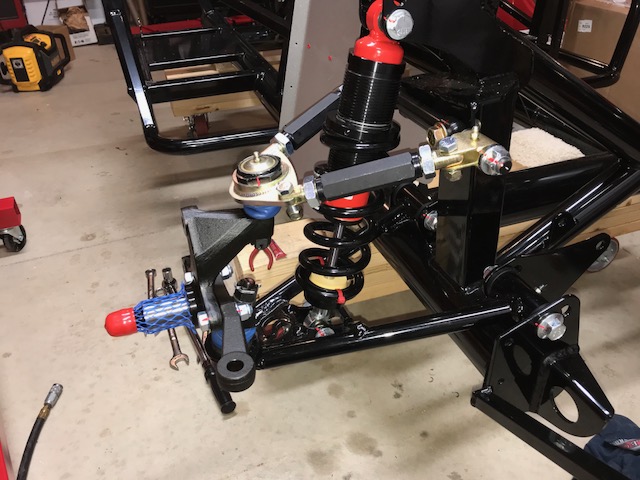

Well, I didn't get as far as I would have liked over the weekend. I got to this point:

RH

LH

I ran into a couple minor questions:

1. Parts list calls out a LH and RH steering arm, but I can't tell any difference between the two parts. Therefore, I just mounted them without regard to LH and RH.

Question: Should there be two unique parts with some discernible difference?

2. Upper control arm initial adjustment... I put this question in

Yama-Bro's thread on his UCA assembly, and will look to see if an answer gets posted there.

Other issues I dealt with (not really questions, unless someone wants to give input):

3. Castle nuts too far engaged on upper ball joints (similar to

this discussion from a '33 build thread). The spindle seats on the upper ball joint, it's just too far engaged for the height of the castle nuts relative to where the cotter pin hole is located. I've decided to get some spacers to put in place, similar to the lower ball joints. I think a spacer should take care of the problem.

4. Tightening the rear bolt for the upper control arm mount. I had difficulty getting a wrench on the nut behind the mounting flange for the rear nut. I was able to get it torqued to spec, but clearance back there is pretty bad. Just did the best I could, and got creative using a tool wedged between the nut and bracket to prevent the nut from spinning while torqueing the bolt.

I'm using the paint mark method on each fastener as I torque it to spec, both as an indicator that I've torqued a given fastener, but also to provide a visual clue of any movement once the vehicle is in use.

After I get the spacers for the upper control arm ball joints, I hope to get the front hubs and brakes installed this week. I'd like to be working on the rear end this weekend (I hope).

Thanks, guys. Let me know if you think anything looks wonky in the pics of my assemblies so far.

--Curt

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

The same spindles are used on the hot rod where they are front steer, which I guess explains the marking difference. The rear bolt for the UCA is fun for everyone. I have a wrench ground down to fit in there.

The same spindles are used on the hot rod where they are front steer, which I guess explains the marking difference. The rear bolt for the UCA is fun for everyone. I have a wrench ground down to fit in there.