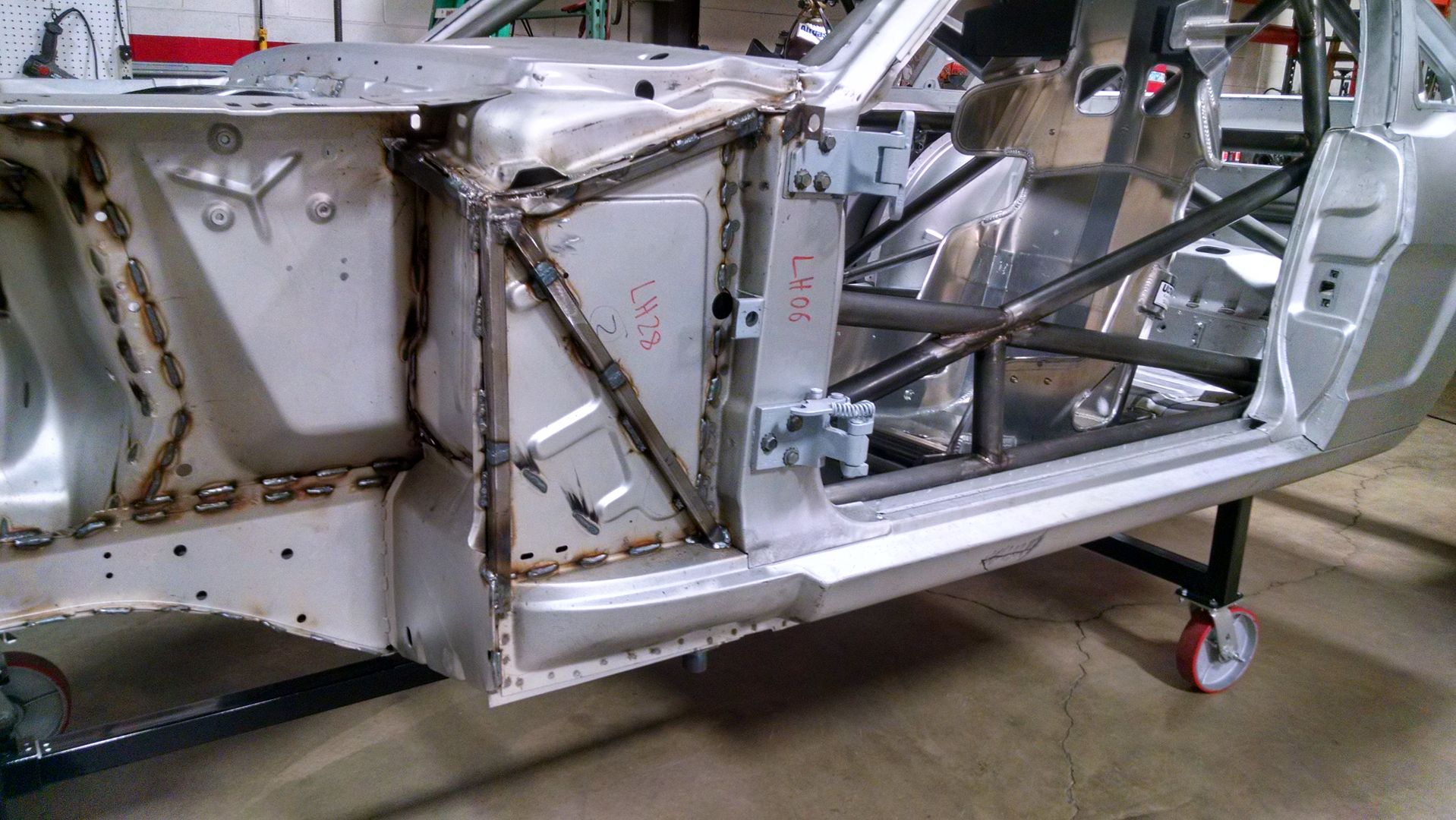

After six weeks at the chassis place, it's back in my shop. Here are a few pics I took during the most recent round of cage and suspension work, which included.....

Finishing up a few of the hard-to-get-at welds;

Adding removable window nets (driver and passenger);

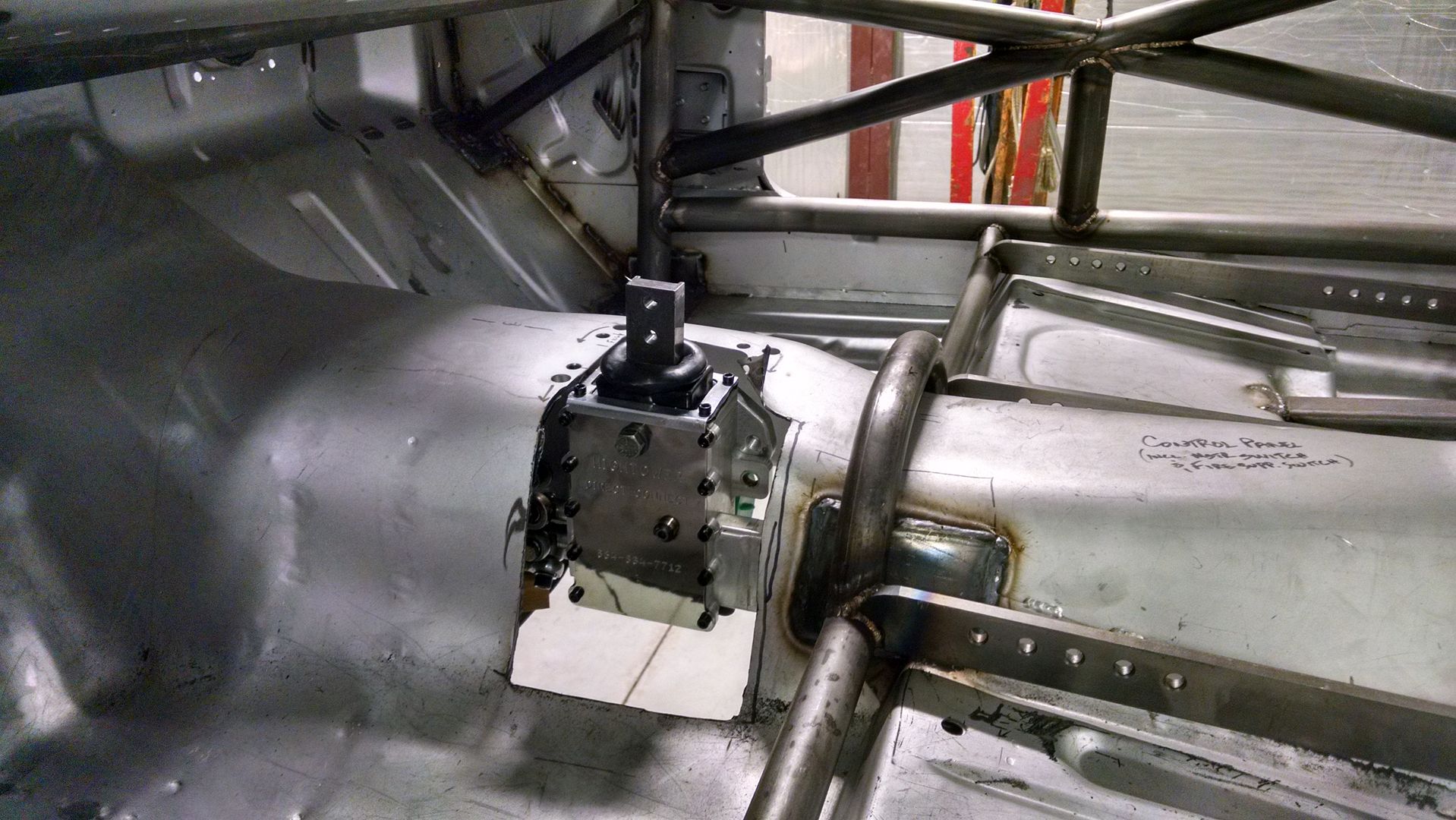

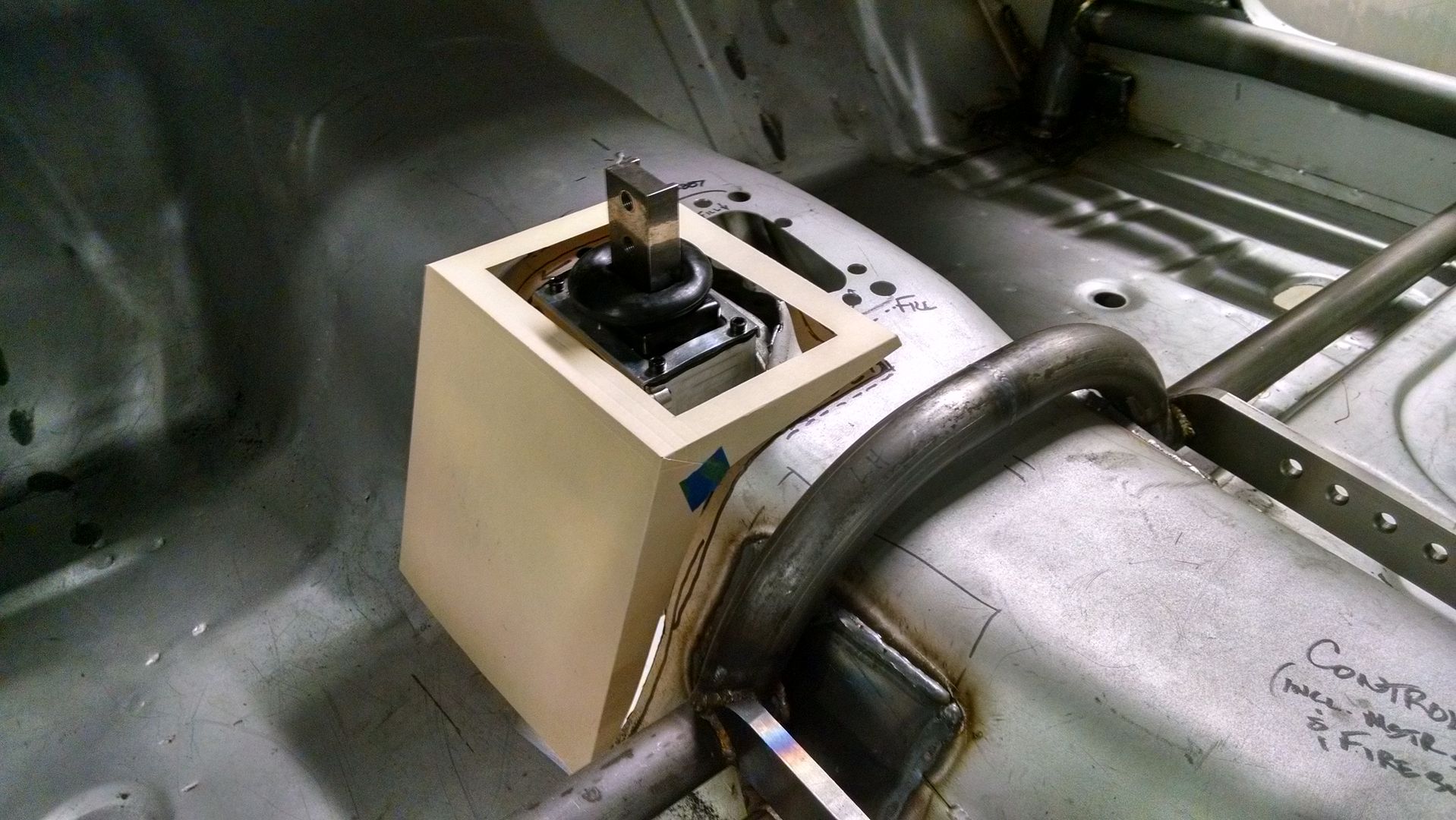

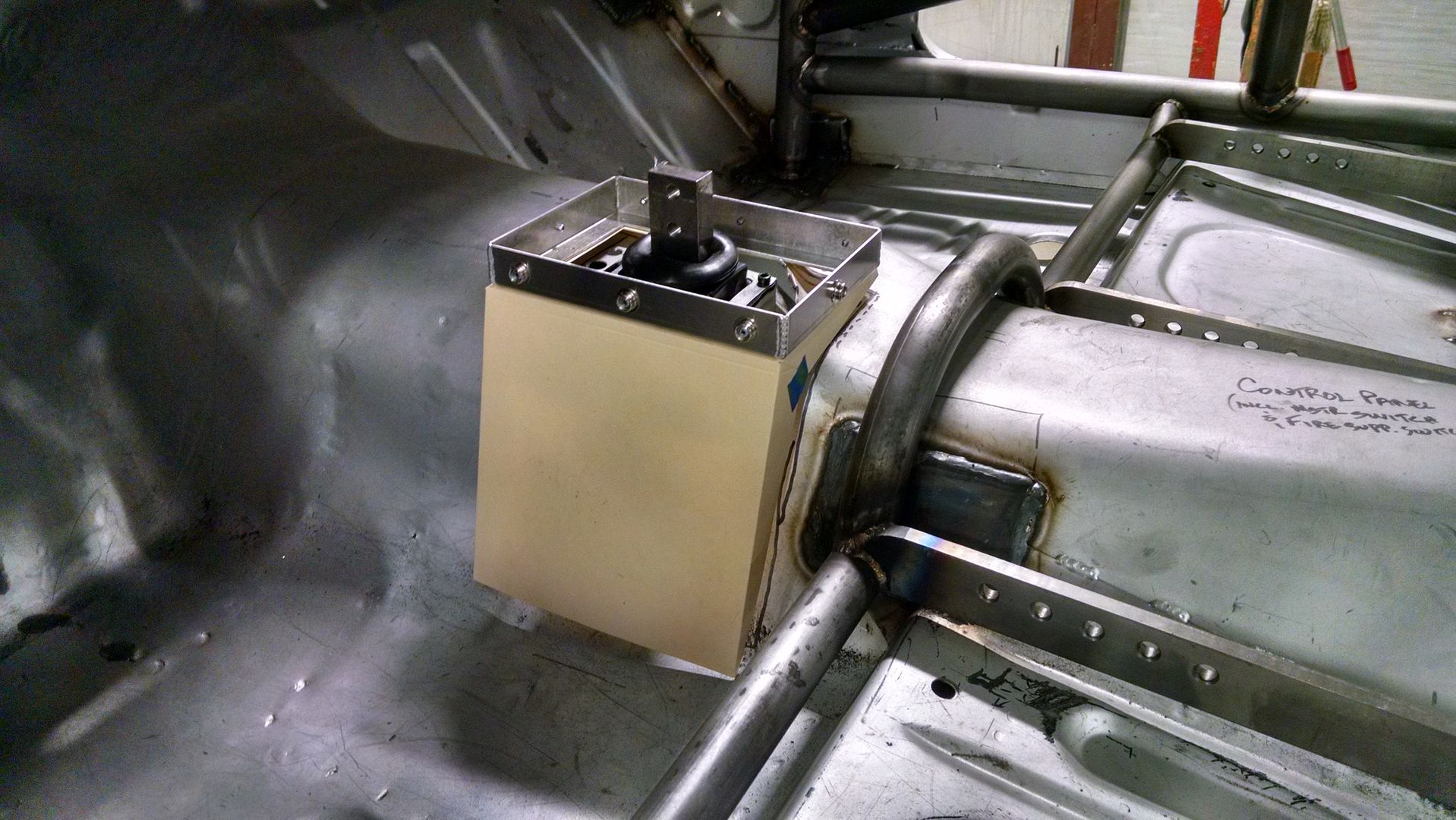

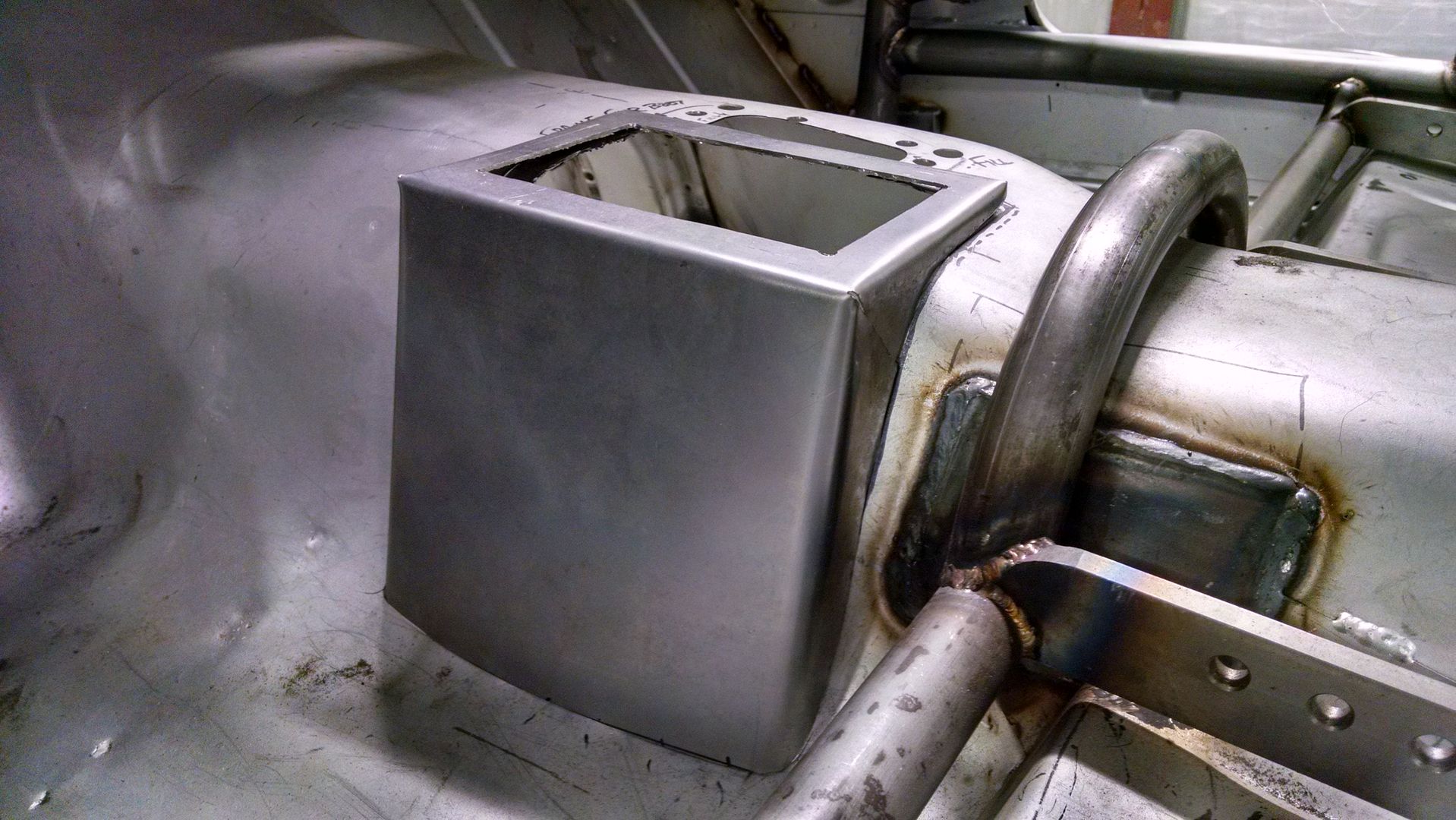

Tabs on the cage for external access to the fire suppression activation and emergency shut-off switch;

Jacking points under the rocker reinforcements;

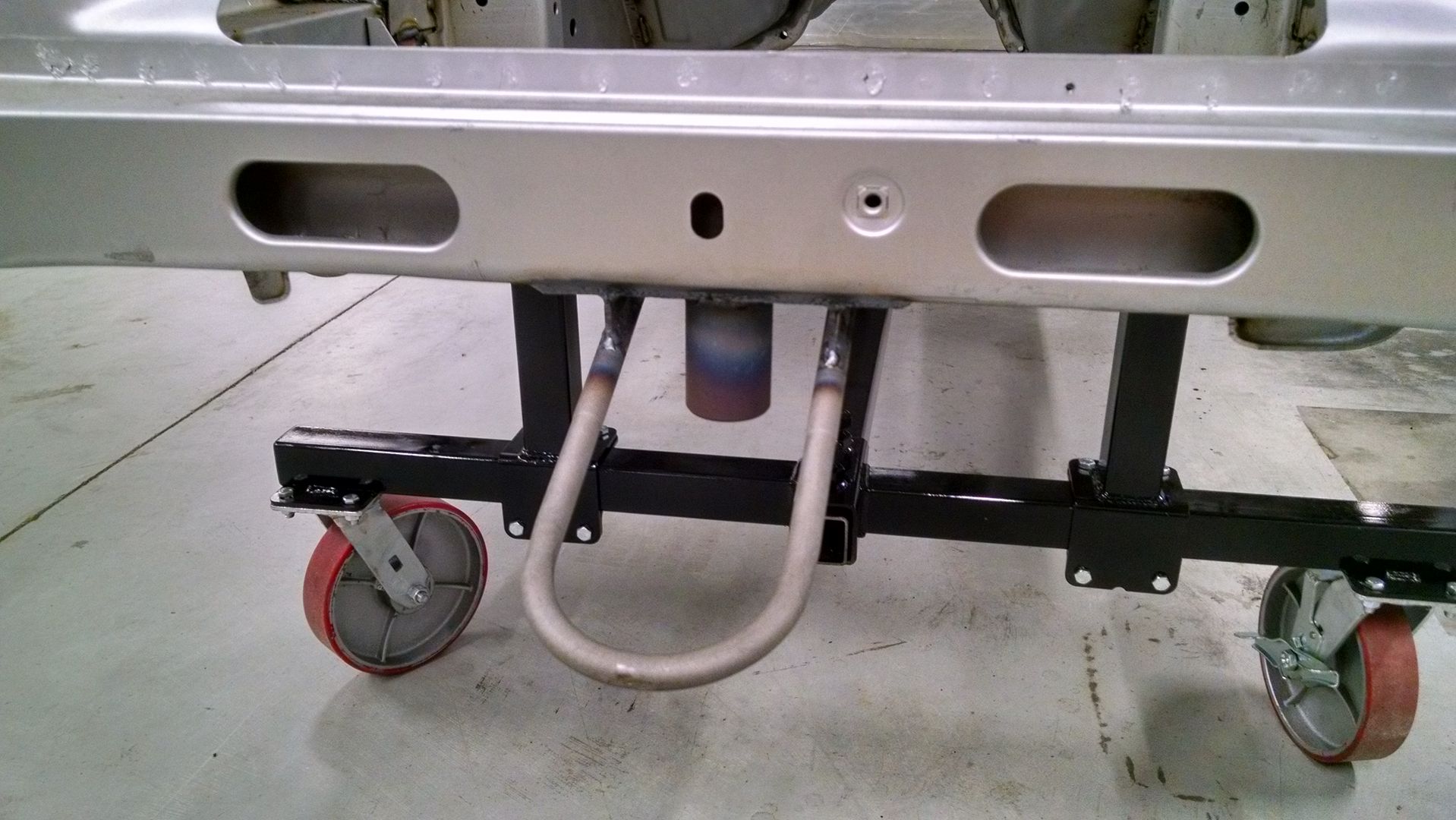

Tow hooks front and rear - including an incorporated jacking point at the front tow hook location;

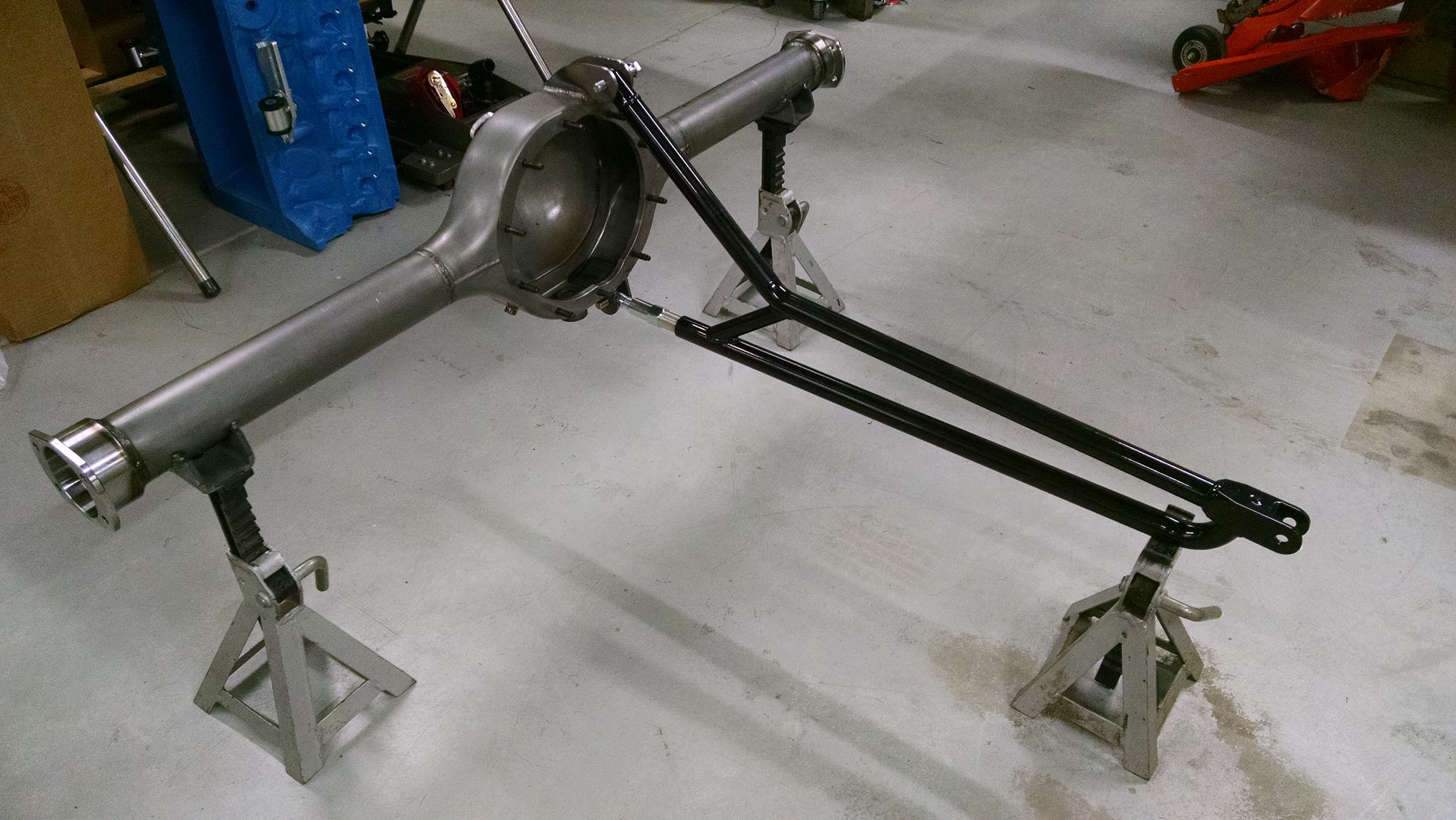

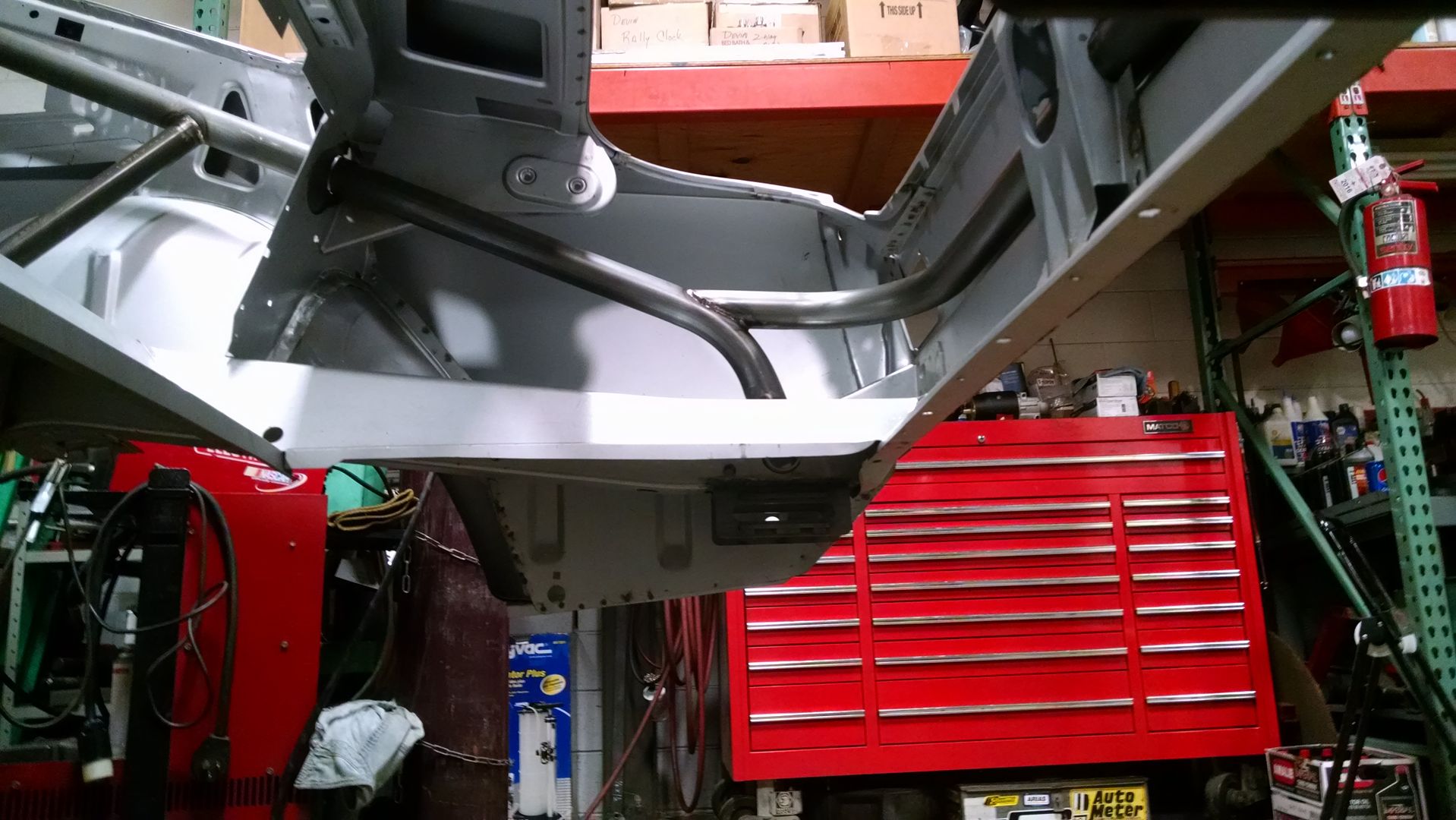

Installation of the sliders for the leaf spring rear mounting point (instead of shackles);

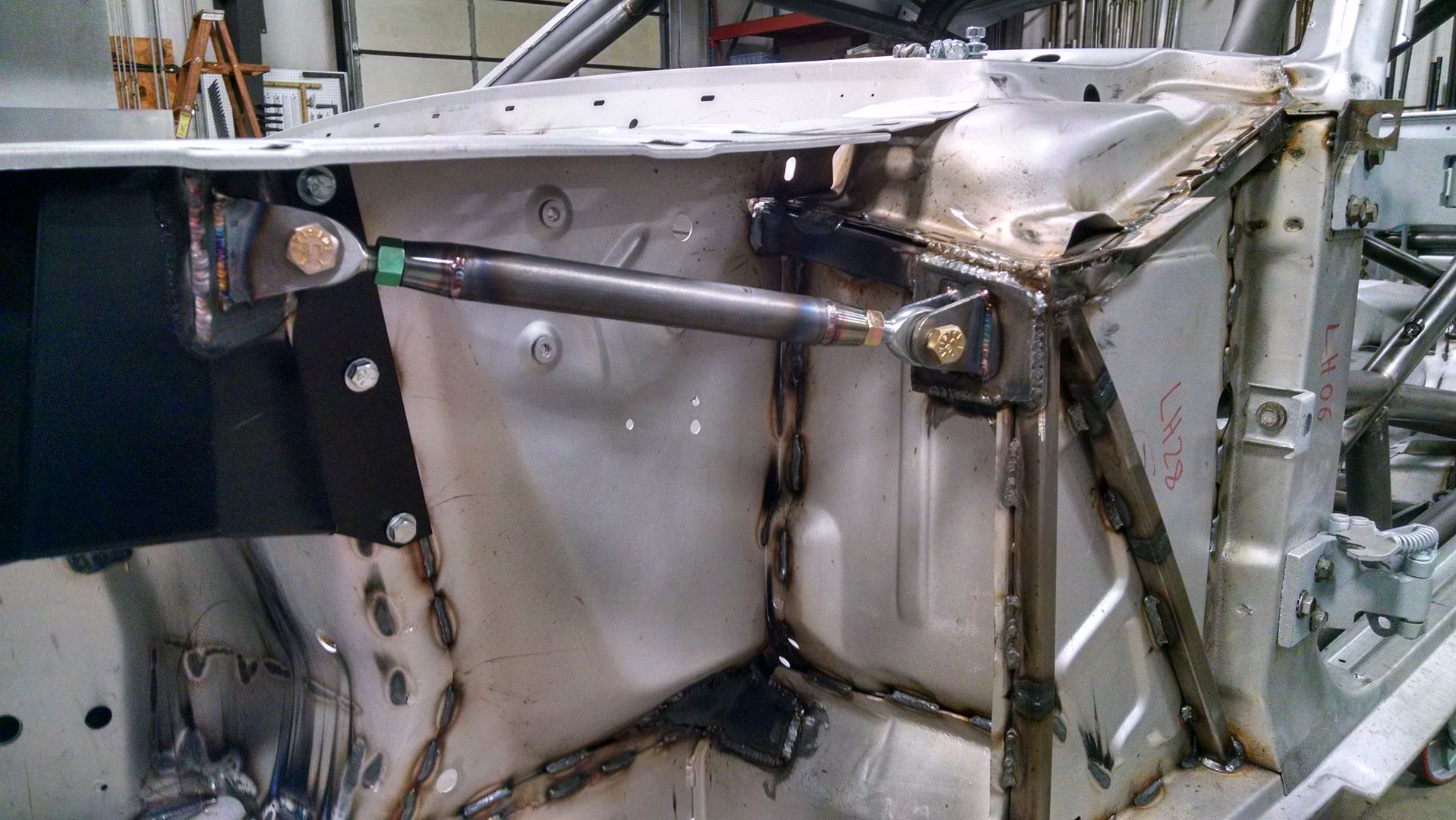

Gusseting - under the dash and at the cage / subframe intersection;

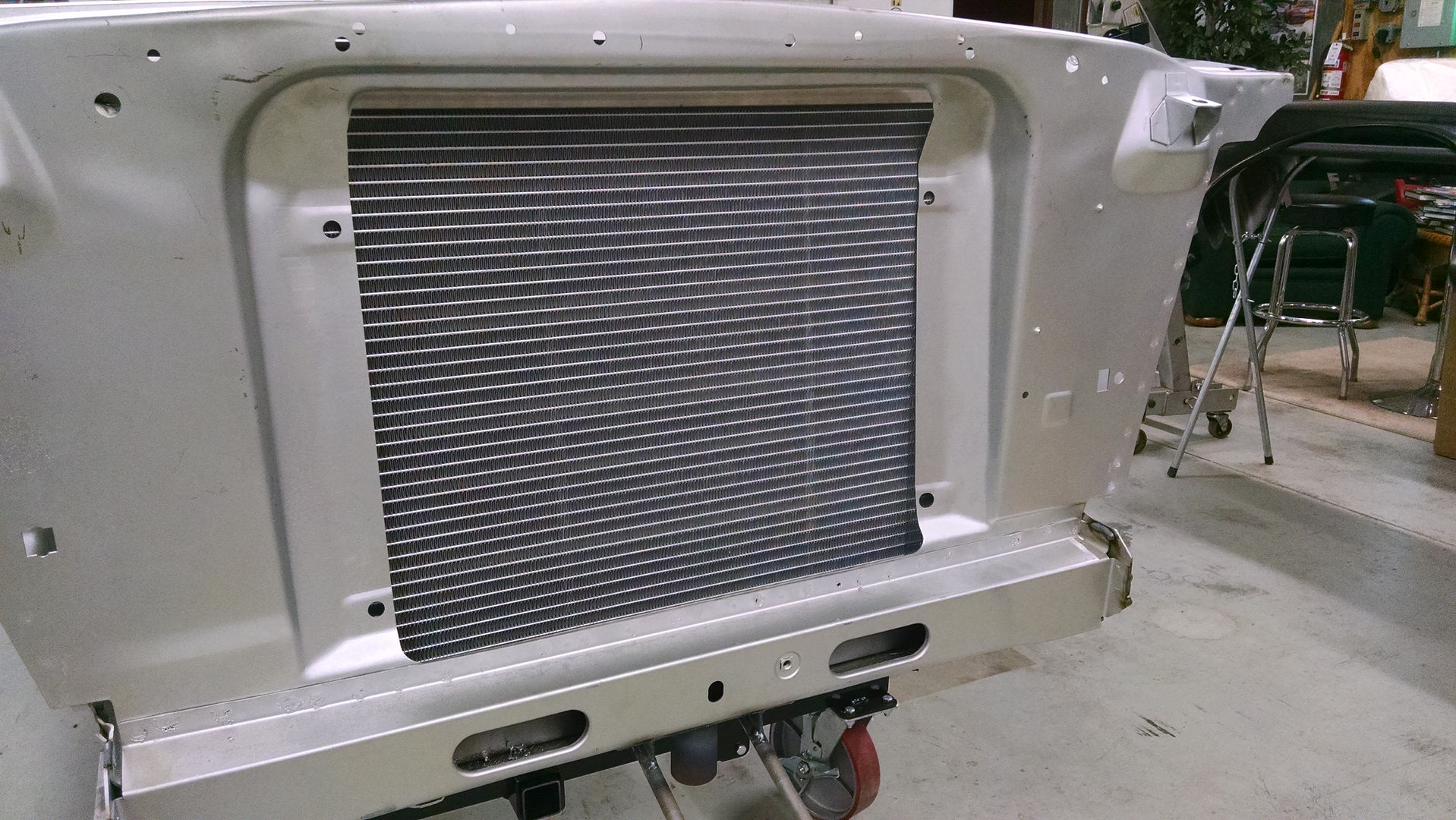

Completion of the "exoskeleton" for the cowl - 3/4" square tube surround that ties the cowl into the cage / "A" pillars and the front suspension;

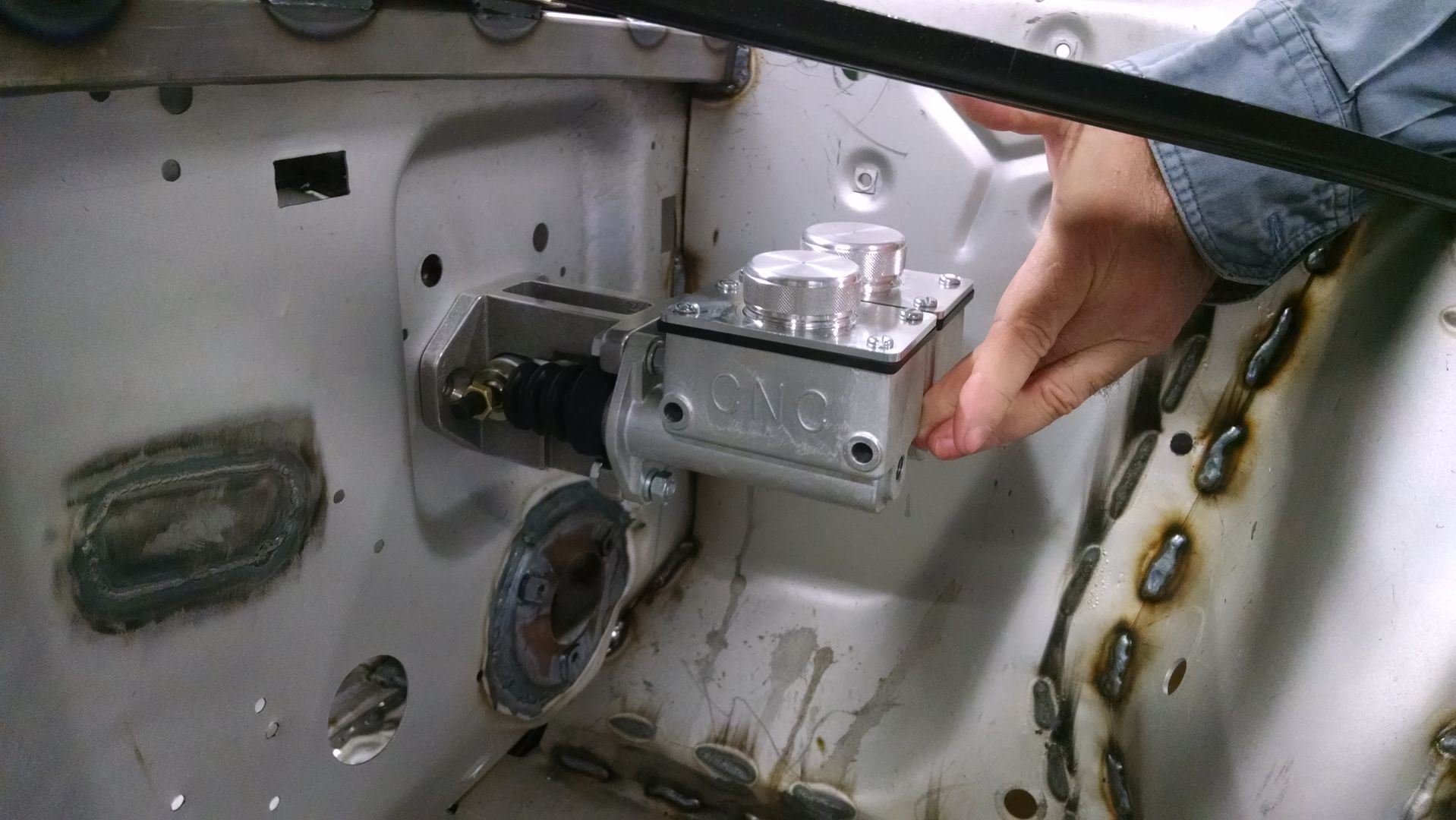

Firewall mounting point for the lower steering shaft bearing mount; and

Recess in the under-dash crossbar for additional steering column clearance

Firewall work for steering shaft bearing....

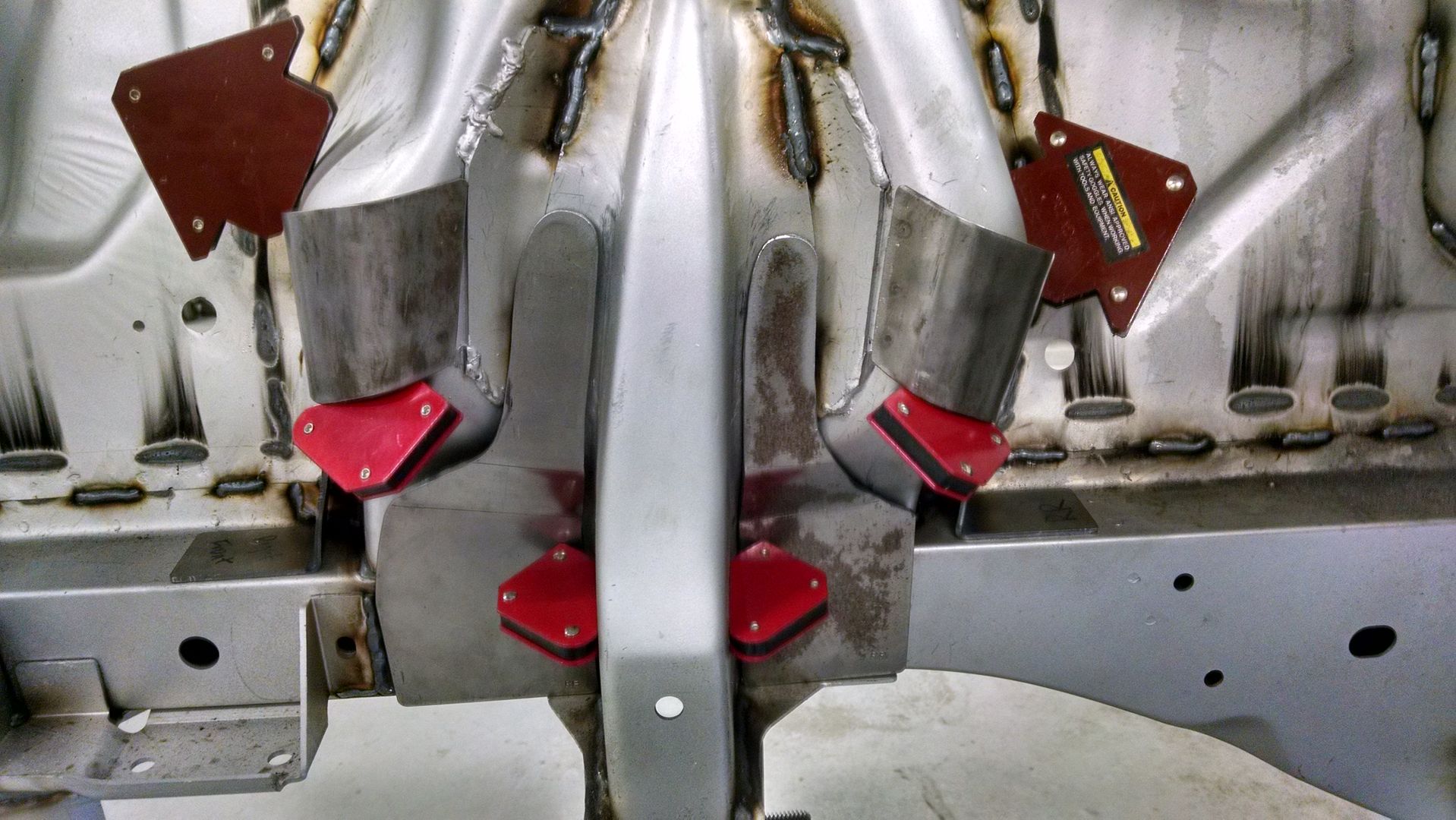

Upper rod for driver's window net....

Passenger side slider located to rear of subframe below trunk floor opening - not the best pic... more to come on this....

Cowl reinforcement.....

- Home

- Latest Posts!

- Forums

- Blogs

- Vendors

- Forms

-

Links

- Welcomes and Introductions

- Roadster

- Type 65 Coupe

- 33 Hot Rod

- GTM Supercar

- 818

- Challenge Series

- 289 USRCC

- Coyote R&D

- Ask a Factory Five Tech

- Tech Updates

- General Discussions

- Off Topic Discussions

- Eastern Region

- Central Region

- Mountain Region

- Pacific Region

- Canadian Discussions

- Want to buy

- For Sale

- Pay it forward

-

Gallery

- Wiki-Build-Tech

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote