-

01-19-2025, 12:58 PM

#241

Senior Member

Tight quarters in that engine compartment - congrats on getting that engine shoehorned in. Well done!

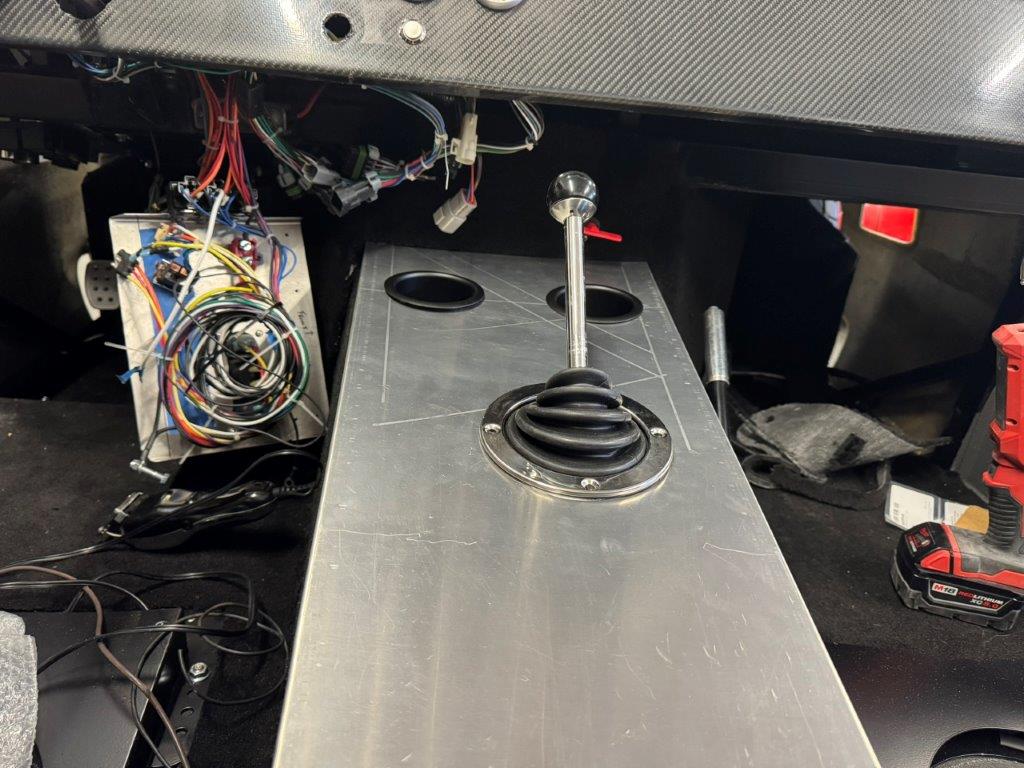

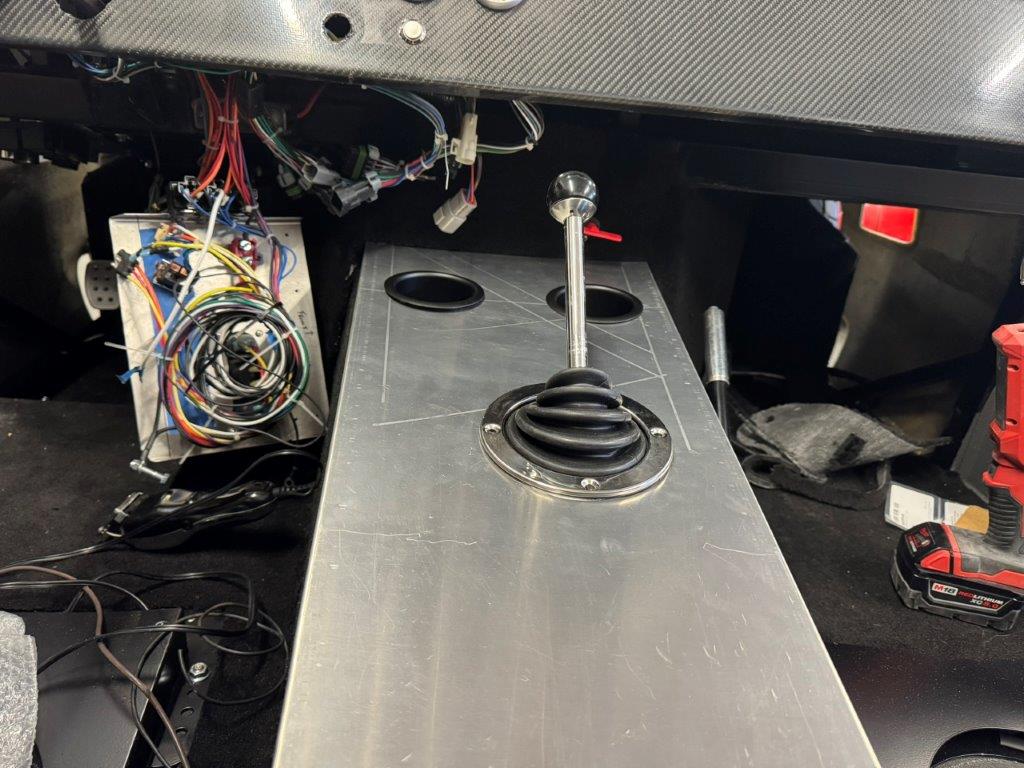

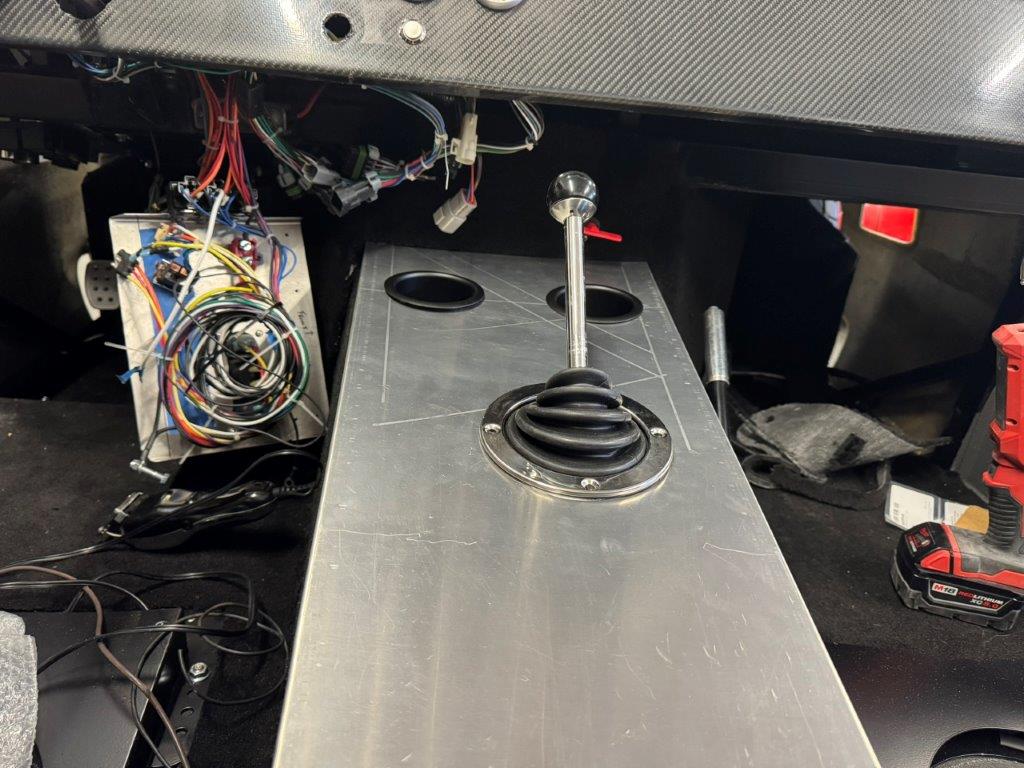

Regarding shifter position, my Mk3 is in the same place in regards to the frame. Since mine is a 302 it is in the “forward” of the two rear options on my TKO. With the supplied shifter’s radical angle everything ends up in a good place. Any further back and my arm gets jammed up against the seat. Hard to tell but here’s some photos:

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-19-2025, 01:24 PM

#242

Originally Posted by

Mike.Bray

That's a lot of yoke showing out f the transmission, are you sure you have the correct length driveshaft?

I agree with Mike. Might want to verify with FFR.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-19-2025, 03:32 PM

#243

Senior Member

That's definitely the wrong driveshaft. That's the driveshaft I have in my IRS/TKX/427W setup. Before I switched to SBF from Coyote, I had a longer driveshaft that came with my kit, and it was longer than my current driveshaft by about the same amount of yoke you have showing there. I think you have the SBF/TKX/IRS driveshaft.

Greg

Built an early MkIII years ago, sold years ago. Back after 18 years to build a MkIV

Build Thread Here Partners: Levy Racing, Summit Racing, LMR, Breeze, Forte's Parts, Speedhut, ReplicaParts

MkIV Complete Kit Ordered 4/18/23, Delivered 7/11/23, Boss 427W, Edelbrock Pro Flo 4, TKX (.68 5th), IRS, Wilwood Brakes, 18" Halibrands, Toyo R888R Tires, Custom Speedhut Gauges

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-19-2025, 06:09 PM

#244

Senior Member

Originally Posted by

Blitzboy54

It's definitely tight on the drivers side. Really only have a couple of mm. I would assume some contact when the engine torques but we will see.

Congrats on the drivetrain install! Yep. It's one. Tight. Fit. So glad I had a local F5 builder help me shoehorn it into place on my Roadster. My driver's side looked similar to yours. I had the TKO and the Gen 3, but I didn't have nearly that much driveshaft exposed.

Squeezing this motor in is one of those experiences you don't forget. As they say, "If you know. You know". Great work!

Chris

Coupe complete kit. Index. Delivered: 4/22/24.

Build Thread. Coyote Gen 4X. T-56. IRS w/3.55. Wilwoods. PS. HVAC. Side windows.

MK4 Complete kit.

Build Thread Index. Delivered: 10/15/2020. Legal: 7/25/23. Coyote Gen3. TKO600 (0.64 OD). IRS w/3.55. PS. Wilwoods. Sway bars. This build is dedicated to my son, Benjamin.

Build Thread.

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-19-2025, 06:23 PM

#245

Senior Member

Thanks gang. Thatís why I have a build thread. Great way to double check. Iíll reach out to FFR.

-

01-19-2025, 09:47 PM

#246

Senior Member

Originally Posted by

Blitzboy54

It's definitely tight on the drivers side. Really only have a couple of mm. I would assume some contact when the engine torques but we will see.

My Coyote was as tight as that. 5 years on the road, with some decent canings. No sign of any contact with the upper foot boxes to date. Engine does not seem to move around at all. Good news

Cheers,

Nige

Mk.4 FFR supplied Right hand drive

Received 12/2012 completed 12/2019

Gen1 Coyote / TKO600 / IRS

Lots of mods to make compliant for Australian design rules

-

Post Thanks / Like - 1 Thanks, 0 Likes

-

01-20-2025, 06:12 PM

#247

Senior Member

-

01-21-2025, 11:01 AM

#248

Senior Member

Originally Posted by

TTimmy

Tight quarters in that engine compartment - congrats on getting that engine shoehorned in. Well done!

Regarding shifter position, my Mk3 is in the same place in regards to the frame. Since mine is a 302 it is in the “forward” of the two rear options on my TKO. With the supplied shifter’s radical angle everything ends up in a good place. Any further back and my arm gets jammed up against the seat. Hard to tell but here’s some photos:

I appreciate the pics! I am going to do a short straight shifter at or near the front. I want it where it would be if it were a modern car. I think the mid shift is too close because I have a screen right there. Looking forward to figuring it all out.

Last edited by Blitzboy54; 01-21-2025 at 11:04 AM.

-

01-23-2025, 06:12 PM

#249

Senior Member

-

01-24-2025, 09:24 AM

#250

Senior Member

Last edited by gbranham; 01-24-2025 at 09:26 AM.

Built an early MkIII years ago, sold years ago. Back after 18 years to build a MkIV

Build Thread Here Partners: Levy Racing, Summit Racing, LMR, Breeze, Forte's Parts, Speedhut, ReplicaParts

MkIV Complete Kit Ordered 4/18/23, Delivered 7/11/23, Boss 427W, Edelbrock Pro Flo 4, TKX (.68 5th), IRS, Wilwood Brakes, 18" Halibrands, Toyo R888R Tires, Custom Speedhut Gauges

-

01-24-2025, 09:24 AM

#251

Senior Member

I see you installed the 'hoop' over the passenger side mount for the steering rack, as provided by FFR as a precaution for weld failure. I did, as well. I didn't like how the PS hard line sits just above it, worried that it may vibrate and wear against that hoop. As an extra precaution, I put a short length of split fuel injection hose on that hard line, secured with a couple of zip ties. Just a thought.

HeadlightTest1.jpg

Built an early MkIII years ago, sold years ago. Back after 18 years to build a MkIV

Build Thread Here Partners: Levy Racing, Summit Racing, LMR, Breeze, Forte's Parts, Speedhut, ReplicaParts

MkIV Complete Kit Ordered 4/18/23, Delivered 7/11/23, Boss 427W, Edelbrock Pro Flo 4, TKX (.68 5th), IRS, Wilwood Brakes, 18" Halibrands, Toyo R888R Tires, Custom Speedhut Gauges

-

01-24-2025, 05:34 PM

#252

Looks good Jesse. Looks like you are faring better than I. The pump I've got from Roush is from Turn One steering and they didn't give me an integrated reservoir. Not a fan of the remote cannister so may change the pump as it's not as simple as just adding an integrated reservoir. Glad you found the right driveshaft!

-

01-25-2025, 07:32 AM

#253

Senior Member

Originally Posted by

gbranham

I see you installed the 'hoop' over the passenger side mount for the steering rack, as provided by FFR as a precaution for weld failure. I did, as well. I didn't like how the PS hard line sits just above it, worried that it may vibrate and wear against that hoop. As an extra precaution, I put a short length of split fuel injection hose on that hard line, secured with a couple of zip ties. Just a thought.

HeadlightTest1.jpg

That tube just passes air back and forth to the grease boots, however what you did is not a bad idea. There is some contact between the power steering hoses and it. The car will vibrate and I can't get a hose clamp in there. I may copy what you did.

Originally Posted by

cv2065

Looks good Jesse. Looks like you are faring better than I. The pump I've got from Roush is from Turn One steering and they didn't give me an integrated reservoir. Not a fan of the remote cannister so may change the pump as it's not as simple as just adding an integrated reservoir. Glad you found the right driveshaft!

The FFR instructions still show a remote reservoir. I like the integrated arrangement better as well. There is only so much room to hang stuff. Should be plenty of pump options for an SBF. Good luck, looking forward to your next update.

-

01-26-2025, 06:13 PM

#254

Senior Member

-

01-26-2025, 11:40 PM

#255

Senior Member

-

01-29-2025, 01:23 PM

#256

Senior Member

I learned something about vacuum bleeders and brakes vs the clutch. I reported not liking the vacuum bleeder on the brakes because it pulls air in past the fitting. You can't tell when the air is all gone. So I had another person help me do it the old fashioned way. On the clutch however I was never able to fully get the air out of the slave cylinder. I tried a number of tricks and I just couldn't get it. I would imagine a pressure bleeder would work for both but just for the sake of informing folks I found the vacuum bleeder worked great for this application. I was unable to remove the "rebound" because of the air behind the cylinder. The vacuum bleeder pulled it right out. The piston rebound was immediately tight while the vacuum bleeder was operating. The clutch now moves mm to mm with the pedal.

I did have to put a spacer behind the pin that engages the clutch as it was not long enough. Based on this experience and having to modify the bracket you may want to go a different route if installing an external slave. MDL is just ok.

I also filled the TKX with sycromesh. The instructions call for 2.75 quarts. I removed the mid shift plate. I put 2.75 in and if you use a flashlight you can see the level from up there. It was right at the upper plug. So it was nice not to have to remove the side plug.

Last edited by Blitzboy54; 01-30-2025 at 11:35 AM.

-

01-30-2025, 11:47 AM

#257

Senior Member

-

01-30-2025, 02:18 PM

#258

Senior Member

The Factory Five supplied fan is definitely loud. I tested it on the bench in my garage and my neighbor came over asking if I was putting a jet engine in my car. Sad thing is it doesn't pull very much air for all that noise.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

02-01-2025, 05:55 PM

#259

Senior Member

-

02-01-2025, 06:12 PM

#260

Senior Member

-

02-02-2025, 04:40 PM

#261

Senior Member

-

02-02-2025, 04:55 PM

#262

Senior Member

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote