-

12-13-2019, 08:37 PM

#121

I finally got some of the SEMA pictures sorted and found the Green Hornet ones I took.

Maybe it will give you some ideas!

SEMA_signcrop.jpg

Last edited by Just puttering; 12-13-2019 at 08:39 PM.

Mk3.1 347 AFR 205cc Heads A9L EFI siemens deca 60lb injectors MSD 6AL ignition Vortech V-3 3 Link PS/PB

-- If you cant fix it with a hammer, you have an electrical problem !

-

12-13-2019, 08:39 PM

#122

Mk3.1 347 AFR 205cc Heads A9L EFI siemens deca 60lb injectors MSD 6AL ignition Vortech V-3 3 Link PS/PB

-- If you cant fix it with a hammer, you have an electrical problem !

-

12-15-2019, 01:06 AM

#123

Originally Posted by

Just puttering

Thanks!! That is indeed getting into the neighborhood!

Kevin

-

12-15-2019, 01:35 AM

#124

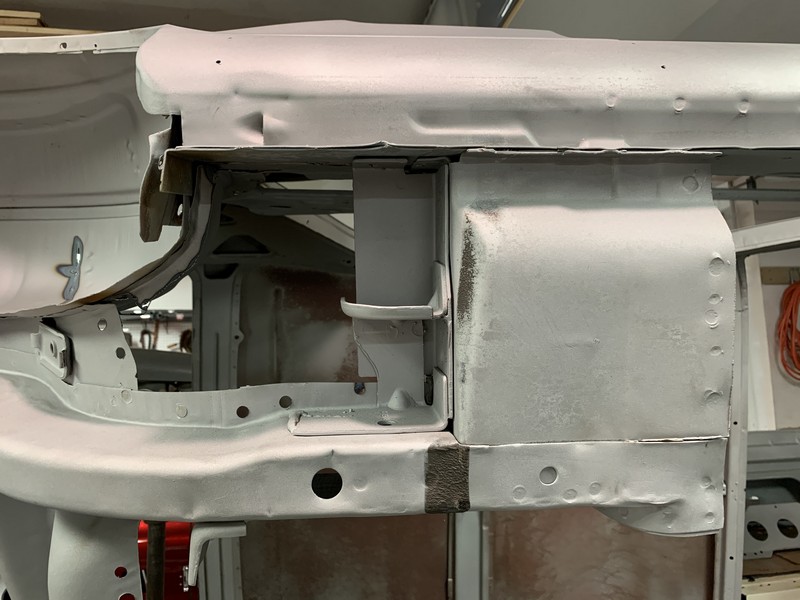

Installing Inner Rockers

In order to turn the coupe into a convertible, I have to install all the reinforcements into the coupe frame to turn it into a convertible frame. This begins (I hope!!) with the installation of the inner rockers. These major girders run all the way from the front of the frame to the back of the back of the cabin area in the original convertibles. After they are installed, the rear torque boxes are attached to the inside rockers. However, in a coupe that already has rear torque boxes installed, it is a bit more complicated. I considered just removing the existing torque boxes and installing new ones after the rockers were in place. However, the coupe frame is already factory welded in exactly where it should be. I really didn't want to mess with it. Because I will be using the MTF front frame that actually attaches to these rear torque box locations, I really did not want to take a chance on getting them in even a slightly different place. So I decided to leave the rear torque boxes where they are and make the inner rocker fit around them. This required cutting and fitting the inner rockers around the rear torque boxes. This was not easy feat!! I started with the easy part: the small section aft of the torque box.

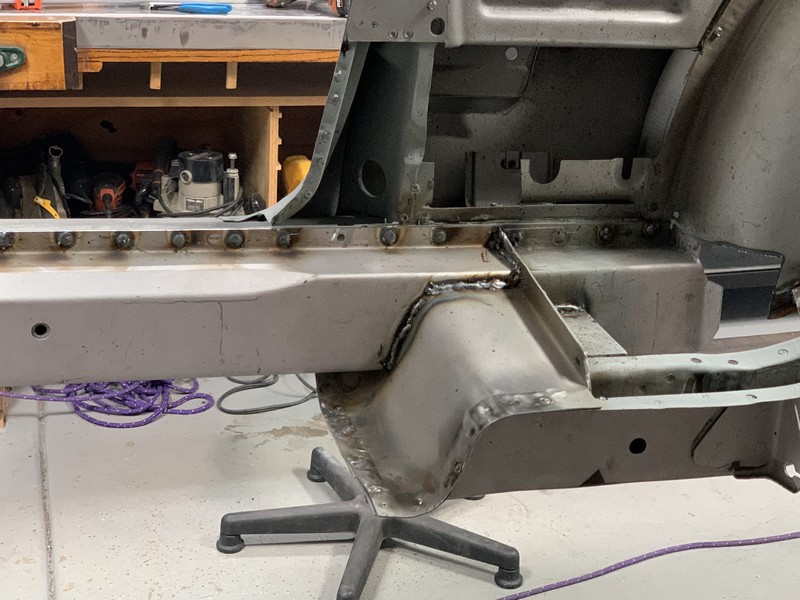

I cut off the rear section of the inner rocker after measuring three times and sleeping on it overnight! (I didn't want to screw this up!!) The basic cut was just a 90 degree cut off, but that's where the simplicity ended. I had to grind the top and bottoms to slightly different lengths, and then had to cut a slot for one piece of the rear torque box.

It took quite a bit of fitting and grinding to get it to fit just right, but I got it.

After drilling eight holes for spot welds, I welded this piece into place. The photo doesn't show it, but I went back and welded the inner rocker rear piece to the torque box whereever I could reach. The inner rocker is a fully attached member of the torque box.

Lesson next: this one is about "weld through" primer. I had picked up a couple of cans from Napa to touch up those areas that I had to cut and grind. The inner rocker itself is already coated with "weld thru" primer material. So apparently weld thru primer has zinc or copper to conduct the weld arc. Long story short, you can weld thru this stuff, but it makes and awful sound and splatters all over the place. I don't know if napa's paint is low quality for this purpose, but I gave up on it and ended up wire brushing off all the "weld thru" primer on and around all the welds after the first dozen or so. What a mess!!

-

12-15-2019, 01:58 AM

#125

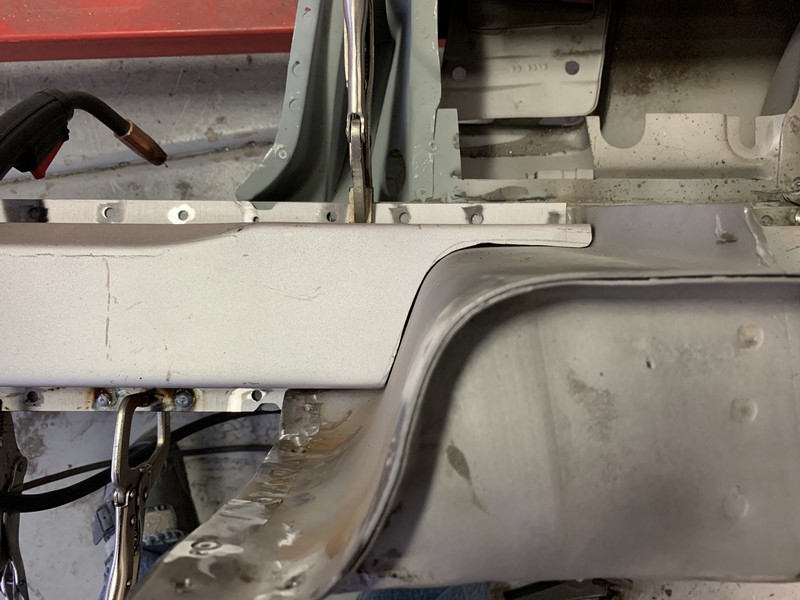

Next I moved on to the front section of the inner rockers. This was considerably more complex. I had to cut a sweeping compound curve around the rear end of the inner rocker to fit tightly to the front and top of the rear torque boxes.

Then I had to cut a rectangular hole through the firewall to allow the inner rocker to pass through the firewall on it's way to the front of the car. To make this process a bit more fun, I had to leave some flanges to weld to the cabin side of the inner rockers to firmly attach the firewall to the inner rocker.

In addition, since I do not currently have a front frame on the car, I had welded a 2" square tube in place to allow me to attach the front of the car to the rotisserie. You guessed it: the square tube was exactly where the inner rocker had to be! So in order to get the rocker through, I had to cut the square tube and reattach it to the inside of the inner rocker. Lots of moving parts all at once!!

After cutting, grinding, and fitting more times than I can count, I finally got it all to fit correctly. I put a boatload of spotweld holes all along the attaching flange. This inner rocker is not going anywhere!

After spot welding the entire inner rocker in place, I went back and welded the rear of the rocker into the torque box. My spot welding is getting pretty good, but my line welding still leaves something to be desired. Forgive me, I'm learning!!

On the drivers side front I also had to remove and replace the outside rocker, but just the front section. Thankfully, this must be a common problem, as you can buy just the front section that needs to be replaced. I had to cut away the old one, which took a bit of doing. The old piece fits under the outer rocker, but the new replacement piece fits on top of the outer rocker. I suspect that is because you would have to tear most of the A pillar area apart to get the replacement piece under the outer rocker. I got the old rotted piece cut out and back to good metal, and with a bit of encouragement got the new piece to fit into place. I did not install it yet because I had to get the inner rocker in place before i do the outer.

I plan to try to install that outer rocker front piece tomorrow. It feels good to have those inner rockers in place. Now I will move on trying to fit the new MTF Rear Tubs until the floor pan arrives. I am avoiding cutting off too much structural material at this point until I know I have the entire frame back together and squared up. The rear tubs should not be a problem, as I will only be cutting out the inner wheel wells, leaving the outer half and all the quarter panels in place for now.

-

12-18-2019, 01:20 AM

#126

Rear Tubs

While I wait for the full floor pan to arrive, I am trying to stay busy by taking small steps. I am tempted to begin cutting away everything that will be replaced. I decided not to do that until i get the new floor pan welded in. I want to make sure to keep the frame unit square. If I get it off square a bit, it could be a real pain to get it all straightened out. I am not sure how likely it is that this would happen, but since I don't know for sure, I am erring on the side of caution.

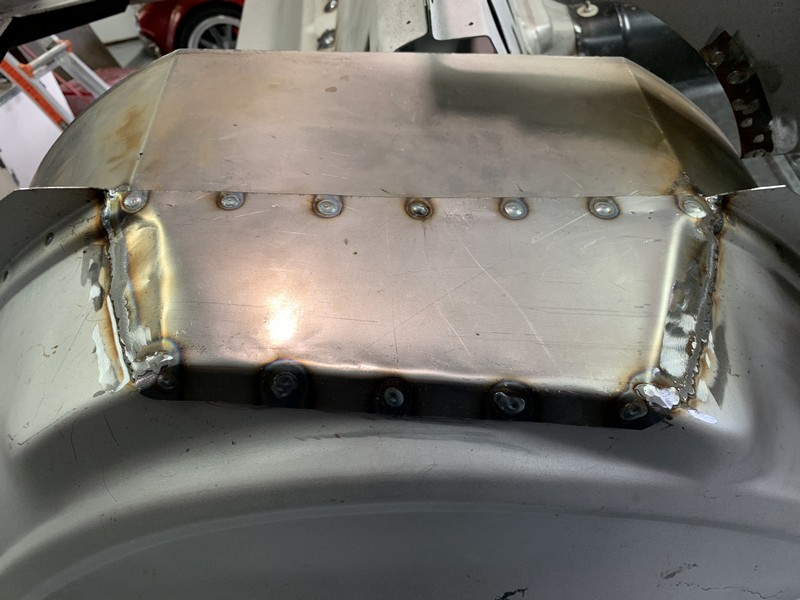

I received a box from Mustangs to Fear late last week containing a pair of their "Mini-Tubs". These tubs provide as much room for larger rear tires as you can get without completely changing the interior structure. They seem very well made. The metal seem a bit thicker than the stock sheet metal and the welds are all sharp. I watched their video on YouTube on how they suggest that these tubs get installed. The first task is to cut out the old inner wheel well and square up the opening. Once again, I learned to love my plasma cutter!

I cut around the perimeter of the old inner tub, leaving all of the outer tub for now. It will come out later, but I want to make sure I have the inner tubs in a solid location before I cut out the outer tub. (And the outter tubs have not arrived yet.) I discovered a bit of a change that I should have anticipated, but did not. As i cut the inner tub out, the weight of the upper half of the car compressed the opening that I had just cut. The tub came out, but I am absolutely sure that there is maybe 1/16"-1/8" of compression. I am not worried about it because everything that sagged will be coming off anyway.

Per MTF's instructions I then ground the edge back to create a straight line from front to back. I also measured the new tub to be sure it would fit and have enough overlap to attach it to the outer tub. Also per their instuctions, I left plenty of metal to be able to grind it back to fit correctly.

Turns out I still needed to cut about 5/8" further back to make it fit. I wasn't going to grind that much off, so I hit it again with the plasma cutter, then ground it back again. Now the rear corner is flush with the frame rail side, and the front edge is 2.5" away from the frame rail, just like MTF suggested. (What a surprise!!) This did, however make a couple of other removals obvious. The rubber bumper attached to the frame rail had to go, and the plate that is welded to the floor to attach the outboard end of the rear seatbelts also had to go.

By this point, I was tired, didn't want to screw it up by trying to go too far in one day, and my son had arrived to watch Star Wars movies in preparation for the new moving coming out Thursday. The first mini-tub is not quite ready for installation, but it's close enough for Jazz. I called it a good day.

Last edited by Jazzman; 12-18-2019 at 01:24 AM.

-

Post Thanks / Like - 0 Thanks, 2 Likes

-

12-31-2019, 01:07 AM

#127

-

12-31-2019, 10:00 AM

#128

Senior Member

Jazzman....Henry Ford will be proud

Jet

-

01-02-2020, 12:56 AM

#129

Originally Posted by

Jetfuel

Jazzman....Henry Ford will be proud

Jet

Judging by the dubious quality of the original construction, Henry Ford should be appalled! What I am doing will certainly be better than new by a wide margin!! Thanks for going along on the journey with me!

-

01-02-2020, 01:31 AM

#130

Happy New Year! Last weekend I got the replacement floor pan installed. That thing took forever! It doesn't hurt that I am putting welds every two inches, and ever one of them has to be drilled and then buffed on both sides to clean away the excess metal shavings and the "weld thru" paint that you really can't weld through! I have long since lost count as to how many welds I have done, but I know that I have used 3/4 of my bottle of welding gas, so it's quite a few! I had to do a few adjustments to make it fit properly. I had to reshape two of the flanges at the back corners because they were too narrow to fill the space. Other than that, It went in pretty much as expected. Slow and tedious, but not particularly difficult.

I put in the seat throne pan. This is a very heavy piece! IT forms are very strong "H" to join and reinforce the frame. This also took dozens of weld, all drilled, marked, buffed, and only then welded. I had to put a couple of bolts through the rear holes right at the top of the transmission tunnel to pull the floor pan and the seat throne pan together tightly. It worked great! That floor is very strong! after welding the plug holes, I polished down the weld flush with the pan. I had to do this because at a much later date there will be another reinforcement pan on the under side of the floor pan, directly opposite the seat throne pan. The two panels sandwich the floor pan for even more rigidity.

While I had the car upside down and the front of the outside rocker was easily accessible, I went ahead and welded the replacement outside rocker front into place. I did all the hard work on this one a few weeks ago, so tonight was pretty simple. I just slid the piece in, clamped it, and welded it on.

I started trying to bold the rear light panel into place to see if the rear quarter panels were going to fit correctly. I discovered why the original panel didn't quite fit right: It was forced to fit. The new panel, when installed on the existing trunk bumper supports, actually sits about 3/8" away from the flange to which it is supposed to be joined! The existing trunk bumper supports will have to be removed and repositioned to allow the rear light panel to be installed correctly. I haven't decided if I will just buy new trunk bumper supports, or try to reuse the ones I've got.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-02-2020, 09:15 PM

#131

Senior Member

Haven't read this in a while Kevin. Nice work. This is quite the project! Any original metal left? haha

MK4 #8900 - complete kit - Coyote, TKO600, IRS - Delivered 6/28/16 First Start 10/6/16 Go cart - 10/16/16 Build completed - 4/26/17 - 302 days to build my 302 CI Coyote Cobra - Registered and street legal 5/17/17

Build Thread

http://thefactoryfiveforum.com/showt...e-build-thread

PHIL 4:13 INSTAGRAM - @scottsrides

-

01-03-2020, 07:23 PM

#132

Originally Posted by

wareaglescott

Haven't read this in a while Kevin. Nice work. This is quite the project! Any original metal left? haha

Not much! the rear frame from the firewall back, but not the floorpan, the A and B pillars and the dashboard, the trunk lid, and both the front and rear valances. That's it! All the rest is gone for one or more reasons. Yep, it's a bit crazy, but it is going to be so much better than new when it is done.

-

01-08-2020, 10:23 PM

#133

-

01-08-2020, 10:53 PM

#134

This is where the fitment issues began. On the right side, everything seemed to pretty much slide in to place. Just a few minor adjustments, and viola! But when I went to fit the left side, i had to fight the fitment where the front bottom of the quarter panel meets the top of the outer rocker panel.

On the right hand side where the rear end of the quarter panel meets the trunk fall off panel, the bottom of the trunk side lined up perfectly with the seam on the inside of the lower rear quarter panel.

However, in order to get the front lower seam on the quarter panel to be straight and tight, the lower rear of the quarter panel ends up about 3/8" too high.

To make matters even more confusing, the rear light panel had to be adjusted 3/8"+ too LOW in order to make the previous items line up well. (to recap, the rear panel is 3/8" too LOW and the rear of the Left quarter panel appear to be 3/8" too HIGH. How can they both be true? You see my problem!!

The right side of the rear light panel also had to be moved down just a about 3/8" to make the left side fit. The right quarter still seems to fit fine, perhaps a bit better. The curves of the very tip of the quarter fit even more nicely into the edge of the rear light panel. The center point of the rear light panel matches up perfectly.

So now I need your help. It appears that I can weld the rear light panel to the frame at the 3/8" low point that it seems to be at. Somehow this doesn't seem right. Literally as I write this, I have a thought as to why the rear panel doesn't line up. The entire car is still on the rotisserie, attached only at the very front of the firewall area directly to the inner rocker panel (which isn't going to bend!) and at only six inches forward of the very back of the frame. Is is possible that the frame is flexing 3/8" from the rear torque boxes to the back of the frame? Do I need to take the frame off the rotisserie and support it with jack stands only at either end of the inner/outer rockers, allowing the rear frame aft of the rear torque boxes to return to it's standard (lower) position? Is there another issue that I might be missing?

Last edited by Jazzman; 01-08-2020 at 10:59 PM.

-

01-08-2020, 11:18 PM

#135

Final question. The outer wheel well that I received for the right side is definitely a Dynacorn item, said so right on the sticker. It was clearly a well made piece, well formed, sharp edges and smooth curves, a nice coat of "can't really weld-thru" primer on it. For whatever reason, the outer wheel well that I received for the left side is clearly a lesser quality piece. It is primered black instead of weld-thru silver, the corners were not as sharp, the edges were more ragged, and one flange wasn't even in the right place. In order to fit correctly, the flange had to be re-bent to line up correctly. All this is manageable i guess, but i noticed that while the Dynacorn piece is a nice round shape, the black piece has a flat spot in the curve near the rear end.

Does it make any difference? Should I get a Dynacorn part for the left to match the right? Once I get it all welded to the inner tub, will it even show up or matter?

Last edited by Jazzman; 01-08-2020 at 11:49 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-11-2020, 06:00 PM

#136

Senior Member

Kevin

As I was reading this I was thinking to myself every time I watch one of these car shows like *****in rides or whatever when they chop a top or work on a convertible they always weld in all these cross braces to keep the frame from flexing. Then I got down to your post about things not lining up quite right. I cant really visualize what the issue is but do you think you need some interior cross bracing of some sort while you progress to help keep everything lined up properly? Doesn't the heat from welding also cause things to move and warp a bit?

Fascinating project. Every time I think I have lost my mind for the scope of my 911 project I like to come check in here to remind myself you are 1000% more off the slippery slope! hahaha

MK4 #8900 - complete kit - Coyote, TKO600, IRS - Delivered 6/28/16 First Start 10/6/16 Go cart - 10/16/16 Build completed - 4/26/17 - 302 days to build my 302 CI Coyote Cobra - Registered and street legal 5/17/17

Build Thread

http://thefactoryfiveforum.com/showt...e-build-thread

PHIL 4:13 INSTAGRAM - @scottsrides

-

01-19-2020, 10:36 AM

#137

OK, at the moment, I am seeing photos in this thread. Would you please "like" this particular post to let me know that you can see photos in my previous posts? If you can't see the photos, please reply directly to this thread.

Thanks for the help.

-

Post Thanks / Like - 0 Thanks, 8 Likes

-

01-23-2020, 02:18 AM

#138

A very trusted adviser on the MTF forum was concerned that I not get everything welded into place before I confirm that the doors were going to fit. Since I had not moved either the A or B pillars, I hoped that the doors would fit, but I had not ordered them yet. I didn't want to store them. But based upon his concern, I decided to order the doors. First impression, wow, I really got them quickly! I ordered them Monday, received them today! Second impression: I was impressed with the nice black protective coating on the outside, and quite disappointed that there was almost no coating at all on the inside of the door. The very reason I had to replace the doors was because the originals had no rust protection on the inside of the door! I had hoped that we had evolved a bit in the past 50 years. Apparently not in this particular area. I have been vacillating about whether to spend the money to have the entire car powder coated inside and out. I am pretty sure the poor protection for the doors pushes me back toward powder coating.

This evening I searched around and found the hinges and the bolts for the doors. It is still going to take some adjustment of the bolts to get the door to gap correctly, but I am pleased to say that my plan of leaving the A & B pillars in placed worked like a charm! The doors fit perfectly right out of the box.

Inside the car between the two rear wheel houses is the rear seat mount panel. It is set in place and held with a couple of clamps, but not welded in. Now that the doors appear to fit, and the since the rear quarters already fit, i believe that I will go ahead and weld in this large piece. (It will be great to get it out of the way!!) Over the weekend I had to change the flanges that previously were attached to the sides of the wheel wells. Since my rear inner tubs are wider than stock, there was no room for the traditional piece that went between the rear seat panel and the wheel well. I bent the flanges flat, then trimmed them to fit snugly between the wheel wells. I then used some 3/4" angle irons to add new points to weld to the wheel wells. I thought I had taken photos of this process, but apparently I didn't. Sorry I didn't document this step. I plan to take the seat mount panel out once more to check everything, and I will try to take some shots of the adjustments at that point.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-21-2020, 08:05 PM

#139

Catching up in the midst of the "Social Media Flu"!

While a large number of people panic from this media driven virus scare, I decided to use the time wisely: work on the Mustang, and catch up on my posts on the forums. A lot of my time for the past couple of months has been taken up with business and family responsibilities. My sister is through chemo infusion #10 of 12. All is going exceptionally well thus far. Praise God!! I have traveled a bit for business, but am glad to be home. Progress has been slow on the Mustang, but rewarding. When I last updated this thread, I was working on installing the seat back unit that separates the cockpit from the trunk. I had to do some creative adaptation to make the unit fit correctly. There was not room between the deeper inner wheel housings and the seat back assembly for the typical pieces. There was a flange built into the assembly that was supposed to be welded to an inner piece, and that inner piece was to be welded to the original wheel well. I re-bent this flange to be flat, and then cut it to fit tightly between the wheel wells. I then welded some 3/4" L material to the end of the newly fitted cuts to create a new flange. I finally could weld the entire seat back unit into place.

The seat back unit fit perfectly against the original upper floor pan between the new floor and the trunk. I clamped it into place and welded it in.

at the top of both the outer wheel housings, you can see that there is a large opening where the flat area of the inner wheel house does not match the arch of the outer wheel house. I could just pound it flat like ford did originally, but no, that is not me. I wanted it to be nice and neat. I started by cutting this extra area out approximately where the top of the inner wheel house would meet. I left it a bit tall, then ground it down until I could get the straight edge to match up flat on the inner wheel house and on the outer edge of the outer wheel house.

I then made a cardboard form and cut out a piece of metal to fit the hole. It took a bit of shaping and adjustment, but I got the new cover cut and fitted. I welded it into place.

I don't have a photo of it, but I turned the car upside down and fully welded all the seams where the inner and outer wheel wells meet from the underside. I want to make sure that all these seams are completely sealed. Now that it is fully welded, I will grind it flat, then seal the entire inner wheel house with under-body coat. I haven't done that yet.

Last edited by Jazzman; 03-21-2020 at 08:07 PM.

-

03-21-2020, 09:24 PM

#140

This one piece, the drip rail, is the reason I had to buy a rusted entire back half of a 67 Mustang just so I could tear it apart, throw 80% of it away, and keep this piece and a few others.

Today I started painting it with POR 15. But there is a lot of story that goes before this photo. Unfortunately most of the photos of this phase seem to have gotten lost. I can't find a whole series of photos. Oh well, you will have to use your imagination. This piece entered my life looking like this:

That drip rail between the red lines is the only piece (thus far) for which no one makes a replacement part. After taking the rusty hulk hulk apart. I had this drip rail sand blasted. It was in rough shape. One of the channels that carries rainwater away from the interior of the car was completly rusted through. Several sections had significant "swiss cheese" rust through. In order to maintain the overall integrity of the piece, I cut away only as much metal as I had to in order to get back to solid metal. It was thin, but it was solid. I then custom made splints that fully encase the lower half of the side rails. (the rear cross member area was in a bit better condition.) You can see the weld lines where I welded the splint to the underside of the drip rail. (keep in mind that the drip rail is upside down on my work bench.)

Fixing all the rust and damage on the drip rail took a lot of time. Now that it is done, I want to protect this piece as best I can. This piece is perhaps the most exposed yet under appreciated piece on the entire car. No one notices it, but when it rains, it carries off all the water that gets under the convertible top and channels it down the sides of the car inside the area where the rear quarter windows live. This piece, and where the water is drained, are both areas that tend to rust out. I want to do all I can to protect them both. I have been going back and forth considering powder coating the entire car, using some sort of epoxy primer on everything, or . . . who knows what! The problem with all these coatings is that they simply cannot get to the areas that need protection most after the car is all welded together. The only way to protect them is to coat them BEFORE the outer skin is welded into place. This requires "paint as you go". When I built the Cobra, I was truly amazed by the quality and adhesion of POR 15. This paint is simply amazing at protecting against further rust. I decided I would use POR 15 on all the hidden areas of the car where no one would ever see anyway! The downside is that POR 15 sticks to everything, and you can't get it off your skin. (I can't stand wearing latex gloves.) I researched POR 15 on their website, and determined that the Silver paint had the most filler built in, and would leave a better overall look than the gloss black (the most common color used.) I ordered up the metal prep and 1 quart of the paint. POR 15 cures due to contact to water, not air. Even though we have had more rain than usual this winter, our humidity is still much lower than most parts of the country. It would cure slower because of this fact.

I tried the metal prep on the drip rail. Since everything had been sand blasted, and the new metal was already cleaned by me, I wasn't sure that the metal prep was really necessary. After using it, I am still not sure. Metal prep is a euphemism for a Phosphoric Acid solution! Keeping it off my skin was very difficult. Keeping it off my clothing was impossible. I did my best to stay clean, but it got on the front of my shirt. It discolored the shirt and began to burn my skin. Needless to say, that shirt is gone and I took a shower! Bottom line, on perfectly clean metal, I didn't see that it made a lot of difference in terms of adhesion. Clearly on rusted metal it works very well. There were a couple small surface rust areas, and they cleaned up right away. THe stuff works, but be careful using it.

I put a first coat on the drip rail, the insides of the rear quarters at the bottom, and all the metal that would be covered and inaccessible after the rear quarter is installed.

This is the area that the drip rail will drain water if it gets in. This is the area that I fully coated with to deal with both primary water drainage as well as splashing.

It has now been 5 hours, and I am going to try to do a second coat. The directions say to wait 2-6 hours. It has been drying so slowly, I had time to come in an write these posts. Good use of time, I thought!!

About 90 minutes later . . .

Finished the second coat. Used 1/2 Pint less than the full quart today. Coated all the important parts so I can now finally weld up the drip rail and permanently install the rear quarter panels. Don't think I will get that done tomorrow. I want to let the POR 15 fully cure before I start messing with it. Some thoughts on Silver POR 15 vs Black POR 15. The black leaves a very consistent, powder coat like finish. The silver leaves a very nice finish, but it shows every run, sag, or imperfection in the underlying metal. Since none of this will ever be seen again, it really doesn't matter for my purposes, but just in case you decide to use it, beware. The metal flake that makes it "silver" also makes it prone to showing imperfections, brush lines (though not many), drips, or sags. I am very pleased with the finish, though I wouldn't want to stake my reputation on the perfection of the paint job. This is about protection against rust. I am absolutely sure that this is far more protection than the original car ever had in all these areas.

I did coat the interior of the rear quarters in those areas that are prone to water damage.

Last edited by Jazzman; 03-21-2020 at 11:15 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

03-22-2020, 05:07 PM

#141

Senior Member

good update Kevin. I think you are more crazy every time I read this thread! hahaha

MK4 #8900 - complete kit - Coyote, TKO600, IRS - Delivered 6/28/16 First Start 10/6/16 Go cart - 10/16/16 Build completed - 4/26/17 - 302 days to build my 302 CI Coyote Cobra - Registered and street legal 5/17/17

Build Thread

http://thefactoryfiveforum.com/showt...e-build-thread

PHIL 4:13 INSTAGRAM - @scottsrides

-

07-24-2020, 12:10 AM

#142

I can't believe it has been four months since my last update. 2020 is turning out to be the longest decade of my life! You would think I had plenty of time to work on this beast. You would be wrong! I can't remember working harder in my life. Ok, maybe not really, but my memory is going, and I sure can't remember the last time I worked this hard. I can't even remember all the steps that have been done in the last four months. First, a short list of what has gone been done:

The rear quarter panels are in place. They look pretty good. All the welds still need to be smoothed out.

The rear deck lid has been set into place. It is not actually attached, but the fitment lines are as close to perfect as I can ever hope for.

I ended up fully removing the front cowl, both upper and lower sections. I decided that I had come this far, and I didn't want to leave this one last piece of known rusted garbage on the otherwise rust free new car. I am glad I did. It was more rusted than I thought. The new one is in place, and almost fully welded in place. I ran out of welding gas, so I stopped before I finished.

I received the full front and rear frames from Mustangs to Fear. Great pieces of kit! very well made, fit perfectly. The front and rear frame pieces join together at the point where the rear suspension attaches, and create a fully end to end frame. Of course, all the parts that would be impossible to paint or powder coat after attachment were painted with POR 15 to prevent rust where I could not see it.

When I ordered the full frame from Mustangs to Fear, I also ordered the front radiator support and the full engine bay panels. The next piece to be installed is the Radiator support so that I can fit the engine panels. The problem is I think I missed a part. The radiator support panel is 1/2" too narrow to be fitted between the frame rails. In the MTF photos that I have been able to find, It looks like there is a large front rail that fits between the front frames and across the triangular jack pad in the middle front of the frame. . However, I didn't get this piece (if there is one) and I am not sure how to fit the radiator support. Suggestions?

Last edited by Jazzman; 07-24-2020 at 12:27 AM.

-

08-02-2020, 11:09 PM

#143

-

08-02-2020, 11:17 PM

#144

-

08-03-2020, 07:45 AM

#145

Looking good Kevin! Keep it up!

Mark

-

08-03-2020, 05:47 PM

#146

Out Drivin'

Kevin,

Absolutely epic build - your metal working skills are really shining!

I'm sure there are times when it seems you're pretty far down that creek, but you have truly shown what's possible when we put our mind (and hands) into a project.

I'm going to continue following along, but I've sworn-off rusty cars for the time being, so hopefully won't soon be joining you in panel replacement.

Keep the updates coming!!!!

Later,

Chris

"There are no more monsters to fear, and so, we have to build our own."

Mk3.1 #7074

-

08-03-2020, 07:40 PM

#147

Originally Posted by

Gumball

Kevin,

Absolutely epic build - your metal working skills are really shining!

I'm sure there are times when it seems you're pretty far down that creek, but you have truly shown what's possible when we put our mind (and hands) into a project.

I'm going to continue following along, but I've sworn-off rusty cars for the time being, so hopefully won't soon be joining you in panel replacement.

Keep the updates coming!!!!

I think after this one I will swear off rusty cars as well!!  Thanks for the encouragement, both Chris and Mark!!

Thanks for the encouragement, both Chris and Mark!!

-

08-08-2020, 04:49 PM

#148

Here is what I am am trying to figure: What is the base length of the frame rail from the point where the frame rail meets the firewall to end of the square channel? Like this:

(yes, I know my yard stick isn't long enough. It is for illustration purposes only.) So here is what I found. PS:

Here:

To Here:

The answer, already known by the observant, is 46".

What about the DS?

Here:

To Here:

You guessed it: 44 5/8".

Now the difference in lengths doesn't concern me much. The firewall very well may be 1 3/8" further forward on the drivers side than on the passengers. It doesn't look like that much, but the firewall fits snuggly on the frame, so I am not particularly worrried about it. What I can't yet determine is "are these the correct lengths for the frame rails for either side? The front cross member is 1.75" over the frame rail at the point where it attaches to the frame rails. I could move it forward 0.75", maybe even 1.0", but it would be well forward of where it appears that it should be based upon the MTF photos. Furthermore, I can only move it forward 3/8" before the tab on the crossmember meets the end of the frame side extension on the front. If I were to move the cross member even 0.75" forward, the tab would be well forward of the end of the frame side extension, but conceivably could Still be welded on. If I tried to move the cross member a full inch forward, the tab will be entirely forward of the end of the side extension, and could not be welded to anything. So to get back to the original, key question: What length are the frame rails suppose to be from the firewall to the end of the 3" Square tubing?

One other thought: Which direction are the top and bottom flanges supposed to face on the radiator support? I have them both facing the back of the car. Should they be pointing forward instead? This would pick up a full inch on the original measurement, but would not change the location of the radiator support panel, and thus it would not change the location of the side engine panels relative to the front suspension components.

Last edited by Jazzman; 08-08-2020 at 04:58 PM.

-

Post Thanks / Like - 0 Thanks, 1 Likes

-

01-24-2021, 09:06 AM

#149

Mustang convertible project goes up for sale

To everything there is a season. The past five months have been some of the hardest of my life. My father died on September 19th. He did NOT die of Covid, he died of medical indifference. He was in excellent and improving health four days before he went into the hospital. Because of Covid, he was ignored for four days and none of his family was allowed into the hospital to speak for him. After they finally did an exploratory surgery, the doctors discovered his appendix had ruptured. He had a raging septic infection. He never came out of the coma.

I never built either of my cars FOR my father, but he was proud of my tenacity and of the work that I had done on these projects. Now that he has Graduated, I have lost the desire to continue building the mustang. I dont doubt I can do it, I simply am not getting enough joy out of this project. I have decided that if someone else wants to finish this project, it is time for me to pass the torch.

If you have found this post, you already know that this car began life as a 1967 Mustang Coupe. After media blasting, it became apparent that almost every exterior exposed sheet metal surface had sufficient rust damage to warrant complete replacement.

The following parts (and others) were completely removed:

Both Front fenders

Both doors

Both rear Quarter panels

The entire floor pan

The rear taillight panel

Entire front Frame

All Engine bay panels

Firewall

Upper and lower cowling

Torque box

The following items have been replaced or added to the car at this stage of construction: Some parts were required to turn the coupe into a convertible.

New rear quarter panels (2)

New doors (2)

New inner rocker panels (2)

New Dynacorn full Floor panel

New outer rear wheel houses (2)

New Mustangs to Fear (MTF) inner rear wheel tubs (2)

New Dynacorn Front Seat Platform

New Outside Front rocker panel

B pillar to Inner rocker reinforcement supports (2)

Rear Seat mount panel: This piece was taken out of a salvaged Mustang rear clip, media blasted, interior areas primed for protection.

Convertible Drip rail: This piece cannot be purchased as new, so it had to be taken out of the Mustang rear clip. It was also media blasted and primed on all sides for protection. It is far better than it was when it was new!!

New Dynacorn Rear Fender Aprons (2) (trunk drop off panels, near the rear quarter panels)

New Mustangs to Fear (MTF) full front frame with Coyote Engine Mounts: This amazing piece ties the front and rear frame sections creating a full end to end frame!

New MTF Rear frame rails to accommodate watts link rear suspension.

Items which I have already purchased but have not yet installed:

MTF full engine panels

MTF upper engine panel rails with stamped VIN number

MTF front Radiator support panel

New front Fender panels

MTF Watts Link Rear Suspension, Shocks, Coilovers, and Hardware

New Left and Right Torque Boxes

Exterior seat reinforcement support pans (two pairs, its a long story!!)

Original parts that I have but are not yet installed: almost all metal parts are media blasted (I later found a couple small ones that I missed.)

Front seats need recovering

Rear seats need recovering

Assorted trim

Headlight buckets

Glove box lid

Front lower valance

Rear lower valance

Steering column

Drive Shaft, Gas tank

Trunk lid the one exterior piece with no rust!!

Window mechanisms for all windows.

At least five large tubs of assorted smaller parts. Some of the parts were bagged and tagged as I removed them from the car. Other were already off the car when I purchased it.

There are more parts, but I cant see them right now! If they are for this car, you get everything I have!

I also have a FoMoCo Welding and Sealant manual with drawings and welding instruction for every welded part on the entire car!

The car is currently mounted on a rotisserie. The rotisserie can be purchased for an additional price with the car, or will be sold separately once the car is sold.

The sheer volume of entirely new parts will ultimately turn this 67 rust bucket into a brand new car, far better than the original in many ways. If you are interest in this project, lets talk. I know what I spent on the car, I know what I would like to get out of it, but I also want it to go to the right person. Contact me directly at [email protected].

Kevin

-

01-24-2021, 10:08 AM

#150

My condolences. So sorry for your loss.

MKIV complete kit w/powder coating and cut outs, serial #9189 delivered 10/10/17, first start - 10/5/18, legal - 10/08/20. Blueprint 306 w/Holley Sniper EFI, TKO 600, power steering, Breeze fan shroud, trunk cubby, & engine compartment battery kit, CNC brake reservoirs, RT turn signal & gas pedal, mechanical throttle linkage, METCO safety loop, GASN side pipes, drop trunk, dual chrome roll bars, vintage gauges, glove box, custom center console, cup holders, and speakers.

-

01-24-2021, 11:11 AM

#151

Senior Member

Great to hear from you again Kevin. But not under these circumstances. My deepest condolences to you and your family. This is such a hard time. We are hoping and praying 2021 will bring some improvements. So difficult to hear what happened to your Dad. Our extended family is going through some things right now too, but nothing like that. Hopefully someone will come along and finish your dream. Or maybe time will let you decide to get back into it. My best to you and your family.

Build 1: Mk3 Roadster #5125. Sold 11/08/2014.

Build 2: Mk4 Roadster #7750. Sold 04/10/2017.

Build Thread

Build 3: Mk4 Roadster 20th Anniversary #8674. Sold 09/07/2020.

Build Thread and

Video.

Build 4: Gen 3 Type 65 Coupe #59. Gen 3 Coyote. Legal 03/04/2020.

Build Thread and

Video

Build 5: 35 Hot Rod Truck #138. LS3 and 4L65E auto. Rcvd 01/05/2021. Legal 04/20/2023.

Build Thread. Sold 11/9/2023.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

01-24-2021, 01:57 PM

#152

Hi Kevin, Sorry for your loss. That's a tough loss to bare when it should have been a happy ending. You have done such a great job piecing the mustang back together with a vision for what it will be when done. I hope you reconsider and decide to finish. You have the talent and patience for this restoration.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

01-24-2021, 02:29 PM

#153

Kevin, I am so sorry for your loss. As you know I am a general surgeon. I deal with appendicitis every call night, sometimes I will get several in a call night and understand how dangerous and tricky it can be. The thought of a patient languishing for four days before their medical team realized they had a surgical problem absolutely torchers me. The only solace I can offer is that I am sure his medical team is devastated by this outcome and will work diligently to prevent it in the future.

I hope you don't give up the build. Your mustang build has inspired me to try something similar with a 1950 Mercury.

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

01-24-2021, 03:44 PM

#154

Senior Member

Jazzman, sorry for your loss.

May the Good Lord keep him is His glory and forever lasting peace

Jet

-

Post Thanks / Like - 1 Thanks, 1 Likes

-

01-24-2021, 08:59 PM

#155

Steve >> aka: GoDadGo

Kevin,

I'm sorry to hear about your father's passing, but understand that life does go on.

If your Pop was anything like mine, and I'm sure he was, he would not want you to grieve.

He would tell you that life is for the living and that nobody survives life, except for one fellow.

Just have faith and know that your Dad is in heaven with the Saver of Souls, The Lord Jesus Christ.

Steve

Last edited by GoDadGo; 01-24-2021 at 09:02 PM.

-

Post Thanks / Like - 1 Thanks, 2 Likes

-

01-25-2021, 10:04 AM

#156

Thank you all so very much for your kind words. This forum is an amazing place. In a world that is seeming going mad at an exponential rate, you prove once again the caring spirit of man. Your words touch me, humble me. It makes all the difference that I have the absolute assurance that Dad is with the Great I AM, Jehovah Rapha, The God that Heals.

Mark, a special "thank you" to you. Sadly, the physicians that didn't provide an appropriate standard of care for my father have never shown any concern for his outcome. For them, it appeared to be be "just another day at the office". I understand that for your own emotional protection, a physician must find a way to control their emotions to an extent. You remind me that there are physicians that care DEEPLY about their patients and truly fight every day for a positive outcome. Thank you for all you do every day! May God bless your work and give you peace, wisdom, and strength.

-

Post Thanks / Like - 1 Thanks, 1 Likes

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote

Thanks for the encouragement, both Chris and Mark!!

Thanks for the encouragement, both Chris and Mark!!